| |||||||||||||||||||||||||||||||||||||

|

|

|

Corduroy road. |

The earliest of our roads might be described as ‘improved’ tracks. Some improvement of the natural landscape would have been desirable at fords, and through mountain passes and swamps. They would have consisted largely of clearing the track of trees and boulders, but as commerce increased the track might be flattened or widened to better accommodate human and animal traffic or, perhaps, sledges. [1] As a result, by about 5,000 BC tracks developed along ridges in England that avoided the need to cross rivers and marshland. Where marshland did need to be negotiated, an improvement could be obtained by placing logs perpendicularly across the line of track, perhaps with longitudinal bracing, a type known as a ‘corduroy’ or ‘log’ road. However, while aiding the passage of human traffic, movement in the logs could prove hazardous to horses.

|

“Considering the fact that such works of engineering skill had all to be done by patient manual labour, through a wild and meagrely cultivated island, we can easily see what a vast expenditure of time and effort must have been involved in it. In some places, great quantities of timber had to be cut down; in others, the ground had to be embanked and drained before it was firm enough to advance upon. The shallower streams were crossed by paved fords, whose courses were marked by large wooden posts. The enduring quality of the works, as well as their great extent, left its impress upon the face of England to such a degree, that these roads are the wonder of the engineering world today.” The Development of Transportation in Modern England, W. T. Jackman (1916) |

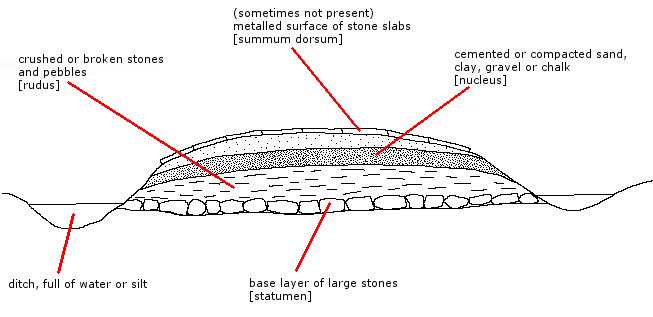

Generally speaking ― for there was no hard-and-fast rule ― road construction commenced by removing loose earth

and excavating a wide trench to a depth at which a foundation was

reached that was sufficiently solid to support the road. [2] Stones were then laid onto the base in strata, each stratum having

slaked lime poured onto it to produce a crude form of concrete. Where

stone was plentiful the road surface might be paved with slabs,

otherwise crushed stone was used.

Cross-sectional diagram of an idealized Roman road as found in Britain.

The road thus formed, several feet thick, was raised slightly above

ground level, its hardened surface being laid with a camber to allow

rain water to run off into the drainage ditches. A kerb prevented the

edges breaking up. In some locations the road was further embanked above

the surrounding land to prevent the road bed becoming saturated in wet

areas, to maintain the gradient, and to help guard against ambush in

violent times. [3] On wider roads, the strips of

ground between the road and the boundary ditches were used by

pedestrians. If shallow, streams and rivers were crossed by paved fords

marked out by stakes or, if not, by timber bridges, sometimes laid on

masonry piers, but the Romans appear not to have built stone bridges in

Britain. Ferries were used to cross major rivers.

|

By the 17th century, the use of wheeled vehicles was becoming much more

common. In order to reduce the incidence of their wheels cutting ruts

into what road surface there was, James I. introduced law that limited

the minimum width of vehicle wheels (to lessen wheel pressure); required

axletrees to be of different lengths (to ensure the rear wheels passed

over a different surface to those at the front); required horses to be

tethered abreast, rather than in line (to spread wear from the horses’

hooves); and limited vehicle weight. Other restrictions were more

intricate; for example . . . .

|

“. . . . the several Nails of the Tire or Tires of the Wheels of every Waggon, Wain, Cart, or other such Carriage used or drawn on any Turnpike Road, shall be so countersunk as not to project beyond One Quarter of an Inch above any Part of the Surface of such Tire or Tires;” Geo. IV., cap 95, RA 19th July 1823 |

. . . . transgressors could be fined forty shillings, if the vehicle

owner, and twenty shillings if the driver, for every incident. But the

law could have had little effect, for even as late as the 18th century

the seasoned traveller Arthur Young (1741-1820) had this to say about

the state of a road in Lancashire over which he was obliged to pass:

|

“I know not, in the whole range of language, terms sufficiently expressive to describe this infernal road. Let me most seriously caution all travellers who may accidentally propose to travel this terrible country, to avoid it as they would the devil; for a thousand to one they break their necks or their limbs by overthrows or breakings down. They will meet with ruts, which I actually measured, four feet deep, and floating with mud, only from a wet summer; what, therefore, must it be after winter?” |

And similar stories abound. However, the 18th Century was to produce

four civil engineers ― each of whom arrived in that embryonic profession

rather by accident ― who between them returned road-engineering to a

standard last attained by the Romans.

