|

NOTES AND EXTRACTS

ON THE HISTORY OF THE

LONDON

& BIRMINGHAM

RAILWAY

CHAPTER 2

DEVELOPMENT OF THE STEAM

LOCOMOTIVE (I.)

THE ‘ATMOSPHERIC’ STEAM ENGINE

“Who could have credited the possibility of

a ponderous engine of iron, loaded with some hundred passengers, in

a train of carriages of corresponding magnitude, and a large

quantity of water and coal, taking flight from Manchester and

arriving at Liverpool, a distance of above thirty miles, in little

more than an hour? And yet this is a matter of daily and almost

hourly occurrence.”

The Steam Engine Explained,

Dionysius Lardner (1840).

Numerous individuals contributed to the development of the

reciprocating steam engine and to its later adaption to railway

traction, but a handful of names stand out. This chapter

summarises their contributions to the state of development that the

railway locomotive had reached at the opening of the Stockton and

Darlington Railway in 1825. Later developments are dealt with in

Chapter 12.

The first practical application of the steam engine was for pumping

water from mines. Until then, the depth at which mining could be

carried out had been restricted by the limited ability of

horse-operated equipment to drain water from the workings.

|

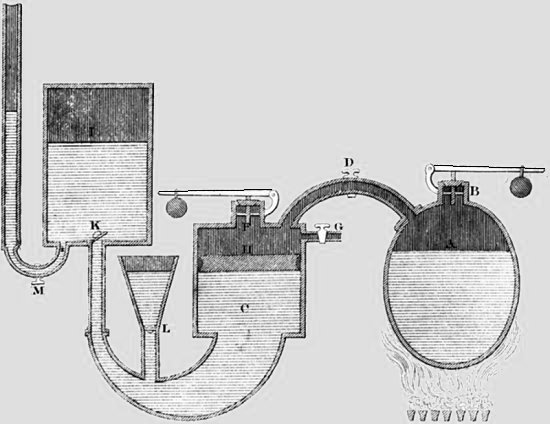

Papin’s pump of

1704.

Water enters the

system through valve L. The boiler (B) and cylinder (C)

are fitted with weighted safety-valves. When

valve D is opened, steam is admitted to the cylinder,

forcing down the piston, which drives the water beneath

it into the reservoir through valve K and in the process compressing the air

above it. The steam in

cylinder C is condensed to form a vacuum, which forces the piston

upwards, drawing more water into the system through valve L and

closing valve K. Closure of valve K removes the steam

pressure causing the water in the reservoir to be expelled

through valve M under the action of the compressed air

above it. |

|

|

|

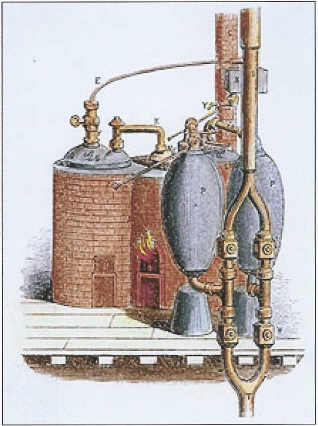

The 1698 Savery

Engine. |

The Frenchman Dionysius Papin (1647-1714) was among the early

inventors of the steam engine and to him goes the credit for being

the first to derive thrust from a piston within a cylinder. From

1690 until about 1707 ― when he published The New Art of Pumping

Water by Using Steam ― Papin built a number of steam engines

including a successful piston-operated water pump, but he did not

develop it commercially. His contemporary, Thomas Savery

(1650-1715), developed a thermic siphon ― other than valves, it had

no moving parts ― which relied on a vacuum created by condensed

steam to draw water up into a storage chamber from where, after the

operation of valves, it was expelled by steam pressure. Because Savery’s siphon lifted water by vacuum, it needed to be no more than

30 feet above the water it was to pump, which for mining operations

was impractical, while the working models are reported to have

suffered failures due the crude engineering methods of the age.

The distinction for creating the first practical steam-driven pump

goes to Thomas Newcomen (c. 1663-1729), an ironmonger from Exeter in

Devon, who succeeded in developing the ideas and techniques advanced

by Papin and Savery to develop an ‘atmospheric’ steam engine, the

earliest working example of which is believed to have entered

service at the Wheal Vor mine on the south coast of Cornwall,

although examples appear to have reached the North of England at

about the same time:

“The first steam engine erected in the north was at Oxclose, near

Washington; the next at Norwood, near Ravensworth. About the year

1713, or 1714, the first steam engine in Northumberland was erected

at Byker colliery, the property of Richard Ridley, Esq.”

An Historical, Topographical, and Descriptive View of the County of

Northumberland,

Eneas Mackenzie (1825).

|

|

|

The Newcomen engine.

– Steam is shown pink

and water is blue.

– Valves move from open (green) to closed (red) |

The Newcomen engine comprised a reciprocating piston (as utilised by

Papin) coupled to a pump rod via a rocking beam. Steam injected into

the engine’s cylinder drove the piston upwards while the beam drove

the pump rod downwards. When the piston reached the top of its

stroke, cold water was injected into the cylinder beneath to

condense the steam. The resulting vacuum caused the piston to be

drawn back to its starting position under atmospheric pressure (as

utilised by Papin and Savery), raising the pump rod in the process. At this point the cycle was repeated.

In the Newcomen engine, the constant heating and cooling of the

cylinder wasted a great deal of heat. Nevertheless, it represented a

great advance in pumping, which enabled mining to be carried out at much

greater depths:

“Newcomen and Cawley’s [1] engines were found to answer the purpose

of raising water so well, that in a few years they were introduced

into Russia, Sweden, France, and Hungary; and about 1760 one was

imported by the proprietors of the old copper mine near Belleville,

New Jersey. They in fact imparted a new and very beneficial impulse

to mining operations, and quickly raised the value of mining stock.

Deluged works were recovered, old mines deepened, and new ones

opened in various districts, both in Great Britain and continental

Europe: nor were they confined to draining mines, but were employed

to raise water for the use of towns and cities, and even to supply

water wheels of mills.”

A Descriptive and Historical Account of Hydraulic and Other

Machines,

Thomas Ewbank (1842). |

Despite being rendered obsolete by the later developments of James

Watt, the cheapness and simplicity of Newcomen engines led to their

continued manufacture until well into the 19th Century.

――――♦――――

THE ‘DOUBLE-ACTING’ STEAM ENGINE

Watt improved the Newcomen steam engine in a number of ways.

He invented the purpose-built condenser, means to produce rotary (as opposed to

reciprocating) motion, the

centrifugal governor and the double-acting engine.

In a Newcomen-type engine, the cylinder doubled up as a condenser.

