|

THE GRAND JUNCTION CANAL

A HIGHWAY

LAID WITH WATER.

CANAL ENGINEERING

CHOOSING THE ROUTE

“The mere digging or cutting into the earth is so common and

obvious an operation that it may seem to require neither skill nor

explanation. This however only applies to small and ordinary

operations, for when the work is extensive, as in the formation of

canals, reservoirs, tunnels, and the like, many expedients are

resorted to that might not occur to common workmen; they have arisen

out of experience and are adopted because they economise labour and

time, and consequently diminish the expense of executing the work.”

Elements of Civil Engineering,

John Millington (1839)

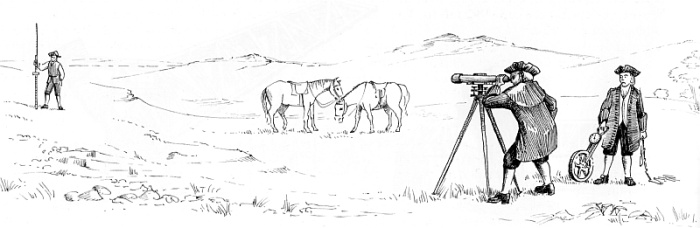

In deciding what route a canal was to follow, its chief engineer

first needed to undertake a preliminary survey of the area, for most

canals were built in an age before reliable maps were generally

available [1] ― they had therefore to be made, and

to a standard sufficient for their purpose. Equipped with

level, staff, measuring chain, compass and surveyor’s barometer, [2]

the engineer and his assistants set off to acquaint themselves with

the landscape.

.JPG)

|

A surveyor's

Y-level by Adams, London, late 18th century.

History of Science Museum, Oxford.

A telescope

supported in y-shaped rests and as a result capable of

being rotated around its own axis or of being taken out

of the supports and turned end for end for purposes of

adjustment. The surveyor uses a level to determine

elevations. In conjunction with a level, the surveyor

uses a ‘level rod’ to read an elevation above or below

the level of the telescope. From these observations can

be determined the differences in elevation of different

points along a route, or an elevation can be transferred

from one location to another. |

|

|

A ‘waywiser’ by

Thomas Wright and William Wyeth, London c. 1740.

History of Science Museum, Oxford.

This is an surveying instrument for measuring distance

travelled over the ground, including its

undulations. As it is moved along, the wheel drives a

mechanism in the dial, which clocks the distance moved. |

|

Surveyor's

Chain.

Campus Martius Museum.

In

the top illustration, the 'chainman’ (to the right of the

surveyor) is holding a surveyor's (or Gunter's) chain,

used to establish horizontal distances accurately

along compass sight lines. A chain is sixty-six feet or

four poles long, and is composed of one hundred links,

connected each to each by two rings. On sloping land,

the chain has to be ‘levelled’

by raising one end to the horizontal, so that

undulations in the ground do not increase the apparent length of the

side or the area of the tract being measured. |

|

In most cases the preliminary survey would identify several possible

routes or variations on them. Other factors would then need to

be considered, not least of which were the locations of any estates

that the canal needed to traverse. If an influential landowner

did not wish to sell a tract of land to the canal company,

objections could be expected during the parliamentary committee

hearing, objections that counsel would be employed to express most

forcibly by cross-examining the chief engineer on the feasibility of

his plan [3] and by embroidering their client’s

grievances to best effect. In practice, canal (and later

railway) promoters often placated influential landowners by buying

them off at much inflated rates. While this was usually an

effective strategy, it was one that became increasingly expensive as

landowners realised that by adopting hindering tactics they could

greatly increase the value of their land.

Another aspect of land purchase to be considered was the higher cost

of land in urban areas; might it be more cost-effective to select a

route around the outskirts of a town rather than through its centre,

or to avoid the town altogether? Traffic levels would also

influence a canal’s dimensions and thus the amount of land required;

a wide canal could accept barges larger than the conventional

‘narrow boat’, [4] and greater loadings earned

more revenue, but it required more land, materials and man-hours to

construct, and thus more capital. Empirical rules were

developed to determine the optimum dimensions of a canal for

whatever size of craft was most likely to be used:

“Although for the sake of saving expense in aqueducts and

bridges, short portions of a canal may be made wide enough for the

passage of one boat, only the general width ought to be sufficient

to allow two boats to pass each other easily. The depth of

water and sectional area of waterway should be such as not to cause

any material increase of the resistance to the motion of the boat

beyond what it would encounter in open water. The following

are the general rules which fulfil these conditions:―

|

Least Breadth at Bottom = 2 x greatest breadth of a

boat.

Least Depth of Water = 1½ feet + greatest draught of a

boat.

Least Area of Water-way = 6 x greatest mid-ship section

of a boat. |

The bottom of the water way is flat. The sides when of earth

which is generally the case should not be steeper than 1½ to 1; when

of masonry they may be vertical; but, in that case about 2 feet

additional width at the bottom must be given to enable boats to

clear each other, and if the length traversed between vertical sides

is great, as much more additional width as may be necessary in order

to give sufficient sectional area.”

A Manual of Civil Engineering,

W.J.M. Rankine (1862)

In an age when canal barges were hauled by horses ― mules and

donkeys were sometimes employed ― the land purchased had also to be

sufficient to permit a towing path to be built, and of a width that

would allow two horses to pass. [5]

In making his recommendations to the Board, the chief engineer

needed to weigh estimated traffic revenue plus any other income

(such as water sales and property rent) against operating expenses

plus interest on loans, to estimate the likely yield on capital ―

was the canal, as proposed, a worthwhile investment?

“A proper engineer being fixed upon, the adventurers [i.e.

the Proprietors] should not tie him down too closely by

restrictions as to time; but allow him leisure to consider digest

and revise again and again the different projects and ways which

will in most instances naturally present themselves to him in an

extensive and thorough investigation . . . . The most eligible route

for a canal being settled in the engineer’s mind, he will then

proceed to make a rough calculation of the quantity of goods of each

kind which may be expected to pass upon the line in a given time; he

will also examine all the canals and rivers with which the proposed

canal is to connect, and ascertain the widths, and depths thereof;

the sizes of their locks and of the vessels usually navigating

them”.

