|

THE GRAND JUNCTION CANAL

A HIGHWAY

LAID WITH WATER.

PART II. - BUILDING THE CANAL

THE PERSONALITIES

INTRODUCTION

“Down to the middle of last century, the trade and commerce of

England were comparatively insignificant. This is sufficiently

clear from the wretched state of our road and river communication

about that time; for it is well understood that without the ready

means of transporting commodities from place to place, either by

land or water, commerce is impossible.”

James Brindley and the Early Engineers, Samuel

Smiles (1864)

The following are pen pictures of the main personalities instrumental in bringing the Grand Junction Canal into

being.

Thousands were involved in some way its construction ― promoters, administrators, accountants, lawyers, civil

engineers, contractors, craftsmen, labourers and no doubt many

others ― but with few exceptions there is little information

about how particular people contributed to the project or

about their careers in general. Even the Canal’s Chief Engineer, William Jessop, an

outstanding civil engineer of his era, had to wait over a

century and a half for a biography, which through shortage of

information caused its authors no small difficulty to prepare.

By comparison the career of the Canal’s Resident Engineer, James

Barnes, who rarely receives

any credit for his substantial input, remains something of a

mystery ― even the attribution of his painting (below) is uncertain

― as do those of his professional assistants.

At the bottom of the social strata one can barely imagine the

harshness of the itinerant canal labourer’s working conditions and his life

spent at other times, while at the opposite end

even the professional engineers endured a tough existence while

pushing to the limits their era’s knowledge of civil engineering to

solve problems, the solutions to which were to lay the foundations

for the following railway-building age and beyond.

――――♦――――

THE 1st MARQUIS OF BUCKINGHAM: CANAL PROMOTER

GEORGE

NUGENT-TEMPLE GRENVILLE (1753–1813), 1st Marquis of

Buckingham, was the second son of George Grenville and Elizabeth

Wyndham. Educated at Eton and Oxford (which he left without a

degree), Grenville entered Parliament in 1774 where he was a sharp

critic of the American War of Independence. In 1782 he served a

short term as Lord Lieutenant of Ireland, returning to English

politics the following year. For his services to George III,

Grenville was created Marquis of Buckingham in December 1784

(although he desired and was

peeved at not having received a dukedom). Between 1787

and 1789 he served a second term as Lord Lieutenant of Ireland,

proving effective but unpopular in the role. Following his return to England, he played little active

part in politics although his views on Irish affairs, in which he

was an early advocate of Catholic emancipation, continued to be

respected.

Buckingham was a man of considerable industry and some financial

ability, but he did not shun expense in what he considered good or

useful causes. He commissioned and paid for James Barnes to

make an initial survey

for a route for the Grand Junction Canal, became a major shareholder in the

Grand Junction Canal Company, and was one of the principal sponsors of the 1793

Grand Junction Canal Act. His

help was recognised by the proprietors at the first ‘General

Assembly’, held on 1st June, 1793 at the Crown & Anchor Tavern in

the Strand . . . .

“Another vote of thanks went to the Marquis of Buckingham, who had

given very strong support to the project and who was described at

the meeting as ‘Projector and Patron of the undertaking’. Indeed,

the Marquis’s coat-of-arms was incorporated into the Company’s

official seal.”

The

Grand Junction Canal, Alan H. Faulkner, David and Charles

(1972)

The Marquis also helped the economy of the area around his family

seat at Stowe by lending the Company the cost of constructing the

Buckingham branch of the Grand Junction Canal. The branch was

to prove of considerable benefit to the town and its locality until

the 1850s, when its trade was taken by the railways. He was

similarly involved at Aylesbury, where a branch canal had been

authorised in the Grand Junction Canal Act of 1794 but eh Company,

believing that the limited trade would not justify the loss of water to the

main line, was reluctant to built it. In 1811, the

Marquis, helped by pressure from Aylesbury traders, succeeded in

having work on the Arm started and it eventually opened in 1814 or

1815 (the exact date is not recorded). The Arm brought industry to

the town and, among other commodities, carried out emigrants

destined for the Americas via Liverpool, much to the delight of the

workhouse superintendents.

In other respects the Marquis appears to have been unpopular with

his peers, exhibiting an overbearing manner, excessive pride and an

extreme proneness to take offence. George III said of him: “I hate

nobody, why should anybody hate me . . . I beg pardon. I hate the

Marquis of Buckingham.” Horace Walpole was even less polite: “He was

weak, proud, avaricious, peevish, fretful . . . and had every one of

those defects in the extreme with their natural concomitant,

obstinacy.” In addition to his unfortunate personality, his great

round bespectacled face and enormous belly made him the subject of

fun and ridicule.

The Marquis died of diabetes at Stowe, the family seat, on 11th

February 1813, his much-loved wife having died in the previous year.

――――♦――――

WILLIAM PRAED: CANAL PROMOTER AND FIRST

COMPANY CHAIRMAN

WILLIAM MACKWORTH

PRAED (1747–1833), a banker by profession, became the first

Chairman of

the Grand Junction Canal Company, a post he held with distinction

from the campany’s formation in 1792 until he retired in 1821.

In the view of Alan H. Faulkner, Praed “proved a tower of strength in the early years of the

concern” [1] and particularly so during the years up to the opening of

the canal in 1805. During this period Praed was involved in much

parliamentary work, in land purchase negotiations and in

investigating problems, such as those posed by the Blisworth

Tunnel (which were to delay the Canal’s opening throughout by several

years) and later with the Great Ouse aqueduct (which failed in 1808). Following the

Canal’s opening, Praed’s name appears

periodically in the press where he is reported presiding over the half-yearly

shareholder meetings at which the Company’s gradually increasing

revenues were announced.

William Praed was the eldest of the six

children of Humphrey Mackworth Praed (1718?–1803), MP and banker at

Truro, and his wife Mary. Educated at Eton and Magdalen College, he

married in 1778 Elizabeth Tyringham (1749–1811), the wealthy

daughter of banker Barnaby Backwell of Tyringham [2] in Buckinghamshire. Elizabeth had just inherited the family estate following the death

of her brother and this became the Praed family’s seat until his

final years, when he appears to have returned to the family’s

ancestral home in Cornwall. In 1792, the old manor house at Tyrinham

was pulled down and the Tyrinham Hall that stands today was built

to a design by Sir John Soane RA. [3]

In 1780 Praed was elected MP for St Ives, [4] holding the seat until

1806 after which he represented Banbury briefly before retiring from

politics. To Praed must go the credit

for guiding the Canal’s enabling legislation through the House of

Commons:

“Endowed with a strong mind and with an active

disposition, he did not confine his public services to the discharge

of duties in the House of Commons. To him the nation is mainly

indebted for one of the most useful and most successful of our

public works, The Grand Junction Canal”.

The Parochial History of Cornwall,

David Gilbert (1838)

In

1793, grateful Company shareholders presented him with a gift of

silver plate for his parliamentary work on their behalf.

In 1779, Praed became a partner in his father’s banking firm at

Truro and in 1801 formed a banking partnership of his own with

Philip Box, Kendon Digby, and Benjamin Babbage, the firm trading

from premises at 189 Fleet Street (another building designed by Soane).

Bankers were inevitably linked to the financing of canals; [5] a local

banker would often be appointed a canal company’s treasurer, and

bankers were involved in providing waterway proprietors with

short-term credit, although they generally took little part in

providing long-term capital. They also helped to place shares. Many of the bank’s customers came from the West Country or

from Buckinghamshire. The business

was eventually absorbed into Lloyd’s Bank.

In 1801, Praed joined his banking partner Philip Box to become one

of the Grand Junction Canal Company treasurers. In 1808, he was a

leading proponent of the ‘old’ Grand Union Canal; this waterway

linked the Grand Junction Canal with the Leicestershire and

Northamptonshire Union Canal to provide access to Leicester and onwards to the

River Trent and beyond. In 1813, in honour of his work as Chairman,

his portrait was commissioned for the boardroom. Praed Street,

Paddington, at the terminus of the Canal’s Paddington Arm, is

another memorial to Praed’s enthusiasm. Built in 1828, it became the

backbone of the Grand Junction Canal Company’s profitable real

estate.

