|

From 1919 to 1925, the Cubitt Car

was manufactured by The Cubitts’ Engineering Company in Aylesbury,

Buckinghamshire.

Of simple and rugged construction, it was produced

using new mass production techniques to enable it to compete on

price with cheap

American imports, but despite being generally considered good

value for money, sales of the Cubitt never reached a level where the

company made a profit. Only 3,000 vehicles of various

models were manufactured

during the six year life of the company, far fewer than the original

sales estimate of 5,000 a year. After a series of difficulties

— including the death of the Managing Director in a motoring

accident — the company folded in 1925 with a serious impact on

local employment.

July 2022

A 1925 Cubitt Model K two-seat tourer with dickey

seat.

Wright & Wright’s premises, Western

Road, Tring.

Western Mail, 9th September 1919.

At the shareholders’

meeting held in November 1920, the Chairman reported a net profit of

£13,340 for the previous fifteen months, this being apportioned to

seven months installation, four months initial manufacture and four

months normal production. In answer to criticism of the

financial position he explained that capital expenditure had proved excessive

in proportion to the capital issued owing to the enormous price increase

in every commodity and wages. Nevertheless, the directors remained

optimistic about the future.

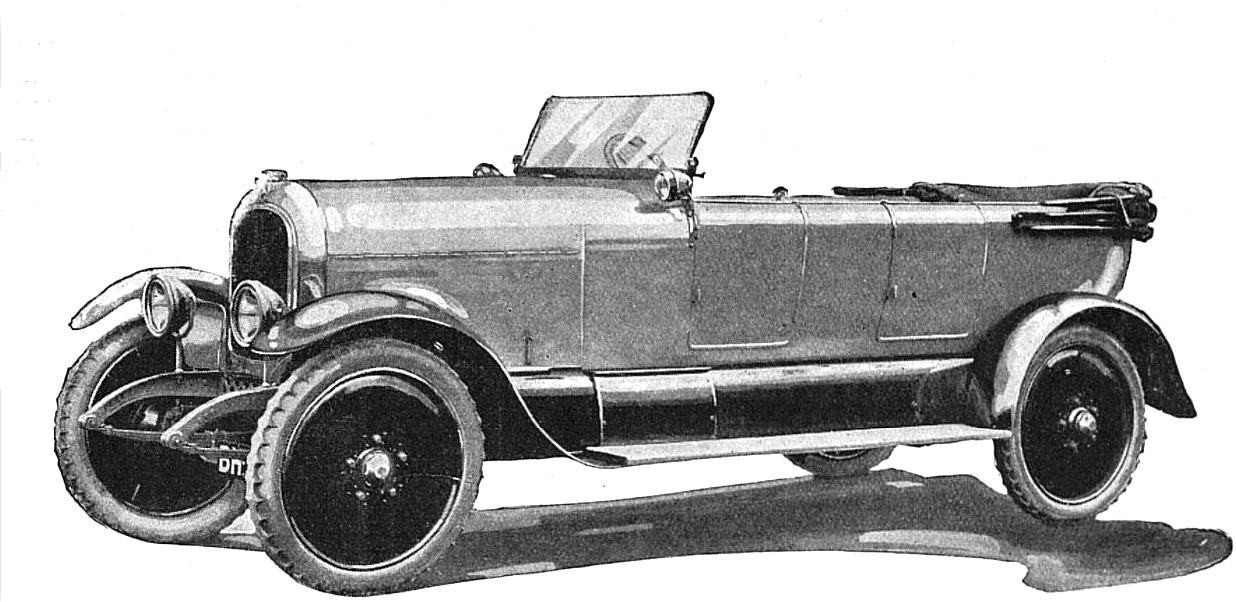

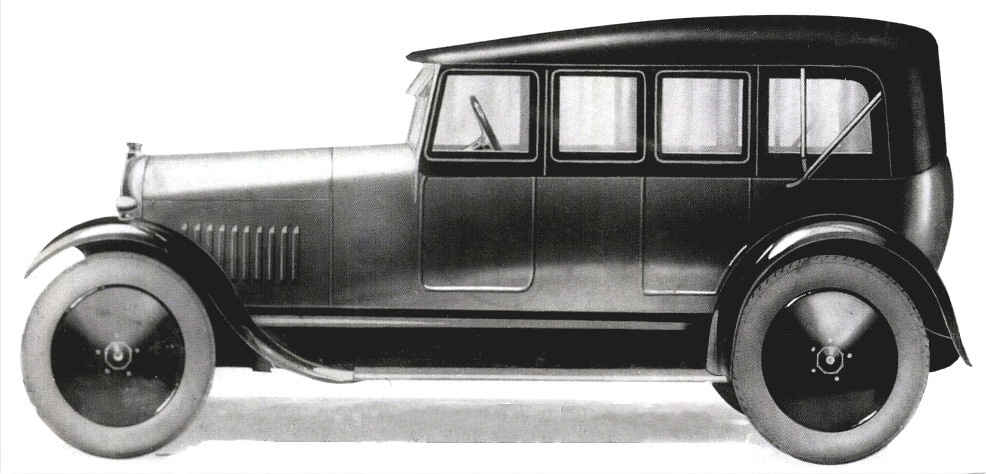

1922 Cubitt Model K Tourer,

A Cubitt in India, 1924.

|

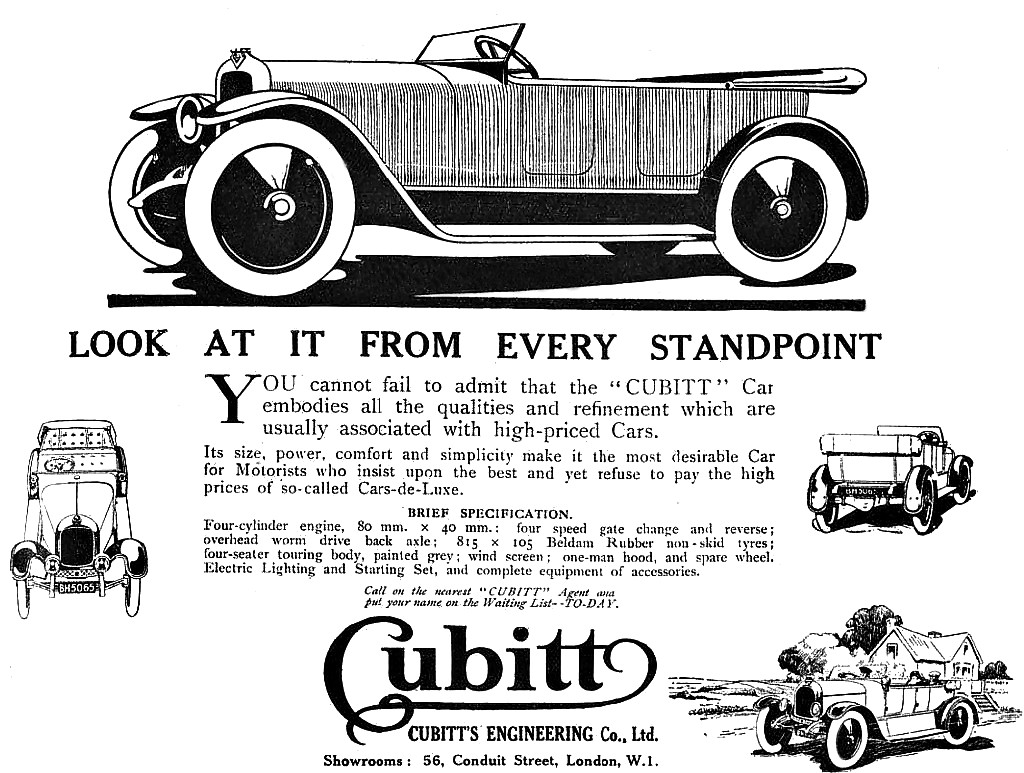

Advertisement, The Sketch, 17th March 1920.

Advertisement, The Bystander, 28th July 1920.