At the end of the up-stroke the steam within it was condensed to

form a vacuum ― cooling the cylinder in the process ― to draw the

piston back to its starting position. However, by exhausting

the spent steam into a separate

condenser, a vacuum was formed beneath the piston without

needing to cool the cylinder, and this significantly improved the

engine’s thermal efficiency. Watt’s development of rotary motion enabled his

engines to be used to drive factory machinery, in which context his

use of the ‘centrifugal governor’ to regulate an engine’s speed of

rotation automatically was another important advance. [2] But

Watt’s

development of greatest importance to railway traction was

the ‘double acting’ steam engine:

“In the specification of his third patent,

1782, he [Watt] says, ‘My second

improvement upon steam or fire engines consists in employing the

elastic power of the steam to force the piston upwards, and also to

press it downwards, by alternately making a vacuum above or below

the piston respectively; and at the same time employing the steam to

act upon the piston, in that end or portion of the cylinder which is

not exhausted. An engine constructed in this manner, can

perform twice the quantity of work (with a cylinder of the same

size) or exert double the power, in the same time which has hitherto

been done by any steam-engine, in which the active force of the

steam is exerted upon the piston only in one direction, whether

upwards or downwards.’”

A Treatise on the Steam Engine, John Farey (1827).

In both the Newcomen and the early Watt atmospheric engines, the

pressure of expanding steam on the piston delivered one power

stroke, while the return stroke was delivered by a vacuum formed by

condensing the spent steam. In a ‘double-acting’ steam engine, the

pressure of expanding steam is used to deliver both power strokes.

[3] This is achieved using what in effect is

a two-part cylinder; the cylinder proper contains the piston that

delivers the thrust, the adjacent ‘steam chest’ contains a sliding

valve (the ‘slide valve’), the backward and forward motion of which

is used to direct the passage of live and exhaust steam, to and from

the cylinder.

|

Two applications of the

double-acting steam engine. Above, a stationary

steam engine powering a drive belt; below, a railway

locomotive. Live steam

(pink) enters the steam chest from the boiler. A slide valve

introduces steam into the cylinder alternately through the two steam

ports. As live steam is introduced to one side of the piston, spent

steam (blue) is exhausted from the other. The slide valve is driven by an

eccentric, coupled at one end to the crank and at the other to the

valve rod. When the engine is in motion, this coupling causes the

slide valve to move back and forth, alternately covering and

exposing the steam and exhaust ports. |

Watt never attempted to apply his developments of the steam engine

to road or rail traction, but he did include that possibility in his

patent of 1784. Of this group of seven ‘new improvements’, the

second ― a method for dispensing with chains and instead connecting

the piston rod of the double-acting engine directly to the rocking

beam, to permit ‘push’ as well as ‘pull’ ― was of the most immediate

practical value. His seventh, however, came as close as Watt ever

approached the subject of traction and is interesting for its

description of his thoughts on the subject:

“My seventh new improvement is upon steam engines which are applied

to give motion to wheel carriages for removing persons or goods, or

other matters, from place to place, and in which cases the engines

themselves must be portable. Therefore, for the sake of lightness, I

make the outside of the boiler of wood, or of thin metal, strongly

secured by hoops, or otherwise, to prevent it from bursting by the

strength of the steam; and the fire is contained in a vessel of

metal within the boiler, and surrounded entirely by the water to be

heated, except at the apertures destined to admit air to the fire,

to put in the fuel, and to let out the smoke; which latter two

apertures may either be situated opposite to one another in the

sides of the boiler, or otherwise, as is found convenient; and the

aperture to admit air to the fire may be under the boiler. The form

of the boiler is not very essential, but a cylindric or globular

form is best calculated to give strength. I use cylindrical steam

vessels with pistons, as usual in other steam engines, and I employ

the elastic force of steam to give motion to these pistons, and

after it has performed its office I discharge it into the atmosphere

by a proper regulating valve, or I discharge it into a condensing

vessel made air-tight and formed of thin plates or pipes of metal,

having their outsides exposed to the wind, or to an artificial

current of air produced by a pair of bellows, or by some similar

machine wrought by the engine or by the motion of the carriage;

which vessel, by cooling and condensing part of the steam, does

partly exhaust the steam vessel, and thereby adds to the power of

the engine, and also serves to save part of the water of which the

steam was composed, and which would otherwise be lost. In some cases

I apply to this use engines with two cylinders which act alternately

. . . .”

Origin and Progress of the Mechanical Inventions of James Watt, J. Muirhead (1854).

He then goes on to describe the means by which the engine would

propel the vehicle.

Watt’s patent recognises some of the requirements that would become

essential to the later development of the steam locomotive, whether

road or rail. It states the need for lightness, and while it allows

for the use of an air-cooled condenser, both to improve engine

efficiency and to save on water consumption, its main suggestion for

handling spent steam is to exhaust it into the atmosphere; but it

seems that Watt did not imagine using exhaust steam to draw the fire

through a blast pipe. A two-cylinder configuration is also

described, which was widely adopted in the development of the

steam railway locomotive, although not at first.

Why Watt never attempted to make practical use of this proposal is a

matter of conjecture. His aversion to the use of high pressure

steam, born of the inadequate boiler technology of the age, ruled

out the development of a power plant suitable for propelling a steam

road carriage; but even if he had developed a high pressure engine,

the carriage it propelled would have had to face the further

challenge of the appalling road surfaces of the age. Watt

appears not to have considered his engine’s

use on a railway, but as events were

to prove a similar problem existed in that the cast-iron

plate rails of the time were too brittle to support the weight and

stresses created by a moving steam locomotive. As Boulton and

Watt’s business in static engines was blossoming, they probably saw

no commercial justification in undertaking the expensive research

and development necessary to develop a reliable steam road carriage

― and, as Trevithick was later to discover, there was at any rate no

market for such a vehicle.

――――♦――――

RICHARD TREVITHICK (1771-1833)

Richard Trevithick takes the honours for inventing and demonstrating the

first workable steam road and rail locomotives. However,

because there are no accurate

contemporaneous descriptions of his trials, what there is had

to be assembled years later by his son Francis, based on

correspondence and on the recollections of those who witnessed them. Unsurprisingly, the accounts so compiled are in places incomplete

and inconsistent.

|

|

|

Richard Trevithick

(1771-1833). |

Richard Trevithick came from a family of mining engineers. Thus,

from an early age he was familiar with the Newcomen and Watt

engines used for mine drainage in his locality and by the 1790s he

was building his own.

By the end of the 18th Century, boiler engineering had reached the

stage at which the safe production of steam at a comparatively high pressure was possible. [4] This permitted

the construction of a double-acting steam engine of much smaller

dimensions than a Watt or Newcomen

engine of comparable power. Furthermore, because a high

pressure engine does not (like its low pressure counterpart) rely on

atmospheric pressure, its spent

steam could be exhausted directly into the atmosphere thereby

dispensing with the need

for a cumbersome condenser. The saving in space and weight

thus achieved made possible the use of high pressure steam engines for road and rail traction.