Praed stepped down as Chairman in 1820, his place being taken by the

Hon. Philip Pleydell Bouverie, R. C. Sale becoming full-time Clerk. He ceased to attend company meetings after 1823, but his sons and

London banking partners retained a close interest on his behalf. Praed’s eldest son, James Backwell, inherited the estate at

Tyringham and his father’s banking interests, while another son,

William Tyringham, was also involved in the London banking firm and

became the Grand Junction Canal Company’s Treasurer.

Praed died at the family seat of Trevethow in Cornwall on 9 October

1833 and was buried at the local parish church in Lelant. In St

Peter’s Church, Tyringham, is a monument decorated with a relief

carving of a canal lock.

――――♦――――

WILLIAM JESSOP: CHIEF ENGINEER.

“It is, we think, a useful rule that if a man desires his work to be

well regarded after his death, he should take care to leave in

reliable hands a large collection of personal papers, into which

historians and seekers after doctorates can happily burrow. Jessop

did not.”

Thus Charles Hadfield in the Preface to his biography of William

Jessop, [6] and it is perhaps for this reason that Jessop’s reputation

is over-shadowed by the other great civil engineers of the late 18th

and early 19th centuries, particularly his younger contemporaries

John Rennie (Snr) and Thomas Telford. Other than

the biography, there exists a Memoir of William Jessop (1843) by the

civil engineer Samuel Hughes, to which Hughes adds this intriguing

postscript . . .

“The author of this paper and the publisher consider it necessary to

state that, although they have not derived from the immediate

relatives of the late Mr. Jessop any of that assistance which they

ventured to expect, yet their thanks are eminently due to several

valued friends of the author who had the happiness of

personal intercourse with that distinguished engineer.”

It is difficult to understand why Jessop’s relatives ― particularly

his sons John, William and George ― apparently felt unable to assist

in providing the information that they must surely have had. As for the

great Victorian biographer, Samuel Smiles, in his Lives of the

Engineers (1862) he makes little mention of Jessop,

most of what he does say appearing as a footnote to his Life of John Rennie . . . . .

“Mr. Jessop was among the most eminent engineers of his day. His

father was engaged under Smeaton in the building of the Eddystone

Lighthouse; and, dying in 1761, he left the guardianship of his

family to Mr. Smeaton, who adopted William as his pupil, and

carefully brought him up to the same profession.

Jessop continued with Smeaton for about ten years; and, after

leaving him, he was engaged successively on the Aire and Calder, the

Calder and Hebble, and the Trent Navigations. He also executed the Cromford and the Nottingham Canals; the Loughborough and Leicester,

and the Horncastle Navigations; but the

most extensive and important of his works of this kind was the Grand

Junction Canal, by which the whole of the north-western inland

navigation of the kingdom was brought into direct connection with

the metropolis. He was also employed as engineer for the Caledonian

Canal, in which he was succeeded by

Telford, who carried out the work. Mr. Jessop was the engineer of

the West India Docks (1800-2), and of the Bristol Docks (1803-8),

both works of great importance. He was the first engineer employed

to lay out and construct railroads, as a branch of his profession;

the Croydon and Merstham Railroad,

worked by donkeys and mules, having been constructed by him as early

as 1803. He also laid down short railways in connection with his

canals in Derbyshire, Yorkshire, and Nottinghamshire. During the

later years of his life he was much afflicted by paralysis, and died

in 1814.”

WILLIAM JESSOP (1745-1814) was born in Devonport, the son of Josias

Jessop, a foreman shipwright in the Naval Dockyard, and his wife

Elizabeth. William was educated locally, proving proficient in

languages and particularly in mathematics and science. Following the

burning of Rudyerd’s Tower, a wooden

lighthouse on the Eddystone Rock, the great civil engineer John

Smeaton designed a new stone lighthouse and Jessop senior was given

the task of overseeing its construction. In 1759, Smeaton took

William as a pupil, lodging him at his home at Austhorpe, near

Selby. Following Jessop senior’s death in 1761,

Smeaton became William’s guardian.

As Smeaton’s pupil, William gained wide experience, excelling on

surveys and designs for river and canal navigations. He assisted

Smeaton in improving the navigation of the rivers Aire and Calder in

East Yorkshire and later of the river Trent in Nottinghamshire. It

was during this period that be met his wife Sarah,

their entry in the marriage register at the Parish of Birkin, East

Yorkshire, reading . . . .

“Married in this Church by Licence: William Jessop of the Parish of

Pontefract and Sarah Sawyer of this Parish, 3rd February, 1777.”

Following their marriage, William and Sarah lived in the parish of

Fairburn adjoining Ledsham, and their first two children were

baptised in the church there. Soon after their second son was born

they moved to Newark-on-Trent, where Jessop played an active part in

Local Government. He was elected an

Alderman of the Borough in 1786, later becoming Mayor (1803) and was

a Justice of the Peace (1805).

In 1772, at the age of twenty-seven, Jessop became an independent

practitioner. Among his first projects was the Selby Canal, for

which he gave evidence in Parliament during the committee hearing

for the Act, and when work commenced in 1775, he was appointed

Engineer at a salary of £250 (with the Pinkerton

brothers as contractors). The canal was completed in 1778

and soon became heavily-used; the town of Selby flourished, with a

custom house that enabled traffic to proceed straight to the North

Sea without stopping at Hull. [7] Other work on the Grand Canal in

Ireland kept Jessop involved there

intermittently between 1773 and about 1787, and again from 1790 to

1804 when he was Consulting Engineer for the company. There was

much other work besides. This was the era of canal mania, and with

an extensive portfolio of projects behind him, Jessop had come to be

regarded as the leading

waterway engineer of his generation. His services were constantly in

demand, with most promoting committees endeavouring to obtain him to

formulate their plans and steer their Bills through Parliament,

where he appeared on twenty-seven occasions, far more than any other

engineer of his day.

Despite the vast amount of work that Jessop undertook in the

Midlands, in 1793 he accepted the position of Chief Engineer to

the Grand Junction Canal Company. This involved, among other

commitments, journeys to London to appear before parliamentary

select committees to give evidence on behalf of the Company’s plans and proposals.

This from a hearing on the 1794

Bill:

“William Jessop, Esquire, being examined, said, That the Petitioners

are now proceeding to make the said Canal, agreeable to the Powers

vested in them by the said Act. That by Levels and Surveys, lately

made, it appears practicable to make certain Navigable Cuts from the

several Towns of Buckingham,

Aylesbury, and Wendover, in the County of Buckingham, and also from

the Town of Saint Alban, in the County of Hertford, to join and

communicate with the said Grand Junction Canal and Collateral Cuts,

or some of them.

And the Witness further said, That the making and maintaining such

Navigable Cuts as aforesaid, together with proper Railways and Roads

to communicate therewith, would afford the Inhabitants of the

several Towns and Places, lying near the intended Cuts, a much, more

regular and better Supply of Coals,

Merchandize, Corn, and Manure, and various other Articles, and at a

much less Expence than at present, and that the making the said Cuts

would, in other Respects, be of Public Utility.”

Journal of the House of Commons, 10th February, 1794.

Among the major engineering problems to confront Jessop and his

Resident Engineer, James Barnes, were the canal’s two tunnels (the

third, at Langleybury, was avoided by a change to the line).

The first, at Braunston, hit quicksand, which had not been detected

during the selective borings made during the survey, but

despite this and other problems the tunnel was completed ahead of

schedule in June

1796. The long tunnel at Blisworth proved a far

greater challenge. Treacherous strata, underground springs,

indifferent workmanship and a deliberate variation in the tunnel’s

alignment, made without Jessop’s knowledge, brought

work to a halt in 1797, and it was to be eight years before the

tunnel was completed. At this point, Jessop appears to have

considered the tunnel impractical, for he proposed to the Board a

scheme for crossing Blisworth Hill using a succession of locks, the

summit being supplied with water by steam pumping. Barnes, on the

other hand, favoured perseverance with the tunnel on a slightly different alignment.

Following an inspection of the works by the civil engineers Robert

Whitworth and John Rennie, who concurred with Barnes, the Board

directed that work on the tunnel continue, although on a different

alignment and under the direction of Barnes. Thereafter, Jessop appears to have been relegated by the Company to

an occasional consulting role:

“In 1797 the Grand Junction referred to Barnes as ‘our Chief

Engineer’ and Jessop was politely removed from office on the pretext

of saving money.”