――――♦――――

THE BEGINNING OF MODERN

ROAD CONSTRUCTION

|

|

|

High pattens. |

So far as we are aware, there is no account of the condition of the

roads in Tring before the era of modern road building, but an account of

conditions in nearby Aylesbury does exist. Writing in 1842, Mr. John Gibbs of

Aylesbury had this to say:

“I recollect the year 1800. At that date the general state of Aylesbury was wretched as compared with its present condition. The footways with few exceptions were bad, neglected, and impassable; allowed to go to decay, they were repaired in a very rough and ready manner. Kingsbury in wet weather was a morass, not ankle deep, but knee deep, in mud. Walton Street was no bettor. The outskirts of the town abounded in filthy ditches. A wide gaping ditch was open all down the west side of Walton Street, and on the east side so had was the construction of the footway that a rail was requisite to keep foot passengers from tumbling into the road . . . . No one thought of entering the town by way of the Oxford Road, in fact from its miserable state it was impassable; the traffic then passed up Castle Street. White Hill was in a like state; the street leading from the Nag’s Head Inn to the Buckingham Road was not considered public; it was with the greatest difficulty that foot passengers could make a way through it, from its bad state. Dropshort was a slough; I have frequently trespassed on the adjoining meadow by crossing it, to avoid being stuck in the mud there. In my young days, before the principal streets in the town were pitched [i.e. sealed with coal tar] by the Trustees of the Turnpike Roads, they were often ankle deep in mud; females without the aid of a pair of high pattens [see illustration] would not venture across them.”

Buckinghamshire: A History of Aylesbury with Its Borough and Hundreds, Robert Gibbs (1885)

The seeds of modern road construction in England were first sewn in

Scotland, in difficult times.

| “Had you seen these roads before they were made, You would lift up your hands and bless General Wade.” |

|

|

|

George Wade, soldier and military

engineer. |

So says

doggerel engraved on an obelisk near Inverness.

The first new road network in any way comparable to that of the Romans

was built for exactly the same purpose, to suppress a hostile

population, a requirement that arose from the Jacobite uprisings. [4] The road builder in question, General (later Field Marshall) George Wade

(1673-1748), is not only remembered for his road-building achievement,

but for appearing in the sixth verse of our National Anthem:

|

Lord, grant that Marshal Wade, |

Wade was sent to Scotland in 1724 to “inspect the present situation

of the Highlanders” and to “make strict inquiry into the last law

for disarming the Highlanders”. He reported that most Highlanders

able to bear arms against the Crown were ready to do so — as later

proved the case — and he recommended the construction of barracks,

bridges and roads to help control the Highlands. Having received

and approved Wade’s

report, King George I. then gave to Wade the task of implementing his

recommendations ― and

Wade built his military roads to last:

|

“The construction of these roads was not dissimilar to Thomas Telford’s practice eighty years later, in that a foundation of larger stones were laid to a depth of 18 inches, covered by a layer of gravel ideally as much as 3 feet deep, but sometimes only half that. Facines [5] were used in lieu of the base course where roads crossed boggy ground, anticipating John Metcalf’s famous use of them after he returned home from the ‘Fortytfive’. Banks, side-drains and cross drains served to remove the copious rainfall from the road. The standard width was 16 feet, but 10 feet was not unknown. About 40 bridges were built to 1736, a few each year, under contract by masons, some of whom came from the Lowlands for the work” Biographical Dictionary of Civil Engineers, Prof. Sir Alec Skempton (2002) |

A well-preserved section of General Wade’s

Military Road near Melgarve,

leading to the Corrieyairack Pass. Only the

foundation stones remain

|

|

|

Wade’s bridge at Aberfeldy. |

Construction took place between April/May and October of each year, the

winter months being too harsh for work. Work in the summer could be

arduous too with uncertain weather and the presence of the ubiquitous

midge. The construction parties consisted of 100 men overseen by 2

corporals, 2 sergeants, 2 subalterns and a captain. A soldier was

expected to complete 1½ yards of road per day on reasonable ground, and

was paid an additional allowance while so employed.

