|

THE GRAND JUNCTION CANAL

A HIGHWAY LAID WITH

WATER.

THE CANAL BUILDERS

THE EARLY CIVIL ENGINEERS

“Civil engineering is both a science and an art: as science

it includes the general principles of mechanics and

construction; shows how we may ascertain the strains to which a

structure is exposed; the dimensions and proportions which

should be given to its several parts so as to be able to resist

such strains without injury. As an art, civil engineering

shows how scientific principles may be applied to the

construction of works and how used and modified so as to meet

the difficulties which constantly arise in practice. The

civil engineer being concerned in almost every kind of

construction ought to be a highly accomplished man of science

and indeed there are few men in any profession who can command

so large an amount of scientific and practical knowledge as the

civil engineer.”

Cyclopædia of Useful Arts,

Ed. Charles Tomlinson (1852)

Designing and building a road, canal or railway is a matter of

civil engineering. What follows is a brief account of the

development of this profession during the age in which our

canals and the first of our public railways were built.

Throughout this period ― say 1760 to 1840 ― civil engineering

construction was accomplished by the labour of men and animals,

occasionally helped by gunpowder. Design was at first

empirical; only as the 19th century progressed did it acquire a

scientific foundation, while mechanical aids in the form of

steam engines to expel water and to provide motive power only

then began to appear in the workings (Robert Stephenson was

probably the first to use steam pumps on any scale when, in 1837,

he employed 13

of them ― capable of raising 2,000 gallons a minute up some

150ft ― in the Kilsby tunnel workings on the

London & Birmingham Railway). These factors must

be born in mind when considering the civil engineering of the

time and its remarkable achievements.

In Europe, prior to the 18th century,

‘engineers’

were almost exclusively men skilled in the construction of

fortifications, barracks, roads and river crossings for military

purposes. [1] Although engineering work

was also carried out for civil purposes, no identifiable

profession had grown out of it. It therefore follows that

there was no recognised professional training with associated

tests of competence, neither were there the forerunners of the

contracting firms that today undertake civil engineering design

and construction projects on a massive scale.

From the 1760s onwards, the success of our first canals in

transporting the materials and finished goods of the growing

Industrial Revolution gave rise to a demand for more of these

new load-carrying highways and for those capable of designing

and building them. In the absence of an established

profession, many of those who were to establish their

reputations in meeting this fast-growing demand came from trades

in which at least some of the necessary skills were inherent in

their work. The trade of the millwright was well

represented, which is understandable when one considers the

range of skills that millwrights needed to deploy in the course

of their work and which could also be applied to the

construction of canals. Designing milling machinery

required the ability to draw and read plans, while a knowledge

of mathematics and mechanics was necessary to calculate

loadings, gear ratios and driveshaft speeds. Making

machinery involved working with wood and iron; erecting

buildings, conduits and watercourses involved working with

brick, stone, iron and clay.

|

|

|

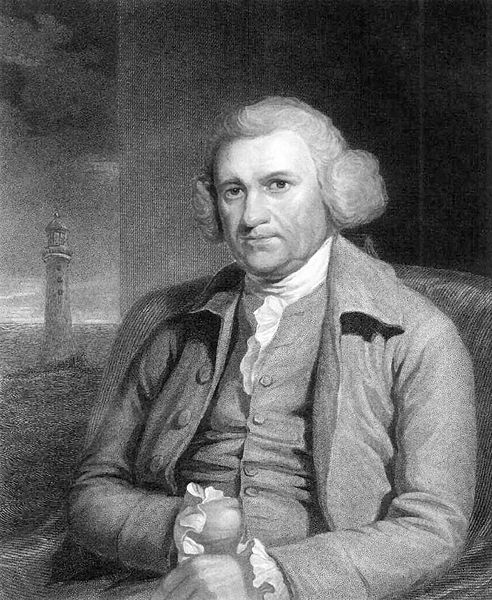

John Smeaton

(1724-92),

one of the first recognised ‘civil

engineers’. |

The best known civil engineers to emerge from the millwright’s

trade were James Brindley, famous for his involvement with the

Bridgewater and other early canal schemes, and John Rennie, who

besides being involved with numerous waterways acquired a

reputation as a bridge builder, with the old Waterloo, London,

Southwark and Vauxhall bridges to his credit. Less well

known was Thomas Yeoman, a waterway engineer and the first

President of the Society of Civil Engineers. From a

slightly later era came former millwrights Sir William

Fairbairn, inventor of the tubular bridge, and Sir William

Cubitt. [2] Cubitt, who was associated

with numerous waterway and railway schemes, received his

knighthood in 1851 for his role as consulting engineer for the

Crystal Palace, built to house the Great Exhibition. A

less laudable achievement of Cubitt’s was his invention of the

treadwheel, a form of human-powered engine cum punishment

device.