Unlike Watt, who had no interest, Trevithick went on to develop the

double-acting

engine for traction purposes, and while he wasn’t the first in the

field of steam road vehicles [5] he was the first to achieve

a measure of success ― albeit short-lived on

each occasion ― with his use of high pressure steam:

“Stuart, [6] writing fifty years after the date of the Watt patent,

clearly defined the difference, in principle and in practice, of the

rival engineers. Trevithick increased the steam pressure from one

atmosphere, or 14½ lbs. on the square inch, to 50 or 60 lbs., and by

it impelled the piston with four times the force of a Watt

low-pressure steam vacuum engine. Hebert, who wrote thirteen

years later, [7]

still illustrates the marked difference in the two men by pointing

out that, in 1784, Watt gave his views of a steam-carriage, and

Murdoch tried his hand at one. Watt proposed a wooden boiler,

a cylinder 7 inches in diameter, with a stroke of 1 foot, and

sun-and-planet wheels. It is not said that it was to carry

condensing water, but such may reasonably be inferred . . . .

Trevithick’s high-pressure engine, which was worked by the force of

steam 60 lbs. or more on the square inch, wholly discarded the

vacuum; and certainly without this radical change there could have

been no locomotion.”

Life of Richard Trevithick,

Francis Trevithick (1872).

|

|

|

Replica of

Trevithick’s Puffing Devil. |

Trevithick’s first road vehicle, the Puffing Devil, emerged in 1801.

Its cylindrical cast-iron boiler produced steam at some 60 lbs per

square inch. The engine’s single cylinder was fixed within the

boiler and exhausted into the chimney, in the process heating the

boiler feed water and causing a draught through the fire. The

Puffing Devil demonstrated an ability to carry a number of

passengers up an incline, but during further testing it overturned

on the poor road surface. Eventually righted, the carriage was left

unattended while its operators retired to a nearby alehouse for

refreshment:

“The travelling engine took its departure from Camborne Church Town

for Tehidy on the 28th of December, 1801, where I was waiting to

receive it. The carriage, however, broke down, after travelling very

well, and up an ascent, in all about three or four hundred yards. The carriage was forced under some shelter, and the parties

adjourned to the hotel, and comforted their hearts with a roast

goose, and proper drinks, when, forgetful of the engine, its water

boiled away, the iron became red hot, and nothing that was

combustible remained, either of the engine or the house.”

From a letter quoted on p117, Life

of Richard Trevithick, Francis Trevithick (1872).

The Puffing Devil must have given Trevithick and Andrew

Vivian, his business

partner, sufficient encouragement to include in their

patent application for a steam-powered sugar cane crushing machine .

. . .

“Methods for improving the construction of steam engines, and the

application thereof for driving carriages, and for other purposes.”

. . . . together with a drawing of the proposed vehicle. A patent,

No. 2599, was granted on 25th March 1802.

In his biography of his father, Francis Trevithick mentions that a

further steam road carriage, the ‘Tuckingmill Locomotive’, was then

built, presumably to replace the Puffing Devil:

“Mr. Anthony Michell came to live at Redruth in November, 1802, and

shortly after, about the spring of 1803, a great many persons went

to Tuckingmill to see Captain Dick Trevithick’s puffer locomotive

that was going to run from Camborne to Redruth, about three or four

miles . . . . I could not go. They said, that in going up the Tuckingmill hill towards Redruth, the driving wheels slipped around

and sunk into the road, and they could not get her on; it was a very

steep and crooked road. Everybody was talking about it . . . .”

From a letter quoted on p120, Life

of Richard Trevithick, Francis Trevithick (1872).

What little is known about the ‘Tuckingmill Locomotive’ comes from

hearsay and from what onlookers recalled years after the event. It is

believed that the carriage performed longer journeys than its

predecessor and that Trevithick reused its engine in his London

steam carriage experiment of 1803.

Another mystery from this period is the ‘Coalbrookdale Locomotive’,

which might lay claim to being the world’s first steam railway

locomotive but for the fact that very little is known about it.

What evidence exists lies mainly in a drawing held in the Science

Museum ― which dimensional evidence suggests is of the locomotive

built at Coalbrookdale ― and in a concluding remark in a letter

written by Trevithick on the 22nd August 1802, while at

Coalbrookdale, to Davies Giddy, in which

he says that:

“The Dale [Coalbrookdale] Company have begun a carriage at their own

cost for the railroads, and are forcing it with all expedition”.

Trevithick was at Coalbrookdale to supervise construction of a

pumping engine, which he describes in his letter; it might be

that the pumping tests that he describes were of the locomotive

under static test. But there is no record of whether the “carriage”

he refers to in his letter was completed and ran successfully on

rails.

In 1803, Trevithick carried out further trails of a steam road

vehicle now generally referred to as ‘The London Locomotive’.

[8] A great improvement on predecessors, it

was lighter and its use of a horizontal rather than a vertical

cylinder, improved its steadiness while in motion, a lesson that was

forgotten by the early railway locomotive designers. Having

wheels of large diameter enabled it to pass more readily over the

poor road surfaces of the age that had brought Trevithick’s Camborne

locomotive to a standstill.

Following trials at Camborne, the engine for the London Locomotive was shipped to the Metropolis in January 1803.

The drawings that accompanied the original patent, together with a

contemporaneous artist’s impression, show the engine mounted on the

frame of a

locally assembled carriage. The body of the carriage, believed

to have been capable of accommodating eight

passengers, was mounted over the engine and boiler between the large driving wheels, and was supported on springs

fixed to the

frame.

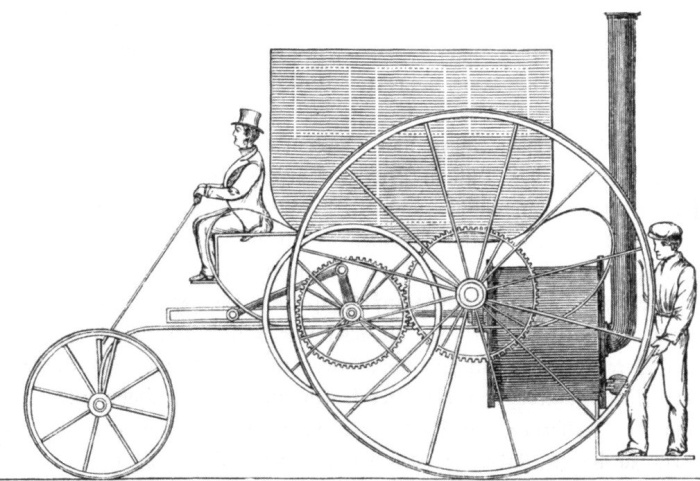

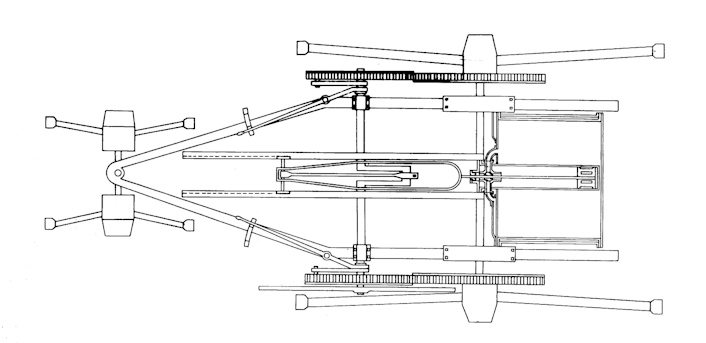

Trevithick’s ‘London Locomotive’

or ‘London Steam Carriage’ in elevation and in plan.