When Wade retired in 1745, work continued under Major (later Lieut-Colonel) William Caulfeild

until his death in 1767, when the highland road-building programme

ended. By then, some 1,100 miles of road had been constructed, Wade being

responsible for 300 and Caulfeild the remainder. Many sections of these

roads remain in use today in a modified form. But perhaps the best

known monument to Wade’s work is the bridge designed by William Adam

over the Tay at Aberfeldy.

|

|

|

Blind Jack of Knaresborough. |

In 1745, Wade was given command of an English army, his task being to

confront the Jacobite army of Charles Edward Stuart (a.k.a. Bonny Prince

Charlie) then invading England. Among his contingent was John Metcalf [6],

a musician and performer on the oboe and violin,

who had a remarkably varied and successful career despite being blind

from the age of six. Although not a member of Wade’s road-building team,

‘Blind Jack’ was present at the English defeat by the Scots at Falkirk

Muir (1746) — where, as a military musician, he played his company onto

the field — and at the Duke of Cumberland’s defeat of the Jacobites at

Culloden three months later.

Following his term in the Army, Metcalf had a spell at horse trading and

then running a stage wagon business between York and Knaresborough.

While engaged in this latter occupation he took up a contract to build a

3-mile section of turnpike road between Harrogate and Boroughbridge,

including a small bridge at the latter. So commenced Metcalf’s career as

a road-builder, during which he built some 180 miles of roads in

Yorkshire, Lancashire, Derbyshire, and Cheshire.

George Bew, a contemporary, gave an account of him in his paper

Observations on Blindness (Memoirs of the Manchester Literary and

Philosophical Society, 1785):

“This is one John Metcalf, who, like the

gentleman already mentioned, became blind at a very early age, so as to

be entirely unconscious of light and its various effects. This man

passed the younger part of his life as a waggoner, and, occasionally, as

a guide in intricate roads during the night, or when the tracks were

covered with snow. Strange as this may appear to those who can

see, the employment he has since undertaken is still more extraordinary;

it is one of the last to which we could suppose a blind man would ever

turn his attention. His present occupation is that of a projector

and surveyor of highways in difficult and mountainous parts. With

the assistance only of a long staff, I have several times met this man

traversing the roads, ascending precipices, exploring valleys, and

investigating their several extents, forms, and situations, so as to

answer his designs in the best manner. The plans which he designs,

and the estimates he makes, are done in a method peculiar to himself,

and which he cannot well convey the meaning of to others. His

abilities, in this respect, are nevertheless, so great, that he finds

constant employment. Most of the roads over the Peak in Derbyshire

have been altered by his directions, particularly those in the vicinity

of Buxton; and he is, at this time, constructing a new one, betwixt

Wilmslow and Congleton, with a view to open a communication to the great

London road, without being obliged to pass over the mountains . . . . I

have met this blind projector while engaged in making his survey.

He was alone as usual, and amongst other conversation I made some

enquiries respecting the new road [from Wilmslow to

Congleton]. It was really astonishing to

hear with what accuracy he described its course and the nature of the

different soils through which it was conducted.”

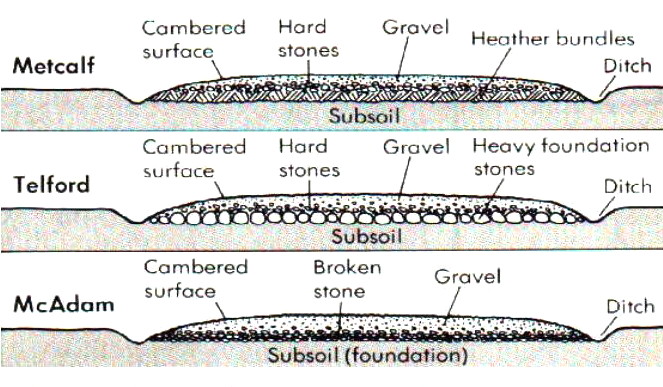

Metcalf returned to Roman road-building principles. He built on a firm

foundation created by excavating any soft surface material until a firm

footing was reached on which the bottom layer of stones could be placed. He found that angular broken stones made a better foundation than smooth

round ones, which were pushed aside when placed under load. In order to

deal with marshy areas Metcalf used fascines (as Wade had done before

him) for the

foundation, and built his road on top; this ‘floating roadway’ proved

very successful, in many places enabling a more direct route to be taken

(years later, George Stephenson used the same method to carry the

Liverpool and Manchester Railway over the bog known as ‘Chat Moss’). Atop the foundation, Metcalf created an elevated road surface, which he

built smooth and convex to allow rainwater to drain quickly into

roadside ditches. It is said that during construction, Metcalf would

arrive early on site and tap every section of the route with a hollow

stick to ensure that it met his standards.

