|

“WENDOVER, a market town and borough of

England, in the county of Buckingham. It is but an

inconsiderable place, consisting chiefly of mean brick

houses, and possesses no trade or manufacture of any

consequence, except lace making, from which the

inhabitants derive their chief support. A branch of the

Grand Junction Canal, called the Navigable Feeder, has

been brought into the town, which may be of some

importance to its trade.”

The Edinburgh Gazetteer, or, Geographical Dictionary

(1822)

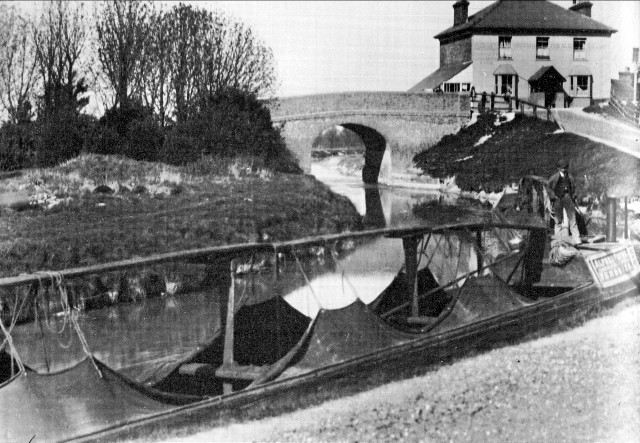

Navigating the Wendover Arm at Little Tring.

――――♦――――

――――♦――――

WATER FOR THE SUMMIT

IN addition to

the many construction problems facing James Barnes and William

Jessop [1], the

Grand Junction Canal’s (GJC)

civil engineers, was that

of locating sufficient water to flood the Tring summit (the Canal’s

other summit at Braunston posed less of a problem).

During the canal carrying era, water shortages, when they occurred, adversely affected the flow of trade and the canal company’s

revenue. But keeping a canal flooded was often no easy task,

particularly at high points along its route where obtaining

sufficient water could prove challenging. Here, the canal

engineer had to resort to various strategies: seeking a route that

avoided high ground so far as possible (which might involve excavating tunnels,

as at Braunston and Blisworth); diverting into the canal

what rivers, streams and drainage channels existed in the locality

(which often gave rise to conflict with local water millers); and

using steam-powered pumps to raise water from low-level sources,

such as reservoirs, bore holes and lower sections of the canal

itself. Maintaining a sufficient supply at the GJC’s

summit at Tring has proved a particular problem, for despite all the usual

strategies having been employed, reports of low water levels

adversely affecting

trade during prolonged periods of dry weather arose throughout the

Canal’s commercial life and continue to the present day. [2]

The Chiltern Hills, a 47 mile-long chalk escarpment, lie

across the path that the Marquis of Buckingham commissioned Barnes

to survey in 1792. Confronted with this unavoidable barrier, Barnes

routed the canal through the ‘Tring Gap’, a lowering in the ridge of

the Chilterns that has been used as a crossing point since ancient

times. [3]

Taking account of the likely traffic levels across the summit and

the water requirement for lockage, it must have appeared that the

springs that rose in the Tring Gap together with local drainage were

unlikely to be sufficient and it

was therefore necessary to import supplies from further afield.

As shall be seen, this task was to present its own challenge over

many years.

The Chiltern Hills are composed of chalk, some 90 million years old.

Because chalk is porous, it absorbs and stores rainwater, in effect

forming a massive underground reservoir (aquifer), which is

maintained by a stratum of impervious clay (gault) beneath it.

Natural springs appear wherever the base layers of chalk come close

to the surface. At Wendover, some 6½-miles to the west of the

Canal‘s summit pound, such a spring

emerges at Wellhead, near to St. Mary’s Church, where water from a

point at which the Coombe and Boddington hills meet wells up to the

surface. This abundant supply formed the Wendover Stream,

which flowed northwards through the valley driving numerous water

mills on its way to join the River Thame. In the absence of a sufficient supply closer to hand, Barnes

planned to divert the Wendover Stream into a channel, which was to follow

the contour eastwards along the northern face of the Chilterns

intercepting other spring-fed streams en route [4]

to join the main line at Bulbourne [thus ― unlike its near

neighbour, the

Aylesbury Arm ― the Wendover Arm is an

example of a ‘contour canal’, one that by following the contour

avoids the need for locks and (for the most part) other engineering

work, such as cuttings and embankments].

|

“A meeting of the commissioners who are named in the

act, for deciding all differences or disputes between

the Company and individuals or bodies of men, began on

Monday morning last, and continued its sittings until

Wednesday, at Aylesbury; when the long existing disputes

between the Company and the Millers on the Thames River

were fully gone into. We are happy to hear, that

the Millers at the conclusion, unanimously agreed to

withdraw all claims for satisfaction, for the water of

which, they have been hitherto deprived; so satisfied

were they, that the measures adopted within this two or

three years past, on the Tring and Wendover summit level

of the Canal, will amply supply it in future, without

sensible injury to the mill-streams.” |

|

Morning Post,

30th August 1805 |

Having received authority under the 1793 GJC Act to construct

whatever feeders were necessary to obtain canal water, the Grand

Junction Canal Company (GJCC) entered into purchase

negotiations with local landowners and the inevitable water-millers

to construct what at the time was to be no more than a feeder

ditch. To placate the millers, whose livelihoods would

inevitably be damaged by the diversion of the Wendover Stream, the GJCC bought the water mills at Weston Turville and Wendover, and the

water rights to the mill at Halton, [5]

only then to find that other millers further downstream at Aylesbury

were also affected. To address this, a new reservoir was built

at Weston Turville. Eventually, the GJCC bought the Aylesbury

mills, thus avoiding the need to supply them with ‘compensation

water’.

Weston Turville reservoir lies about a mile to the north of

Wendover town centre and adjacent to the Arm. It accumulates

water mainly from two streams below the level of the canal and from

any overflow from the canal itself. Built in 1797-8, it is the

earliest and most westerly of the five reservoirs that lie along the

foot of the Chiltern escarpment. Although not intended to

supply the canal, in 1814, following several years of poor water

flow, a temporary Newcomen-type pumping engine was installed to

raise water from the reservoir as and when required. No clear

information remains as to the capacity of this pumping station, but

it is known that its outflow pipe into the canal was four inches in

diameter. Weston Turville pumping station remained in use

until about 1838, and was eventually scrapped in April 1841.

Since then water has occasionally been taken for the canal during

periods of drought, but today the reservoir is used for recreation.

Further to the east lie the four Tring Reservoirs.

They comprise Wilstone (1802, heightened in 1811 and 1827, and

extended in 1836 and 1839), Marsworth (1806), Tringford (1816) and

Startops End (1817). Of these, Wilstone is by far the

largest.

The opening of the GJC in 1800 [6]

resulted in more traffic than had been anticipated, added to which

the Aylesbury Arm (opened c. 1815) imposed a significant

drain on the main line. Consequently, the demand for water

at the summit increased. To address this, the Tring reservoirs

were built in stages to provide further supplies, which

they accumulated from local streams and any surplus from the canal

itself.

The visible remains of Whitehouses pumping station.

Originally, the reservoirs were worked by three pumping stations

located above them on the Wendover Arm; Whitehouses pumping station

(between Drayton Beauchamp and Little Tring, capacity believed to

have been 30 locks per day) worked Wilstone

Reservoir, a pumping station near Bulbourne Junction worked

Marsworth Reservoir, and Tringford pumping station (sited by Thomas

Telford) worked the Startops End and Tringford reservoirs.

Each pumping station lifted water into the Arm to flow into the main

line at Bulbourne Junction. In his Encyclopædia of Civil

Engineering (1847), Edward Cresy states that:

“. . . the principal engine at Tring is estimated as a 70

horse-power; its consumption of coals is about 1½ cwt. per hour,

with a 40 feet lift; this engine works at a pressure of 24 pounds,

makes ten strokes per minute, and pumps up sufficient for eighty

locks in 24 hours.”