The engine and boiler were of wrought iron. The boiler had an

internal return fire-tube, which meant that the fire-door and chimney

were at the same

end (see illustration). The cylinder, fixed horizontally within the boiler,

drove a

crank placed under the carriage (a cranked axle did not appear in

railway locomotive use until the Rainhill Trials in 1829). Coal and water were carried on

the engine platform. Spent steam was directed into the chimney;

this helped draughting, thereby assisting the small boiler to produce the necessary

amount of steam.

Trials of the carriage took place on the streets of central London

on a number of occasions over several months. Writing in 1837,

Hebert says that . . . .

“There are thousands of persons now living in London who saw the

steam coaches of Messrs. Trevithick and Vivian running about the

waste ground in the vicinity of the present Bethlehem Hospital; and

likewise in the neighbourhood or site of Euston Square. This was

thirty four years ago.”

A Practical Treatise on Rail-roads

and Locomotive Engines, Luke Hebert (1837).

. . . . and 1845, Andrew Vivian’s son recalled that . . . .

“My father went to London in 1801, and again in 1802. He himself

worked the engine when it ran from Leather Lane, from the shop of

Mr. Felton (who built the carriage, and he and his sons were with

the engine all the first day it ran), through Liquorpond Street,

into Gray’s Inn Lane, by Lord’s Cricket Ground, to Paddington and

Islington, and back to Leather Lane.”

. . . . and speaking in 1860, a shopkeeper remembered seeing . . . .

“Mr. Trevithick’s steam-carriage go through Oxford Street; the shops

were closed, and numbers of persons were waving handkerchiefs from

the houses; no horses or carriages were allowed in the street during

the trial. The carriage moved along very quickly, and there was

great cheering. At that time she kept a shop next door to the

Pantheon, and it, like the others, was closed.”

But despite its apparent success, the steam carriage attracted no

commercial interest and the trials, which were proving expensive,

came to an end. The steam carriage was sold for what it

would fetch, its engine eventually powering a rolling-mill.

During this period, Trevithick had been building high-pressure steam

engines for industrial use, one of which, a forge engine, had been

installed to drive hammers at the at the Pen-y-Darren Ironworks at

Merthyr Tydfil in South Wales. This was to become the setting for the

world’s first recorded locomotive-hauled train. Rees Jones, the works’

engine fitter, helped Trevithick with the installation after which

construction began on a railway locomotive. Jones later recalled that he

helped with the assembly using components manufactured on site, but

other sources claim that some parts were manufactured in Cornwall.

The story now took a interesting turn. Samuel Homfray, the

proprietor of the Pen-y-Darren Ironworks, while discussing the

principles and feasibility of locomotive haulage with Richard

Crawshay, ironmaster of the nearby Cyfartha Ironworks, entered into

a 1,000 guinea [9] wager with him that he could

not convey a load of

iron along the Merthyr Tydfil tram-road, from Pen-y-Darren to Abercynon, a distance of 9¾ miles. Whether the bet led to the

locomotive’s construction or was made while this was in progress, is

unclear; suffice it to say that a great deal of money was at stake

on the outcome of the venture.

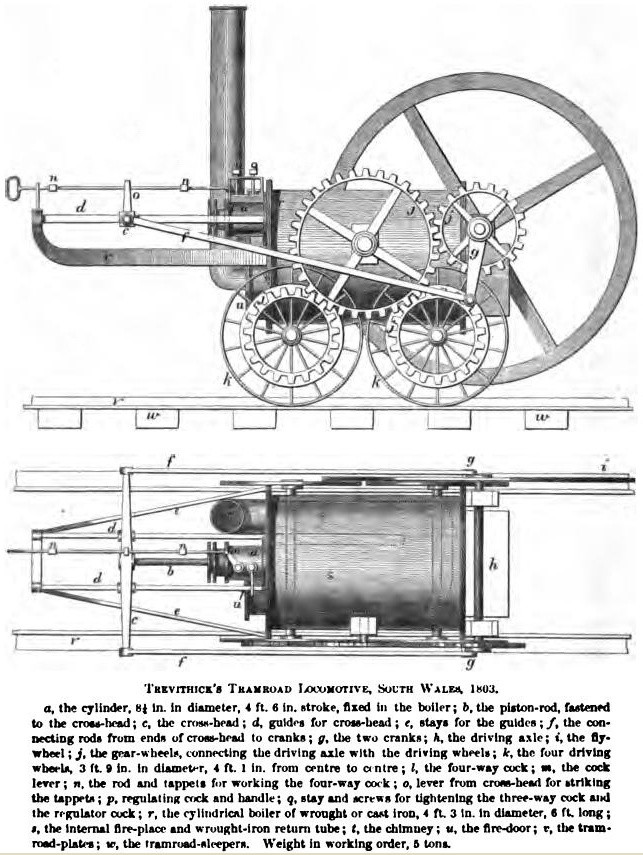

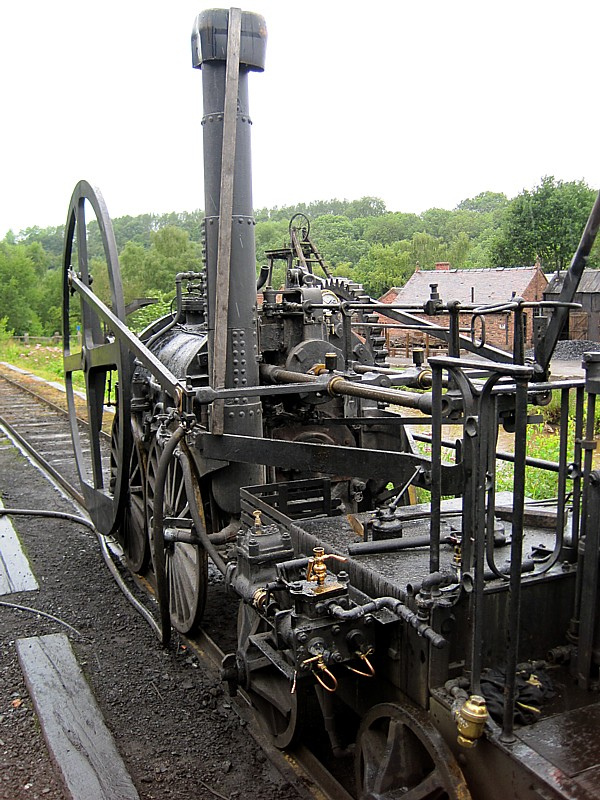

There are conflicting descriptions of the locomotive, but

according to Jones, who was on the spot ― albeit writing 54-years

after the event . . . .