Metcalf continued road building until reaching the age of seventy-five

(in 1792). In the course of his career he constructed over 120

miles miles of high-quality road, attributing his success to his

excellent memory for detail that had resulted from his blindness.

He made a valuable contribution to communications in the late eighteenth

century by improving routes and thus enabling wheeled vehicles to move

more easily in the critical period of rapid industrial expansion.

Thomas Telford (1757–1834)

|

“Every valley shall be exalted, and every mountain and hill shall be made low; and the crooked shall be made straight, and the rough places plain.” Isaiah xl. 4 |

The extent to which the methods of Wade and Metcalf influenced later

road builders is unclear. The great civil engineer Thomas Telford knew

of Wade’s military roads, which he condemned as poorly aligned, steep,

rough and badly drained — overall, “as to be unfit for the purposes of

civil life”. But this is unfair criticism, for Telford’s road-building brief

was very different from that given to Wade and Caulfeild. The fact remains

that the Highland military roads were suitably engineered for their

purpose, while there is every reason to believe that if the pair had

been required to deliver roads for civil use — e.g. by mail coaches —

they would not have lacked the necessary skills to build them.

Nevertheless there can be no doubt that the road works of the next two civil

engineers were to have widespread influence.

|

|

|

Thomas Telford FRS, FRSE, civil engineer. |

Commencing in about 1804, Thomas Telford began to deliver this biblical

vision. A stonemason by trade, Telford became a prolific civil engineer. During his long career he was responsible for building a number of

significant roads, canals and bridges, but not railways, which came to

prominence at the end of his life. Among his major achievements is the

London to Holyhead road, the A5, which crosses the Menai Straits on the

579 ft span stone and wrought-iron Menai Suspension Bridge (begun in 1819 and

completed seven years later). But arguably his best known work is the

18-span, 126ft high iron trunk Pontcysyllte Aqueduct, which carries the Llangollen

Canal over the valley of the River Dee at a point between Llangollen and

Ruabon.

In 1815, Telford was appointed Engineer to the Holyhead Road

Commissioners with responsibility for estimating the cost of a new road

to link Holyhead with the Capital. His estimates and designs having been

accepted, an Act of Parliament was passed authorising the work (today

one marvels at its trivial cost!):

“An Act to amend an Act passed in the Fifty fifth Year of His

present Majesty, for granting to His Majesty the Sum of Twenty

thousand Pounds towards repairing Roads between London and

Holyhead by Chester, and between London and Bangor by

Shrewsbury; and for giving additional Powers to the

Commissioners therein named, to build a Bridge over the Menai

Straits, and to make a new Road from Bangor Ferry to Holyhead,

in the County of Anglesea”.

Public Act 1819, 59 George III., c. 48

Telford’s method for road building required digging a trench, installing

a foundation of heavy rock, and then surfacing with layers of smaller

stones topped with

gravel. During construction, the centre of the road was raised,

producing a crown that allowed water to drain off:

|

“In terms of construction his major roads were commodious, well drained and incorporated a hand-pitched stone foundation. Unlike McAdam’s roads, they were properly engineered to improved lines and gentle gradients, and although more expensive initially, facilitated traction and reduced maintenance costs. On its completion the Holyhead Road was described as ‘a model of the most perfect road making that has ever been attempted in any country’ (Sir Henry Parnell)”. Biographical Dictionary of Civil Engineers, Prof. Sir Alec Skempton (2002). |

|

|

|

John Loudon McAdam, road builder. By 1823, McAdam was advising 32 turnpike trusts and his three sons were responsible for 85 more, including the Sparrows Herne. His road system became widely used both at home and abroad. |

Although Telford’s method was faster and less expensive than that

employed by the Romans, it was much more expensive than that of McAdam.