Writing some years ago, Tring local

historian Bob Grace stated that:

“. . . the great reservoirs at Tring were not constructed in their

present form in the first instance. First of all they were

just ‘heads’ - the Ashwell Head at Wilstone and the Bulbourne Head

at Marsworth, which were dammed up and small pumping engines put in

to pump direct into the Wendover navigable feeder, one pump being

halfway between the main arm and New Mill and the other pump being

at the White House, above Wilstone reservoir. These were the

first engines of the neighbourhood and the men who came to work them

were, of course, engineers, the first to come into this part of the

world.

The engines were vacuum engines, which meant that they worked on

very little steam pressure (about 5 p.s.i., I think), from very

simple boilers. The engine was activated by the weight of the

pump bucket drawing up the piston and the piston cylinder being

filled with steam from this boiler, then a jet of water was squirted

in condensing the steam. The vacuum then formed drew up the

bucket and brought up the water to the canal level. These two

engines were extremely inefficient, even by the standards of those

days, and they were soon replaced by engines put in at the Tringford

station. These were two great beam engines.”

When Tringford pumping station was built in 1817, it was equipped

with a Boulton and Watt beam engine of 80 locks per day capacity, so

it is probably this engine that Cresy refers to. However, in

the period 1836-38, the Tring reservoirs were interconnected by a

system of tunnels to enable all pumping to be centred on Tringford.

A second (second-hand) steam pump (capacity unknown) — named the

‘York’ — was then installed to handle

the increased load, and this engine remained in operation until 1911

when it was replaced by

diesel-electric plant.

Following the centralisation of pumping on Tringford, the pumping

stations at Weston Turville and Whitehouses were demolished ―

Marsworth pumping station had been dismantled in 1819, as this

reservoir could then be pumped from Tringford through the new

Startopsend reservoir. Nothing remains of

the pumping stations at Weston Turville and Marsworth, but some brick

foundations and culverts on

the canal bank mark the site of Whitehouses. [7]

In 1927, Tringford pumping station became wholly

electrically-driven. The original Bolton and Watt engine was

then removed – it was offered for preservation, but in the absence

of any takers it was sold for scrap – and the building

greatly

altered (and much for the worse!) including the removal of its prominent chimney.

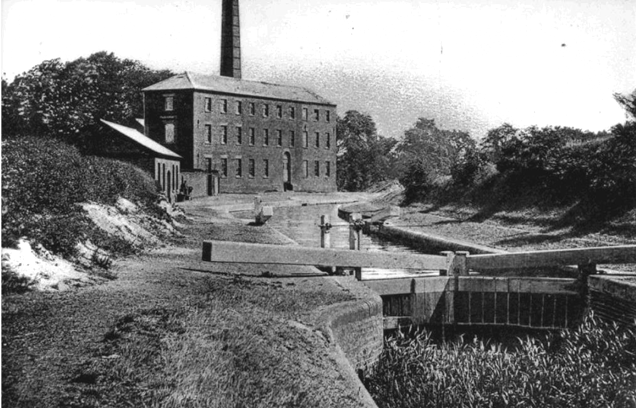

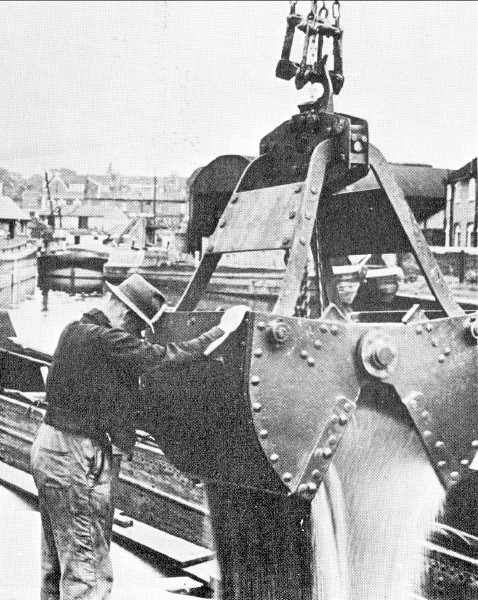

Above: Tringford pumping station and stop lock, c. 1910.

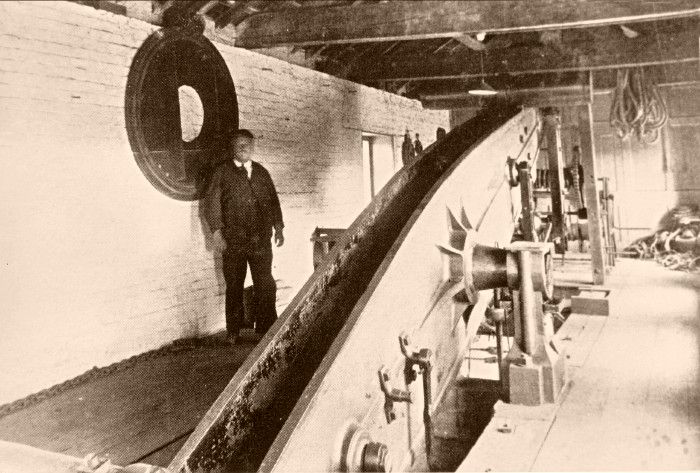

Below: the beam of one of the station's steam pumping engines.

.jpg)

|

A

Mirrlees 2-cylinder slow-speed diesel engine

of the type employed at Tringford Pumping

Station.

The York engine was removed in 1911 and

replaced by a diesel electric pump to work

the original deep well. A second diesel

electric pump was installed in a newly

constructed high-level well with a new

incoming heading from Tringford Reservoir

only. These pumps designated No.1 and No.2

were powered by two diesel generating sets,

one a 50hp single cylinder, and one a 100hp

twin cylinder (pictured above), supplied by

Mirrlees, Bickerton and Day. These

generators remained in use until the 1960s

when the pump motors were replaced with A.C.

motors powered by mains supply. |

In 1870, the GJCC came into legal conflict with the Tring

Local Board of Health over contamination of Tringford Reservoir and

the spread of disease:

“Part of the drainage of this town [Tring] is carried away

by a sewer which empties itself into the canal-reservoir to the

north. Before this sewer was made the reservoir received only

spring-water, a matter of some importance, as some neighbouring

villages drew their water from the stream that flows from the

reservoir. After the turning in of the sewer, in summer, when

the water in the reservoir was low, it stank abominably; and worse,

diphtheria, typhoid fever, and other such diseases, were frequent in

the villages.”

The water supply of Buckinghamshire and of

Hertfordshire by W. Whitaker (1921)

The GJCC sued for damages. They complained of the pollution

and of the additional expense incurred in pumping water up from

Tringford reservoir that would otherwise have flowed directly into

the Wendover Arm along Tring Brook. However, the Master of the

Rolls dismissed the case (with costs) on the grounds that the Board

of Health were acting in the lawful exercise of their powers.

The following year, the GJCC mounted an appeal. The Master of

the Rolls had apparently misdirected himself, for according to The

Times the GJCC were granted an injunction against the board of

Health (with costs), the Lord Chancellor ruling that “the right of

enjoyment of surface water in a flowing stream must not be

interfered with” ― public health issues did not appear to enter into

the argument! Standards of public health have of course

improved out of all measure since 1870, and today the summit pound

obtains a useful supply of cleaned water from Tring sewage works,

which is pumped into the Wendover Arm just to the east of Gamnel

Bridge.

And where does the Wendover water released from the Tring

Summit finish up? That which flows southwards along the canal

eventually reaches the Thames at Brentford. That which flows

down the sixteen locks of the Aylesbury Arm eventually enters the

River Thame, discharging into the Thames in the vicinity of

Dorchester (Oxfordshire). Water that flows northward along the

canal discharges over weirs into the Rivers Ouzel and Nene until at

Cosgrove, where the canal commences its ascent towards Braunston

Summit, it discharges into the Great Ouse, this flow eventually

reaching the Wash.

――――♦――――

An outing to Wendover by members

of the Akeman Street (Tring) Baptist Church in 1897.

Top: approaching Little Tring. Bottom: at Hare Lane bridge

(No. 8).

THE COMMERCIAL CANAL

IN addition

to its role as a feeder for the Tring Summit, the Wendover Arm

enjoyed a century of commercial life; indeed, on its eastern

section, shipments of grain to Tring Flour Mill continued

until the end of WWII, when road transport took over, while the

adjacent Tring Dockyard survived until 1952.