|

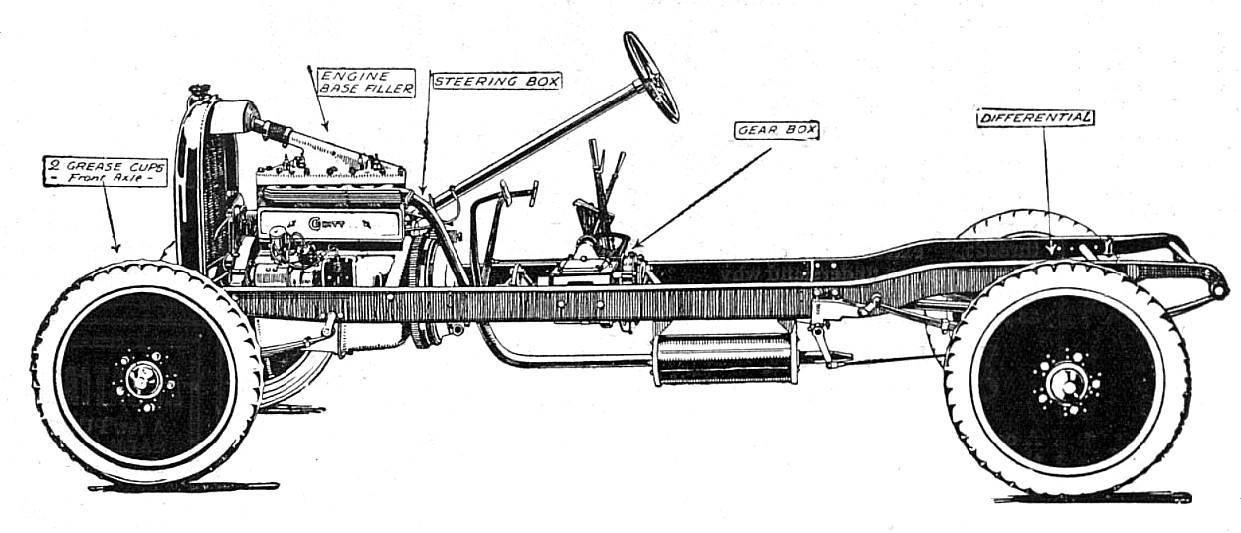

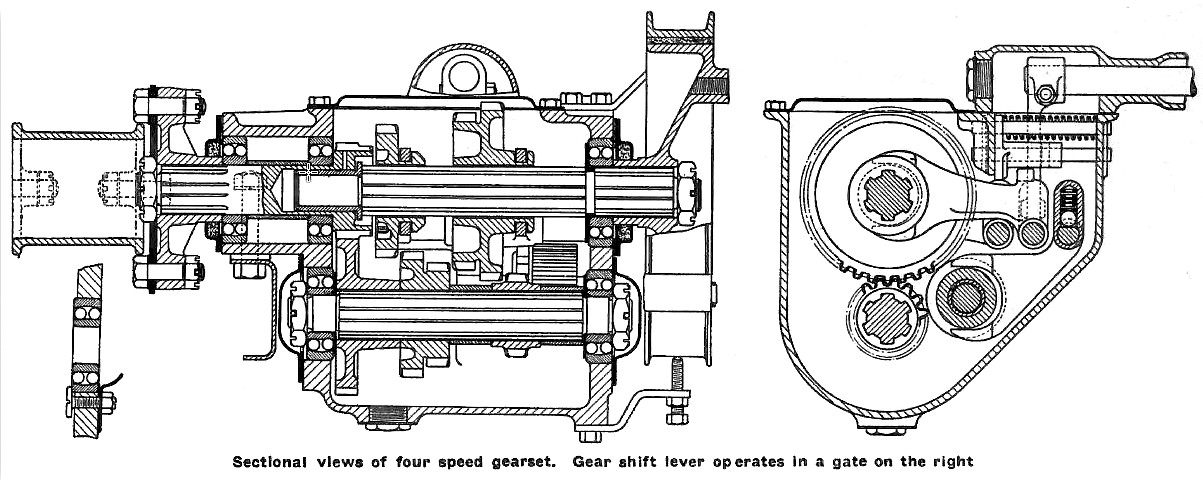

Gearbox.

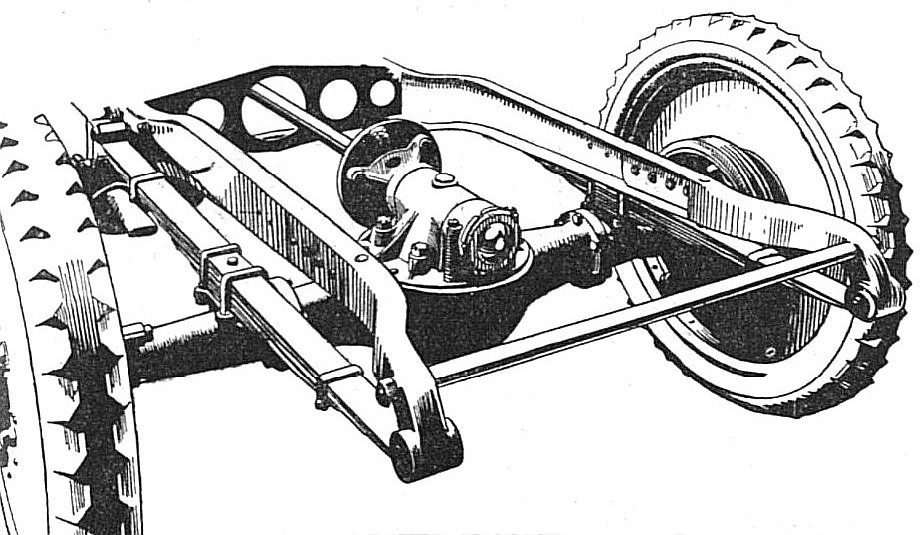

Rear axle.