An Encyclopædia of Agriculture,

J. C. Loudon (1871)

The need to solve problems such as these illustrate why the civil

engineering profession evolved quickly from its trade roots, such as

those of stone mason or millwright, into that of seasoned

professionals who could handle large projects rationally.

Promoters of canal (and later on of railway) schemes eventually came

to expect their chief engineer to possess the knowledge and

experience to plan the entire project, not merely one of its parts

however important that part might be.

|

|

|

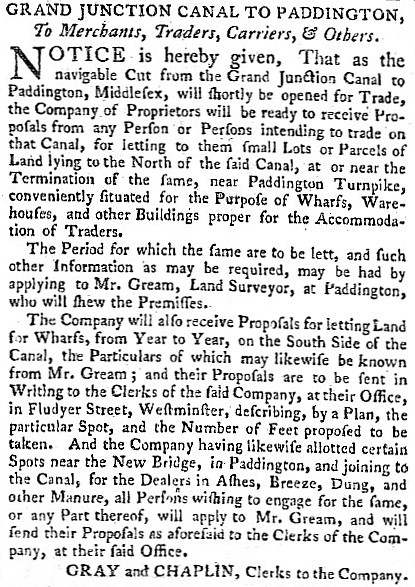

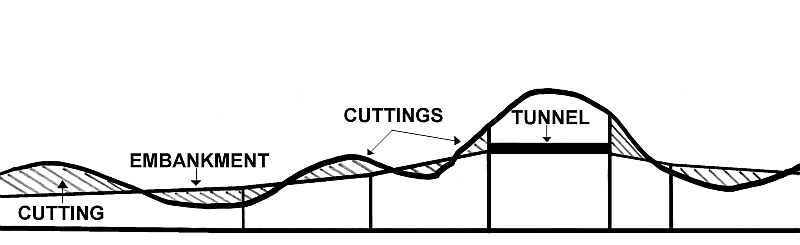

For many

years Edward Gray of Buckingham and Acton

Chaplin of Aylesbury served as Clerks to the Grand

Junction Canal Company, with press notices such as

this frequently appearing above their names. |

All factors having been considered and the route decided, a detailed

survey was then necessary to determine accurately the form and

dimensions of the ground to be traversed and the positions of

objects upon it, processes called ‘triangulation’ and ‘levelling’, [6]

and to make trial borings which (it was hoped!) would reveal

potential problems with geological formations invisible to the naked

eye. This information allowed maps to be prepared, showing the

position of the canal in relation to land boundaries and the

physical features on the landscape, and

cross-sectional diagrams on which were represented the

positions of slopes in relation to the horizontal, enabling the

chief engineer to examine the gradient at any point along the route.

Engineering works could then be designed to reduce gradients to a

sequence of level sections by the construction of locks, cuttings,

embankments, aqueducts and tunnels, while reservoirs and pumping

stations could be sited where necessary.

The rules for applying to Parliament for a private Act required

canal promoters to provide the committee who were to consider their

application with the details of the intended route and of the

landowners who would be affected. Collectively, these are

known as the ‘deposited plans’. [7] If

the promoters’ Bill succeeded, thereby becoming an Act, it was this

route, perhaps modified by objections made during the committee

hearings, which became the authorised ‘Parliamentary Line’ from

which the canal company was not permitted to deviate by more than

100 yards. The Act also authorised the canal company to

acquire the land they needed by compulsory purchase, but with the

inclusion of an arbitration procedure to be followed in cases where

the parties could not agree on valuation.

Having raised the finance, engaged the services of a solicitor

(‘Clerk to the Company’) and civil engineer, completed the surveys,

posted public notices, obtained the necessary private Act, purchased

the land, and agreed terms with earthwork and other contractors,

construction could begin. Activities often commenced with the

ceremony of ‘cutting the first sod’, at which the company chairman

and other dignitaries attended to turn a token spade-full of earth

(rather less than the twenty tons that each navvy would subsequently

consider to be a fair day’s work) before sitting down to a sumptuous

dinner, which contemporary news reports suggest followed each major

achievement during a canal’s construction.

――――♦――――

RIVERS, NAVIGATIONS AND CANALS

Although this account is of a canal, it is worth mentioning

what distinguishes a canal from the other types of navigable

waterways that are referred to occasionally in the following text.

A ‘river’ is a natural watercourse that drains water off the land

into the sea; in its natural state it is vulnerable to drought and

to flooding. If a river is to be used for navigation, its

natural course generally needs to be straightened and deepened by

dredging and by the construction of weirs and locks. Rivers

made navigable in this way are termed ‘river navigations’ or

‘canalised rivers’; which term applies appears to be much a matter

of scale. For instance, the extensive Aire & Calder Navigation

in West Yorkshire [8] is referred to as a ‘river

navigation’, while the more modest section of the Grand Junction

Canal between Hanwell bottom lock, where it is joined by the River

Brent, and the end of its journey at Brentford Creek is described as

a ‘canalised river’.

In contrast, a canal is a man-made trench or channel that is filled

with water to a depth sufficient to permit navigation [9]

and which, unlike a river, connects predefined locations. In

effect it is a manmade highway laid with water. If properly

managed, a canal should be much less vulnerable than a natural river

to drought and flooding, and because it is built in level sections

and includes weirs to carry off any excess water, what current there

is is negligible, thereby permitting the comparatively easy haulage

(or propulsion) of heavily-loaded craft in either direction.

However, as still water freezes more quickly than running water ―

especially if the latter is saline ― a canal is more vulnerable to

freezing over.

|

A canal is a manmade highway

laid with water. Here, the Wendover Arm of the Grand Junction

Canal

is being restored. This section of the Arm was abandoned in

1904

due to incurable leakage and

its water fed into a pipe to supply the Tring summit via Tringford

pumping station. Today’s navigators

ensure the canal is watertight with the use of Bentomat© sheeting,

seen here being rolled along the bed before being topped with 300mm of earth.

Bentomat sheeting is also laid behind the

protective blockwork along the canal

banks. |

――――♦――――

CANALS ON LEVEL GROUND

On level ground, a canal was formed by cutting the ground [10]

and using the excavated spoil to form its banks. ‘Cutting’

commenced with the ground being cleared of obstructions. The

chief or resident engineer would then mark out the course of the

canal (in accordance with the deposited plans) and the position and

height of its banks with pegs and stakes.