Plan of the Feeder ditch as originally conceived.

The route that was to be followed at New Mill differs considerably

from that eventually constructed.

Plan

(jpeg, 3.3MB - back arrow to return)

Although originally planned as a feeder channel,

at some stage during the land purchase negotiations the GJCC decided

― believed to have been in response to local lobbying ― to make the

feeder navigable and thus revenue-earning. Enlarging the feeder

involved little extra cost, but its change of use did require a

further Act of Parliament. Thus, the following statutory

notice appeared in the newspapers published along the line of the

GJC, giving notice of the Company’s intention to apply to Parliament

for an Act which, among other things, would authorise them:

“. . . . to make navigable, the cut or feeder now making, and

intended to be made, by the company of Proprietors of the Grand

Junction Canal, from the town of WENDOVER, in the said county of

Buckinghamshire, to the summit-level of the Grand Junction Canal, at

Bulbourne, in the parish of Tring, which is to pass in, to, or

through the several parishes of Wendover, Halton, Weston-Turville,

Aston-Clinton, Buckland, and Drayton-Beauchamp, in the said county

of Buckingham; and the parish of Tring; till it joins the said

summit-level at Bulbourne aforesaid. Dated this 5th day of

September, 1793.”

E. O. Gray, Aston Chaplin, Clerks to

the Company

|

|

|

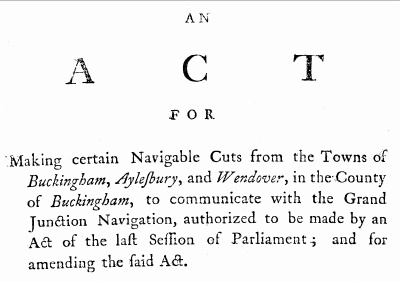

Title of

the 2nd GJC Act; 34 Geo, III. C. 24 |

Reference to the “feeder now making” illustrates that

construction of the Arm commenced at an early date, well before the

main line reached Tring Summit (probably) early in 1799. The new

Act (34 Geo, III. C. 24) was obtained on 24th March, 1794, together

with statutory authority to build branches to Buckingham, Aylesbury and

Saint Albans (the latter not proceeded with).

Although the exact date of the Wendover Arm’s completion is

unknown, it was probably during 1794, for in his progress report of

May of that year, Jessop states that “About seven-eights of the

Wendover Canal is cut”, and in a GJCC circular of November,

1797, reference is made to “The Wendover collateral line, now

finished for the sake of the water”. However, as the main

line, which opened to Berkhamsted late in 1798, probably reached

Tring Summit early in 1799, trade on the Arm would not have

commenced until then. The first clear intimation that the Arm

was fully in business appears in Jackson’s Oxford Journal,

which reported that the section of the GJC from Tring to Fenny

Stratford was officially opened on 28th May, 1800.

|

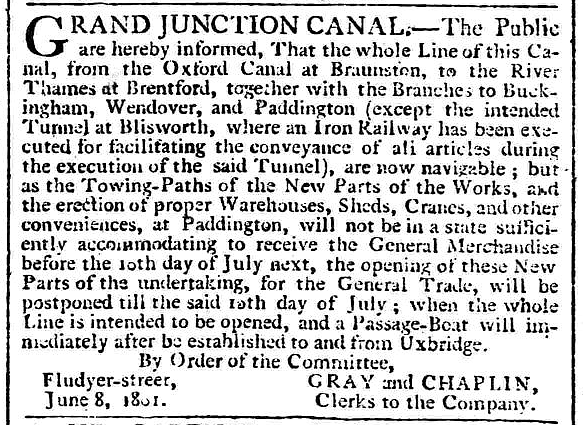

Morning Post ― announcement of the opening of the GJC, 18th

June, 1801. From the south, the GJC probably reached

Stoke Bruerne late in 1800, where a break in the Canal (bridged by a

horse-drawn railway) existed until the Blisworth Tunnel

was completed in 1805. |

For most of its working life the western section of the Arm

avoided railway competition, and until the opening of the Aylesbury

Arm (c. 1815), also carried traffic destined for Aylesbury:

“The Oxford canal, constructed under the superintendence of

Brindley, was finished in 1790, and was opened with great

rejoicings; it materially affected Aylesbury; coals and heavy goods

were brought by it to within 25 miles of the town, the intervening

distance being accomplished by road-waggons. The main supply

of coals for Aylesbury was then obtained from Oxford. In the

year 1799 the Wendover Branch of the Grand Junction Canal was

completed, which was a great advantage to this district. The

traffic in coals and heavy goods was transferred from Oxford to

Wendover Wharf, within five miles of Aylesbury.”

Buckinghamshire: A History of Aylesbury,

Robert Gibbs (1885)

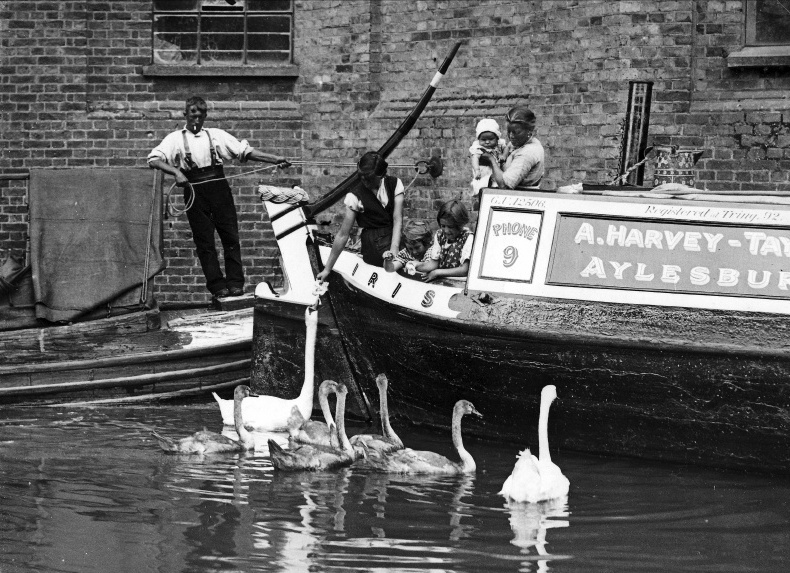

‘Wendover Band of Hope’ outing at Wendover

Wharf, 1889.

The narrow boat owner is Alfred Payne of Wendover.

Wendover Wharf lies a short distance to the north of the town

centre, [8] the

original access being from the end of Clay Lane across grazing land

belonging to Manor Farm. In 1796, Wharf Road was built (at

that time ending at Wendover Wharf) to give proper access to the Arm

from Aylesbury Road. Wharf Cottage, which still stands, was

the wharfinger’s

residence and warehouses (long gone) were built at the wharf

opposite the tow path. It is known that grain was landed there

for milling at the great octagonal brick-built tower mill (now

converted into a beautiful private dwelling) that stands on the opposite side of Aylesbury

Road, perhaps including that referred to in the following report:

“Philip Goodenough was indicted for stealing four bushels of

wheat, the property of Joseph Hoare. The prisoner was the

master of a barge . . . . in which a quantity of wheat was sent from

London to Wendover, consigned to Mr. Hoare . . . when this wheat

arrived at Wendover, four bushels of it were found missing.

The only evidence against the prisoner was that of a lad, named

Merchant, who had acted as his servant in the barge. He said, that

after the barge had passed Chelsea bridge, the prisoner took a spare

sack and filled it, by taking a small quantity from each of the

other sacks that were full; when the barge arrived at a place called

Harwood, on the Grand Junction Canal, a man came up and took this

sack so filled from the prisoner.”

The Times, 15th January,

1801.

Shrinkage of the sort described must have been common ― it

certainly was with coal. Hay and straw were also brought to

the wharf from the surrounding fields and shipped to London, and

manure was received in return. Slater’s Directory for

1852 lists several coal merchants at the wharf; indeed, a

correspondent writing in the Bucks Herald in 1906 had this to

say about the Wharf’s coal

trade: “Fifty or 60 years ago [c.