In 1783, McAdam became a trustee of the Ayrshire Turnpike and from then

on he became increasingly involved with road construction. In the 15

years from 1798, he claimed to have travelled 30,000 miles gathering

information about road making and, of equal importance, road

administration. He was encouraged to present his ideas in evidence to

Parliamentary enquiries, before which he argued that roads needed to be

raised above the surrounding ground and constructed from layered rocks

and gravel in a systematic manner.

Although both engineers were adamant on one point, the provision of

adequate drainage,

McAdam’s view — contrary to that of Telford — was that a well-drained

roadbed did not require a foundation of large stones, carefully laid and

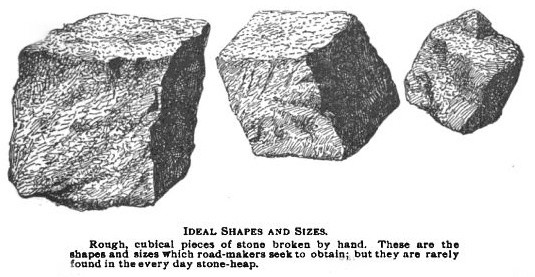

infilled. Instead, McAdam specified two layers of broken stones laid

directly onto the subsoil. First came a closely compacted 10 to 12-inch

layer of stone that had been broken to an inch in diameter and which was

raised in the centre by three inches to facilitate drainage. This was

followed by a carpet of finer-grained stone that was hand-rammed into

place, the better the ramming the harder and smoother the running

surface, which was further improved by filling the small surface gaps

with sand and stone sweepings from the stone-breaking operation.[7]

Both engineers also provided a camber to get the surface water off the

road, and outlets and ditches to ensure that the soil beneath the road

did not become waterlogged.

However, not all stone is suitable for forming a good McAdam surface, a

point taken up by an American journal on road engineering:

|

“An important item in the making of a Macadam road is the obtaining of broken stone of suitable quality and size. It should have careful consideration, since it relates to the wearing surface of the roadway, and upon the quality of the stone used will largely depend the life of the Macadam crust and its smoothness. A hard stone should be used; not hard in the sense that it is brittle, for many brittle stones are quite unfit for use as road metal, but rather stone of a tough texture such as will resist the abrasion of wheel tires and the crushing force of heavy loads.” |

The writer then goes on to discuss the properties of several types of

stone, among which is limestone:

|

“Limestones are both good and bad. The softer limestones wear rapidly, form a road on which mud quickly collects, and roads of softer limestone yield readily to the action of the weather. The upland or mountain limestones, on the other hand, are frequently well adapted for use as road metal. They bind quickly and make a smooth and durable roadway. The rubbing and wearing of limestones form a dust which, when wet, becomes a sort of mortar, filling the little spaces between the pieces of stone and consolidating the entire roadway into a solid and sometimes into a durable crust. Some of the best limestones are found in the Devonian and the older Silurian rocks.” Good Roads, Vol. 4 No. 1, July 1893 |

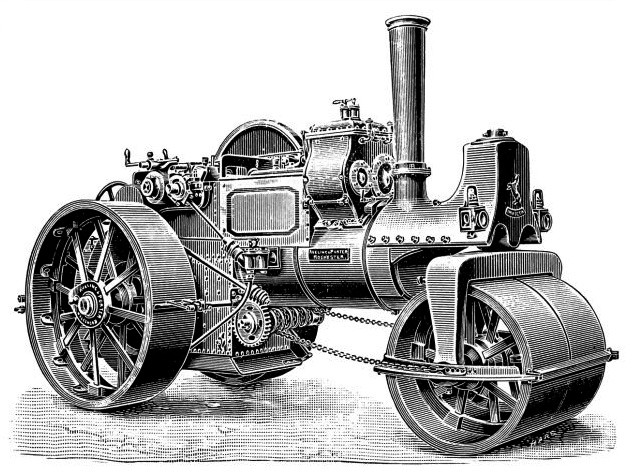

It was later found that compacting the road material was quickened using

a heavy cast-iron roller, instead of allowing for compaction by traffic,

and to answer this need the steamroller was developed.

Before the steamroller

Generally speaking ― particularly where large stones were available ―

Telford’s method of construction was preferred for many years.