|

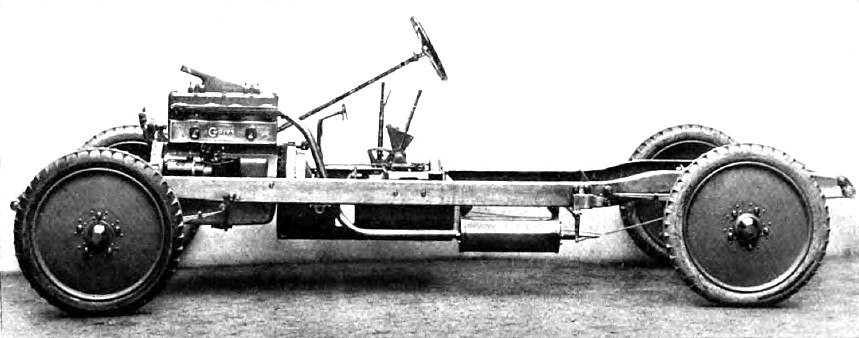

Side view of the Cubitt chassis.

|

|

The Cubitt Car, The Tatler, 13th

April 1921.

|

|

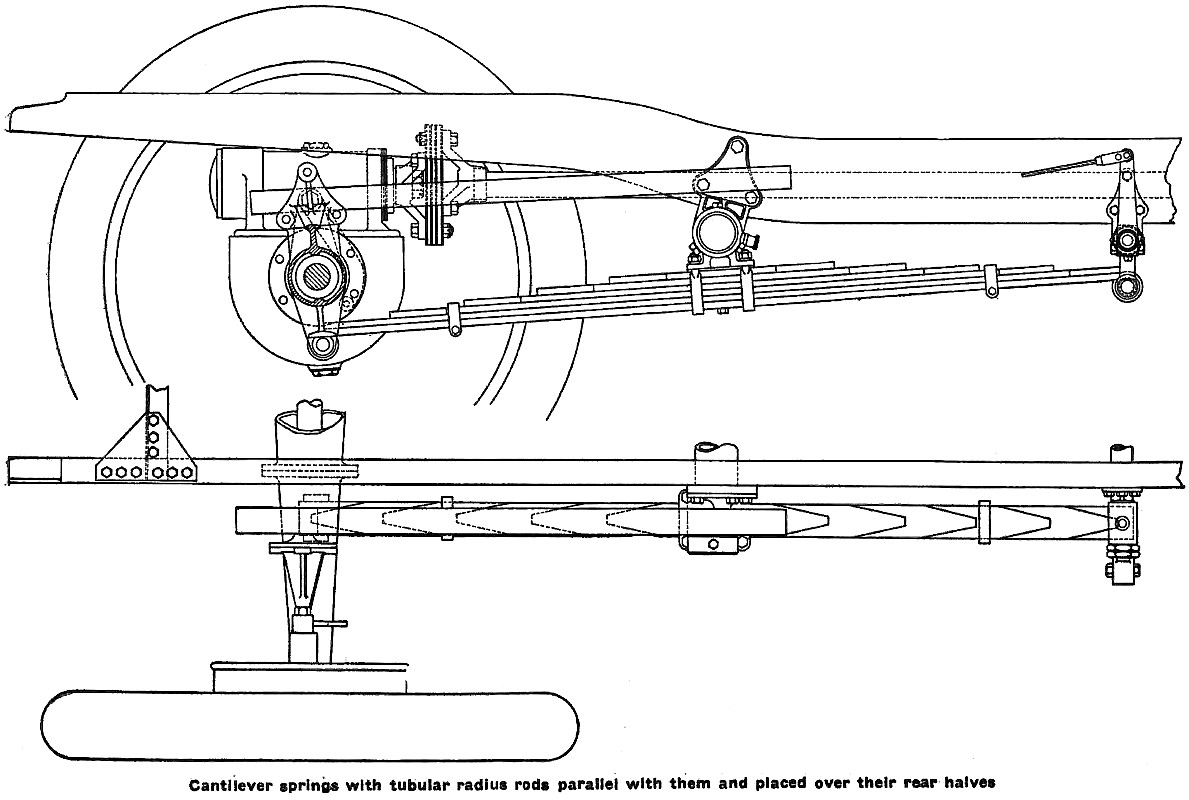

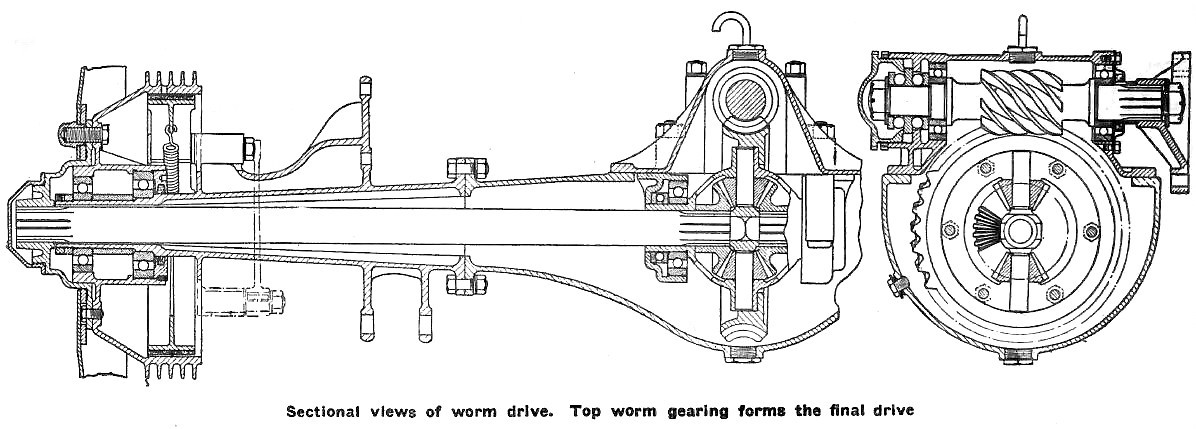

Cubitt Car chassis, The Tatler, 10th August 1921

Cubitt Car’s rear axle, The Tatler, 8th June 1921.

|

|

The Tatler, 12th October 1921

|

|

|

|

CUBITT SHOWS A

LOSS

|

|

|

THE CUBITT

CAR. There is a charm and beauty about the Cubitt that is distinct among cars of this class. The body lines are clean, and possess an air of sturdiness and comfort. Although built to sell at a price which is phenomenally low, it contains all those quantities which make for reliability, long life and comfort. Would be purchasers would be well advised to visit the Cubitt Stand [1922 Olympia Motor Show] before deciding on their 1923 model. Messrs. Cubitt have specialised in one chassis, and have steadily improved it, and the 1923 model will be found as near perfection as humanely possible. It is entirely British built, and thus free from all import duty.