1850] waggons from places as far off as Lewknor and Aston Rowant

were to be seen en route through Bledlow all the way to Wendover

Wharf, for coal brought there by canal”. The wharfinger at

that time was John Bell, who offered water conveyance “To London

and forward, goods to most parts of the kingdom”.

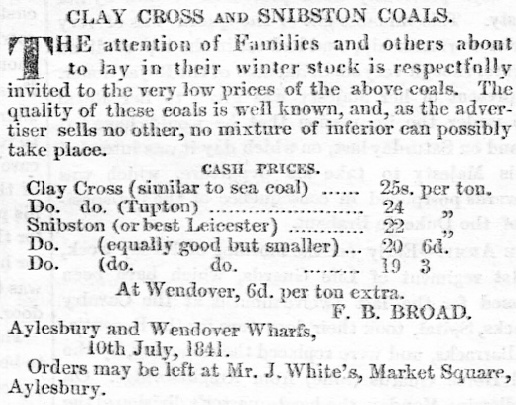

|

|

|

Coal from Wendover Wharf – Bucks Herald, July

1841. |

There were a number of other wharfs on the Arm (App.

I.), the main ones being at Gamnel (also known as Tring

Wharf) and at Buckland to the south of Aston Clinton. A trade

directory listing of 1854 suggests that Buckland wharf was managed

by the landlord of the adjacent New Inn, whose other listed

activities were “coal

merchant and collector of taxes”.

A pair of Alfred Payne (Wendover) narrow boats at Buckland.

The New Inn is in the background, Buckland Gas Works was opposite

the narrow boats.

The site of Gamnel Wharf had previously been occupied by a

water mill that had been bought for its supply of water and

dismantled by the GJCC. The first reference to the Wharf itself

occurs in the GJCC Minutes. On 14th October 1800, a wharf at Tring

(presumably Gamnel Wharf) was auctioned for three years from 29th

September. It was taken by James Tate, a coal merchant, for £15 per

annum (the Company Minutes for this period also record that the

fishing rights for most of the Wendover Arm were let in June 1800 to

Acton Chaplain, the GJCC’s Clerk, for twenty one years, at £2 10s a

mile). A deed of transfer records that on 5th July, 1810, the GJCC sold to William Grover, for £400, “all that wharf land and buildings thereon

containing one acre and three roods more or less situate next Gamnel

Bridge in the Parish of Tring.” Grover must have seen a

business opportunity to continue the milling previously done on the

site, but by wind power; the tower

mill that he erected at Gamnel became the seed from which eventually

grew Heygates Mill, the large flour-milling complex that occupies the

site today.

Gamnel Wharf windmill ( built c.

1812, pulled down in 1911) and steam mill (built 1875) ― note the

lightening boat in the foreground.

Mr. & Mrs. Ward, daughter Phoebe and

her family from Startops End,

discharging Manitoba

wheat at Tring Flour Mills c. 1930s.

The 50th birthday

celebration for William Mead (owner of Tring Flour Mills -

background) in 1918, during which

he entertained wounded soldiers and airmen from RAF Halton Camp

hospital, near Wendover.

The narrow boat Victoria is registered to Frederick Mead of

Paddington.

Grover was also active as a canal carrier, his listing in Pigot’s

trade directory for 1839 advertising “To London

and all places on the line of the Grand Junction Canal, and goods

forwarded to all other parts of the Kingdom, by Grover and Son, from

Gamnel wharf, and Thomas Landon, from Cow Roast wharf, daily”.

Nothing then is known of Gamnel Wharf until the business changed

hands in January 1843, when the following notice appeared in the

Bucks Advertiser:

“William Grover, in the town of Tring in the County of

Hertfordshire, having on the 28th day of January last disposed of

the business of wharfinger, coal and coke merchant and mealman, and

dealer in hay, straw, ashes, and other things, lately carried on by

him in partnership with Thomas Grover, at Tring Wharf, and at

Paddington in the County of Middlesex, under the firm of ‘WILLIAM

GROVER & SON’ to his sons-in-law, William Mead and Richard Bailey.

Messrs. Mead and Bailey beg to announce that they will continue to

carry on the same business, upon the said premises, in partnership

under the name of ‘MEAD & BAILEY’. All debts due to and owing from

the said William Grover, will be received and paid by Mead &

Bailey.”

Bucks Advertiser,

January 1843.

The notice gives a good indication of the nature of the business

carried out, not just at Gamnel Wharf, but at Wendover and at many

wharfs in rural locations at that time.

|

|

|

Transhipping grain from lighter to narrow boat

at Brentford. |

Mead and Bailey continued to offer a diverse range of

services, later advertising themselves as millers, coal merchants,

wharfingers, and water carriers. [9]

A few years later the partners advertised London horse manure

(mountains of it were generated in the horse-powered Metropolis of

that age), which they shipped by canal from their wharfs at

Paddington. Paddington Basin was also the scene of another

William Mead & Co. activity, that of transporting by canal London’s

rubbish for disposal in worked-out gravel and sand pits, and at

nearby brick-yards (which recycled the cinders) ― a magazine article (App.

II.) written in 1879 describes both the early use of

electric light for illuminating the refuse wharfs and the unsavoury

nature of Mead’s rubbish disposal business.

Shipments of imported grain were also delivered to Mead’s flour mill

at Tring by canal from the London docks via Brentford, where the

grain was transhipped from lighters to narrow boats for its

journey up the GJC. Grain shipments to the mill continued until the end of World War II, when road haulage took

over.

In addition to the commercial wharfs on the Arm, there were

two small canal-side gas works, which supplied town gas to the

Rothschild mansions at Aston Clinton and at Halton. Wendover Gas,

Coke & Light Company was also located near the Wendover canal wharf. The

close proximity of these plants to the Arm suggests that they

received supplies of coal by narrow boat and might also have

exported the by-products of the town gas manufacturing process (coke, coal tar, sulphur and

ammonia) by this means.

The last business to use the Arm was Bushell Brothers, a firm

that over the years built and repaired a wide range of craft

including canal barges of various types, pleasure boats, maintenance

flats, tugs and a pair of fire floats for John Dickinson’s paper

mills. The firm ceased trading when the brothers retired in

1952, although by then the boat trade had diminished and the firm

were building bodies for a range of commercial motor vehicles.

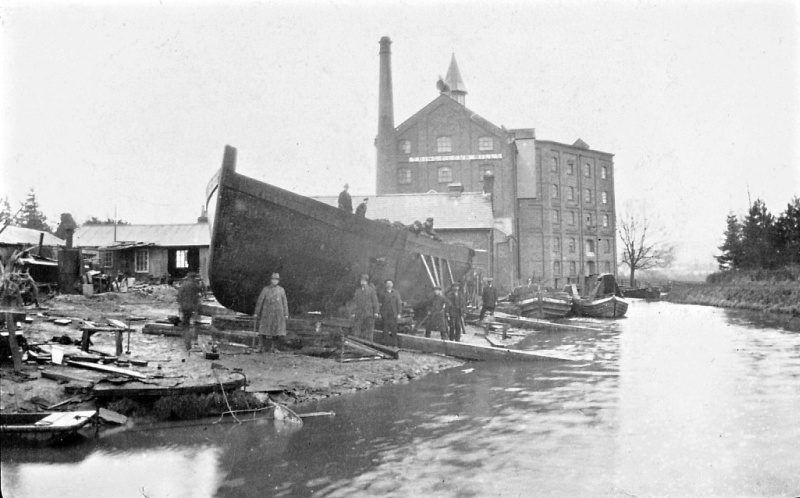

Bushell Bros. boatyard (Tring Dockyard) ― Tring Flour

Mill to the rear.

Reproduced by kind permission of Miss Catherine

Bushell.

Tug ‘Bess’ under construction at Tring Dockyard, 1921.

At 75ft x 14ft 6ins x 5ft 6ins draught, her size was such she could

only just pass along the Canal to London.

Reproduced by kind permission of Miss Catherine

Bushell.