Following cutting, it was often necessary to make the canal

watertight. If the ground over which it passed absorbed water

― such as sand, gravel or chalk ― an impervious

lining was needed to prevent leakage. [11]

Although a lining of clay might appear the obvious solution, it is

unsuitable, for if the water level in the canal sinks below the

upper part of the lining, pure clay, on drying out, shrinks and

cracks. When the water level returns to normal the cracks

remain and cause leakage. The canal builders therefore used a

modified form of clay for lining called ‘puddle’, the process of

laying it along the canal bed and its banks being known as

‘puddling’.

|

|

|

The application of puddle

(‘A’ in the diagram) to canals in cuttings and on level ground, from

. . . .

Illustrated Glossary of Civil Engineering - S.

C. Brees (1852). |

Puddle clay does not occur naturally. It is made from loam

mixed with sharp sand and water, which is then worked intensively

into a plastic state in which it forms an impervious seal. A

civil engineering manual of the age described the process:

“No cheap and common material is found to oppose the filtration

and passage of water so effectually as a soft loamy clay when it is

well worked or kneaded into a soft paste with water and is not

permitted to get dry again. Even if a little fine gravel or

what is called by the navigators in England hoggin, being small

sifted gravel no stone of which is larger than a common pea is mixed

with it, it seems to hold better but this can only arise from these

small stones assisting in the kneading process.”

Elements of Civil Engineering,

John Millington (1839)

The puddle was then applied in layers and left to mature ― but not

dry out ― as the handbook goes on to inform the budding canal

engineer:

“The ground is loosened in the bottom by the scoop [digging

tool], but is not thrown out; that done, a pretty copious supply

of water is sent into the puddle gutter by buckets or a temporary

pump, and the workmen, by pressing down the scoop tool and walking

backwards and forwards in the puddle gutter, reduces all the natural

soil that has been disturbed into a state of very soft mud, or

slush, as it is called. This is done for the purpose of

producing an intimate union and incorporation between the natural

soil and the puddling stuff to be afterwards added.

The puddling stuff is now brought in barrows and cast into the

gutter, to be treated in the same manner; a copious supply of water

must constantly be given and the more the puddling stuff is trod and

worked by the feet and scoop the more perfect the puddle will be.

Nothing is found to answer the purpose so effectually as treading

with the feet and the layers of puddling stuff should never exceed

nine inches in thickness without being trodden and worked. The

stuff should be kept so wet that the feet sink in eight or nine

inches at every step and this same operation is continued until the

puddle gutter is filled to the top or at any rate to a greater

height than that at which the water in the canal or reservoir will

stand. Dry earth is then placed over the top of the puddling

to protect it from the sun and air . . . .”

Elements of Civil Engineering,

John Millington (1839)

The total thickness of puddle varied between 2ft and 3ft depending

on the nature of the underlying soil. The process of treading

it in, by navvies wearing thigh-length boots, must have been

extremely tedious and tiring, and it is unsurprising that there is

anecdotal evidence of cattle being herded over the puddle to achieve

the same effect. Rushes might then be planted to help

consolidate the banks.

Re-puddling a canal bed.

While puddling controlled leakage, water level had also to be

limited, for a canal overflowing its banks could result in a breach

and serious flood damage to the locality. ‘Overflow weirs’

take the form of a section of wall built into the canal bank to a

height corresponding to the maximum permitted depth; should this be

exceeded, the excess water flows over the top of the weir into a

channel. Weirs built at locks channel any excess water around

the lock into the section of canal (‘pound’) below it. Excess

water might also be channelled into a reservoir to be pumped back

into the canal at times of low water level, or into a nearby stream

or river where it might then have been used to drive water mills

(disputes between water millers and canal companies over the

latter’s use of river water were common) or simply run off to waste.

Temporary dams (‘stop gates’) and sluice gates enabled sections of

the waterway to be isolated and drained completely. Again, the

manuals of the day provide the novice civil engineer with sound

advice:

“Each reach of a canal should be provided with waste weirs in

suitable positions to prevent its waters from rising to too high a

level; also with sluices through which it may be wholly emptied of

water for purposes of repair; and in a reach longer than two miles,

or thereabouts, there may be stop gates at intervals so that one

division of the reach may be emptied at a time if necessary.

The rectangular channel under a bridge or over an aqueduct is a

suitable place for such gates.”

A Manual of Civil Engineering, W. J. M. Rankine

(1862)

This overflow weir at New Bradwell permits

surplus water from the Canal’s two summits

to spill into the Great

Ouse.

The narrow boat

has just crossed the New Bradwell

Aqueduct (opened in 1991).

Originally, only the nearside canal bank was protected, usually with

dry-stone walling backed with puddle clay, its main purpose being to

support the towpath. When powered craft began to appear late

in the 19th century, it was found that the turbulence they caused

resulted in erosion of the unprotected bank, resulting in weakening

and debris, which subsided into the channel where it caused silting.

Over many years, hundreds of miles of piling ― concrete at first,

steel later ― had to be driven into canal banks to provide the

necessary bank protection.

|

New sheet steel piling on the Wendover Arm

at Bulbourne Junction. The interlocking sheets are driven into the canal

bed using a pile driver. To the rear, the piling is held in place with steel

rods sunk into the embankment, back-filled with rubble and topped with coir

rolls (just visible). |

Bridges were needed ― indeed, they were usually specified in a

canal’s Act of Parliament ― to carry public roads and to connect the

opposite sides of estates that had been divided by a canal.

Bridges were also necessary to carry the towpath across the canal

where it changed banks, [12] or where it crossed

the entrances to docks or intersections with other waterways.

This attractive turnover bridge is at The

Grove on the Grand Junction Canal.

This type of bridge is so

constructed that horses could proceed with the tow-rope remaining

attached to the boat.

――――♦――――

THE PROBLEM OF GRADIENT

A significant factor to affect the canal engineer’s choice of route

was that of ‘gradient’, or the steepness of the ground over which

the waterway was to pass.

Sections of a canal need to be built on the level if it is to

provide still water for navigation. In some parts of the

country it was possible to build long stretches on the level merely

by following the contour of the land. Such ‘contour-following

canals’ tend to be characterised by their long, meandering course.

In contrast, a direct route, while shorter and requiring less land

to be bought, generally required more engineering work in the form

of locks, cuttings, embankments, tunnels and aqueducts to permit the

canal to be built in level sections across whatever gradients lay in

its path.