James Watt, whose steam engine came to drive many of the mills and

factories of the Industrial Revolution, became a canal surveyor

early in his career. Watt’s background was that of a

scientific instrument maker, in which craft he would have been

familiar with the design, construction and operation of

astronomical, navigational and land surveying instruments, such

as the theodolite. John Smeaton, famous for his

rediscovery of the secret of modern cement (lost since Roman

times) and for numerous bridges, canals, harbours and the third

Eddystone Lighthouse, also trained in this craft.

Numerous civil engineers trained as land surveyors, one of the

most notable being Thomas Brassey. Brassey was among the

most important civil engineering contractors in the world during

the 19th century, building railways in France,[3]

Italy, Belgium, Spain, Russia, India, Argentina and Australia.

Thomas Telford, first President of the Institution of Civil

Engineers,[4] originally trained as a

stonemason, becoming a civil engineer relatively late in life

when he was appointed county surveyor for Shropshire, and

Resident Engineer (under William Jessop) for the construction of

the Ellesmere Canal.[5] Telford first

established his civil engineering reputation with the

magnificent stone and iron Pontcysyllte Aqueduct, which

continues to carry the canal over the River Dee.

But in any profession, some notable members will emerge from

unusual backgrounds. For instance, James Barnes, who with

William Jessop built the Grand Junction Canal, was a brewer, a

trade that he continued while working as a canal engineer.

From where he acquired his civil engineering knowledge remains a

mystery. Sir Edward Banks raised himself from the humble

station of a day labourer to form a partnership with William

Jolliffe to become one of this country’s principal civil

engineering contractors.

――――♦――――

CIVIL ENGINEERING BECOMES A PROFESSION

For most of the canal-building era, [6] there was

no governing body to provide a forum for regular discussion, to

disseminate best practice, maintain a register of competent people,

and set standards and ethics for the profession. Thus, the

early civil engineers learned mostly by experience, supplementing

their on-the-job training by collaborating with each other.

The established practitioners also took pupils who became the civil

engineers of the future.

Take John Smeaton. Generally recognised to be the first

full-time ‘consulting engineer’, he remains one of civil

engineering’s heavyweights, the breadth and depth of his influence

being phenomenal. Smeaton collaborated with, among others,

James Brindley on site investigation for the Trent & Mersey canal,

with Thomas Yeoman on the River Lee Navigation, and with John Grundy

Jnr. in planning the Holderness Drainage scheme. And through

collaboration between his professional descendants, Smeaton’s

lineage comes down through the years. For example, a link can

be traced from Smeaton to our last great canal project, the

Manchester Ship Canal, which opened in 1894, just over a century

after Smeaton’s death:

Smeaton’s pupil, the great canal engineer William Jessop, worked

with Thomas Telford on the Ellesmere and Caledonian canals;

Thomas Telford associated with Sir William Cubitt on the Birmingham

& Liverpool Junction Canal (Telford thought highly of Cubitt to the

extent of leaving him a legacy);

Cubitt worked with Edward Leader Williams on the improvement of the

River Severn, Williams later becoming chief engineer to the Severn

Navigation Commissioners;

Williams trained his

son, Edward Jnr., who became Chief Engineer for the construction of

the Manchester Ship Canal.

All this means that the early civil engineers not only worked as

professionals, but collaborated in a way characteristic of a

profession. This was to lead, in 1771, to the founding of the

profession’s first association ― also the first engineering society

in the world ― the Society of Civil Engineers. Again,

Smeaton’s name comes to the fore as one of the seven founding

members, whose intention was that practising engineers should dine

together periodically so that they might get to know one another,

thereby avoiding potential hostility that might arise in their

public dealings. The Society met fortnightly at the King’s

Head Tavern in Holborn and encouraged “conversation, argument

and social communication of ideas and knowledge”.