A Biographical Dictionary of Civil Engineers in Great Britain and

Ireland, A. W. Skempton, Ed. (2002).

In the intervening period a road was built on which to transfer

goods across Blisworth Hill, but when this proved unsatisfactory,

Jessop and the engineer Benjamin Outram proposed a plate tramway.

Completed in 1802, the double-tracked tramway sufficed to open up

the route to commercial traffic until Blisworth Tunnel was completed

in 1805. The convoluted economic argument

that Jessop uses to justify the tramway’s construction survives

(Appendix I.)

― no doubt he, Outram and the Butterley Iron Works

(referred to below) benefitted.

During this period Jessop was also involved with other major canal

projects. The Bill for constructing the Rochdale Canal to link the

Bridgewater Canal in Manchester with the Calder & Hebble Navigation

(a broad canal) fell to Jessop to pilot through Parliament, which he

did successfully in 1794 after two earlier attempts had failed

through opposition from water mill owners. Jessop’s plan for the canal

included ninety-two locks over its thirty-three mile length, and to

placate the mill owners, it was designed to avoid drawing water from

the natural rivers and streams, but to be supplied from a series of

reservoirs fed by surplus water. Mostly complete by 1804, the canal

became the main highway of commerce between Lancashire and

Yorkshire, carrying cotton, wool, coal, limestone, timber, and salt

as well as general merchandise. [8]

Towards the end of 1793, Jessop was appointed Consulting Engineer to

the Ellesmere Canal Company. This was his first collaboration with

Thomas Telford, twelve years his junior, and they worked together

periodically throughout the remainder of Jessop’s career. The Ellesmere Canal

[9] has

a complicated history, for what was planned differs considerably

from what was eventually

delivered. [10] Suffice it to say that the canal

includes, for its time, one of the major civil engineering achievements in the

British Isles, the Pontcysyllte Aqueduct. Completed in 1805,

the aqueduct strides across the Dee Valley on 18 ashlar stone

piers, each with a span of 53 ft to their centres – 45ft clear – and

a maximum height above the valley floor of 126ft, the canal being

suspended in a cast-iron trough, 11ft 10in wide. It is unclear

exactly with

whom the credit for the conception and design of this fine aqueduct

should rest, but between them Jessop and Telford delivered a

masterpiece in utility and appearance. Today, the Pontcysyllte

Aqueduct is recognised by its status as a Grade I Listed Building and a World

Heritage Site.

To add to his waterway achievements, Jessop engineered railways on

which the traffic was horse-drawn. In June 1801, he was appointed

engineer to the Surrey Iron Railway, which ran from Wandsworth to

Croydon and was the first public railway, independent of any canal, to

be built under an Act of Parliament. He also designed the railway

from Kilmarnock to Troon, opened in 1810.

Outside of his civil engineering activities, Jessop had interests in

commercial ventures, including investments in several of his canals. But his most successful business venture was The Butterley Company. Based at Ripley in Derbyshire, the company was set up originally by

fellow-engineer Benjamin Outram to manufacture cast-iron edge rails,

a design that, in 1789, Jessop had used successfully with flanged

wheels on a horse-drawn railway for coal wagons in Loughborough. In

1793, with Outram’s assistance, he constructed the Cromford Canal. During the excavation of the Butterley Tunnel, large quantities of

coal and iron were discovered. Fortuitously, Butterley Hall fell

vacant and Outram, with the financial assistance of Francis

Beresford, a solicitor, purchased the Hall and its estate. The

following year they were joined by Jessop, who became one of the

founding members of the Company, which grew and prospered . . . .

“The extensive iron works of the Butterley Co. were established

about 1793. They consist of three blast furnaces, foundry, and steam

engine manufactory, and give employment to a great number of

persons. They have also extensive works at Condor Park, and

extensive collieries in the neighbourhood. The Cromford Canal is

conducted underneath these works through a tunnel of 2,966 yards in

length.”

History, Gazetteer and Directory of Derbyshire (1846)

By 1796 Butterley was producing nearly a thousand tons of pig iron a year. By the second decade of the next century, the company had expanded

with another works at Condor Park, both works having two blast

furnaces and an output of some 4,500 tons per year. In 1814 the

company produced the ironwork for the Vauxhall Bridge over the River

Thames, and later the ironwork for the train shed at St. Pancras

Station. On his Jessop’s death in 1814, his third son inherited

his father’s interest and continued to develop the firm into the long-lived Butterley Company, which continued

in business until

2009.

During his career, Jessop was involved in a wide range of civil

engineering work, his portfolio listing canals, river improvements, land drainage schemes, docks (including the

West India Docks), harbours (including Bristol Floating Harbour) and

railways/tramways ― indeed, his career bridges the gap between the

canal and the railway engineers who came later.

Alas, Jessop has failed to gain the lasting fame that he deserves

due principally to his modesty, with some of his work even being

attributed wrongly to his assistants. The scarcity of documentary

material also extends to his personal life. But in his day he was

highly regarded by almost all those who had worked with or for him. Although Telford has come to be considered the man of greater

genius, he placed firm reliance on Jessop’s judgment . . . .

“In all matters of masonry work he felt himself master of the

necessary details; but having had comparatively small experience of

earthwork, and none of canal–making, he determined to take the

advice of Mr. William Jessop on that part of the subject; and he

cordially acknowledges the obligations he was under to that eminent

engineer for the kind assistance which he received from him on many

occasions.”

Life of Thomas Telford, Samuel Smiles (1862)

Writing about the construction of the Ellesmere Canal, Telford’s

biographer Sir Alexander Gibb remarks . . . .

“. . . . and so began a connection between Telford and Jessop that

lasted a quarter of a century to the pleasure and advantage of both. Telford had a profound trust in Jessop’s judgement, and up to his

death in 1814 sought to bring him into any work with which he was

connected requiring special engineering skill, particularly in

regard to water or harbour work. Jessop was of a retiring nature,

and is consequently among those who have passed almost

unchronicled”.

Gibb goes on to say that . . . .

“Jessop’s report and his advice were valuable because they were

always constructive, and he never suggested an alternative from any

conscious or unconscious desire to exhibit his own learning.”

The Story of Telford: the Rise of Civil Engineering, Sir Alexander

Gibb FRS CE (1935)

But Telford’s own view is unclear, for in his writings he makes

no mention of Jessop’s participation or leadership in the Caledonian

Canal project, nor does he acknowledge his senior colleague’s

contribution to the engineering of the Ellesmere Canal. Such

surprising omissions serve to detract from Jessop’s reputation while

they reflect no credit on Telford. But let the last word rest with

the civil engineer Samuel Hughes, who departs from the general view

that the Grand Junction Canal is Jessop’s most notable achievement .

. . .

“The promoters of the first great public dock establishment in

the metropolis [London] called upon Mr. Jessop to conduct

their works, and he had the honour of completing the great project

of the West India Docks, with their numerous accompanying details,

in a manner which entitle him to rank among the greatest engineers

which this or any other country has ever produced.”

Memoir of William Jessop, Samuel Hughes CE (1843)

Late in life Jessop became increasingly inflicted by a form of

paralysis, and he died at his home at Butterley Hall on 18 November

1814. He, his wife Sarah (d.1816) and his son Josias (d. 1826)

―

also a successful canal engineer ― are buried in Pentrich churchyard,

where they are commemorated.

――――♦――――

JAMES BARNES: RESIDENT ENGINEER

Another who has passed almost unchronicled is James Barnes, “the

eminent engineer” to use Joseph Priestley’s description of him.

[11]

|

|

|

Believed to be

James Barnes. |

Although Barnes’s

recorded portfolio of civil engineering projects is nothing

like as impressive as that of Jessop, he nevertheless shares with

Jessop the fate of being too little known for what he did

achieve. As Chief Engineer, credit for engineering the Grand

Junction Canal usually goes to Jessop, although as the project

progressed much of his input was on the basis

of occasional consultancy. Despite having surveyed the

canal [12] and most of

its branches, Barnes’s contribution is often

ignored. In his role of Resident Engineer, he drove the work

forward throughout the canal’s twelve years of construction. Most of the

credit for what in its day was a significant feat of civil

engineering, the Blisworth Tunnel, should also go to Barnes, who

persevered after the initial failure brought work to a standstill

[13] and who on two occasions took over the direct

supervision of its construction after the

contractor had failed. And yet the source of Barnes’s training as a

canal engineer is a mystery.