Thus, the choice for the canal engineer was whether to select a

longer, flatter route that bypassed rising ground, or to cut across

it with engineering work. A longer slower journey did not

matter that much when the first canals were built, for their

carrying capacity far exceeded anything that had previously been

practicable. Furthermore, because civil engineering was at the

time in its infancy, canals of this period tend to follow the

contour to avoid the need for risky and expensive earthworks; the

meandering southern section of Brindley’s Oxford Canal is an

example. [13] Later canal engineers took

more direct routes, an example being the Birmingham and Liverpool

Junction Canal (now part of the Shropshire Union). Engineered

by Thomas Telford and completed in 1835, this was one of the last

canals to be built and exhibits the characteristics of the railways

that were shortly to follow. By taking a direct line across

country at the cost of building cuttings and embankments, some of

which were massive undertakings, [14] Telford’s

route saved some 12 miles.

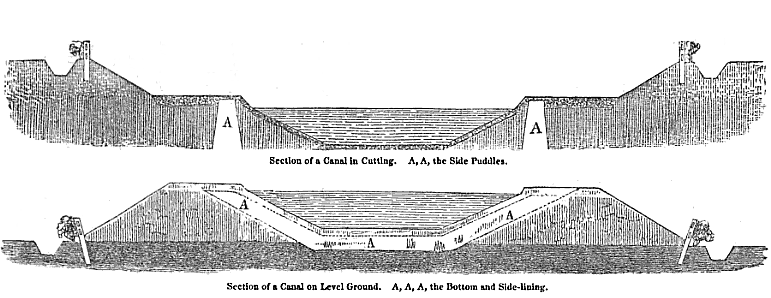

An illustration of how engineering work can

be used to reduce the gradient of a road crossing rising ground.

A canal follows the same

principle, using a series of level steps, each separated by locks.

――――♦――――

CUTTINGS

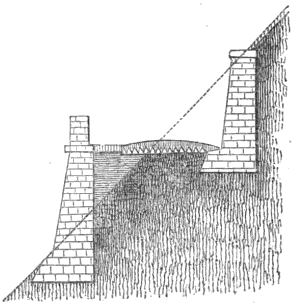

|

|

|

The principle of

the ‘side cutting’,here applied to

a road traversing the side of an incline. |

Cuttings and embankments are two means of eliminating gradient.

In a sense one is the opposite of the other; a cutting is cut

through the ground, an embankment is built above it, [15]

while the term ‘cut and fill’ describes the process by which, in an

ideal situation, the spoil dug out of a cutting matches the quantity

needed to build a nearby embankment.

Cuttings come in two types; a ‘side cutting’ is created on one side

of a slope and is formed by cutting into the high side of the hill

and using the spoil to build up the low side. Alternatively,

the low side might be built up from below. But more often a

cutting is excavated with rising ground on both sides, and the spoil

is carried away for use elsewhere, or if there is no use for it, it

is spread on the surrounding land. [16]

During the period of canal and railway building, cuttings were

excavated manually with the assistance of gunpowder for blasting

rock. Compared with the problems that can be encountered in

excavating a tunnel, forming a cutting or embankment might appear

straightforward by comparison, but they too present engineering

difficulties.

|

An

extreme example of a canal cutting. The Corinth Canal

connects the Gulf

of Corinth with the Saronic Gulf in the Aegean Sea.

The limestone terrain permitted its

walls to be cut nearly vertical ― they rise 90 metres (300 ft) above sea level at an

80° angle. Cutting through softer

terrain would have required a

much shallower angle of repose to prevent the walls slipping into

the channel. As things turned out,

the stone proved to be heavily faulted resulting in landslips, and

much remedial work has had to be carried out over the years to

stabilise them. |

The problem with cuttings lies in landslip, or the walls of the

cutting slipping or otherwise falling into the channel. This

can result from the walls being built too steeply, perhaps to

economise on the amount of land that has to bought. In the

case of cuttings driven through clay, poor drainage can cause the

clay to expand as it becomes saturated ― much difficulty was

experienced with this particular problem when building the cuttings

into Euston on the London & Birmingham Railway. Unstable rock,

particularly when it becomes fractured by ice, can fall away from

the walls.

‘Angle of repose’ describes the natural angle at which a granular

material, such as earth or sand, will rest without slipping. A

knowledge of this property for different materials plays an

important part in the construction of cuttings and embankments when

deciding what angle the walls will stand at without other measures

having to be taken to prevent slip. The angle varies for

different types of materials, and also whether they are dry, wet or

waterlogged. For example, no matter how much dry sand

is added to a pile, it won’t form a slope steeper than approximately

35º, which is the angle of repose for sand in this condition.

In contrast, by making the sand damp, the capillary

attraction or cohesion between the sand grains increases, allowing

the creation of up to vertical walls. But as more water is

added, the sand begins to act like a plastic substance, and in its

waterlogged state the angle of repose drops to about 12º. From

this can be seen the need to build good drainage into the walls of

cuttings and embankments, particularly where the terrain is a

granular material rather than hard rock.

Some of the techniques that are used to prevent slopes slipping are:

-

the construction of retaining walls;

-

putting drains through retaining walls so that water is not

trapped behind them;

-

constructing terraces to reduce the angle of slope;

-

using grasses or other plants (such as rushes in soft canal

banks) whose roots anchor the slope;

-

sinking piles through unstable debris down to firm bedrock;

-

inserting bolts (rock bolts) to hold unstable rocks.