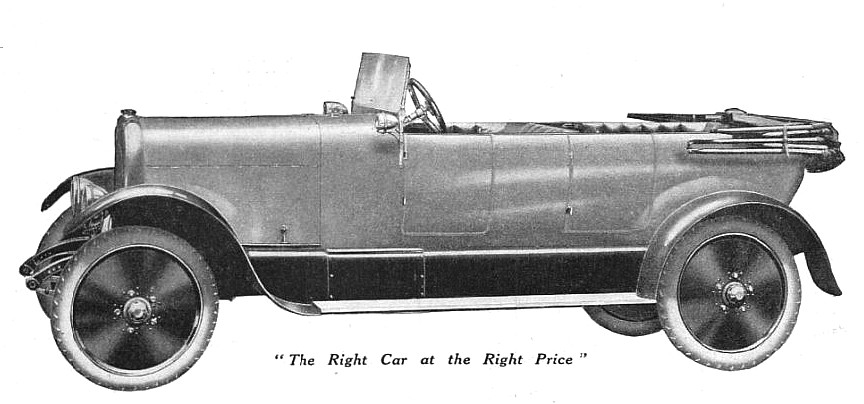

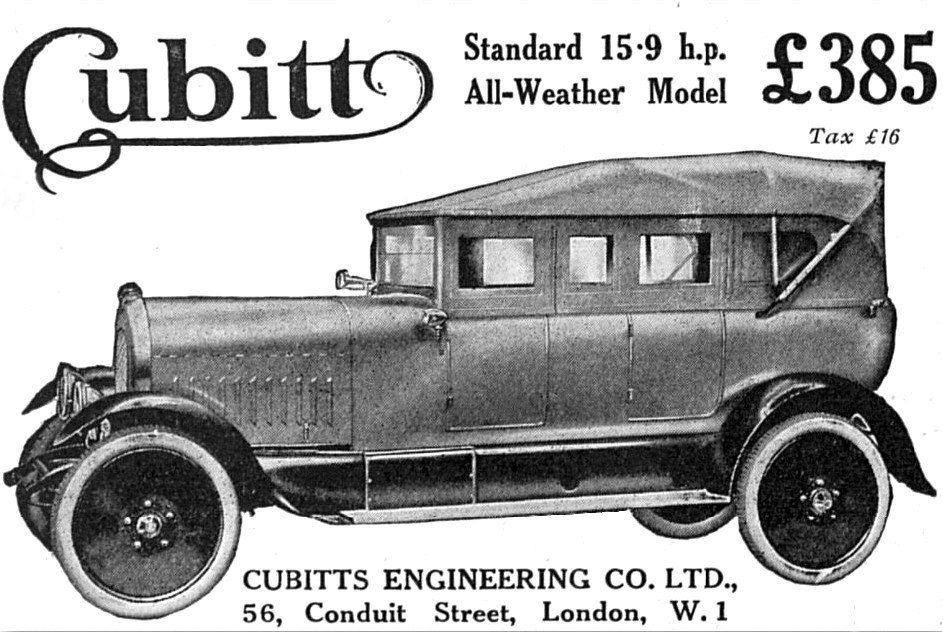

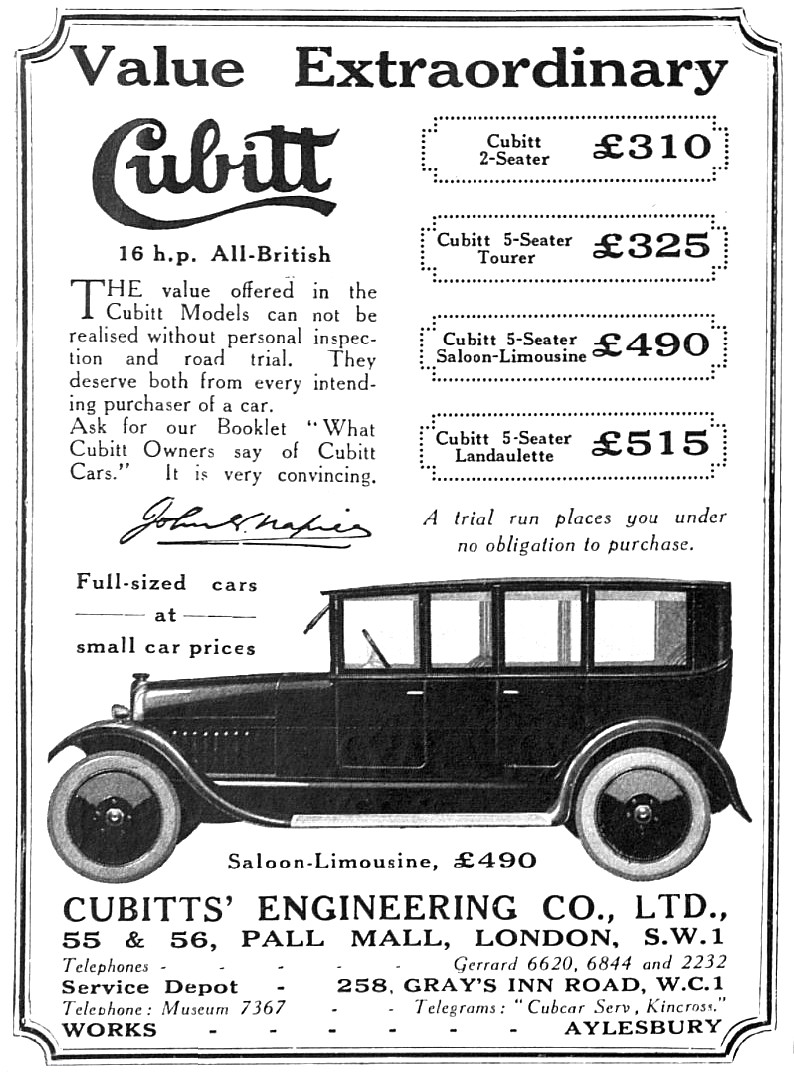

CUBITT. When first put on the market some years ago, the Cubitt was intended to provide a large and comfortable family car at a really low price. It succeeded admirably in this, and with its latest improvements and large reduction in price it has exceeded all expectations. The bodywork has been greatly improved and the rear springs are now on the full cantilever system. The power unit has been greatly refined, and the crankshaft is now dynamically balanced. Four models are shown, the standard five-seater at £360, the deluxe at £495, a two-seater, and an all-weather model. |