JAMES

BARNES is believed to have been born in 1739. His place of

birth is unknown, but was possibly in the locality of Banbury, a

town in which he spent most of his life engaged profitably in his

parallel occupation of maltster and brewer. The earliest

mention of his canal engineering activities is in connection with

the Oxford Canal on which, in 1786, construction had been restarted

following an eight-year pause due to lack of money. Barnes was

appointed “Surveyor of the Works of the Canal” for the

remaining section

from Banbury to Oxford, with six surveyors reporting to him

including the engineer Samuel Simcock. [14]

Barnes’s business acumen had already shown itself in the growth of

his brewing and malting activities in Banbury, while his interest in

the Oxford Canal Company was evident through his holding of £80 of

4½% loan stock, but one can but wonder what engineering credentials

gained Barnes this appointment. Speculation suggests that he was at

least a driver of men and one who learned quickly ‘on the job’, for

a contemporary account describes him as being “strong minded but

very illiterate” and that he . . . .

“. . . . made all his calculations by the strength of his memory,

and [was] equally at a loss to explain what he had conceived

to any other person, and from being lowly educated he had no means

of conveying to paper his designs, yet would cost up the most

intricate accounts without difficulty or error.”

A Tour of the Grand Junction Canal, John Hassell (1819)

Against this background, it is unsurprising that Barnes completed

the southern section of the Oxford Canal on 1st January 1790, a year

earlier than the contracted date.

While work on the Oxford Canal was in progress, Barnes, together

with Samuel Simcock and Samuel Weston, surveyed a route for a canal

from the River Kennet at Newbury to Bath. This project did not

proceed as such, but following a further survey undertaken several

years later by John Rennie Snr., a revised route was adopted to become the

Kennet & Avon Canal, which following some 40 years of restoration

from a near derelict condition has now become popular with leisure

boaters.

Despite his achievement in completing the Oxford Canal ahead of

schedule, attention to his brewing interests appears to have given

Barnes’s employers cause for dissatisfaction, for in December 1791

they expressed their view that his “various occupations and

connections prevent that attention which is particularly necessary

in his department . . .” At the same meeting the Oxford Canal

Company agreed to pay arrears of salary amounting to £835, for to

help ease the company’s precarious financial position Barnes had not

drawn his pay since 1787. He and the Oxford Canal Company then

parted company, Barnes being swept up in the canal mania of the

early 1790s. He undertook two surveys for a quicker route from the

Midlands to London than by the existing Oxford Canal and the Thames.

First he surveyed the busy northern section of the Oxford Canal to

show how it could be widened and shortened (work that was eventually

undertaken in 1829 to plans by William Cubitt). He was then

commissioned by the Marquis of Buckingham to survey a route from

Braunston on the Oxford Canal to Brentford on

the Thames. With minor adjustments by Jessop ― and a choice

later being made between routing the Canal through Harrow or

Uxbridge ― this route became the

Grand Junction Canal.

For Barnes, now appointed Resident Engineer under Jessop, the major

challenge proved to be construction of the 3,076 yards-long tunnel

under Blisworth Hill where, in addition to failing contractors

leaving him to take over supervision of the work on

occasions, there were problems with the tunnel’s alignment, with

quicksand and (throughout) with serious flooding. Following a

collapse in 1796, construction halted, not to restart until 1802,

and then on a new alignment.

During this period, Jessop’s position with the Grand Junction Canal

Company appears in some way to have been impaired, for by 1797

Barnes was referred to in the Company minutes as “Chief Engineer”,

although Jessop continued in a consulting role. [15]

After many and varied problems the

tunnel was eventually completed in 1805, almost five years after the rest

of the canal. To celebrate the occasion, the proprietors held a

dinner to which Barnes was invited. On his health being drunk, “Old

Barnes”, as he was usually called, returned the compliment . . . .

“Mr. Chairman and gentlemen ― I beg to return you my thanks ― and

since we are met together, and the tunnel ended ― the least said is

the soonest mended.”

A Tour of the Grand Junction Canal, John Hassell (1819)

Today, the Blisworth Tunnel is the longest in regular use on British

Waterways.

To Barnes should also go credit for the huge embankment across the

valley of the Great Ouse between Wolverton and Cosgrove. It

had been planned to cross the valley using flights of locks, but at

Barnes’s suggestion the Cosgrove embankment was built to save water

and provide quicker and more reliable transit, the Ouse valley being prone to

flooding in times of heavy rainfall. Although some slippage has been

experienced, Barnes appears to have been lucky to avoid the severe

difficulties caused by unstable material that Robert Stephenson was

later to face when constructing the nearby Wolverton railway

embankment.

In addition to his work on the Grand Junction Canal main line,

Barnes also undertook surveys for branch canals to Aylesbury,

Northampton, Buckingham, Chesham, Dunstable, Hemel Hempstead,

Newport Pagnell, St. Albans and Wendover ― he probably surveyed the

short Daventry branch, a section for which is included in the GJC deposited

plans. Of these proposed

branches, five were eventually built; from Bulbourne to Wendover

(needed to supply water to Tring summit; completed c. 1794, closed

to navigation past Little Tring in 1904), from Marsworth to

Aylesbury (opened c. 1814), and from Gayton to Northampton (opened

1815). [16] The celebrations that accompanied the opening of the branch

from Stony Stratford to Buckingham [17] were typical of what occurred

when the canal came to town:

“A numerous party was handsomely entertained by the Marquis of

Buckingham, at the Cobham Arms Inn, on the occasion, and a liberal

supply of beer was given to the populace. ― This branch of the

canal, nine miles and a quarter in length, has been completed in

eight months, under the superintendence of Mr. James Barnes,

Engineer to the Grand Junction Canal Company, and will secure to an

extensive district of country the most substantial benefits.”

Jackson’s Oxford Journal, 9th May, 1801.

By far the most important of the Grand Junction Canal branches was

that from Bulls Bridge, at Hayes, to Paddington. Surveyed by

Jessop and Barnes, the Paddington Arm opened in 1801 to be followed

in stages (between 1816 and 1820) by the Regent’s Canal (Engineer,

James Morgan), which in

effect extended the Paddington Arm to provide a highly profitable

link around the outskirts of the City and, via the Regent’s Canal

Dock, to the Thames at Limehouse (and thence to other Thames-side

wharfs and docks) and to the River Lee Navigation.

In addition to his work on the Oxford and Grand Junction canal

projects, Barnes was also involved with the two waterways that link the Grand

Junction Canal with

Leicester. In 1796 he was engaged as consultant to the

Leicestershire and Northamptonshire Union Canal Company to survey

the Saddington Tunnel, which was discovered to be out of

alignment. Subsequently, three lengths of the tunnel were rebuilt

and widened to permit the passage of Thames barge traffic, which was

then expected from the Grand Junction Canal. [18] In 1799, 1802 and again in 1808, he undertook

surveys for the Grand Junction Canal Company with the aim of connecting the two canals

― Thomas

Telford also surveyed a route in 1803-4. The ‘connecting’ canal, the Grand Union Canal (not to be confused

with the canal system of that name created in 1929), was eventually constructed under the supervision of the civil engineer Benjamin

Bevan, who chose the shorter route proposed by Barnes in preference

to that by Telford. Opened in 1814, the (old) Grand Union

Canal

extends from Norton Junction to Foxton, where it connects with the

former Leicestershire and Northamptonshire Union Canal. Today, both

canals form the southern section of the Leicester Line of the Grand

Union Canal.

Towards the end of his career, Barnes was employed in the

construction of several railways, of which the Carmarthenshire

Railway is significant. Having gained its Act in 1802 it

opened in the following year, thus predating the Surrey Iron Railway

as the earliest operational public railway in Britain. This

horse-operated 4ft-gauge ‘plateway’, built with substantial earthworks,

was planned to open up the coalfield to the north of Llanelli, but

it never achieved its expected results and by 1830 most of its

16–mile route was derelict. It finally closed in 1844.

Outside of his engineering activities, Barnes was a successful

brewer at Banbury . . . .