――――♦――――

EMBANKMENTS

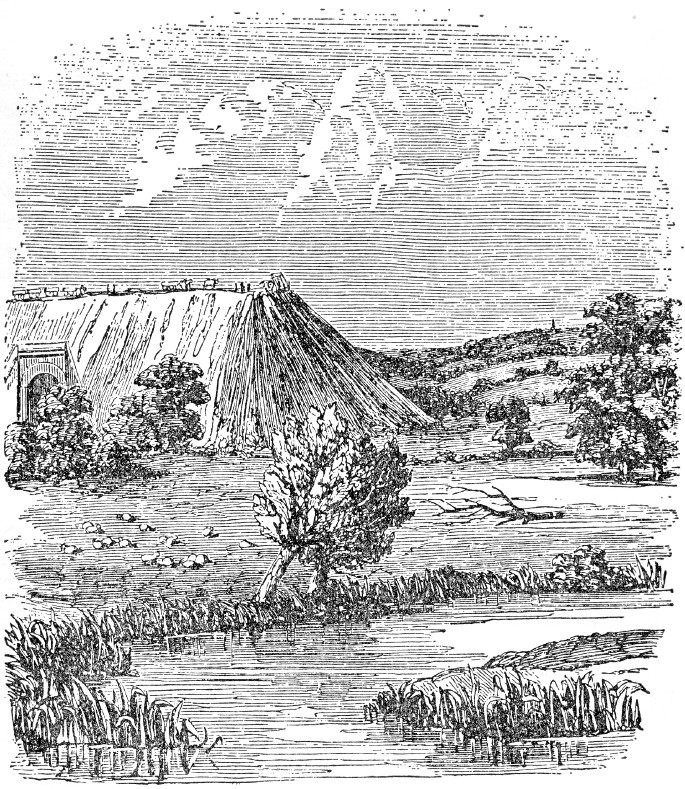

Whereas a cutting lowered the level of a canal below that of the

surrounding land, an embankment raised it.

Building an embankment.

Ideally, the spoil from a cutting would provide the material from

which a nearby embankment is formed, assuming that it is suitable

for load-bearing. For this reason, in planning a route through

undulating country, the Chief Engineer attempted to locate

embankments and cuttings near to each other. If there was no

cutting near at hand to provide the material to form an embankment,

it needed to be excavated from a site nearby, which involved buying

land. And if the material could not be obtained from a site

above the level of the planned embankment, there was the added

difficulty of building the embankment ‘bottom up’ rather than ‘top

down’.

In building a canal embankment, the spoil from which it was formed

was conveyed by canal boat, floating in a temporary wooden trough

that was extended as far as possible up to the edge of the workings.

Alternatively, a temporary railway would be run up to a point at the

edge of the workings where a large baulk of timber was fixed across

the rails to form a buffer. Tipper trucks filled with spoil

were then worked up to a good speed, either by gravity or by horse;

if the latter, on approaching the buffer the driver would untether

the horse, which was trained to move smartly to one side leaving the

tipper truck to continue on its way. On hitting the buffer,

the truck would stop dead, allowing its inertia to cause the

‘tipper’ to swivel upright, spilling its contents over the edge onto

the workings below. The track and buffer would be advanced as

the work proceeded, which was generally from both sides of the

valley simultaneously.

Building an embankment.

Much civil engineering at this time was based on the trial and error

of past experience, rather than on proper scientific investigation.

Because the underlying scientific principles were not well

understood, canal and railway embankments were made of relatively

uncompacted material, [17] which sometimes caused

them to settle over time. Further problems occurred with the

gradients of embankment slopes, which were often too steep and

poorly drained; both could result in collapse. The Grand

Junction Canal was raised on several substantial embankments,

including one across the Great Ouse Valley. Opened in 1805,

this large embankment, which incorporated an aqueduct, sank in the

following year (to be followed in 1808 by the collapse of the

aqueduct). And so the wisdom of the age was that . . . .

“Great care is necessary to be taken in making high embankments.

No person should be intrusted with these works who has not had

considerable experience as a canal or road maker; for, if the base

of an embankment be not formed at first to its full breadth, and if

the earth be not laid in regular layers or courses of not exceeding

four feet in thickness, it is almost certain to slip. . . . . No

doubt, a chief reason for making cuttings and embankments, as is

frequently the case, with slopes of one to one [1:1] has been

to save expense in the purchase of land and moving earth. But

the consequence of making such slopes is that the earth is

constantly slipping, so that in the end the expense is always

greater in correcting the original error than it would have been if

proper slopes had been made in the first instance.”

A Treatise on Roads, Sir

Henry Parnell (1833).

――――♦――――

AQUEDUCTS

|

Among the most recognisable feats of civil

engineering in the world,

the Pontcysyllte Aqueduct comprises a cast iron trunk

mounted on iron arches supported by stone piers. Opened in 1805, it was

constructed by Thomas

Telford and William Jessop

to carry the Ellsemere Canal across the River Dee valley at Froncysyllte near

Llangollen. |

Navigable aqueducts (as opposed to those used for water supply) are

bridge-like structures designed to carry canals over other

waterways, valleys, railways and roads. The first navigation

aqueduct to be built in this country was constructed by James

Brindley. Opened in 1761, the Barton Aqueduct carried the

Bridgewater Canal over the River Irewell. Brindley’s

biographer, Samuel Smiles, described it thus:

“The Barton aqueduct is about two hundred yards in length and

twelve yards wide, the centre part being sustained by a bridge of

three semicircular arches, the middle one being of sixty-three feet

span. It carries the canal over the Irwell at a height of

thirty-nine feet above the river — this head-room being sufficient

to enable the largest barges to pass underneath without

lowering-their masts. The bridge is entirely of stone blocks,

those on the faces being dressed on the front, beds, and joints, and

cramped with iron. The canal, in passing over the arches, is

confined within a puddled channel to prevent leakage, and is in as

good a state now as on the day on which it was completed.

Although the Barton aqueduct has since been thrown into the shade by

the vastly greater works of modern engineers, it was unquestionably

a very bold and ingenious enterprise, if we take into account the

time at which it was erected. Humble though it now appears, it

was the parent of the magnificent aqueducts of Rennie and Telford,

and of the viaducts of Stephenson and Brunel, which rival the

greatest works of any age or country.”

James Brindley and the Early Engineers,

Samuel Smiles (1864) [18]

Aqueducts were not much liked by the early canal builders due to the

considerable weight of the water and the clay (needed to keep the

trunk watertight) to be supported. Another engineering problem

to solve was how to build-in sufficient lateral strength to overcome

the outward (spreading) thrust of the water. [19]

However, cast iron trunk (or trough) aqueducts appeared at the close

of the 18th century. The strength and rigidity of cast iron

was sufficient to contain the outward thrust of the water, while

bolting the plates permitted a watertight seal to be formed more

easily than using layers of puddle clay, hence cast iron trunk

construction came to replace masonry.