Samuel Smiles, in his biography of Thomas Telford (1862), records

that the Society:

“. . . . was discontinued in 1792, in consequence of some

personal differences amongst the members. It was revived in

the following year, under the auspices of Mr. Jessop, Mr. Naylor,

Mr. Rennie, and Mr. Whitworth, and joined by other gentlemen of

scientific distinction. They were accustomed to dine together

every fortnight at the Crown and Anchor in the Strand, spending the

evening in conversation on engineering subjects. But as the

numbers and importance of the profession increased, the desire began

to be felt, especially among the junior members of the profession,

for an institution of a more enlarged character.”

These informal gatherings led, in 1818, to the formation of the

Institution of Civil Engineers, the chartered institution that now

governs the profession in the United Kingdom. [7] Thomas Telford occupied the President’s Chair from 1820 until his

death in 1834, and it was he who in 1828 was instrumental in

obtaining a Royal Charter. The older Society [8]

continues to this day, but mainly as a dining club of around 50

senior engineers and twelve ‘Gentlemen Members’, the latter

including HRH the Duke of Edinburgh.

――――♦――――

PROMOTER, ENGINEER AND CONTRACTOR

The Duke of Bridgewater was the only canal promoter to finance a

significant canal from his own resources; he also recruited, equipped

and managed his own workforce. The project having absorbed his personal

fortune, he then borrowed from whoever he could, even from his

tenants and those from whom he purchased land.

For a single promoter to finance and construct public infrastructure

on any scale and manage the entire works directly was not

feasible in the long run, and the canals that followed the Bridgewater were

financed by public subscription. Each scheme’s shareholders put

up the cash, which the canal company might then supplement by raising loans.

The work was then divided into parcels, put out to tender and

undertaken by contractors. Broadly speaking, this meant that

three parties became involved: the scheme’s promoters, whose concept

it was, who paid for the work and who took ownership of the finished

product; the chief engineer, whose role was to translate the

promoter’s concept into a feasible design; and the contractor(s),

who translated the chief engineer’s design into reality using

equipment and a workforce possessing a range of constructional

skills.

Of course these lines of demarcation did not mean that each worked

in isolation of the others, rather to the contrary. A scheme’s

promoters often took a keen and understandable interest in the

mounting cost of the work and the date at which the completed

project could be expected to earn revenue. The chief engineer

dealt with tenders submitted by contractors for the work to be

carried out, supervised the progress of a construction contract,

monitored the quality of the contractor’s work and arbitrated in any

disputes between contractor and promoters. The contractor(s)

endeavoured to undertake the specified work at a profit. There

were even cases when engineers acted as contractors, and vice-versa

as circumstances dictated. [9] Negotiations between the three parties

[10]

often concerned requirements that

changed in the course of the contract, the quality of the

contractor’s work, overdue payment, and the numerous unanticipated

problems that were (and remain) bound to arise in the course of any

large-scale civil engineering project. Sometimes one party

interfered in the role of the other, for civil engineering was a

young profession and many promoters considered themselves as capable

as their chief engineer. Thus, John Smeaton rebuking the

promoters of the Forth & Clyde Canal by whom he was then employed as

their chief engineer (1768-73):

“If, instead of making plans, I am to be employed in answering

papers and queries, it will be impossible for me to get on with the

business . . . . All the favour I desire of the proprietors is, that

if I am thought capable of the undertaking, I may go on with it

coolly and quietly . . .”

Reports of the Late John Smeaton, FRS

(1812)

Engineer and proprietors sometimes came into conflict over who

should select the assistant engineers and the contractors for the

work, the chief engineer taking the view that such tasks should not

be left to laymen. In situations such as these the views of

the promoters sometimes prevailed, but where they were confronted by

a strong and highly competent personality, like Brunel or Robert

Stephenson, the chief engineer’s view held sway. A story is

told about Sir John Hawkshaw [11] who, attending a

promoters’ meeting, was faced with a refusal to pass for payment a

certificate issued by him as chief engineer on the basis it exceeded

estimate. When silence eventually fell on the meeting he said,

quietly, “Excuse me! What John Hawkshaw signs, you pay”

― and that was the end of the matter.

Sir John Hawkshaw inspecting the works

on the Severn Tunnel (1887).