“The boiler was made of wrought iron, having a breeches tube also of

wrought iron, in which was the fire. The pressure of steam used was

about 40 lbs. to the inch. The cylinder was horizontal; it was fixed

in the end of the boiler. The diameter of the cylinder was about 4¾

inches. The three-way cock was used as a valve. The engine had four

wheels. These wheels were smooth; they were coupled by cog-wheels. There was no rack-work on the road; the engine progressed simply by

the adhesion of the wheels. The steam from the cylinder was

discharged into the stack.”

A replica of Trevithick’s

Pen-y-Darren ‘tram-waggon’ at Blists Hill,

Ironbridge Gorge Museum.

Rees Jones goes on to confirm that the locomotive ran well, a point

taken up by Trevithick in a letter dated 15th February 1804, in

which he informed Davies Giddy that . . . .

“. . . . we lighted the fire in the tram-waggon, and worked it

without the wheels to try the engine. On Monday we put it on the tramroad. It worked very well, and ran up hill and down with great

ease, and was very manageable. We had plenty of steam and power. I

expect to work it again to-morrow. . . .”

. . . . and a few days later . . . .

“The tram-waggon has been at work several times. It works

exceedingly well, and is much more manageable than horses. We have

not tried to draw more than 10 tons at a time, but I doubt not we

could draw 40 tons at a time very well; 10 tons stand no chance at

all with it. We have been but two miles on the road and back again,

and shall not go farther until Mr. Homfray comes home.”

There is no definitive account of the event, those that

exist being written some years later. In 1812, Trevithick set down

his recollections:

“About six years since I turned my thoughts to this subject, and

made a travelling steam-engine at my own expense, to try the

experiment. I chained four waggons to the engine, each loaded with

2½ tons of iron, besides seventy men riding in the waggons, making

altogether about 25 tons, and drew it on the road from Merthyr to

the Quaker’s Yard, in South Wales, a distance of 9¾ miles, at the

rate of four miles per hour, without the assistance of either man or

beast; and then without the load drove the engine on the road

sixteen miles per hour. I thought this experiment showed to the

public quite enough to recommend it to general use; but though a

thing that promised to be of so much consequence, has so far

remained buried, which discourages me from again trying its practice

at my own expense.”

From the Life of Richard

Trevithick, Francis Trevithick (1872).

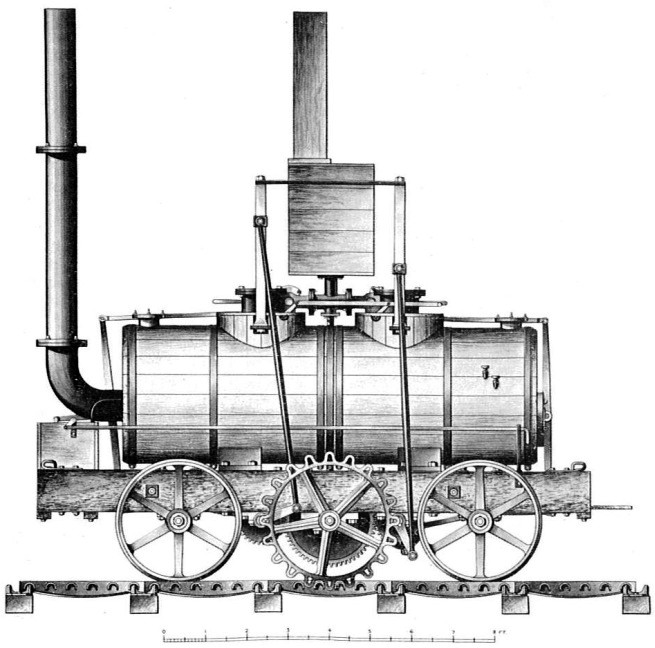

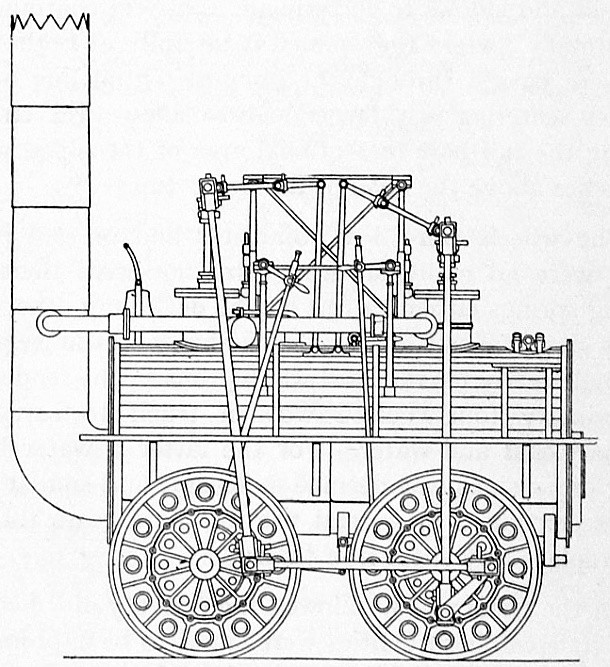

|

|

|

The Gateshead

locomotive. The piston is at the opposite

end

to the Pen-y-Darren ‘tram-waggon’. |

The outcome of the experiment ― which is what it proved to be ― was that Homfray won the wager. But although Trevithick’s locomotive

succeeded within its limitations, it was too heavy for the tram-road

to which it caused considerable damage, and it spent the remainder of

its days employed in a static role.

It is unclear how many railway locomotives Trevithick built

following the Merthyr experiment. In 1805, he speaks of

visiting Newcastle to see “some of the travelling engines at work”,

while Wood talks of a locomotive being sent there, but without

stating when:

“The engine erected by Mr Trevithick had one cylinder only, and a

fly wheel, to secure a rotatory motion in the crank at the end of

each stroke. An engine of this kind was sent to the North for Mr Blackett, of Wylam, but was, for some cause or other, never used

upon his Rail-road, but applied to blow a cupola at an iron foundry

in Newcastle. Mr Blackett however had, in 1813, an engine of this

kind made, and set upon his Rail-road, which worked by the adhesion

of its wheels upon the rails. Still the supposed want of adhesion

formed the great obstacle to their introduction, and the attention

of engineers was directed to obtain a substitute for this supposed

defect”.

A Practical Treatise on Rail-roads,

Nicholas Wood (1825).

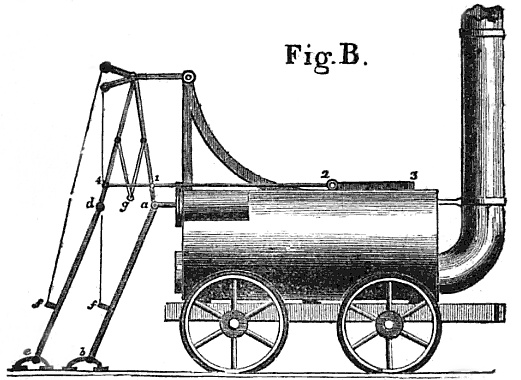

|

|

|

A replica of

Catch-me-who-can. |

Whether a Trevithick locomotive was sent to Newcastle at this time

is doubtful; what is less so, is that an example that drew on

Trevithick’s design was constructed at Gateshead by John Steel, who

had worked on the assembly of the ‘Pen-y-Darren Locomotive’.