The Pontcysyllte Aqueduct, which carries the Llangollen Canal across

the River Dee, is the most famous example of an iron trunk aqueduct

in the UK, or possibly anywhere. Opened in 1805 and generally

attributed to Thomas Telford, although William Jessop probably

contributed, the Aqueduct consists of a cast iron trunk, 11 feet 10

inches wide, supported on 18 ashlar stone piers, and reaches a

maximum height of 126ft over the lowest point of the Dee valley.

The trunk is made up of ¼-inch thick cast iron plates bolted

together along flanges, the joints made watertight with a mixture of

flannel, white lead and iron borings. [20]

Canal aqueducts continue to be constructed. One such example,

opened in 1991, is the concrete

New Bradwell Aqueduct, which carries the Grand Junction Canal

across the Grafton Street dual carriageway at Milton Keynes.

――――♦――――

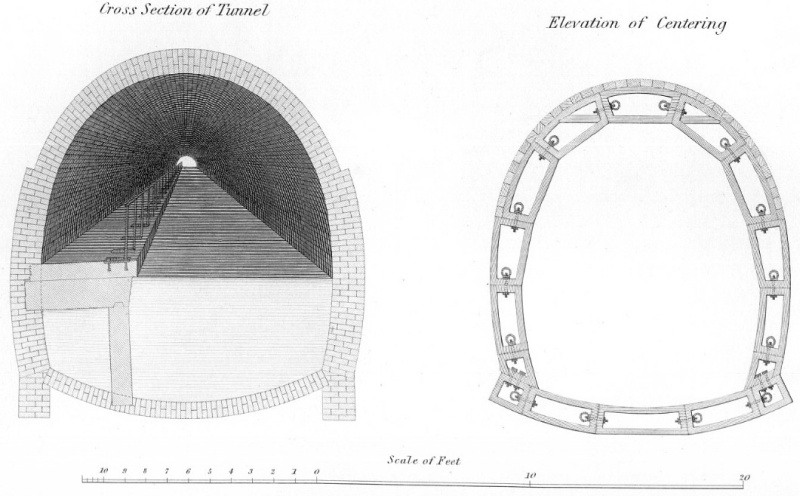

TUNNELS

Cross section of Thomas

Telford’s Harecastle Tunnel on the Trent & Mersey Canal.

Opened in 1827, at 2,926 yard

it is the UK’s forth longest navigable canal tunnel still in use.

Building the early canals required the use of new and sometimes

untried engineering methods on a grand scale. Tunnelling was

the most difficult challenge facing the early canal engineers, and

one that they avoided so far as possible:

“We have already noticed the evils of this mode of establishing a

canal or part of one; sometimes it becomes absolutely necessary

however in which case the greatest care is necessary in blasting

rocks in consequence of the fissures which explosions will cause

from which filtrations [leakage] will inevitably follow.

The excavation may be made with the pick if the soil is soft and

cohesive which is the most favourable case for tunnelling.”

An Elementary Course in Civil Engineering,

M. I. Sganzin (1837)

In commencing the construction of a tunnel, the over-ground route

across the ridge was first marked out using a telescope to secure a

straight alignment. A detailed investigation was then made of

the ground conditions through which the tunnel was to pass by

collecting samples from boreholes dug along its route. As

these only represented samples at the locations where they were

taken, there remained a considerable risk that any strata of hard

rock, subterranean springs and pockets of loose gravel and quicksand

[21] that lay in between would go undetected ―

such was the case with Blisworth Tunnel on the Grand Junction Canal,

resulting in serious flooding:

“As tunnels compared with open excavations are an expensive and

tedious class of works and as they form inconvenient portions of a

line of communication the engineer should study to avoid the

necessity for them as far as possible . . . . The nature of the

strata through which a proposed tunnel is to pass should be

carefully ascertained not only by means of borings and shafts, but

in some cases also by means of horizontal or nearly horizontal mines

or drifts along the intended course of the tunnel . . . . The most

favourable material for tunnelling is rock that is sound and durable

without being very hard. Great hardness of the material increases

the time and cost of tunnelling but gives rise to no special

difficulty. A worse class of materials are those which decay

and soften by the action of air and moisture as some clays do; and

the worst are those which are constantly soft and saturated with

water, such as quicksand and mud.”

A Manual of Civil Engineering,

W.J.M. Rankine (1862)

Surveying techniques were at first basic. Plumb lines, lowered

down shafts from ground level to that of the tunnel, were used to

gauge its alignment; the result was that the horizontal sections of

the tunnel didn’t always meet up perfectly. The Saltersford

Tunnel on the Trent & Mersey canal (opened in 1777) is far from

straight; although only 424 yards long, one end cannot be seen from

the other.

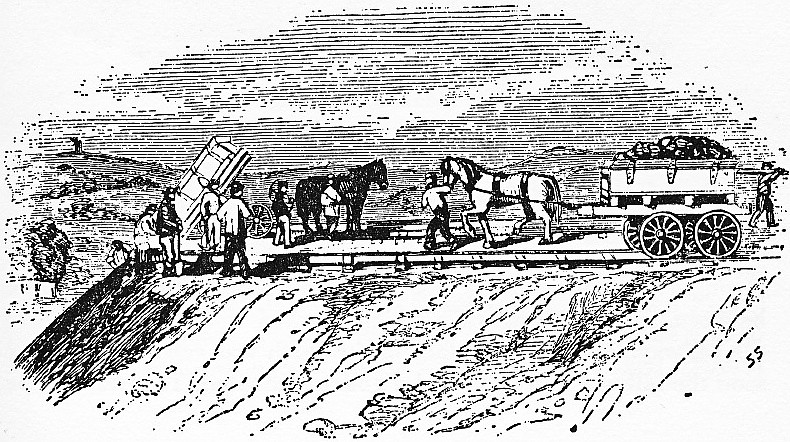

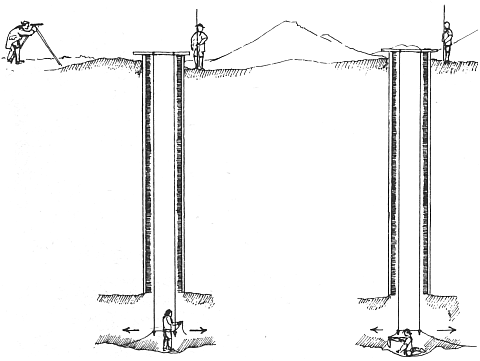

|

The

tunnel’s alignment is established at surface level using

telescope and staff. Two plumb lines are then

lowered down a shaft sunk to the tunnel’s level, aligned

in the same direction as that established by the

surveyor at the surface. The two plump lines then

indicate to the tunnelers the direction in which

excavation is to take place.