――――♦――――

THE CHIEF ENGINEER

In the early canal projects, the chief engineer’s activities were

confined to the works where, among other things, he was expected to

perform the roles of manager and agent for the promoters, acting on

their behalf (sometimes under their direction) in the purchase of

building materials, the hire of labour, handling land purchases, and

placating landowners and others with grievances caused by some

aspect of the work, a common problem being damage caused to local

roads by the heavy increase in site traffic.

As the building of the canal network progressed, eventually leading

into the railway era, so developed the

civil engineer’s role, with chief engineers coming to form a small

but distinguished group employed in consulting, designing, directing

works and giving evidence before parliamentary committees . . .

.

“One of the principal exhibits of a Civil Engineer’s talent and

resources is displayed in the Committee Rooms of the Houses of

Parliament, in his examination as a Witness to prove the

practicability or the contrary of proposed Public Works, comprising

the numerous Railways, Canals, &c. throughout the kingdom. And

as the same individual has frequently to advocate and support

totally opposite systems and contingencies, upon different

undertakings, much ingenuity is consequently displayed on these

occasions ― for instance, where an Engineer appears as a Witness in

favour of a Line of Railway with very favourable Gradients, his

answers to the questions are always full and explicit, and he states

boldly, without fear of contradiction, the great advantages of a

level railway, compared with an undulating line, containing long and

steep inclinations thereon; but he is not so communicative

respecting the means which are taken or the sacrifices which are

made to obtain this advantageous run of levels.”

Railway Practice, S. C. Brees, C.E. (1839)

. . . . and often performing two or more of these roles

simultaneously. Much of

the administrative work was taken over by the company’s Secretary

(sometimes called the Clerk) and Solicitor ― particularly the former

― while the chief engineer came to sit at the head of a team of

engineering assistants. On complex projects, chief engineers

were sometimes engaged full time on the works, examples being Marc

Brunel on the Thames Tunnel and (by the railway era) George

Stephenson on the Liverpool & Manchester Railway, while on the

London & Birmingham Railway, Stephenson’s son Robert . .

“. . . almost lived on the line, and the first occasion on which

he visited the portion in question, after the contracts were let,

accompanied by the Secretary and by four or five Directors, was the

twelfth time that he had walked the whole distance from London to

Birmingham.” [12]

Personal Recollections of English Engineers,

F. R. Conder (1868)

|

|

|

Robert Stephenson

(1803-59), civil engineer. |

But in general it became rare for a project’s chief engineer to be

on site permanently; instead, his role became one of laying out the

route of the canal or railway, designing its main engineering

features and preparing the necessary plans and specifications.

He would then hand over the designs to a resident engineer who,

acting in the client’s interest, supervised the execution of the

designs with assistant engineers under him to supervise the building

contractors on sections of the work. Periodically the chief

engineer would visit the works to review progress and deal with any

problems that were too complex for the men on the spot to resolve.

This management structure, which reached its maturity under Telford

on works such as the Caledonian Canal, would be familiar to British

civil engineers today.

A common class of problems that gradually fell to the chief engineer

to resolve were disputes involving some aspect of the contract.

Here, the chief engineer came to be regarded as Arbiter, a role in

which his independence from the scheme’s promoters, shareholders and

contractors was important in establishing confidence in his

judgement. As the great civil engineer John Rennie Snr.

put it:

“Engineers should be entirely independent of these connections ―

not dabblers in shares [13] ― and free

alike of contractors and contracts.”

Lives of the Engineers

(Vol. 2), Samuel Smiles (1862)

|

|

|

John Rennie Snr.

(1761-1821), civil engineer. |

Robert Stephenson appears to have become a past master at

arbitration, much to the dismay and financial loss of our learnèd

friends:

“From the time of construction of the London & Birmingham Line,

when he acted so frequently as arbitrator between the company and

their numerous contractors, Robert Stephenson was constantly

referred to in the disputes of business men. He was no good

friend to lawyers. The amount of litigation he prevented by

amiable counsel would almost justify his memory being held in

abomination in Chancery Lane.”

Life of Robert Stephenson,

J. C. Jeaffreson (1864)

And so the more successful chief engineers came to be paid at daily

consultancy rates [14] for the time they actually

spent on the work and they would, at any time, have numerous

projects of different types and in various stages of progress around

the land. In an age when travel was slow and difficult, much

of their time was thus spent traversing a wide area and, in the case

of canal and railway projects, the entire length of the works

themselves.