For some reason this locomotive did not enter service, but among the

many who came to see it on trial were George Stephenson and Timothy

Hackworth, each of whom left their mark on the development of the

steam railway locomotive.

Trevithick’s last railway locomotive, of which there is a reliable

record, was constructed in 1808 for exhibition in London where it hauled a passenger carriage around a circular track

making it the world’s first passenger engine. In a letter to

Davies Gilbert, dated 28th

July 1808, Trevithick spoke of having

constructed a line on which he ran an 8-ton locomotive that had been named

Catch-me-who-can by

Gilbert’s sister. But the ground would

not support the locomotive’s weight, which also damaged the rails, and

the entire track had to be re-laid.

The only existing drawing of Catch-me-who-can (shown below) appears on a card or admission ticket to Trevithick’s ‘Steam

Circus’. Judging by it, the locomotive that Trevithick constructed

for this venture was a considerable step forward over that he

designed for Pen-y-Darren. The horizontal cylinder, flywheel, and geared

drive of the Pen-y-Darren locomotive are replaced by a vertical

cylinder ― still encased within the boiler ― driving one pair of

wheels directly by means of connecting rods. The boiler was

Trevithick’s usual return-flue type with an internal firebox.

The locomotive and its primitive passenger carriage were

built by John Urpeth Rastrick (whose name appears later) at the

Hazeldine Foundry at Bridgnorth.

Trevithick’s circular railway is

described in the following letter, published in the Mechanics’

Magazine, 27th March 1847:

“Observing that it is stated in your last number (No. 1232, dated

the 20th instant, page 269), under the head of ‘Twenty-one Years’

Retrospect of the Railway System’, that the greatest speed of

Trevithick’s engine was five miles an hour, I think it due to the

memory of that extraordinary man to declare that about the year 1808

he laid down a circular railway in a field adjoining the New Road,

near or at the spot now forming the southern half of Euston Square;

that he placed a locomotive engine, weighing about 10 tons, on that

railway — on which I rode, with my watch in hand — at the rate of

twelve miles an hour; that Mr. Trevithick then gave his opinion that

it would go twenty miles an hour, or more, on a straight railway;

that the engine was exhibited at one shilling admittance, including

a ride for the few who were not too timid; that it ran for some

weeks, when a rail broke and occasioned the engine to fly off in a

tangent and overturn, the ground being very soft at the time.

Mr. Trevithick having expended all his means in erecting the works

and enclosure, and the shillings not having come in fast enough to

pay current expenses, the engine was not again set on the rail.”

John Isaac Hawkins, Civil Engineer.

With this speculative venture proving unsuccessful, Trevithick’s contributions to the development of the steam

railway locomotive was almost at an end ― his final contribution,

made some years later, is described in

Chapter 12. Other than being the first engineer to employ

high pressure steam generated within a cylindrical boiler, his use

of the engine’s exhaust to draw the fire and, in his earlier

designs, coupling the

locomotive’s driving wheels, were both to become common practice in steam

locomotive design. Overall, Trevithick proved that the steam railway

locomotive was a viable proposition, an outcome that would inspire

others.

Richard Trevithick died penniless, of pneumonia, at Dartford on the 22nd April

1833. Those he had been working with contributed

towards his funeral expenses and acted as his pall bearers.

――――♦――――

IN THE WAKE OF TREVITHICK

In the period immediately following Catch-me-who-can, little interest was shown

in taking Trevithick’s experiments forward, with one exception.

The inflationary

pressure of the Napoleonic War was driving up the cost of animal

feed and with it the cost of conveying coal in horse-drawn wagons from the mines in the

North of England to the staithes [10] for shipping.

Thus, the next phase of development was driven by a search for

economy, which

prompted Christopher Blackett, owner of the Wylam Colliery near

Newcastle-upon-Tyne, to invite Trevithick to construct a locomotive

for use on the colliery’s wagonway:

“Among the charges, rendered so onerous by the war, to which the

colliery at that time was subjected, by far the heaviest was

incurred in conveying the mineral to the river, which pressed

heavily upon the undertaking as a profitable investment. Economy in

the conveyance of coal became therefore an object of primary

importance . . . . Mr. Blackett, in the year 1809, wrote to the

celebrated Trevithick on the subject of an engine; his reply stated

that he was engaged in other pursuits, and having declined the

business he could render no assistance . . . . Mr. Blackett, at a

period subsequent to his communication with Trevithick, applied to

the most eminent engineers of the day, by whom he was told that the

idea of an engine to convey carriages along a line of railroad was

chimerical, and that to carry it out was physically impossible. The

fate of the locomotive engine in South Wales was quoted as

establishing the fact. The matter was considered quite hopeless.”

Who Invented the Locomotive Engine? Oswald Dodd

Hedley (1858).

And so development of the railway locomotive languished until, in

1811, interest was reawakened. But in one respect the next phase

took a

retrograde step, for it was generally believed ― without any basis

in fact ― that the low friction between a locomotive’s smooth iron driving wheels

and the equally smooth surface of the rails would prevent the wheels

from gripping, consequently a locomotive would be unable to haul a

useful payload. The outcome was that much effort was spent

in finding a solution to this exaggerated problem.

Against this background, the next steam locomotive to emerge was at

the Middleton collieries at Leeds:

“We believe we are correct in assigning to Mr. Trevithick, of

Cornwall, the honour of first applying the steam engine to the

propelling of loaded waggons on railways; his scheme was improved

upon by Mr. John Blenkinsop, manager of the collieries at Middleton,

near Leeds, belonging to the late Charles Brandling, Esquire, of

Gosforth House, Northumberland, who obtained a patent for the

construction of the railway, and the steam carriage thereon, which

he immediately put in practice on the road from Middleton to the

coal staith at Leeds, a distance of about four miles, on which road

the coals for supplying that town are daily conveyed by steam. Since

his application of the principle, most of our eminent engineers have

turned their attention to the subject, and the consequence is, that

in a few years we may expect travelling in steam carriages to be of

as common occurrence as the conveyance of coal by the same means is

now.”

Historical Account of the

Navigable Rivers, Canals, and Railways, etc. Joseph Priestley

(1831).

The colliery manager, John Blenkinsop, knew of Trevithick’s

experiments and decided to try a steam locomotive on the colliery

wagonway. [11] Trevithick’s railway experiments had been marred by

the tendency of the brittle cast-iron plate rails to break under his

locomotive’s weight. Thus, the challenge for Blenkinsop was to

construct a locomotive light enough to run on cast-iron rails

without damaging them, but of sufficient

adhesive weight to haul a useful payload without slipping.