The sinking of shafts would then be repeated at

intervals along the tunnel’s alignment. Twenty-one

shafts were sunk during the construction of the

Blisworth Tunnel on the Grand Junction Canal, giving 44

working faces underground plus the two tunnel entrances. |

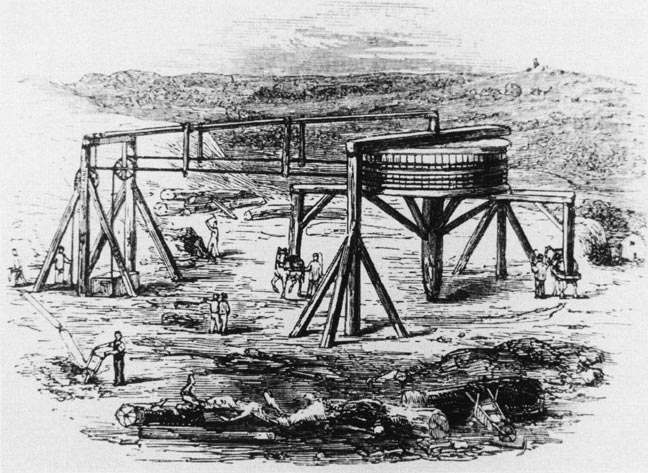

|

A

horse gin would be employed to work each shaft,

raising and lowering men, materials and excavated debris to and from the

subterranean workings. |

By the age of the railways, tunnelling technique had improved. A

small central tunnel (or ‘head-way’) was first excavated as a

further test of the strata to be passed through, to prove correct

alignment and to act as a drainage duct for the main tunnelling

operation ― the technique is thought to have been first used in the

construction of the Blisworth Tunnel on the Grand Junction Canal. Francis Conder, in describing the excavation of the

Watford Tunnel on the London & Birmingham Railway, talks of the

completion of the head-way . . . .

“. . . the pupil of the sub-engineer [Conder] . . . had

the extreme satisfaction of viewing the red signal lamp, fixed at

the north end of the head-way, from the southern extremity over a

regular exact line of candles, one close to each shaft. The question

of the direction of the tunnel was thus solved.”

Personal Recollections of English Engineers,

F. R. Conder (1868)

After the head-way was complete, the excavation of the tunnel was

gradually enlarged. Miners carried out the work, which commenced

from each tunnel entrance. In a long tunnel, a number of shafts,

generally of about nine feet diameter, would be sunk at intervals along

its route to the required level and excavation would take place from

the bottom of each, working outwards in both directions. A horse gin

(later on, a small steam engine) would be installed at the top of each shaft

for the purpose of raising or lowering skips or buckets. The spoil

removed from the workings by this means was carried away for use in

the construction of embankments, or if there was no such need it was

spread over the adjacent land. During construction of the Blisworth

Tunnel on the Grand Junction Canal, 21 working shafts were sunk

which, including the two tunnel ends, gave 44 working

faces.

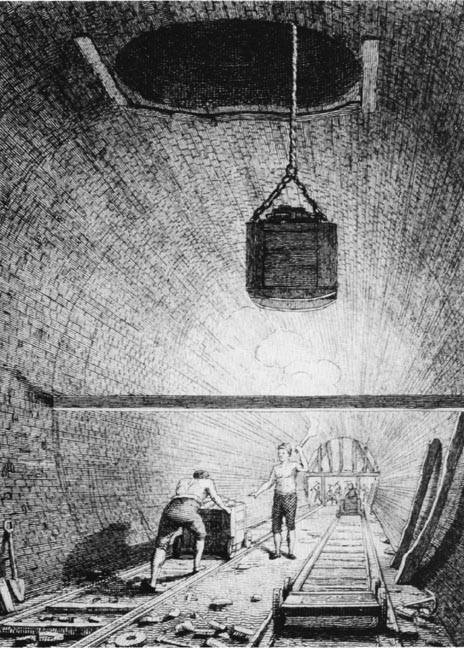

|

Section showing a horse gin working a shaft (or

‘pit’),

the excavations proceeding in both directions. |

Tunnelling in the

canal-building era.

Blasting was resorted to when sinking a shaft and driving a tunnel

through rock. The technique was to hand-drill a shallow hole in the

rock formation, which was then dried out with oakum, packed with

black powder and plugged with clay. On lighting the fuse, the miners

clung, one above the other, to a winding rope and at a signal were

hauled some distance up the shaft where they remained until the

shots were fired. They were then lowered into the choking fumes to

remove the broken rock and debris, and then to repeat the process. Unsurprisingly, accidents occurred when the miners were not lifted

sufficiently high above the danger zone.

Tunnelling was hazardous in other ways. Many lives were lost due to

subterranean streams or quicksand deposits suddenly bursting

through, or the tunnel collapsing due to unstable rock; such

problems also meant extra time and cost to remedy. Leakage of water

into the workings was a continual problem and it was not unusual for

steam-driven pumps to be required to prevent flooding until the

tunnel’s interior could be lined, and sometimes even after that ―

the railway tunnels under the Severn (1885) and the Mersey (1886)

need to be pumped continually to prevent flooding.

Where flooding or quicksand proved a problem, or the formation of

the rock was unstable, the tunnel interior was lined with brick. Quicksand deposits were very difficult to tunnel through and

required heavy brick lining . . . .

“The manner in which the brickwork is laid is of great importance

. . . In a quicksand it has been found necessary to lay the lining

to the thickness of twenty-seven inches in the sides and top, and

eighteen inches in the inverts, Roman cement being used. [22]

This, however, is the greatest strength ever required; and, as the

nature of the ground will allow of it, this may be lessened to the

point where the material will stand by itself.”

Our Iron Roads, F. S.

Williams (1852)

Clay required similar treatment.