――――♦――――

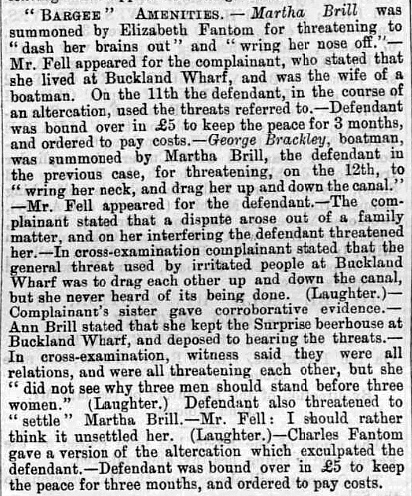

|

|

|

|

Canal-side trouble at

Buckland Wharf.

Bucks Herald, 27th September 1884. |

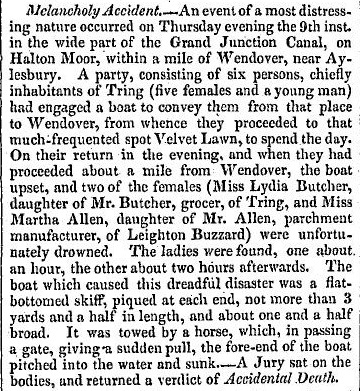

Melancholy

Accident at Halton Moor.

Jackson’s Oxford Journal, 18th September 1824 |

Sunday school outing about to depart from Gamnel

Wharf, 1931.

Reproduced by kind permission of Miss Catherine Bushell.

――――♦――――

LEAKAGE AND PARTIAL CLOSURE

CONSTRUCTION of

the Wendover Arm started soon after the 1793 Act had been obtained,

for in a report submitted in May 1794, Jessop informs the Board that

the Arm was almost complete, but not yet flooded. From the

outset it appears that he knew that the chalk terrain over which

part of the Arm was to pass would prove difficult and that leakage

might be a problem:

“About seven-eights of the Wendover Canal is cut, — the remainder

having corn on the ground, will rest till after harvest; in the mean

time what is done will be gradually tried with Water, for much of

the ground in this line is very leaky, and must be lined with Earth,

and be saturated with muddy Water: the rule that has been generally

observed — of avoiding plain cutting until necessity calls for it,

has a reasonable exception in this case, for by exposing it to the

changes of Weather, and particularly to Frost, the Chalk will

dissolve into a pulpy substance, and facilitate the operation of

Puddling.”

William Jessop, London, 27th May 1794.

The first reported leakage was in 1802, and in the following

year the Arm was closed for some months for remedial work.

This was carried out under the supervision of the canal engineer

Benjamin Bevan, who during the project procured more water for the

Arm at

Wendover (App. III.)

and submitted his proposal for what was to become Marsworth

Reservoir. When the civil engineer Thomas Telford inspected

the GJC in 1805, his report picked up on Jessop’s concern, expressed

a decade earlier, about leakage on the Arm:

“A great proportion of the Wendover Branch is cut through loose

chalk; and Mr. Bevan appears to have laboured with much activity and

zeal to render the whole watertight: in this he has partly

succeeded; but much perseverance is requisite to make this important

part of the canal perfectly secure; the lining with clay must be

continued, and the banks must, in several instance, be made stronger

and higher. As much depends upon the perfection of this summit

I cannot help strongly recommending that every attention be paid to

it.”

Report on the General State of the Grand Junction

Canal, Thomas Telford, May 1805.

Further problems with leakage occurred for the remainder of

the Arm’s working life, the costs of significant repairs being

announced periodically in newspaper reports of the Company’s Annual

General Meetings. In 1855, the Arm was closed due to leakage,

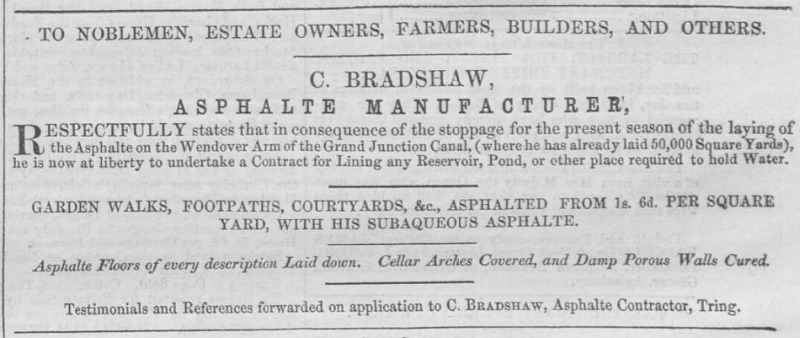

but on this occasion repair was effected using a new form of lining,

asphalt, in place of the traditional puddle clay. This was

applied to the section of the Canal between Little Tring and Aston

Clinton and although it stemmed the leakage to some extent, it

became damaged by a combination of earth movement, by canal boats

brushing against it and through the use of poles. (App.

IV.) By 1897, the leakage had reached such an

extent that the Arm was drawing water from the main line. This

led to the Canal being dammed at Little Tring, where much of the

stop lock (built c. 1901) remains.

A number of schemes were then considered for restoring

navigation or, as an alternative, reverting the Arm to its original

role as a feeder. With the arrival of the Metropolitan Railway

at Wendover in September, 1892, the commercial future of the Arm

must have looked bleak, added to which the numerous attempts to stop

leakage over the years had proved expensive and unsuccessful.

These factors probably influenced the GJCC’s decision to abandon the

Arm as a navigable waterway west of Little Tring. However, the

closure was contested in the High Court, where their Lordships,

sitting as the Railway and Canal Commission, ruled unanimously in

favour of the GJCC, the gist of their argument being that the

Company was under no legal obligation to maintain the Arm as a

navigable waterway, and at any rate the economics of so doing would

have been prohibitive (the legal costs of the case would probably

have paid for the Arm to be repaired!).

The report of the case (brought by Lord

Rothschild, Lady de Rothschild and Mr Alfred de Rothschild) in

The Times also provides some interesting information on the

level of traffic on the Arm during its final years of commercial

operation:

“The earning, which at one period yielded a good profit, had been

on the decline for some time before 1898. In 1883, the number

of tons carried was 12,800, but the tonnage fell to 4,800 tons in

1893, 2,600 in 1894, and to less than 2,000 in 1896-7; and the

decrease in the receipts from tolls was from £1,100 in 1883 to £423

in 1893, and to about £200 between 1893 and 1898. One reason

of the traffic falling off was in 1894 the Metropolitan Railway was

opened to Wendover [reported elsewhere as Sept., 1892], and

from that time the Wendover traffic in coals was transferred from

the canal to the railway. On the other hand it is estimated

that the sum, that would have been expended on the part of the canal

at present closed, before it could again be used as a navigable cut,

would not be less than £22,000. The ground on which the canal

is constructed is chalk, and the necessity of preventing the loss of

water from the porousness of the chalk accounts for a large part of

the £22,000.”

Rothschild and others vs. the GJCC, The Times,

9th May, 1904.

The Arm was finally abandoned as a navigable waterway west of

Little Tring in 1904, although for some years before (probably since

at least 1897) it had only been in intermittent use. However,

as late as 1906, an appeal (typical of those that were to arise

during the branch-line closures of the Beeching era) was made to the

newly-convened Royal Commission on Canals to bring pressure on the

GJCC to reopen the Arm to navigation:

“. . . . With capable handling, however, the Canal could be made

to hold water effectively, and at no unreasonable cost. The

following figures represent part of the traffic in the year 1897,

immediately before the canal was closed:

Manure ― 500 tons were sent to Wendover, and 120 tons to Buckland

Wharf;

Hay and straw ― 350 tons were sent from Wendover, and 150 tons from

Buckland Wharf.

This represents part of the traffic when the Canal was only half

full of water, and boats had a difficulty in getting along partially

laden . . . . In many ways those living in the parts of the counties

served by the two branches are injuriously affected. By

increased cost of carriage of goods, equal to 2s. per ton to the

nearest railway Station. By inability to obtain manure for

farmers at a reasonable cost. By wear and tear of roads

through having to cart goods and coal which ought to come by water.

By having to cart hay, straw and cereals to the Railway Stations,

which represents 2s. in the ton extra cost to the farmers, and a

reduced rental to the landowners, besides extra rates to the general

public to cover wear and tear on the roads . . . .”