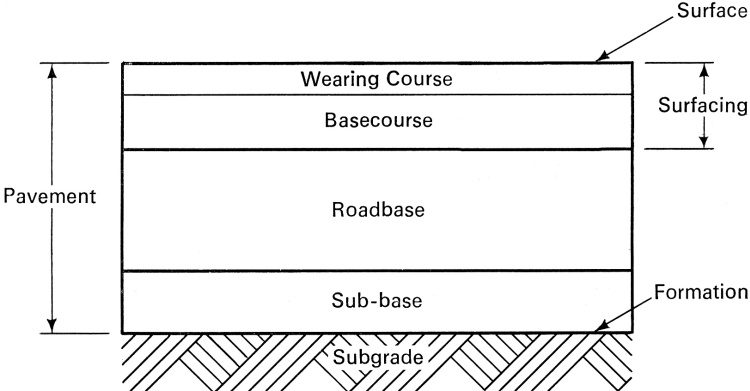

However, the method of road construction has now reverted to that

proposed by McAdam, i.e. a series of layers of relatively small

aggregates with appropriate modifications to meet to requirements of

present day traffic.

The steamroller

As road making in Britain improved, heavy rollers hauled by men or by

horses were used to compact the surface. [8] Steam was

first used to propel road rollers in the 1860s, and the ‘steamroller’

went on to give most of our roads their first compacted foundations and

good running surfaces. Steamrollers, their caravan (in which the driver

sometimes lived with his wife and family) and water cart were once a

familiar train on our roads as they progressed from job to job.

An Aveling & Porter steamroller. This firm

built more steam rollers than all the

other manufacturers combined. They also built steam traction engines

Steamrollers usually weighed between 10 and 15 tons, 10 tons being the

most desirable for general use, as machines of this weight compacted

well while not being so liable to damage drains, water pipes, and other

utilities buried beneath the road. Operating a steamroller was a two-man

job, one man being responsible for maintaining steam pressure while the

other steered and operated the gearing. In a day’s work, a 10-ton

steamroller could be expected to consolidate 1,500 yards of road

material 4-inches thick, the rolling being done slowly to avoid crushing

the stone.

The steamroller was to remain in use until the 1960s, one of its last

major tasks being the

construction of sections of the M1.

|

The surface was first coated with tar. While the tar was still hot, the surface was covered with stone chippings evenly spread. A steamroller then rolled the surface to embed the chippings in the hot tar and complete the job. |

|

‘Tarring’ |

|

|

|

|

|

Ron

Kitchener, |

|

――――♦――――

MODERN ROAD BUILDING

An early motorist (1904) with accompanying dust cloud

Telford’s and Macadam’s roads were a great improvement on their

predecessors; nevertheless they suffered the disadvantage of having

unsealed surfaces, which gave rise to dust in dry weather (and the need

in towns for suppression by water-spraying) and mud when wet. With the

arrival of faster-moving motor traffic, the dust and mud it raised

became even more of a problem. McAdam’s roads were also subject to

erosion by heavy rain and they proved to have insufficient strength

to accommodate motor traffic; in this respect Telford’s system of a

heavy foundation had the advantage, particularly when mechanised road

building equipment became available making it much easier to obtain,

place and compact large thicknesses of crushed rock. Added to

these problems, the loose chippings from unsealed road surfaces thrown

up by faster moving motor vehicles were a danger to other road users and

pedestrians, while exposed sharp edges from the road’s sub-layer risked

puncturing their pneumatic tyres.

Before moving on to outline today’s approach to road construction, it is

necessary to distinguish between three road building materials that were

to come into widespread use in countering the above-mentioned problems, the names of which are often used

interchangeably although the materials are quite different.

|

Tar (also called pitch): a sticky, black,

highly viscous thermoplastic [9] liquid

obtained by the destructive distillation of a variety of organic

materials including wood and coal. Originally used to seal the

gaps in the planking of wooden ships (‘caulking’), tar was later

used to bind the aggregates used in road construction due to its

good adhesive and waterproofing properties. Tar used for this

purpose was produced as a by-product from heating coal to

extremely high temperatures in the manufacture of town gas and

coke. |

Methods to stabilise unsealed surfaces with tar date back to at least

1834 when John Henry Cassell patented ‘pitch macadam’. This method

involved spreading tar on the ground (the ‘subgrade’), building a

macadam road on top, and finally sealing the surface with a mixture of

tar and sand. Another process, ‘tar-grouted macadam’, involved scaring

an existing macadam surface, spreading tar, and re-compacting. However,

little use was made of tar until the arrival

of the motor vehicle at the start of the 20th century and the invention

of Tarmac.