THE CUBITT. The Cubitt is the only British car of the larger types which in any way competes with corresponding American vehicles. the result has been obtained without the sacrifice of British principles of construction, and the appearance and general equipment leave nothing to be desired when the price is taken into consideration. The engine is rated at 16 h.p., and an unusual point for a car of this price is that four forward speeds are provided. The body space is generous, and wheels and tyre equipment thoroughly up to their work, and a good electric lighting and starting set, and complete equipment with a full-sized five-seater body is offered complete at £360 complete. This is a remarkable achievement, and while, of course, the finish and detail work cannot be as good as on some vehicles at about double the price, they are quite good, while the design and construction are thoroughly sound. Some people have a peculiar prejudice against British goods which are not of the very highest finish, and would rather buy an American car than a medium-priced home product. I think that many such people would do well to give careful consideration to the Cubitt. |

The Cubitt All-Weather Model

|

|

| OLYMPIA. | |

|

The Scotsman, 31st January 1923.

|

Western Daily Press, 2nd November 1923.

|

The Cubitt All-Weather Model, The Tatler, 30th May 1923.

|

|

Saloon-Limousine, The Bystander, 16th July 1924.

|

――――♦―――― OLYMPIA |

|

|

CUBITT CARS

FOR FAMILY USE

|

The springing is excellent, and the body is so designed that neither passengers nor driver experience the least discomfort on even the longest journey. The Cubitt is a British reply to the challenge of line medium-priced American car, and is remarkable value for money.

|

|

|

|

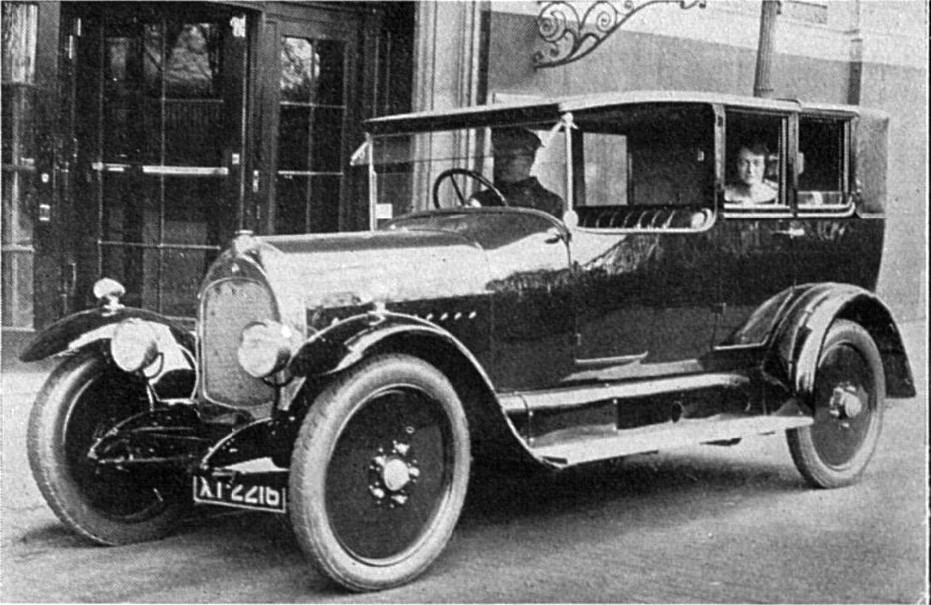

Miss Dorothy Tetley (actress) in her

Cubitt Landaulet.

The Bystander, 11th June

1924.

――――♦――――

1925.