Bucks Herald, 2nd

November, 1906.

It is interesting to note the Arm’s importance to its local farming

community. Reference to it being “half full of water”

refers to the use of stop planks to block off the Arm prior to

construction of the Little Tring stop lock (c. 1901).

It appears that, as early as 1891, boats navigating the Arm to the

west of Little Tring had first

to be lightened to reduce their draft on account of its shallow water:

“The Clerk [to the Council] had also received a letter

from Mr Thomas Mead, of the [Tring] Flour Mills, complaining

that boats bearing dung [were] lightening their loads (for

the purpose of entering the shallow water of the Wendover Arm) near

their mills, and he wished the practice, if the matter came under

the jurisdiction of the Board, to be stopped. ― Mr Clarke

corroborated the facts of the complaint. ― Mr Baines [the

Council’s surveyor]

said that he had been to the spot, and told the boatmen that the

practice must be stopped, and that they must lighten elsewhere.

They asked him to allow them to lighten in the middle of the night,

and he gave permission for this to be done.”

Bucks Herald, 4th July,

1891.

Following closure, the section between Wendover and Drayton

Beauchamp was relined, the water level lowered and the flow from

Wendover diverted into Wilstone Reservoir. This scheme was

later changed, the water being channelled from Drayton Beauchamp

direct to Tringford pumping station through a pipeline laid along

the canal bed.

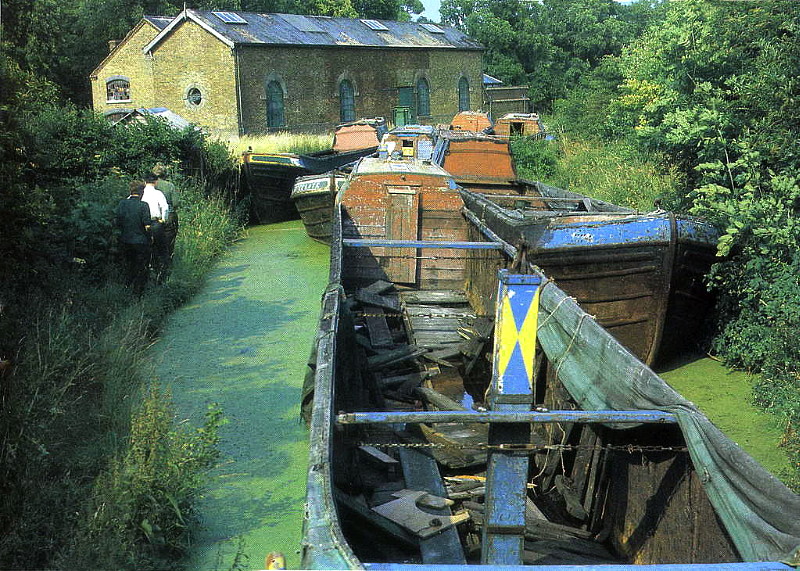

The much disfigured Tringford pumping station in the

late 1960s ― the Arm was then being used as a

dump for redundant narrow boats. Note the

condition of the tow path!

――――♦――――

RESTORATION

THE formidable

project of restoring the Wendover Arm to a navigable waterway beyond

Little Tring is being undertaken by members of the

Wendover Arm Trust. The Trust is a charitable body

formed in 1989 with the aim of restoring and promoting the Canal.

Its membership ranges from organisations with a specific interest

(such as the environment) to individuals who support the aims of

restoration in general. The Trust does not own the Canal; it

is owned by The Waterways Trust, who work closely with the Trust on

planning and undertaking its restoration, and are represented on the

Trust’s Board.

The engineering problems in restoring the Arm are believed to

be relatively straightforward, although the solutions are expected

to be expensive, with funding being a major obstacle. At the

time of writing, progress has been slow but significant.

Although some work had been completed earlier, the first

phase of the planned restoration was completed in March 2005.

It comprised the refurbishment of the stop lock at Little Tring; the

replacement of a road embankment across the canal bed at Little

Tring with a concrete road bridge, built to a traditional design and

faced with bricks to provide an authentic appearance; construction

of a winding basin at the terminus to allow boats to turn; and the

reinstatement of about ¼ mile of canal.

The second phase (expected completion in 2016) involves

restoring to navigation the section between Little Tring and an

isolated section of restored and re-watered canal to the west of

Drayton Beauchamp. The latter was constructed during the

building of the Aston Clinton Bypass in 2003, [10]

and involved a slight realignment of the Arm to provide navigable

headroom under the new bypass road bridge. Restoring the phase

2 section includes re-profiling the Canal to its original shape and

lining its sloping sides with concrete blocks on top of waterproof

Bentomat© lining [11]. Two new timber footbridges have already been erected

to enable the Canal to be crossed safely, and reinforced concrete

covers are being laid over the 100-year old buried pipeline to

prevent any subsidence should it collapse.

.JPG)

Relining the Wendover Arm - the upper part of the Bentomat liner, visible above the

protective blocks,

is about to be covered with turf.

At the canal bed, the liner is covered with 300mm of earth.

The main obstructions to be met during Phase 3 concern bridge

restrictions, these being the accommodation bridge at Buckland

Wharf, the ex-A41 road bridge and the lowered Halton Village Bridge.

The restoration of this section is technically feasible but

expensive.

――――♦――――

RECREATION, SPORT ― AND ALGAE

ANY large expanse

of water holds a certain fascination and from their early days the

Tring Reservoirs have been sites of recreation. Walking and

fishing provide much enjoyment, but at the head of the list must

come interest in wildlife. In recognition of this, the

reservoirs were designated a National Nature Reserve in 1955; in

1987, they were redesignated a Site of Special Scientific Interest

on account of their wealth of wildlife, particularly birdlife.

Because there are few natural lakes in Southern England, the

reservoirs provide an important haven for wintering water birds.

Weston Turville Reservoir is outside this group.

Although it continues to be owned by

The Waterways Trust, it is no longer

used to supply canal water. Managed by the

Berkshire,

Buckinghamshire and Oxfordshire Wildlife Trust, it too is

recognised as an important nature reserve while at the same time

providing an expanse of water for the enjoyment of members of the

Aylesbury Sailing Club, a nice mix of uses.

Lord Rothschild and

party duck shooting on one of the canal reservoirs, 1921.

Somewhat at odds with the above, for 130 years the sporting

rights to the reservoirs were retained by the landowners of the

Tring Park Estate, who arranged shooting parties for their

distinguished guests, which included on one notable occasion King

Edward VII. Until recent times the owners were entitled to

shoot on up to six days per year, their quarry being captive-bred

mallards reared on Marsworth reservoir and the smallest of the

reservoirs at Wilstone. A gamekeeper employed by the Estate

also managed the three reservoirs stocked with coarse fish and the

fourth with trout. From April 2008 British Waterways acquired

both the fishing and shooting rights, of which the latter has now

been discontinued.

As for swimming, during the first decades of the 20thC this

was a popular pastime and organised swimming galas were a regular

fixture. They were probably supervised and safe enough, but

the general practice was eventually banned due to several fatalities

caused by swimmers becoming entangled in water weed.

Swimming lessons, Wilstone Reservoir in the 1930s.

Prolonged dry spells, when the water levels fall drastically,

cause deep cracks in the reservoir beds and the growth of a toxic

phenomenon,

Blue-green Algae (Cyanobacteria).

These algae grow so rapidly they are difficult to control and can

produce toxins that are dangerous to humans as well as to animals

and marine life in general. Although susceptible to

herbicides, the problem can also be addressed with the use of barley

straw, which, in a complex chemical action, inhibits their spread.

Each of the reservoirs except Tringford, which is not affected, is

now strung with lines to which barley-straw mattresses are attached.

――――♦――――

APPENDIX I.

THE WHARVES.

TODAY it is

difficult to imagine that during the canal carrying era ― and

particularly before the onslaught of the railways (c. 1840s)

wiped out many of our canals (vide, for example, the fates of

the Kennet & Avon and the Thames & Severn canals) ― these waterways

were the trunk roads, even the motorways of their day.