Tarmac —Edgar Purnell Hooley (1860–1942)

The story has it that, in 1901, Edgar Hooley, County Surveyor to

Nottinghamshire County Council, was passing a tarworks when he noticed

that a barrel of tar had been spilled on the road. In an attempt to

reduce the mess, gravel had been dumped on top of it, the result being

that the area was remarkably free from dust compared to the surrounding

road. From this observation Hooley went on to develop and patent

‘Tarmac’ (short for ‘Tarmacadam’). Hooley’s invention was to change the

way we live by, quite literally, paving the way for the motorised world

we now inhabit.

The production of Tarmac originally involved mechanically mixing tar —

which had been modified by adding small amounts of Portland cement,

resin, and pitch — and aggregate (slag) prior to road surfacing. As petroleum

production increased, bitumen became available as a by-product and

supplanted tar.

Tarmac is a registered trade mark for a specific product, whereas

‘asphalt’ is a generic term for a similar group of road surfacing

materials. The basic premise of a Tarmac or asphalt surface is that the

material is prepared, transported to site in insulated wagons, laid

while hot and viscous, and levelled and compacted by rolling as

quickly as possible. It is then allowed to cool so that it sets, and

each particle becomes firmly bound to its neighbours. Two courses are

usually laid.

Structural layers in a modern road

From Modern Flexible Road Construction

Earth moving equipment: bulldozer, grader and dump truck.

When the foundation is complete and has been inspected, the pavement can

be laid. The most common material used for paving roads is asphalt. This

is heated to about 150°C and transported to site in insulated trucks,

where it is spread and compacted onto the road foundation in several

courses. The final tasks include painting road marking and installing

crash barriers, road signs, lighting, emergency telephones and

landscaping.

Road maintenance

Most road surfaces are made of asphalt, still colloquially called tarmac

although tar is no longer used as a binder. When new, asphalt is able to

flex and stretch a little, but as it gets older the bitumen binder

becomes brittle, and cracks can then open in the road surface. Water

then penetrates, freezes and in so doing widen the cracks. This

‘freeze-thaw’ effect can lead to a rapid deterioration of the road

surface and the formation of potholes, which is why they are more

common in cold, wet weather. If this deterioration continues, water can

seep into the lower layers of the road, damaging them too. For this

reason, keeping the surface sealed is key to getting the most life out

of a road.

Road rebuilding is very expensive, so the practice is to concentrate

resources (always in short supply) on keeping the existing road surface

watertight. For this reason surface treatment is considered before more

drastic measures, such resurfacing or reconstruction:

|

|

The process of road building has changed dramatically over the past

century, moving from large gangs of workers with picks and shovels to

enormous specialised machinery. Today, an old road surface is removed by

a process called ‘planing’ where a large machine with a toothed rotating

drum chews off the old surface. While noisy and dusty, the process is

quick. Sometimes only the surface layer is removed (30-40mm) but if the

damage to the surface is deeper then more of the existing road will be

removed in this way. The ground up surface is dumped directly into

trucks for recycling. The planed surface is then cleaned and sprayed

with bitumen to help the new asphalt stick to it.

Planing

New asphalt is brought

to site from the asphalt manufacturing plant in insulated lorries and

laid at a high temperature by a paving machine, which lays a controlled

thickness that is then rolled to compact it and form an even surface.

A paving machine. Hot asphalt is being

loaded into its hopper by

the insulated truck at the rear

The sheer weight of traffic on busy main roads eventually

causes damage that requires deep structural work to correct. This

involves digging down to repair or replace some or all of the foundation

layers of the road, and then laying a new surface on top. The process

varies considerably depending on the structure of the road and the

nature of the problems, but it usually involves removing the old road

and replacing or repairing the structural foundation layers. This

typically means removing the surface layers as if resurfacing the road,

and then digging out the layers below using excavators. These layers can

then be replaced with new ones and new surface layers laid on top.

In England, the maintenance of motorways and trunk roads are the

responsibility of the Highways Agency, an executive agency of the

Department of Transport responsible for operating and maintaining our

strategic road network. Other public highways are the responsibility of

county and city councils.

――――♦――――

FOOTNOTES

1. From the beginning of human history, people have dragged loads too

heavy to be carried. But large objects are often of awkward shape and

texture, liable to snag on any roughness in the ground. The natural

solution is to move them on a platform with smooth runners, a sledge. Sledges are not only useful in winter, but can be drawn over wet fields,

muddy roads, and even hard ground.