“The Dunnell brewery was in North Bar, where, at the beginning of

the 19th century, James Barnes had owned a small brewing business;

his son-in-law Richard Austin [19] became a partner in 1808 and took over

complete control in 1818. By 1840 the brewery was exporting to

India. The brewery was purchased by Messrs. Harman c. 1850 after

Richard Austin’s son Barnes had squandered much of his inheritance”.

[20]

A History of the County of Oxford: Volume 10 (Banbury)

In 1814 the North Bar brewery was described as having a hop garden,

two malthouses, ten inns in Banbury and thirteen in the surrounding area.

Barnes also played an active role in Banbury’s public life. In 1799

he was elected a ‘Capital Burgess’ of Banbury Corporation, an

Alderman in 1806 and was Mayor in 1801 and again in 1809. And at a

time predating the secret ballot, Barnes is known to have voted in

the parliamentary elections of 1806 and 1807 for his former chief,

William Praed, Chairman of the Grand Junction Canal Company.

Barnes’s wife Mary died in 1807, this brief announcement appearing

in the British Register . . . .

“Mrs. Barnes, wife of James Barnes Esq. formerly principal

engineer, and conductor of the Grand Junction Canal, but now an

alderman and common brewer, of Banbury.”

James Barnes followed her on 18th January 1819, an announcement in

Jackson’s Oxford Journal reading simply “A few days since died,

suddenly, Mr. Barnes, an eminent brewer, of Banbury, in this

county.” His will shows that he owned 45 £100 shares in the Grand

Junction Canal Company,

then selling for about £280 each and returning an annual dividend of

7%.

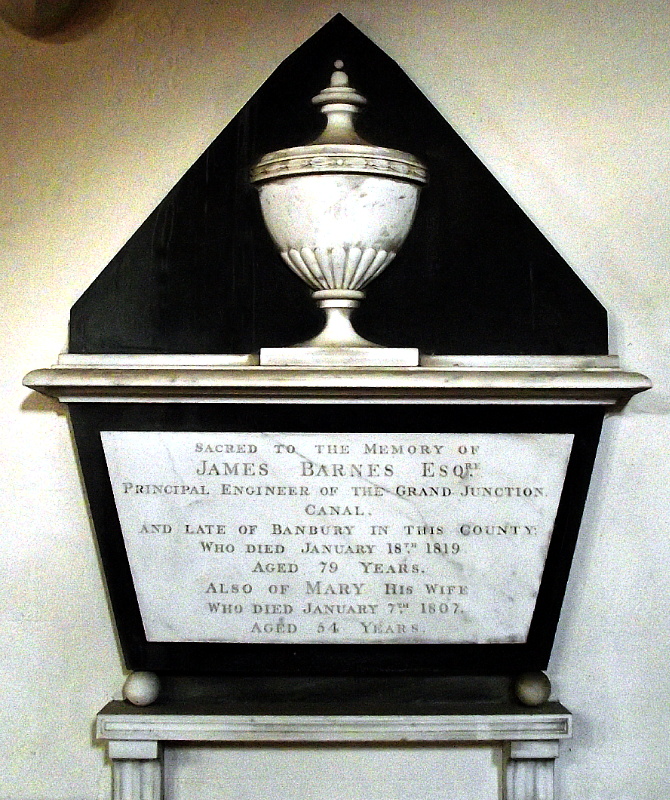

Memorial to James Barnes,

“Principal Engineer of the Grand Junction Canal”.

James Barnes was buried at Bodicote Church, just south of Banbury,

where lie the remains of his wife Mary and daughter Mrs. Mary

Austin. His memorial describes him as “Principal Engineer” of the Grand

Junction Canal Company, a fitting epitaph, for it was Barnes, principally, who

surveyed the canal

and, on the ground, brought the grand plan to fruition.

――――♦――――

BENJAMIN BEVAN: ASSISTANT ENGINEER

In addition to Jessop and Barnes, a handful of other civil engineers

appear fleetingly during the construction of the Grand Junction Canal and its early years

in operation; that is not to say that their contributions were

insignificant, but rather that the record of what they achieved is

far from complete. One such was Benjamin Bevan.

Besides being a notable canal engineer, Bevan was something of a

polymath who throughout his life showed a great love of science as

well as considerable power in promoting its uses. He submitted

papers to learnèd journals and to institutions, such as the Royal

Society, on a range of subjects including the use of the slide rule,

geometry (a guide to Carpenter’s Rule and the Bevan Point),

materials science, astronomy and geology. He also corresponded with

the computing pioneer Charles Babbage, with whom he shared a common

interest in astronomy.

BENJAMIN BEVAN was born at Ridgemont, Bedfordshire, on 26th

December, 1773, the eldest of the four children of Joseph Bevan, a

farmer and prominent local Baptist. Benjamin’s brother William and

sister Mary died in infancy, and when Joseph Snr. died in 1782, he

bequeathed to his eight-year old son his considerable farming

interests. In 1799, Bevan married Mary Allen at Bedford; they were to

have five children, the eldest of whom (Benjamin Jnr.) also became a

surveyor and canal engineer.

Bevan appears to have made the transition from farming to surveying

early in life, for during a parliamentary committee hearing in 1826

he claimed that he had been a surveyor and civil engineer for 30

years, and that was how he was described at the time of his marriage in

1799. In the publication 200 years of British Hydrogeology,

[21] the

section on the geologist and canal engineer William Smith throws a

little more light on Bevan’s early connection with canal engineering

. . . .

“One further point of importance when considering Smith’s canal work

is his role as a teacher. One of this country’s later most active

and important canal engineers, the above mentioned Benjamin Bevan

(1773–1833), had been a brewer and land surveyor in Leighton

Buzzard, Bedfordshire. He was encouraged to become a canal engineer

after meeting Smith in 1801, when Smith taught him the rudiments of stratigraphy

[22] on tour [23] with Farey.”

Whatever its roots, Bevan’s earliest recorded connection with the

Grand Junction Canal was in 1804, when he was employed to supervise the repair of

leakage on the Little Tring to Drayton Beauchamp section of the

Wendover Arm. Presumably he dealt with the problem at the time,

although leakage was to defy a permanent solution and recurred

periodically over the next century, eventually leading to the

canal’s closure west of Little Tring in 1904. [24]

It is possible that during his work on the Wendover Arm Bevan

utilised the geological ‘tuition’ he had received from William Smith

to tap into a subterranean water supply, water being needed badly at

the Tring summit (Appendix II.). He also proposed a reservoir to collect

surplus water from the Canal and from various local feeds, with

steam–driven pumping being used to return it to the summit ― the

outcome was the Marsworth Reservoir which,

together with its pumping station (replaced by Tringford pumping station in

1818), was opened in 1806.

Bevan was associated with the early use of side–ponds as a

means of saving water at locks. [25] In 1805, he reported on the

construction costs and extra time spent passing through locks 58 and

59 at Berkhamsted, which had experimental side ponds, and in 1815 he

constructed four more at King’s Langley as part of efforts to

resolve a long running dispute over water rights with the owners of

Nash mills. Although long out of use, side ponds can still be

seen at various locks of the Grand Junction Canal, such as

those on the Marsworth to Bulbourne flight.

Following completion of the Blisworth Tunnel in 1805, James Barnes

retired from the Grand Junction Canal Company after thirteen years of service. Bevan, Henry

Provis and John Woodhouse were appointed jointly to succeed him,

Bevan being allocated the central section of the canal from Leighton

Buzzard to Hunton Bridge.

Although it fell outside of his area of responsibility, Bevan became

involved with the construction of the embankment and aqueduct across

the Ouse at Wolverton. The original plan had been to take the canal

across the Ouse at river level, using two four lock flights to

descend into and ascend out of the Ouse Valley. This scheme would

have slowed canal traffic and wasted water, besides leaving the canal

vulnerable to river flooding. In 1800 Barnes suggested, as an

alternative, carrying the canal cross the Ouse Valley on a high

embankment using an aqueduct to bridge the river. This proposal was

accepted, but as the embankment and aqueduct [26] were expected to take

two years to complete, a temporary locking system was installed to

permit traffic to cross the Great Ouse valley while the embankment

and aqueduct were being built. The work was put out to tender, and

in December 1802, a contract was let to a consortium headed by

Thomas Harrison of Wolverton. Work on the embankment and on the

three-arched brick and stone aqueduct, to Jessop’s design, commenced

in August 1803 and was opened to traffic on 25th August, 1805. However, in January 1806, a section of the embankment failed; this

was repaired, the failure being attributed to poor workmanship by

the contractor, who disputed this claim and submitted an account of

additions of his own. In 1807, Bevan and Henry Provis were assigned to

examine the contractor’s claims. By this time Jessop’s aqueduct was

showing signs of failure and in February 1808 it collapsed, severing

the canal. Fortunately the locking system across the Great Ouse

valley was still in place and was used to bypass the failed

aqueduct.