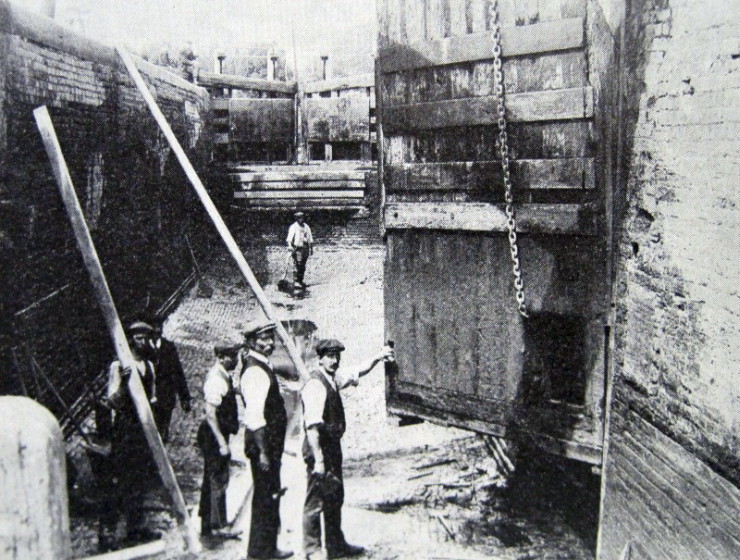

It was sometimes necessary to build

brick-lining into the sides of the shafts (following construction, some of

these

were then extended above ground to form small

towers, and used for ventilation). However, lining tunnels

with brickwork provided no protection against subsidence, which

could be very expensive to repair ― Brindley’s Harecastle Tunnel on the Trent

& Mersey Canal became one such casualty, the cost of repair being so

high that it was abandoned.

Few early canal tunnels had towpaths ― the Braunston and Blisworth

tunnels on the Grand Junction Canal being examples ― so boat horses were

led over

the ground above and the boatmen, possibly with paid help, would

‘leg’ the boat through by lying on their backs and pushing with their feet against the tunnel roof,

or lie on planks extending from the boat‘s sides (‘wings‘) and push

with their legs against the tunnel walls. Legging was a slow and arduous job, often taking two or three hours in

a long tunnel and causing considerable bottlenecks, especially if

the tunnel was too narrow for boats to pass. Such was the case

with Brindley’s Harecastle Tunnel ―

Telford’s later

tunnel, which was built to relieve the congestion, did have a

towing path. Some tunnels had ropes

or chains connected to the walls with which to pull boats through. Later, steam

or electric tugs were used before powered narrow boats

became common.

――――♦――――

LOCKS

|

A flight of locks at Foxton on the

‘old’ Grand Union Canal.

These locks have been built as a ‘staircase’ ― because the

incline is steep, the upper gate of one lock forms the lower gate of

the next. |

|

A narrow boat descending Foxton

Locks. This is a narrow (7ft) lock ― that in the photograph

below is broad (14ft 3ins).

The man turning the windlass is

raising the paddle to drain the lock chamber and lower the boat. |

A lock enables a boat to move between sections of canal at different

levels. In this respect it is identical in purpose to a step,

which performs the same function for a pedestrian ― moving from one

level to another through a small vertical distance. And as

steps are built into flights to permit higher inclines to be

negotiated, flights of locks perform the same function for a canal.

If rising ground that could not be bypassed was too

substantial for taking the canal through in a cutting, crossing over

it using flights of locks was generally considered a safer civil

engineering option than tunnelling, assuming that was possible.

However, the choice of which technique to use was not always clear-cut.

Flights of locks slowed traffic, while providing a sufficient water

supply to the summit could prove challenging. On the

Grand Junction Canal, the Chief

and Resident engineers couldn’t agree on whether to use flights of

locks or a tunnel to negotiate Blisworth Hill, so the canal company

engaged two eminent canal engineers to decide for them. Blisworth Tunnel

was the outcome, but it has proved exceedingly expensive to maintain

over the years. Further south at Cosgrove, the valley of the River Great

Ouse was originally crossed by two flights of four-locks.

These were

later replaced by a substantial embankment and an aqueduct, both of

which initially gave problems, subsidence in the embankment and structural

failure in the aqueduct. Thus, each approach for negotiating

inclines has its pros and cons.

|

A broad lock. The square

aperture in the lock gate is the ‘paddle hole’. The hole is

blocked by a sliding panel, the ‘paddle’. When shut, the lock

can be filled with water from the upper pound; when lifted (by the

‘paddle gear’ at the top of the lock gate), water can flow out to

the lock chamber to the lower pound. Note the ‘invert’, the

inverted arch of brickwork that forms the floor of the lock chamber.

This is built to resist upward and lateral pressures on the lock

chamber ― in effect, reinforcement. |

A lock consists of a chamber, usually built of brick and masonry, at each end of which

are fitted one, or a pair of

watertight gates. Traditionally, lock gates are built of oak or elm

and strengthened with ironwork. The size of lock chambers vary between

canals and even within the same canal. [23] However, many canal locks will accommodate a 72ft by 7ft narrow

boat, although narrow boats are now usually built to smaller

dimensions to give them a wider radius of operation. The

change in water level provided by a lock is termed its ‘rise’; that

for a single canal lock is usually in the range 7 to 12 feet.

A boat ascending from the lower to the higher level of a canal

passes into the empty lock chamber and the gates are closed behind

it to form a watertight seal. Water from the higher level of the

canal is then admitted to the chamber through valves, gradually

raising the water level in the chamber and with it the ascending

boat. When the water level in the lock chamber equals that in the

upper level of the canal ― the water pressure across the upper gates

then being equal ― the upper gates are opened and the boat passes

out of the lock chamber into the higher section of canal. The same

principle applies in reverse to a descending boat.

Using flights of locks to cross rising ground meant that the canal engineer had to solve the

problem of supplying the summit of the system with sufficient water

to carry the traffic, making due allowance for losses through leakage and

evaporation. Each time a boat crosses a canal summit, it uses two lockfulls of water, one on its ascent and one on its descent. This

quantity of water [24] flows down the canal and

has to be replaced if the summit is to remain adequately

flooded. Because water resources become less plentiful on higher

ground, a sufficient supply might require the construction of one or

more reservoirs to capture and store drainage water from the

surrounding area. If the reservoir(s)

was below the summit, steam pumping would be

necessary to raise the water to the summit level ― pumping water from

bore holes was another possibility to consider. Thus, if

either was required, the Chief Engineer needed to include its construction and operation in his costings (in periods of

drought, the cost of pumping could make a significant dent in the

canal company’s profits,

as will be seen). |