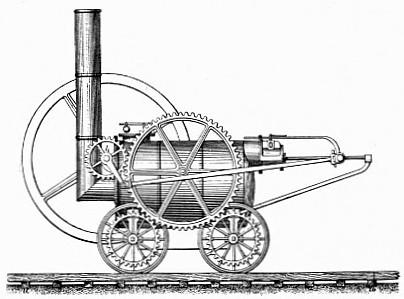

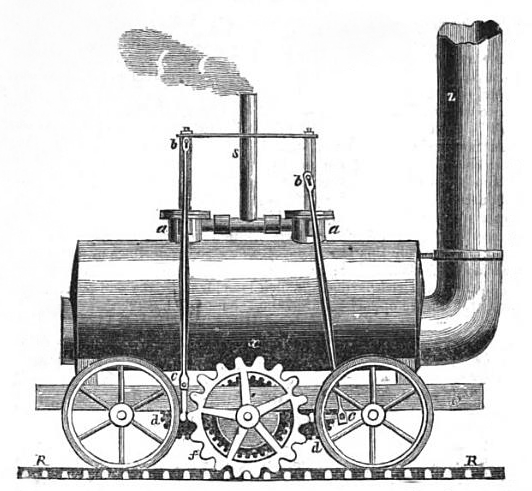

Blenkinsop and Murray’s

Salamanca.

Together with Matthew Murray, a partner in the engineering firm of

Fenton, Murray and Wood, Blenkinsop constructed a locomotive that exploited

a patent that he had taken out for a ‘rack-and-pinion’ system. [12]

Salamanca,

[13] the name given to the locomotive that emerged from Murray’s works, advanced Trevithick’s work by employing a twin-cylinder drive,

but instead of the cylinders being coupled to the driving wheels

they drove a cog, the teeth of which engaged with a toothed rack

fitted to the outside of one of the rails. In this way Blenkinsop

ensured that his engine would not lose adhesion. His boiler had a

single flu, the engine’s spent steam being exhausted directly into the

atmosphere via a flue mounted on top of the boiler

barrel. This departed from Trevithick’s scheme of directing

exhaust steam into the chimney, where the draught so created helped

to draw the fire.

On the 24th June 1812, a public trial took place of what became the

world’s first commercially viable steam railway (see also the press report at Appendix I.):

“On Wednesday last a highly interesting experiment was made with a

Machine, constructed by Messrs. Fenton, Murray and Wood, of this

place, under the direction of Mr. ― BLENKINSOP, the Patentee, for

the purpose of substituting the agency of steam for the use of

horses in the conveyance of coals on the Iron-rail-way from the

mines of J. C. Brandling, Esq. at Middleton, to Leeds. The machine

is, in fact, a steam engine of four horses’ power, which, with the

assistance of cranks turning a cog-wheel, and iron cogs placed at

one side of the rail-way, is capable of moving, when lightly loaded,

at the speed of ten miles an hour. At four o’clock in the afternoon,

the machine ran from the Coal-staith to the top of Hunslet Moor,

where six, afterwards eight waggons of coals, each weighing 3¼ tons,

were hooked to the back part. With this immense weight, to which, as

it approached the town, was super-added about 50 of the spectators

mounted upon the waggons, it set off on its return to the Coal-staith,

and performed the journey, a distance of about a mile and a half,

principally on the dead level, in 23 minutes, without the slightest

accident.

The experiment, which was witnessed by thousands of spectators, was

crowned with complete success; and when it is considered that this

invention is applicable to all rail-roads, and that upon the works

of Mr. Brandling alone, the use of 50 horses will be dispensed with,

and the corn necessary for the consumption of, at least, 200 men

saved, we cannot forbear to hail the invention as of vast public

utility, and to rank the inventor amongst the benefactors of his

country.”

Leeds Mercury, 27th June 1812.

Murray went on to build three further locomotives of the type, one

of which subsequently worked on Tyneside where it was seen by George

Stephenson, who used it as the model for his own adhesion

locomotive, Blücher, [14] and another

suffered a catastrophic boiler failure:

“We lament to state that the steam-impelled engine of J. C.

Brandling, Esq. employed on the rail-way of his colliery near Leeds,

exploded about five o’clock on Saturday afternoon. We regret to add,

that the engineer is literally blown to pieces. Several children who

were near the place have been severely scalded, but we believe that

no other life has been lost on this melancholy occasion.”

Morning Post, 3rd March 1818.

Two further approaches to solving the imagined adhesion problem

appear ― to modern eyes at least ― unconventional. That

advanced by Chapman has a present-day descendent in the ‘chain ferry’:

“In December, 1812, Messrs. William and Edward Chapman obtained a

patent for a mode of effecting the loco-motion of the engine by

means of a chain stretched along the middle of the Rail-road, the

whole length, properly secured at each end and at proper intervals. This chain was made to wind partly round, or to pass over, a grooved

wheel, turned by the engine, of such a form that the wheel could not

turn round without causing the chain to pass along with it. When

this wheel was turned round by the engine, as the chain was fastened

firmly at the end, it could not be drawn forwards by the wheel, the

carriage was therefore moved forward in the line of the chain. The

carriages containing the goods were attached to the engine carriage,

and thus conveyed along the Rail-road.”

A Practical Treatise on Rail-roads,

Nicholas Wood (1825).

In effect, the Chapman locomotive put in reverse the use of

cable-haulage by a stationary steam engine, a system later used at,

among other places,

the Stockton and Darlington Railway and the Euston to Camden incline of the London and Birmingham Railway. Tried out at Heaton and Lambton collieries, according to

Nicholas Wood “it

was soon abandoned; the great friction, by the use of the chain,

would operate considerably against it, and also its liability to get

out of order”.

Brunton’s

‘Mechanical

Traveller’ of 1813.

A number of inventions appeared at this time that were designed to

be pushed along by mechanically operated legs. One example was

William Brunton’s

‘Mechanical

Traveller’, which to a contemporary

writer appeared to be “a machine of great singularity”.

Surprisingly, perhaps, there is evidence that the locomotive

actually worked, but its boiler exploded killing 13

onlookers and ending its trials.

Setting aside eccentric solutions to this imagined problem,

a locomotive appeared in 1813 that was capable of hauling a useful

payload without the need for rack and pinion, chain haulage,

mechanical legs or any aid to adhesion other than its own weight. Commissioned by Cristopher Blackett, owner of the previously

mentioned Wylam Colliery, the design of the world’s first practical

adhesion steam locomotive, Puffing Billy, was

based on experimental data:

“Hitherto . . . . the only feasible scheme of obtaining effectual

locomotion seemed to be the procuring some fulcrum, as it were, upon

which to operate with steam, or to propel by rack work, pulling, or

thrusting. To operate by mere friction or gravity had not as yet

occurred to any one, until the late William Hedley, Esq., Viewer,

who had the direction of Wylam Colliery, conceived the idea and

having satisfied himself by a variety of experiments with the waggon-way

carriages, he took out a patent for the invention, which bears date

March 13th, 1813. The experiments were made by men placed upon the

carriages, and working the teeth gear by means of handles. The

weight of the carriage, and the number of waggons drawn after it

varied, but came to corresponding results, which were decisive of

the fact, that the friction of the wheels of an engine carriage upon

the rails was sufficient to enable it to draw a train of loaded

waggons. So conclusive were the experiments, that an engine was

immediately constructed.”