Communities who were lucky enough to live near a canal route saw the

prices of coal, timber, building materials and even food fall

dramatically when the canal came to town. Those in rural areas

especially found a cheaper and quicker route to market for their

farm produce; there is much evidence, for example, that the Wendover

Arm was used to export hay and straw to the horse-powered

Metropolis, where it was converted into horse dung (manure) and

shipped back by canal for use as an agricultural fertiliser.

Although it was never particularly common, even humans travelled by

canal:

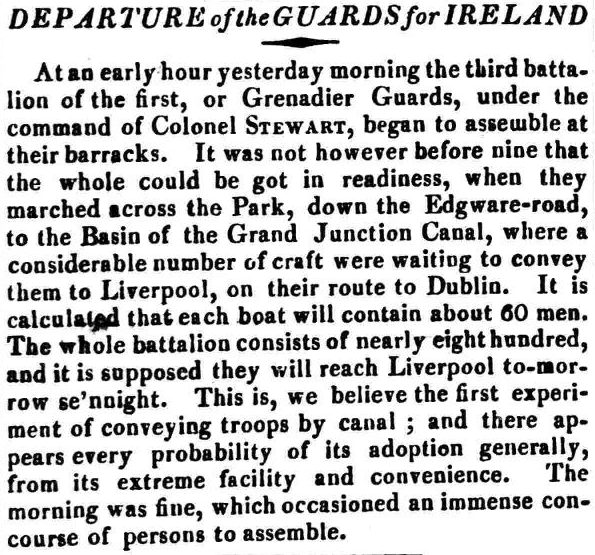

Passengers by canal on the Paddington branch of the GJC.

It is recorded that the poor left Aylesbury by barge on

the first stage of their journey in search of a better life in the

colonies or the New World, while newspaper reports of troop

movements by canal were quite common before the railway age:

The Morning Post, 5th December, 1821

Indeed, the military even constructed a large barracks and

arsenal adjacent to the GJC at Weedon, and into which Barnes built a

short branch canal that entered the walled site through a portcullis.

Much cargo-handling on the Wendover Arm was probably carried out by

boatmen drawing up their craft adjacent to a farmer’s field, and

loading/discharging over planks between the boat and the bank. Where

an accommodation bridge was conveniently placed, it would probably

have been easier to moor under the bridge and transfer goods over

the parapet. But there is archaeological evidence of other

wharfs on the Arm in addition to those generally known about.

Research carried out by Barry Martin suggests there were wharfs of

some type at the following locations (moving upstream from Bulbourne

Junction):

-

on the right (non-towpath side), a few hundred yards above the

overspill weir, was the wharf edging for the Marsworth

Engine/Pump;

-

on the left bank just before Gamnel Bridge (bridge 2) there is

evidence of a wharf;

-

above Gamnel Bridge wharves associated with the various mills

and the boatyard;

-

further upstream, beyond the Tring Feeder, there was a small

wharf on the off-side, its edging being visible during

wintertime when the foliage recedes. Local

recollection is that it was a coal wharf;

-

the wharf edging associated with bringing coal supplies to the

Tringford pumping station remains in place;

-

the next definite wharf edging was for the Wilstone (Whitehouses)

pumping station;

-

just before Drayton Bridge (bridge 5) there was a brick wharf,

on the off-side, adjoining Bridge Farm. This was

certainly very evident when the first undergrowth clearance was

done in about 1977, but when BW restored this section of canal

the wharf was demolished;

-

next upstream was the wharf behind the New Inn, then beyond

bridge 6 (the old A41) there was the wharfage for the Buckland

Gas Works;

-

upstream of the Stable Lane (Wellonhead) Bridge (bridge 7) there

was a further slewing bridge which provided access from the Aston

Clinton House to the towpath side; although this is the site of

the “concreted narrows”, a brick-fronted wharf was visible a few

years ago;

-

if there were wharves at Halton, in the area of the now lowered

road bridge, they would have disappeared during the construction

of that bridge;

-

on the off-side, about 200 yards

further on, there is another small brick-fronted wharf which may

have been associated with the Dashwood estate. An old map (see

fig. ‘5’ at

Halton) of the

area shows that the Canal was widened locally and there was a

boathouse;

-

just before Perch Bridge, the Halton Gasworks would have had a

wharf on the off-side. Working boats were also known to

have moored upstream of Perch Bridge (out of site of Sir John’s

residence) and their crews visited the nearby Perch Inn, but

there probably wasn’t a wharf at this location.

-

the final wharf was probably that at Wendover, of which very

little remains today other than the name, Wharf Road, and the

wharfinger’s house.

――――♦――――

APPENDIX II.

FILTHY LUCRE

From GOOD WORDS

(Volume 20, 1879)

by

CHARLES CAMDEN.

I HAVE chosen my

title with reference to the nature of the materials from which the

gain of which I have to speak is extracted — very fertile “farms of

two acres,” some of our dingy dust yards prove — not with the

slightest to the character of the extractors. Through the courtesy

of Messrs. W. Mead and Co, I have been allowed to pay a visit or two

to a “contractor’s yard,” which claims to be the largest, at any

rate to do the largest business, in London. It is one of

several bordering the Paddington Basin, which from that circumstance

might be called, by a trade pun, a “slop” basin.

Most of the London dust-yards are at the water-side, for the

sake of the water carriage which the canal or river gives them for

their dust and cinders to the country brick makers.

In Messrs. Mead and Co.’s yard, the electric light is used

after dusk in winter, to enable the men to go on with the loading of

the barges. Wandering along the muddy North Wharf Road, with

its dozens of empty tumbrils resting with their shafts up in the

air, or crossing the canal and railway bridges in Bishop’s Road, you

catch sight of an aurora in the sky, and on entering the yard you

see a big meteor star, pulsing white and bluish white, suspended in

solitary brightness over the black heaps from which the weary

sifters have gone home to rest, weirdly lighting up the men plying

pick and shovel down by the canal, and making part of the sluggish

water seem to be phosphorescently afire. As far at the

influence of the light extends, the separate stones can be

distinguished on the gravel wharf, and within that circle the

lamp-posts and the buildings of the yard stand out clear as by

daylight, or rather clearer, since the mysterious brilliance seems

to purge them of their grime. But all gas-jets are turned into

mere faint bilious blotches and outside the magic circle the

darkness, both on land and water, is intensified into ebon gloom.

And now for the daylight aspect of the yard, or rather yards.

An apology for untidiness on a contractor’s premises has a somewhat

droll sound, but one is made for the “muddle” in which the

“slop-yard” is found. The slop is just thawing after long

frost. A wide mass of dark, very unappetising batter-pudding

is pent up on the wharf, waiting for a barge to come alongside; when

a trap will be opened and the unsavoury mess cascade in a mudfall.

This accumulation of scavenging is indiscriminately called slop, but

formerly street dirt dirt used to be divided into mud and “mac,” the

latter being the product of traffic friction on macadamised roads,

and the more valuable for builders purposes because freer from

manure than mud. When I asked my obliging guide at what rate

the yard sold its slop, I was astonished to hear, “We get nothing,

give it away to brick-makers fifteen or sixteen miles down the

canal. Yes, the cost of the carriage falls on us too. We

own twenty barges, with two men and a horse apiece, and we hire as

well. The brick-makers know that we must get rid of the slop,

and so they won’t give us anything for it. If” he added, “the

yard were close to a country district, so that farmers could come

with their carts, they would be glad enough to pay us for it, it

makes excellent manure.”

Separate from the slop wharf by the gravel wharf, which, from

its contrast to its neighbours on both sides looks strangely clean

and almost goldenly bright, is the dust-yard. Outside the

gates empty dust and mud carts, so thickly furred with mud and dust

that the owners’ names are often almost illegible, are congregated

in the manner I have described. Other carts are rolling out

empty and rolling in full. One of them unfortunately goes over

a poor follow, who is taken up tenderly by two brother dusties and

lifted with care into a cab, backed into the yard to receive him,

and in this he is carried off to hospital in charge of a clerk.

The firm owns a hundred and twenty horses, manifestly well

fed, and they are well housed also. In their stables under the

granary which contains their hay, straw, chaff, and crushed oats,

hot as well as cold water is laid on for use at night. Their

drivers look as if they would be all the better for similar

accommodation. The dust that thickly covers the tracks in the

yard is much like that one flounders through in iron-works.