At the opposite end of the hierarchy to the chief engineer were his

‘pupils’, in effect apprentices. From the earliest days of

civil engineering, the established practitioners took pupils, the

term being seven years. There were no suitable university

courses until well into the 19th century and even books on the many

aspects of civil engineering did not become generally available

until the 1800s. Pupils learned by experience, generally under

the direction of their master, but it was not unusual for one chief

engineer to ‘lend’ a pupil to another, who happened to be short of

an assistant to undertake some mundane task:

“The younger men, unable to front a public meeting or a board of

directors, were in demand everywhere for field work. Engineers

who had pupils to spare, lent them to one another, or let them out

on terms of hire agreeable to all parties. Thus the scene of

recollection may readily change from the busy hive of workmen, that

filled the great open ditch of the Euston extension [London and

Birmingham Railway], to the Derbyshire moors, the Essex corn-lands, or the

Norfolk fens.”

Personal Recollections of English Engineers,

F. R. Conder (1868)

Francis Conder, a pupil of Charles Fox, [15]

continues by recounting his experience of being ‘lent’ to John

Braithwaite, chief engineer of the Eastern Counties Railway, to

undertake some surveying. And so Conder set off for the

fen-lands and to the rigours of overland travel in the pre-railway age:

“After receiving a decorous lecture, as to the exactitude

requisite, both in the discharge of his [Conder’s] scientific

work and in the control of the expenditure he was about to incur, he

set off on the exploration of a portion of this line furnished with

level, staff, chain, Ordnance tracings, written instructions, and a

very moderate sum of money. Desirous to give full obedience to

the excellent advice which he had received with some awe, he engaged

a place on the outside of the mail [stagecoach]. With

the advance into Essex the evening mist thickened into rain, and the

journey was not half accomplished before the wet began to find its

way through the ‘warranted water-proof’ cap which formed part of the

strictly limited wardrobe with which, as usual with most

inexperienced travellers, he thought it convenient to travel.”

Arriving at his destination wet through, Conder was about to

discover that learning by experience was not confined to stagecoach

travel, for he found the area to be surveyed under water:

“On approaching the coast, with the purpose of identifying the

few unintelligible lines by which the tracings of the Ordnance

Survey (for the real map had not been forwarded with the

instructions) indicated the localities to be traversed by the

parliamentary section [the line of the railway], not a single

boundary or division was discernible. A long perfectly

straight road ran from the verge of the fens proper to the bridge

separating that district from the sea-port terminus. . . . the road

in question was not shown in the tracings, and the fens were under

water. One broad, unbroken sheet of inland lake was all that

was presented to the eye.”

On reporting this to the chief engineer, he received the following

instruction, short and to the point: “Set so-and-so to run his

level along the road from Yarmouth to Acle, and ****** the Fens!”

――――♦――――

THE CONTRACTOR

If honest ― and some were not ― the civil engineering contractor

endeavoured to complete the specified work within the time, cost and

quality requirements laid down in his contract with the promoters.

The first contractors were roving gangs of labourers who undertook

excavations and other tasks at piecework rates, performing the work

with their own equipment and sharing the proceeds among themselves

in whatever manner they pleased, assuming that the ganger had not

made off with them as sometimes happened.

The practice for letting small contracts in this way continued, but

in 1767 a significant development took place when a partnership was

formed between John Dyson and James Pinkerton, who set up as

earthwork contractors and before long were operating on a national

scale. A further step was taken in 1788, when John Pinkerton

took on a contract for constructing the entire Basingstoke

Canal, [16] thus marking the beginning of the

‘general contract’ system. However, Pinkerton acquired a

reputation for dishonesty and poor quality work, and became no

stranger to complaints, rescinded contracts and litigation. As

contractor for the Birmingham to Fazeley Canal, he even went so far

as to build a tunnel at Curdworth where a cutting had been

specified! Despite his failings, when he died in 1813 he left

an estate valued at £7,500.