|

|

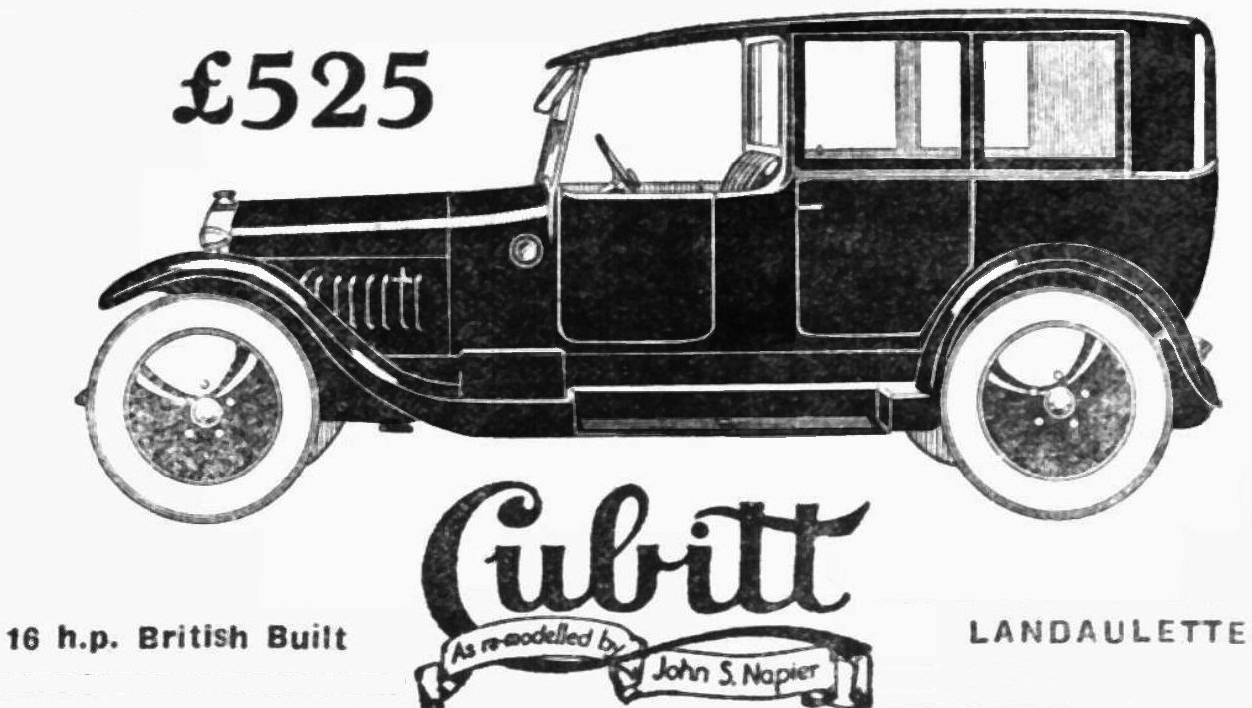

Landaulette, Bucks Herald,

3rd January 1925

Remodelled by John S. Napier

|

|

|

British Cubitt

Car Designed to Compete

|

Engine compartment, 1925 Cubitt 1925 Model K

|

|

|

Lubrication is on

the hollow crankshaft system. The oil pump is of unusual

design; it is of the plunger type and is operated by a short

eccentric strap from the camshaft. There is only one

spring-loaded ball valve, on the delivery side, a suction valve

being eliminated by causing the plunger to uncover inlet ports just

before completing its outward stroke, when the vacuum in the pump

cylinder draws up oil from the crankcase sump through an external

pipe leading from a flanged fitting supporting the cylindrical

filter in the sump. It is claimed that by eliminating the

usual ball valve on the inlet side the most frequent cause of

trouble with the plunger type of pump is removed, the high pressure

on the delivery side permitting a stiffer spring to be used, so that

the ball is far less liable to stick off its seat.

The gearset, as

already mentioned, provides four speeds forward; the gear shift

lever operates in a gate on the right, being supported by a tubular

extension of the cover of the selector mechanism. The casing

is of aluminium with two integral arms of deep inverted channel

section extending from the rear end to the side members of the main

frame. Excepting for the pilot, which has a plain bush,

double-row self-aligning ball bearings are used throughout the

gearset, the primary shaft with integral constant-mesh pinion having

two such bearings separated by a distance piece 134 in. long.

Both main shaft and lay shaft are splined, the gear sleeves on the

latter being free to float axially but for distance pieces and the

presence of the end bearings when the component is assembled.

The main shaft splining is continued through the rear bearing to

carry the combined transmission brake drum and spider for the front

universal joint of the propeller shaft; to form an abutment for the

drum, a groove is turned in the splining of the shaft for a split

collar between which and the drum boss the inner race-of the ball

bearing is pinched by the tightening of the nut on the shaft end.

To locate and secure the outer ball races of the lay shaft in the

straight through machined holes of the aluminium casing, 5/16 in.

bolts with extra large round heads pass through holes drilled in the

casing so that the heads within overlap the outer race, while the

nuts hold steel plate washers overlapping the race on the outside;

these nuts also secure the pressed steel end caps. Although

this arrangement eliminates shouldered bores, it appears to open up

possibilities for abuse by allowing over-tightening of the nuts to

give rise to end thrust on the bearings, for the outer races project

slightly within the casing.

Top worm gearing

forms the final drive with a ratio of 4.125 to 1. The worm

integral with its shaft is carried on ball journals with a double

thrust race at the rear end. The method of locating the latter

is unusual, for the central ring of the thrust unit is held against

an internal flange of the housing by the threaded end-cap and a

locking nut. |