As a temporary solution, Provis designed a wooden trough to

bridge the Great Ouse, Bevan being given the task of designing a

permanent replacement. Telford’s cast iron trough aqueduct at Pontcysyllte had by now proved itself, and Bevan adopted this

construction for his structure, although the Ouse aqueduct troughs

had to be substantially larger and stronger than at Pontcysyllte due

the Grand Junction Canal’s greater width. The iron units were cast at the Ketley

foundry at Coalbrookdale, transported to Cosgrove by canal and

assembled and erected on site. During its long life, Bevan’s iron

aqueduct has experienced only two stoppages for maintenance, in 1921

and in 1986.

During Bevan’s time with the Grand Junction Canal Company, he undertook other civil

engineering assignments. He surveyed the River Ivel from Biggleswade

to Shefford, with a view to making it navigable (1807), reported on

the state of the navigation of the River Welland (1810), and

supervised the construction of the ‘old’ Grand Union Canal from

Foxton to Norton Junction, notable for its flight of ten locks at

Foxton and for the Crick (1,528yds) and Husbands Bosworth (1,166yds)

tunnels (1810-14). Bevan also supervised the construction of

the Northampton Branch (1813-15), and planned and estimated

the cost of the short (1¼-mile) Newport Pagnell Canal, which opened

in 1817:

“The conveniences afforded by this communication with the Grand

Junction Canal in the transit of coal agricultural produce timber

deals stone and groceries are important to the town and

neighbourhood of Newport Pagnell.”

Navigable Rivers and Canals, Joseph Priestley (1831)

. . . . that said, the Newport Pagnell Canal was short-lived. In

1864 it was bought by the Newport Pagnell Railway Company who used

it to form part of their track bed.

Following Bevan’s departure from the Grand

Junction Canal Company in 1817, he engaged in

other bridge design, river improvement, sewage and drainage schemes,

as well as being retained until the time of his death in 1833 as

Engineer to the ‘old’ Grand Union Canal, his son then taking over

that role.

Bevan’s death on 2 July, 1833, came about as he might have wished,

in the pursuit of knowledge. His wife reported that they had been in

bed, but that he had got up and gone into the front room to observe

an eclipse of the Moon. While it was taking place he succumbed

peaceably, probably to a heart attack.

――――♦――――

HENRY PROVIS, ASSISTANT ENGINEER

HENRY

PROVIS was born at St. Gluvias, Cornwall, in 1760. Thought to

have trained as a surveyor, he was employed in 1791 by the architect

Sir John Soane as a clerk of works. Among other

projects with which Provis was associated was the building of Tyringham

Hall, the seat of the Grand Junction Canal Company’s Chairman, William Praed. Tyringham’s

close proximity to the embryonic Grand Junction Canal probably led Provis to see

in it an

employment opportunity ― he would certainly have known Praed ― for in 1802 he commenced work for the

Company at a salary of £200 p.a.

supervising work on the southern end of the canal. However, it is

clear from the occasional references to him that Provis was also

given a range of work on the northern section, including supervising

work on the new locks at Stoke Bruerne, taking over work on the

Blisworth Tunnel after the contractor had been dismissed, and work

at Wolverton, both before and following the collapse (1806) of a

section of the embankment leading to Jessop’s Great

Ouse aqueduct. When the aqueduct itself collapsed in 1808, Provis planned and

supervised the construction of a temporary wooden trough to carry

the canal across the Ouse until Bevan’s iron aqueduct was completed

in January 1811. The Grand Junction Canal Company later awarded him a 50 guineas gratuity

for this work.

Following the opening of the Paddington Arm in 1801, a strain was

placed on the water supply to the Canal’s southern section, which

by 1809 had become serious. To remedy the problem, Provis proposed

building a 3½-mile feeder from the River Brent at Kingsbury, through Neasden to join

the Paddington Arm at Lower Place. The project went ahead, a

conveyance document dated 5th May, 1810, recording that £215 was

paid by the Grand Junction Canal Company for land “being of the width of 15 feet little more

or less and containing together by survey 1 acre and 24 perches

little more or less.” The feeder was brought into use c. 1811.

In 1835, the Brent Reservoir was opened and the feeder was

then supplied through a tunnel in the dam wall.

Undoubtedly, the most enduring of Provis’s contributions to the

Grand Junction Canal is the

6¼–mile Aylesbury Arm. The Arm was originally intended to form part of a

larger canal project, the Western Junction Canal, which was to link

Aylesbury to the Wilts & Berks canal at Abingdon. In 1810, Provis,

together with William Whitworth and John Barker, surveyed the route.

Had the canal been built, its 36½ mile route would have run from

Abingdon, crossing the Thames on an aqueduct, and then via Thame, Cuddesdon, Long Crendon and Stone to Aylesbury and onward to connect

with the Grand Junction Canal at Marsworth. However, the parliamentary Bill

was withdrawn by the promoters after strong opposition from

landowners, leaving the Aylesbury Arm a mere branch canal, although

today the focal point of major commercial redevelopment in the town. Following its opening

c. 1814, Telford, no less, was asked to

undertake an inspection; his report stated that the Arm was “in a

very perfect state”, a tribute to Provis’s work.

While working on the Grand Junction Canal, Provis won a 100-guinea prize for the

design of what became the Islington Tunnel on the Regent’s Canal (a waterway

that connects the Paddington

Arm of the Grand Junction Canal to the Thames at Limehouse, and to

the River Lee Navigation). The company advertised the competition in 1812, the committee

of judges including Jessop. It is, perhaps, of little surprise

that the award went to

Provis, for his was a copy of a Jessop design! However, it appears to have been considered unsuitable, for

the tunnel was eventually built to a design by the Regent’s Canal’s

engineer, James Morgan.

During his time with the Grand Junction Canal Company, Provis accepted commissions

elsewhere, the most important of which was for the cast iron

Tickford Bridge across the Ouzel at Newport Pagnell. Dating from

1810-11, it is one of the oldest cast iron bridges capable of

carrying modern traffic, although with some strengthening. Designed

by Provis, the bridge was based on Thomas Wilson’s patented method

for the construction of iron arches. Commenting on the North and the Tickford bridges, Hassell observed that:

“Both these bridges were built by Mr. Provis of Paddington, an

engineer of celebrity, from his own designs: they are specimens of

durability and pure taste, and highly ornamental to the entrances to

the town either way.”

A Tour of the Grand Junction Canal, John Hassell (1819)

Following his departure from the Grand Junction Canal Company in 1816, Provis was appointed

county surveyor for the northern district of Buckinghamshire and, in

1822, for the county. Among his projects were improvements to

Aylesbury Goal. In 1828, the scheme for the Western Junction Canal

re-emerged and Provis was again consulted. He prepared a new line,

building on a survey undertaken by Telford in 1819, [27] but departing

from the direct line taken by Telford between Thame and Aylesbury

preferring to follow the Thame Valley. However, demands from the Grand

Junction Canal Company for compensation should the proposed canal lead to a loss of

profits brought this final attempt to link with the Wilts & Berks to nothing.

Provis died at his home, Bridge Lodge at Sherrington,

Buckinghamshire, on 23rd August 1830. At the time of his death he

was working on the design of Olney Bridge over the River Great Ouse

in Buckinghamshire. Provis’s structure replaced the 17th century bridge referred to by

the poet William Cowper in The Task; it was opened in 1832

and is now classified as an Ancient Monument and listed building.

Three of Provis’s sons became civil engineers; William and John both

worked under Telford and were involved in the construction of the

London to Holyhead Road and the Conway and Menai suspension bridges,

while William also assisted Telford in surveying the Apsley

deviation on the Grand Junction Canal.