Here the foot sinks over the ankle in dry, black powder, and there

sticks fast in viscous, blacking-like mud. Even on a winter

afternoon, with the mercury dropping to freezing point, the perfumes

floating, or, rather brooding in the atmosphere are not those of Araby the Blest. On a sweltering summer day, after a shower,

what must be the odours steaming up from such a conglomeration of

ashes, egg-shells, oyster-shells, herring-heads, greasy rags and

bones, old boots and shoes, and miscellaneous rubbish! And yet

the people employed in the yard, both men and women — so far as

their flesh can be made out through the dirt with which they have

peppered and besmeared it — look healthy, some quite plump and

ruddy; and the same may be said of the men who go out with the dust

carts and the scavengers.

Paddington Basin today.

――――♦――――

APPENDIX III.

OBTAINING A WATER SUPPLY FROM WENDOVER

(From “On the Utility, Structure and Management of

Canals” by Joseph Townsend: published in

The Universal Magazine of Knowledge and

Pleasure, Vol. XX, July-Dec 1813.)

MOST canals are

distressed for want of water, because either they are above the

springs, or they are not permitted to derive a supply from mill

streams. A knowledge of geology will, in most situations,

relieve the engineer from distress, and teach him distinctly to what

distance he must drive a level, or to what depth he must sink his

shaft, that he may find ample supplies of water, such as no one can

claim, because they nowhere break out in springs, till they issue

either into the narrow seas, at the bottom of the ocean, or in the

great abyss. . . .

It was this knowledge, derived from Wm. Smith, which enabled

Mr. Bevan to direct his shaft into the chalk hills at Tring, by

which he secured a supply of water for the Grand Junction Canal. . .

.

In Dr. Rees’s

New Cyclopedia we have a very interesting account of the manner

in which Mr. Bevan supplied a part of the Grand Junction Canal with

water. This ingenious artist discovered, that on the north

side of the chalk summit between Tring and Wendover, different

water-tight beds in the lower chalk held up springs a considerable

height above the canal, and, in order to avail himself of these, he

began a tunnel in the upper bank of the canal near Wendover, which

he drove half a mile southward to intercept the springs in their

descent. But observing that the principal of this water was in

the winter and spring months, when the other sources were more than

sufficient for the supply of the canal, he placed a strong

water-tight valve in the most favourable part of his tunnel, which

as soon in the autumn as the canal is amply supplied from its other

feeds, he keeps shut until these begin to slacken in their supply.

The water in the immense planes of these beds of chalk

accumulate, as in a vast subterranean reservoir, the springs rise to

the level to which they originally rose, before this tunnel was

begun, that is, twenty feet above the canal, and for many weeks

after the opening of the valve in the beginning of summer they pour

forth a most surprising stream of water into the canal, which

otherwise would have found a vent miles off in the chalk vallies, or

have slowly made its way down through the joints and fissures in the

strata, to springs which issue at the bottom of the chalk below the

level of the canal.

Had the Grand Junction, like the Kennet and Avon canal, been

cut to the south-east of the chalk hills instead of being on the

north side, as it is near Wendover, and had this canal been formed

in a bed consisting of chalk rubble and of flinty gravel, Mr. Bevan

would have had no need of penning up his chalk feeders in the

autumn, in the winter, and in the spring. Of this we can have

no doubt, when we take a view of that immense quantity of water,

which flows in the thick bed of gravel, far beneath the surface, all

the way down the valley from Crofton, Bedwin, and Hungerford, to

Kintbury, Newbury, and Reading.

――――♦――――

APPENDIX IV.

THE CAUSES OF LEAKAGE AND THE ASPHALT LINING

The following text draws on research undertaken by

Barry Martin and Professor Timothy Peters

THE Wendover Arm

and the Llangollen Canal were the only significant canals built with

the primary purpose of supplying water, in the case of the latter,

to the central section of the Ellesmere Canal. It is

coincidental that they are also the only known canals where asphalt

lining was used, although in the case of the Llangollen Canal it was

only to effect a small repair.

From the outset if was realised that the ground over which

the Wendover Arm was built would prove troublesome and, as outlined

above, leakage soon became a problem that was to prove intractable

in the long term. There were probably two reasons for it:

• the porous nature of the ground through which the Arm was cut

meant that it had to be lined, and there is evidence to suggest that

this was not done properly. The original puddle clay was

sub-standard, having been excavated during the construction of Tring

Cutting and used because it was cheap and readily available.

Commercial pressure to keep the Arm open left insufficient time for

relining to be completed properly, while recent analysis of the

asphalt lining put down in 1856-7 revealed it was poorly laid and

not to the specified thickness;

• probably a more important reason is that the canal bed was roughly

on the level of several ‘seasonal springs’, which from time to time

punctured its lining. With the low rainfall experienced in

recent years it is now believed that the water table has fallen

considerably and that this problem ought not affect the restoration

work now being carried out.

In 1856, the Wendover Arm was again losing water and John

Lake, the GJCC’s Engineer, visited some reservoirs (locations

unknown) to inspect their use of asphalt as a liner. His

conclusion – supported by Sir William Cubitt, the Company’s

consulting civil engineer – was that it would be far cheaper to

repair the Arm using asphalt (£4,470) as against puddle clay

(£12,500). On this basis it was decided initially to apply a

two inch thick lining of asphalt to the section of the Arm between

Little Tring Bridge and the Wilstone Swing Bridge (¾mile ― the

swing bridge has

long since gone).

The asphalt mix that was used comprised one part of coal tar,

one part of crushed limestone, one part of sand and some coal oil.

The sand was readily available from Leighton Buzzard, the limestone

from local sources and John Bethell, owner of the Greenwich Gas

Works (now the site of the Millennium Dome), was to supply 2,000

tons of coal tar at 10 shillings and 6 pence per ton, and 6,000

gallons of coal oil at 4 pence per gallon (records indicate that he

was unable to supply more than 1,500 tons of coal tar, while other

records show that considerable less actually arrived at Little

Tring).

In June 1857, the Committee reported that the trial length of

lining was satisfactory and that it should be extended further

up-stream. By the time the asphalting had reached Drayton

Beauchamp, the mix had changed; the limestone had been replaced by

crushed chalk and no coal oil was being used, while a recent

analysis of a sample taken near Drayton Beauchamp revealed the

presence of crushed coke (coke is a by-product in the production of

town gas, and might have come from the nearby Buckland Gas Works).

On March 21st 1857, Sir William Cubitt tested and reported

favourably on the quality of the asphalt.

In application, the asphalt was prepared in situ by

crushing and mixing the ingredients, which were then heated in flat

pans over braziers and poured and spread while still workable.

However, recent excavations have revealed that, in general, the

applied thickness of the asphalt lining was one inch as opposed to

the two inches specified, while it did not extend above normal water

level on the canal banks! Only a few small examples of asphalt

lining have been discovered whose thickness exceed one inch –

notably a nine inch thick section on the tow-path side of the canal

bed near bridge No.4, which is thought might be a repair. The

GJCC Minutes record a quantity of surplus coal tar being sold off.

On May 13th 1858, Lake tested for leakage over a 3,828 yards

section and recorded a rate of 1½ locks per day compared to 15 locks

per day before relining. GJCC records indicate that the

asphalt repairs were initially considered successful, but after 12

years the Arm was again experiencing leakage, the integrity of the

lining probably have being affected by several causes including an

excessively rich lining mixture, poor construction practice, and

damage from boats, ice breaking and earth movements. Recent

excavations have also revealed that the existing clay puddle was

removed prior to the asphalt being laid, and that it received no

protection afterwards (the current restoration practice includes

putting down a considerable layer of earth ― 300 mm ― on top the

Bentomat liner in the bed, concrete blocks over the lining on the

banks up to water level, and turf above).

.jpg)

The former Whitehouses swing bridge c. 1896.

Reproduced by kind permission of Mike Bass.

Below, the same bridge after the Arm had

been abandoned -

Marsworth Reservoir in the background.

――――♦――――

FOOTNOTES |