|

|

|

Thomas Brassey

(1805-70), civil engineering contractor. |

Today, there are large, well-established contracting firms and

industry standard contracts [17] and arbitration

procedures for public infrastructure projects based on a great many

years of experience. But in the canal and the railway-building

eras there was little experience on which to base large-scale

contracting, resulting in tenders based on guesswork ― sometimes

inspired, sometimes not ― about how much a gang could excavate and

bricklayers build in a given period. If the contractor’s

estimate erred sufficiently on the side of caution, while remaining

competitive, he might earn a fortune; and some did. It is said

that more cash passed through the counting house of the great

Victorian railway contractor Thomas Brassey than through the

treasuries of half a dozen European principalities. Said to be

self-contained and self-sufficient, Brassey had the gift of being

able to cost work quickly in his head and then live contentedly with

whatever the consequences might be. These were mainly

unforeseen engineering difficulties and poor cash flow due to

promoters being tardy in settling their accounts, but rising labour

costs in the course of a long contract could reduce or eradicate the

profit margin. Without adequate contract terms to cover such

events, the work might be skimped in an effort to contain rising

costs while problems might also leave unpaid gangs and a bankrupt

contractor. [18] In this situation, and in

the absence of finding another suitable contractor, the resident

engineer was left to complete the job.

Eventually men of outstanding ability arose from these gangs and

other sources that had the necessary personalities and experience to

organise and direct large operations, and they in turn gradually

gained the confidence of financiers who were prepared to back their

activities. Frederick Williams, writing in 1852, summed up the

financial burden that lay upon the civil engineering contractor, and

for which he required capital:

“In the best-managed contracts, the time for completion, and the

fines for exceeding that period, are stated; with the condition that

all payments are subject to the engineer’s approval of the work.

The contractor finds tools, labour and materials, gets out all

foundations, excavations, centreings, pumping apparatus,

scaffolding, fencing and other requisite materials of every

description, according to the specifications, plans and drawings,

and the instructions that he may from time to time receive from the

engineer.”

Our Iron Roads, F. S.

Williams, (1852)

While much of the early work continued to be undertaken by numerous

small contractors, the general contractor gradually came to

dominate. Two of the firms that rose to early prominence were

those of Hugh McIntosh and Edward Banks (from 1807, Jolliffe and

Banks). Both began in the 1790s on small canal contracts, but

eventually grew to become capable of handling several large works

simultaneously, employing a site ‘agent’ (the counterpart of the

resident engineer) to oversee each contract. Jolliffe and

Banks grew into one of the main construction companies of the era,

their portfolio including Waterloo Bridge (1817), Southwark Bridge

(1819) and the New London Bridge, which was opened by King William

in 1831. Banks was knighted in 1822.

During the railway building era, the partnership of Peto, Brassey

and Betts were both promoter and contractor of the Victoria Dock ―

the first London docks to be served by rail ― and the London,

Tilbury & Southend railway, which the partners ran on a 21 years

lease after they had built it. Thus were sown the seeds of

today’s constructional industry.

――――♦――――

THE WORKFORCE

The promoter, engineer and contractor were, between them, one

component in bringing a new canal or railway to fruition.

Theirs was the project’s concept, design and management, and in

their own way each carried an element of risk. The promoter

and contractor had a direct financial stake in the project ― would

their particular interest in it yield an adequate profit? And

in the case of engineer and contractor, the risk to their

professional reputation of failure would inevitably impact on their

future earnings.

A construction project’s other and equally essential component was

its army of skilled and unskilled workmen. Digging cuttings,

forming embankments and excavating tunnels ― not to mention the

construction of bridges, locks, aqueducts and viaducts ― required

substantial numbers of men with a wide range of skills.

Collectively, these men became known as ‘navvies’ [19]

and they moved with their families to work on engineering projects

wherever there was a demand for their labour. Although many

were escaping poverty (and later the famine) in Ireland, contrary to

the oft-held belief that the navvies were Irish, [20]

they came from all parts of the British Isles and even from Europe.

Out of their harsh working conditions and communal living there

gradually evolved a lifestyle, culture and even a language.

They also acquired a reputation for hard living, hard drinking

(alcohol probably providing a temporary release from the toil and

privation of their daily lives) and fighting, which often led the

local communities within which they worked to regard them as

degenerate and a threat to the social order.

Although the navvies’ drink-fuelled rioting was not that uncommon,

killings were. In his book Navvyman (Coracle Press,

1983), Dick Sullivan describes the outcome of one such incident, [21]

the hanging, by the side of the Edinburgh-Glasgow railway track, of

two Irish members of a navvy gang who, in 1840, murdered an English

ganger:

“Police and soldiers of the 58th Foot (later the Northamptonshire

Regiment) drove up from Glasgow in omnibuses to arrest the whole

gang. Over the next few days they were driven in noddies from

the Bridewell to the Sheriff’s Chambers in Stockwell Street for

questioning. In the end, James Hickie, Dennis Doolan and

Patrick Redding were brought to trial. Hickie was transported,

the others hanged.