――――♦――――

JOHN WOODHOUSE, ASSISTANT ENGINEER

JOHN WOODHOUSE was the son of Jonathan Woodhouse, a mining engineer. He was born

c. 1776, probably at Bedworth in the locality of

Nuneaton where his father resided.

Woodhouse’s first involvement with the Grand Junction Canal Company was in 1802 when he and

his brother Jonathan were members of a syndicate that was awarded

the contract to complete the Blisworth Tunnel. Work on the tunnel

had been pretty much suspended for the previous five years in order

to expedite completion of the remainder of the canal and increase

the Company’s revenue (part of the Company’s cost–cutting at this

time included Jessop’s change of position from Chief Engineer to

occasional consultant).

The syndicate was to receive stage payments for work at the

rate of £15.65 per yard of completed tunnel, as certified by Barnes,

with a bonus of £1,000 if the work was successfully completed in two

years and three months. However, by 1803 the Grand

Junction Canal Company had become

increasingly concerned about the sums they were advancing to the

contractors to pay for materials (advances were offset against stage

payments). By the beginning of 1804, it was apparent that the

syndicate had lost financial control of their operations and had

sustained a substantial loss. The outcome was that the contractors

were dismissed and the Grand Junction Canal Company took over direct control, John Woodhouse

being retained to manage the works.

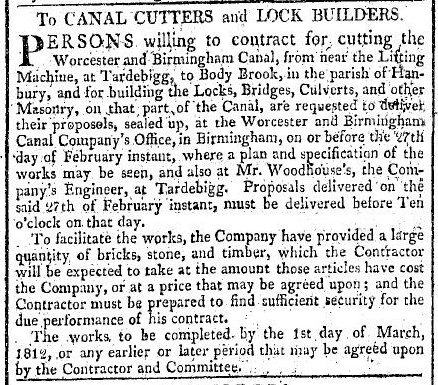

|

|

|

Woodhouse

advertising for contractors -

Jackson’s Oxford Journal, 16th February 1811 |

The tunnel ― and thus the canal ― was finally completed on 25th

February, 1805, at which point Barnes retired. John Woodhouse

was appointed area engineer

of the Northern district. However, he did not remain

long in the Company’s employment, for in 1808 he appears to have

been at work on the Worcester and Birmingham Canal where, at Tardebigge,

he installed a boat–lift to a design that he had patented in 1806 as

“an improved method for conveying boats, barges,

or other vessels, from one level of a canal to another without the

use of locks”. [28] The canal company was concerned at the expense of the

58 locks needed to take the canal down to the River Severn at

Worcester; a series of Woodhouse’s patent lifts offered to reduce

this number to twelve. A trial lift was constructed, partly at his

own expense, which appears to have performed the task. However, the

eminent civil engineer John Rennie gave it as his opinion that the

lift was too fragile for permanent use, and it was removed.

Following the boat lift experiment, Woodhouse was appointed Engineer

to the Canal, but in 1811 he took up the role of contractor, where the standard of his work appears to have been

unsatisfactory and resulted in arbitration. In 1815, he undertook

further work for the Grand Junction Canal Company, being awarded a contract

to build side ponds for the six locks at Hanwell near the Thames at

Brentford, and two at nearby Norwood. These two flights of locks

raise the canal by 68 feet in the course a mile, the

side ponds being constructed as a water-saving measure. When Provis inspected the work, he reported that the side ponds

were unusable due to poor workmanship and Woodhouse was obliged to

make repairs.

Further work for the Company commenced in 1817, when Woodhouse was

awarded the contract to install the Tringford pumping station on the

Wendover Arm. [29] The reservoirs at Tringford and at Startopsend were

built between 1814 and 1818, in part to supply the recently opened

Aylesbury Arm, which draws its water from the main line. A further

pumping station was required to service these reservoirs and to

replace the pumping station at Marsworth. Built during 1817-18,

Tringford pumping station was equipped with a Boulton and Watt beam engine

capable of pumping 80 lockfulls of water per day, the water being

drawn from a well situated some 50 feet below the pumping station,

which is fed by tunnels from the two reservoirs. After Tringford

commenced operation in 1818, the Marsworth pumping station was

dismantled. Tringford still performs its function, although the

water supply, the building and its machinery are now much altered.

Following his work for the Grand Junction Canal Company, Woodhouse was appointed Engineer to

the Gloucester and Berkeley Ship Canal, but on Thomas Telford’s

recommendation he was dismissed in 1820 for purchasing from a son,

masonry of a dubious quality for use in a sea wall.

Nothing else is known of Woodhouse, but his sons Thomas (1793-1855)

and George (1801-68) had successful careers as civil engineers, both

being associated with the eminent civil engineering contractor,

Thomas Brassey.

As for John’s brother, Jonathan, he had gained experience in the

family business installing Newcomen-type pumping engines into mines.

In 1802, he was contracted by the Grand Junction Canal Company to supply and erect such an

engine [30] above Wilstone Reservoir and to erect the engine house, the

keeper’s house and the smith’s shop. This project was completed by

August 1802, but due to problems driving the heading to Wilstone

Reservoir ― several large springs were tapped ― the pumping station

was not operational until June 1803. Jonathan was then employed to

drive the engine, but by 1835 had moved to become the engine

attendant at Tringford pumping station where he remained until he

retired in January, 1849, at the age of 74 and after 46 years’

service with the Company. His son William (born 1814) succeeded to his

father’s position.

――――♦――――

THOMAS TELFORD, CONSULTING ENGINEER

Telford’s contributions to the GJC were small, but they are worth

mentioning due to his eminence in the history of civil engineering.

|

|

|

Thomas Telford FRS

(1757-1834) |

THOMAS

TELFORD was born in Eskdale, Dumfriesshire, in 1757. In

common with many other civil engineers of his era he received no

training as such, but entered the profession through one of its

linked trades, in Telford’s case that of the stone mason. [31] Through a

range of work he acquired not only a wide experience as a mason,

but also in the specification, design and management of construction

projects, all skills essential to the complete civil engineer.

In 1787 Telford became Surveyor of Public Works in Shropshire. Six

years later, with a portfolio of successful bridge and other

building work to his credit, he was appointed General Agent under

Jessop in the construction of the Ellesmere Canal. [32]

By the time Telford was first consulted by the Grand Junction Canal Company,

he had become one of the nation’s leading civil engineers.

Following the opening of the Blisworth Tunnel, the Company

sought a professional opinion on the now fully completed Canal, and unsurprisingly they

engaged an

engineer of Telford’s eminence to provide it. Telford duly delivered

his report ― ‘The General State of the Grand Junction Canal’ (May

1805) ― which included a favourable verdict on the Blisworth Tunnel.

While even he could not foresee

the extent of the repairs and rebuildings that the Tunnel was to

require down the years, it is surprising that he failed to

predict the problems that were shortly to be experienced with the

Cosgrove embankment and its aqueduct.

Other inspections and reports that he was to undertake for the Company

were, in 1815, of the newly completed Aylesbury Arm, on which

he delivered a favourable report, and, in 1817, he selected

the site of the Tringford pumping station, which eventually replaced

those at

Marsworth, Weston Turville and Whitehouses.

Telford’s tangible contribution to the present day canal

stemmed from a problem experienced by most canal promoters, that of disputes with

the owners of watermills. The usual strategy was to buy the

mills in order to acquire their

historic rights to the water-flow that powered them. But the

Company did not acquire the ancient Apsley and Nash mills, [33] probably

through a combination of cost and an absence of any hint of the long running

disputes over water

supply that were to arise, principally with John Dickinson, a

determined man of

volcanic temperament. The problems stemmed from

the Company’s diversion of

the rivers Bulbourne and Gade into the canal, resulting in the loss of

some of the mills’ motive power and of water for making paper pulp. In an effort to

remedy the problem, the Company installed a Boulton and Watt beam engine to back-pump water from the canal below

the four locks next to Nash Mills, in effect recycling water that

had already flowed down through the locks. But this failed to

provide a complete solution, due in part to a further problem, that of

water loss through leakage in the bed of the canal in this section, which appears

to have been badly constructed.