2. If a firm foundation could not be readily attained due the swampy

nature of the ground or from any peculiarity in the soil, a corduroy

road foundation was formed artificially using logs; conversely, if the

route led over a rocky surface, excavation might be dispensed as the

terrain formed a sufficiently load-bearing foundation.

3.

|

“In Britain we find considerable variation in the Roman method of construction. An embankment is a very usual feature, and, constructed with the utmost care on a solid foundation with suitable materials, it constitutes the ridge of the road, which often remains almost unchanged by time when man has not disturbed it. The height of the embankment or ridge was sometimes considerable, not only where a low place had to be crossed, but on high ground. Perhaps the most striking example remaining is the embankment called Atchling Ditch or Dyke to the south-west of Salisbury, which for four miles runs across the high open down almost unchanged in profile, five yards across the top and five to six feet high. Another example may be seen between Doncaster and Pontefract, where for several miles there is an embankment four, six, and eight feet high, and six yards wide, on high ground with a rock subsoil.” Roman Roads in Britain, Thomas Codrington (3rd edition, 1918) |

4. The Jacobite risings were a series of uprisings, rebellions and wars

in Great Britain and Ireland that occurred between 1688 and 1746. Their

aim was to restore the Stuart kings, the last of whom, James II

(Jacobite is derived from Jacobus, the Latin form of James), had been

deposed and exiled in 1688. Although each Jacobite rising had unique

features, they were part of a larger series of military campaigns by Jacobites, culminating in the Battle of Culloden in 1746.

5. Fascine: a cylindrical bundle of small sticks of wood, bound

together, used in raising batteries, filling ditches, strengthening

ramparts, and making parapets; also in revetments for river banks, and

in mats for dams, jetties, etc.

6. Metcalf was born at Knaresborough in 1717 and died at Spofforth near

Knaresborough in 1810, aged 92. His fascinating life is recorded in a

biography, The life of John Metcalf, commonly called Blind Jack of

Knaresborough (1795).

7. Remarks on the Present System of Road-Making and Practical Essay

on the Scientific Repair and Preservation of Roads, by John Loudon

McAdam, published in nine editions between 1816 and 1827.

8. It is sometimes believed that rolling levels the ground; it does not.

Rolling compacts (or consolidates) the road materials. If these have

been laid on an unlevelled surface, it will remain so after rolling.

9. A material that softens when heated and hardens again when cooled.

10. The World’s largest natural deposit of bitumen is claimed to be the

Pitch Lake (a.k.a. Lake Asphalt) in Trinidad, which covers about 40

hectares and is believed to be 75m deep.

11. Some examples are the Newberry bypass and the Stonehenge road tunnel

schemes. The Stonehenge scheme was first proposed in 1995. After

protests and public enquiries in 2004 and 2011, work finally commenced

on an alternative scheme in 2012. Between January 1996 and April 1996

the clearance of approximately 360 acres of land including 120 acres of

woodland, and the felling of nearly 10,000 mature trees to make way for

the construction of the Newberry bypass, led to some of the largest

anti-road protests in European history. Around 7,000 people demonstrated

on the site of the bypass route in some way and over 800 arrests being

made. By December 1996, the cost of policing the protest had reached

approximately £5 million. An additional £30 million was spent on private

security guards, security fencing, and security lighting while the works

were in progress, of which only £7 million was budgeted for in the

original contract. The road was eventually finished in November 1998 at

a cost £104 million, against the original contract price of £74 million.

12. Compulsory purchase is the power to acquire rights over an estate in

English land law, or to buy that estate outright, without the current

owner’s consent — but in return for compensation. In England and Wales

Parliament has granted several different kinds of compulsory purchase

power, which are exercisable by various bodies in various situations. Such powers are for the public benefit, but this expression is

interpreted very broadly. Compulsory purchase orders can be issued by

local authorities, highways authorities, Regional Development Agencies,

English Partnerships, and, in the case of Greater London, English

Heritage. In all cases, public bodies are expected to exhaust other

options before issuing a compulsory purchase order.

13. Storm sewer (or storm drain): a system designed to carry rainfall

runoff and other drainage, but not sewage or hazardous wastes. The

runoff is carried in underground pipes or open ditches and discharges

untreated into local streams, rivers and other bodies of surface water.

――――♦――――

[Contents]

|

|