“Doolan and Redding shambled to the gallows, as ungainly in their

shackles as quadrupeds made to walk upright, until the chains were

struck from their ankles at the foot of the gibbet. A bishop

prayed for them. Then there was the black hood, then the

noose, then the drop that broke their spines with a loud crack in

the bright May air. A young soldier, pale as the hanging

corpses, blacked out and fell.”

Strikes for more pay, which occurred from time to time, were

sometimes met in a robust manner. During construction of the

Wolverton Embankment on the Grand Junction Canal, a demand for

higher wages met with this directive from the Board to the site

engineer . . . .

“ . . . . to discharge at all risqué these offenders, and to use

his utmost endeavours to bring them to Justice, and to call on the

Magistracy and Yeomanry of this County to repress and punish all

acts of Outrage and Violence and an illegal conspiracy or

combination for increase of wages.”

GJCC Minute Book, 5 May, 1801.

But such a response is hardly surprising in an age when a

‘combination’ of protesters was to lead to the Peterloo Massacre.

Despite their way of life, it was the navvies who carried the

gruelling physical burden of construction work, usually in appalling

conditions, with a life spent at other times (when not on the

‘tramp’ between jobs) living in rough timber and turf huts alongside

the bridges, tunnels and cuttings on which they worked. It was

inevitable that such conditions would foster disease, and outbreaks

of cholera, dysentery and typhus were not uncommon. Sometimes

navvies were able to lodge in nearby towns and villages, but even

where suitable accommodation lay nearby, their reputation for

thieving and not paying the rent made them undesirable tenants.

Of this community, the ‘skilled’ element comprised the masons,

bricklayers and blacksmiths. The products of the masons’ and

bricklayers’ crafts are well preserved in their many surviving stone

and brick bridges, viaducts, etc., alas, now sometimes abandoned.

As for the blacksmiths, they sharpened the picks and chisels, and

hammered out new tools from wrought-iron. They also shod the

horses, fettled the wagons and ― as the nearest to a mechanic on

site ― kept the pumps in working order.

It is, perhaps, inaccurate to refer to the other element as

‘unskilled’, for it took up to a year to turn a common labourer into

a navvy capable of excavating 20 tons of earth in a day. It

was they who dug the thousands of miles of our canals and railways

using the standard tools of their trade, the pick, the shovel and

the wheelbarrow, helped along by horse and cart. When not

digging, other tasks that formed part of a navvy’s typical day were

rock blasting (using black powder), spoil tipping, puddling,

ballasting and laying railway track. For this they were

comparatively well paid, a good navvy earning up to 30 shillings a

week, three times the wage of an agricultural labourer. But it

was dangerous work and the risk of accidents was an accepted part of

the job, especially when blasting rock or building tunnels (by

candlelight), which were vulnerable to collapses and to gas

explosions. The contractors cared little for the wellbeing of

their men, who were poorly trained and often poorly supervised;

driven by the principle that ‘time costs money’, speed rather than

safety was their main concern. It was said that a navvy

working on the construction of Woodhead Tunnel during the 1840s was,

as a percentage of the workforce, at greater risk of injury than a

soldier at the Battle of Waterloo.

When the canal and railway-building eras eventually ended, there was

more work for the navvies, especially during the Victorian period

with its impressive record of constructing new docks, dams, roads

and public buildings. British navvies also acquired a good

reputation as a workforce abroad, many going on to work on European

railway projects where their capacity for unremitting toil earned

them twice the pay of the indigenous labourers. Some went

further afield to North America, were high wages attracted many

Irish navvies to the construction of the Erie Canal in New York

State and to similar civil engineering projects. Many later

found jobs in South Africa, Canada, New Zealand and Australia.

Essentially, the navvy was a short-lived product of our industrial

expansion and engineering achievement. Just as canals and

railways were vital to the progress of our Industrial Revolution, it

should not be overlooked that the work of the navvies ― shifting

millions of tons of soil and rock from one place to another ― was

also crucial to the development of Britain as an industrial nation. |