By 1812 the mills had been acquired by John Dickinson, who commenced

litigation against the Company. The outcome was that the Company was

required to act to prevent the loss of water referred to. Side ponds

were built at the four locks in the

disputed section in an attempt to reduce the water loss, but

Dickinson’s complaints continued, resulting in further litigation. Telford had already been consulted by the

Company on the extent of

water loss in the disputed section ― his opinion conflicting with

that of Dickinson’s consulting engineer ― and he was now engaged to

survey a deviation around the problematic section of the canal, a

solution that had been proposed by Dickinson himself. The survey,

undertaken by Telford and W. A. Provis, [34] resulted in a new Act (17th

March, 1818) to authorise the abandonment of the existing section of

the canal and the construction of a deviation. The Act

stated that the route was to be along the course of the united

Bulbourne and Gade, between Frogmore Swing Bridge and its junction

with the tail-water of Nash Mills:

“On 14 March 1818 water fell for the first time over the new

tumbling bay and on the 22nd Ann records: ‘Mr. D. opened the Channel

from Nash Mill head to new line of Canal.’ In August a new line of

canal at Batchworth was opened, and Dickinson dined with the Canal

Committee afterwards. Dickinson had contracted to carry out the

brickwork for the new canal, and supervised it himself.”

The Endless Web, Dame Joan Evans, 1955.

The deviation opened to

traffic in the following year.

Elsewhere Telford left an outstanding legacy of civil engineering

work, among which are the Pontcysyllte Aqueduct, the Caledonian

Canal, [35] the Göta Canal (Sweden), sections of the A5 trunk road ―

together with the fine suspension bridges across the River Conwy and

the Menai Straits ― and the Shropshire Union Canal.

Thomas Telford lies in the central part of the nave of Westminster

Abbey, where he was buried on 10 September 1834. The inscription on

his gravestone reads:

1757 THOMAS TELFORD 1834. PRESIDENT OF THE

INSTITUTION OF CIVIL

ENGINEERS

――――♦――――

RODOLPH FANE DE SALIS, COMPANY CHAIRMAN

RODOLPH FANE DE SALIS (1854-1931) was the last chairman of the

Grand Junction Canal Company. Together with W. H. Curtis,

Chairman of the Regent’s Canal and Dock Company, he was responsible for

the merger that in 1929 took the waterway into the next phase

of its history, as a constituent of the Grand Union Canal Company.

|

|

|

R. F. de Salis and

daughter Edith Margery

(c. 1888). |

Born in 1854 at Fringford, Oxfordshire, he was the son of Henry

Jerome Augustine Fane de Salis and Grace Elizabeth Warner Henley. Educated at Eton and at Trinity Hall, Cambridge (M.A.), de Salis

became a Fellow of the Geological Society of London and an Associate

Member of the Institution of Civil Engineers, professional

accomplishments that, taken together, suggest a man well qualified

to run a canal company. Other roles in business that de Salis

undertook were as Chairman of Singer Motor Company of Coventry,

President of the Canal Association; and as a director of the North

Staffordshire Railway, the Great Central Railway and the Coventry Canal

Company.

De Salis became a director of the Grand Junction Canal Company in 1888, serving as Company

Chairman from 1914 to 1928, when he retired. This was a period

encompassing not only the taxing operating conditions of the Great

War but, in 1925-28, the negotiations that led to the takeover of the Grand

Junction Canal Company’s canal

assets by the Regent’s Canal and Dock Company. Parliamentary approval having been given, on 1st January, 1929, the Grand

Junction Canal Company became a constituent of the newly formed Grand Union Canal Company, although

the takeover excluded the Grand Junction Canal Company’s valuable property portfolio at

Paddington. It fell to de Salis to oversee the terms of the

takeover, which were approved at a shareholders’ meeting at the

Company’s offices in the Strand on 8th February, 1928. The meeting

was reported in The Times the following day. Much of what was

discussed related to the terms of the sale and to the protection of

the conditions of service of the existing employees, on which, to de Salis’s credit, much thought had been given. The Chairman concluded

his address by saying that:

“. . . . It is my duty today to ask your assent to a Bill promoted

by the Regent’s Company for the purchase of the canal portion of our

undertaking. This is a part of a larger scheme for taking over by

the Regent’s Company of the Warwick Canals and making a through

route to Birmingham . . . . I must say a personal word. I have been

on this committee upwards of 40 years, and shall have been Chairman

for close on 15 years when the Bill becomes law. I hope I have been

a not unworthy successor to our first Chairman, Mr. Praed, whose

portrait is over the mantelpiece. He made the canal; I am

instrumental in forming it into a larger company with better

prospects than it ever had, and I hand it over in a better condition

than when I took the chair, and with the shares considerably

enhanced in value.”

At the final shareholders’ meeting later that year — perhaps

bolstered by the prospects falling to a much larger trading

organisation — de Salis responded to a pessimistic radio broadcast

on the future of canal transport vis-à-vis road and rail thus:

“ . . . . but I do not think that he [the broadcaster]

took sufficient account of the great advantages water has over other

forms of transport in direct delivery to and from ship in towns and

factories inland . . . . we find traders wish more and more to use

the water route where possible, and it is the business of our

traffic department to foster that tendency. There will always

be a large traffic in heavy goods, for which canals can beat

competitors.”

Even the substantial investment that the new company was to make

during the early 1930s in modernising their London to Birmingham

route fell far short of what was necessary to bring the waterway up

to a standard at which it could compete on favourable terms with

road and rail, and its long-distance business gradually withered and died. But in

his closing address de Salis could not reasonably have foreseen the

resurgence in the use of our canal system as a leisure resource, a

resurgence substantially unaffected by their antiquated design.

See also Thirty Days on English Canals by R. F. de Salis (Appendix

III.)

――――♦――――

APPENDIX I.

THE BLISWORTH HILL RAILWAY

To the CHAIRMAN of the General Committee of

the GRAND JUNCTION CANAL

SIR,

CONFORMABLE to the directions of the

Committee, we have surveyed a line for a railway at Blisworth; and

you will receive with this, a profile of the Line extending from

Blisworth to the crossing of the Towcester River, three miles one

furlong and six chains, and an estimate of the expense amounting to

£8,098. To carry it further than this point is unadvisable, as

the ground is some of the most favourable in the whole Line, and

there will require four Locks to Stoney Stratford; the canal will

cost to compleat it not much more than a railway.

It appears upon the whole probable that the communication between

Blisworth and Stratford Bridge by the railway and canal will not

exceed the expence of £24,000.

We will now state the probable advantage to result from this

communication. There is no proposition generally more true or

self evident, that in the extension of a canal from any given point

which supplies a country with necessaries (and particularly where

coal is the principal article,) the extension increases the quantity

of Conveyance, [in a duplicate ratio of the length to which it is

extended], making allowance for local exceptions, such as

interfering with districts, which have part of their supplies from

other sources.

You will easily conceive that a canal might be so short, that no one

would think it worth while to use it at all, in preference to land

carriage from its originating point; extend it a little further and

a few would make use of it; if in a canal of six miles in length, a

person living in its vicinity would go three miles to it rather than

go to its beginning, a person at twelve miles from its end would

with equal reason go six miles to the canal, and one at eighteen

miles distance would with still more reason prefer going nine miles

to the canal, because it would be within one day’s journey, which is

a very strong inducement to all who are so circumstanced. On

this principle you will conceive that a canal will accommodate a

triangular district of country; not strictly so, but the sides of

the triangle will be a mean between some in the inside of it, who

will not come into the computation, and others on the outside who

will.

The distance from Braunston Wharf to Blisworth in a direct line is

thirteen miles and a half; from Braunston to Stratford Bridge is

twenty-one miles, which bears the proportion of nine to fourteen.

The area of the country comprehended within the triangle, the

perpendicular depth of which is from Braunston to Blisworth, will be

to the area of that from Braunston to Stratford as the square of

nine to the square of fourteen.

The carriage in the northern district of the canal from the 1st

April, 1798, to the 1st April, 1799, also interrupted by two months

of frost, has been 41,500 tons, exclusive of limestone, but

deducting from this Mr. Pickford’s carriage and a few other goods

conveyed to and from London, which may be about 7,000 tons (for we

have no particular account of this) there will remain 34,500 tons of

local trade, which is subject to increase by extension of the canal;

if this were not affected by local exceptions, it would be fair to

suppose that the increase by extension would be in the ratio which

is assumed, from 34,500 to 83,481, making an increase in addition to

the first quantity of 48,981 tons (it may also be fair to observe,

that the existing canal is also subject to its share of local