Who Invented the Locomotive

Engine? Oswald Dodd Hedley (1858).

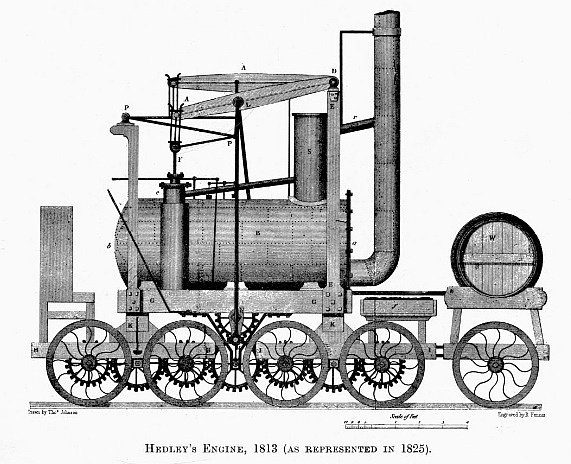

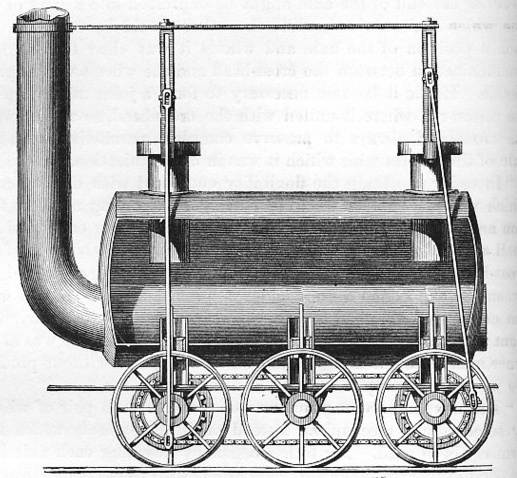

The locomotive was built by Blackett’s manager, William Hedley, assisted by the

colliery’s enginewright Jonathan Forster and blacksmith Timothy

Hackworth. [15] As with other locomotives of

its era,

Puffing Billy

was really a stationary beam engine mounted upon a suspensionless

carriage. Hedley used two externally mounted vertical cylinders

― in itself a step forward ― to drive a single crank-shaft connected

to the driving wheels through gearing. Steam was produced in a

cylindrical boiler working at 50 lbs per sq. in., which, as was

typical of the return-flue type, was fired

from the chimney-end of the locomotive, the driver being

stationed at the opposite end of the boiler facing the fireman.

In its original four-wheeled form, the locomotive proved too heavy

for the colliery’s cast-iron plateway, which it damaged. To remedy

this, Puffing Billy was rebuilt with four axles (as shown

above) to reduce its axle weight. Later in her career, when the plateway was replaced with wrought

iron edge rails, she was returned to four flanged driving

wheels and in this form remained in service until withdrawn in 1862. Two further

locomotives, Wylam Dilly and Lady Mary, were later built to broadly

the same design: [16]

“On the Killingworth railroad locomotive engines are used. One of

these engines, it is stated, draws twelve waggons at the rate of

four miles an hour for twelve hours each day. The locomotive

machines on Wylam rail-road travel with nine waggons at a much

quicker pace. A stranger is naturally struck with the imposing

appearance of an engine moving without animal power, with celerity

and majesty, along a road with a number of loaded carriages in its

train. The coal waggon, which is formed like an inverted prismoid,

is moved on four wheels of cast-iron, and has a false bottom hung

with hinges, and fastened by a hasp. When the waggon has arrived at

the staith, the hasp is knocked out, and the coals fall into a spout

below, which conveys them into the ships or keels, or into a

storehouse underneath.”

An Historical, Topographical, and Descriptive View of the County of

Northumberland,

Eneas Mackenzie (1825).

Puffing Billy

still at work in 1862.

Note the fireman and driver stationed at

opposite ends of the return flue boiler.

――――♦――――

GEORGE STEPHENSON

George Stephenson (1781-1848),

civil and mechanical engineer.

Having watched the progress of the Wylam locomotives, George

Stephenson suggested to the owners of the Killingworth Colliery that

they would benefit

from the use of steam traction:

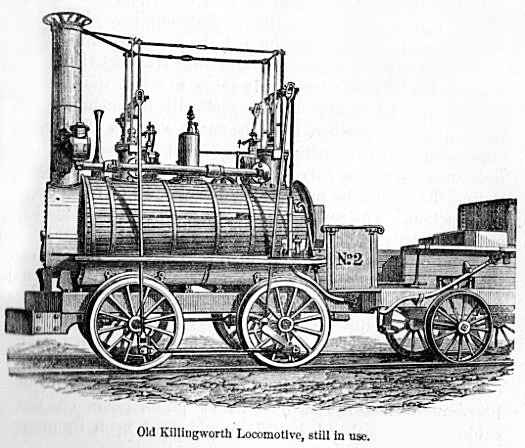

“In the early part of the year 1814, an engine was constructed at

Killingworth Colliery, by Mr. George Stephenson, and on the 25th

July, 1814, was tried upon that Rail-road. This engine had two

cylinders each eight inches diameter, and two feet stroke; the

boiler was circular, eight feet long, and thirty-four inches

diameter; the tube twenty inches diameter, passing through the

boiler . . . . This engine was tried upon the Killingworth Colliery

Rail-road, July 27, 1814, upon a piece of road with the edge rail,

ascending about one yard in four hundred and fifty, to draw after

it, exclusive of its own weight, eight loaded carriages, weighing

altogether about thirty tons, at the rate of four miles an hour;

and, after that time, continued regularly at work.”

A Practical Treatise on Rail-roads,

Nicholas Wood (1825).

Named Blücher, after the Prussian general, and built in the colliery workshops

under Stephenson’s direction, the locomotive had four smooth flanged driving wheels of 3 feet

diameter. These were driven by two vertical in-line cylinders of 8

inches bore by 24 inches stroke, which were semi-immersed in the boiler

at opposite ends. As in the Hedley locomotive, the piston-rods were connected

to the wheels through a system of crossheads, coupling rods,

crankshafts and gearing. The wrought iron boiler ― 8 feet long by 34 inches in

diameter ― contained a single 20-inch diameter

flue, at one of which was the fireplace and at the other a 20-inch diameter

chimney.

The locomotive proved capable of hauling a 30-ton train at a speed

of 4 mph up a gradient of 1 in 450, but the geared transmission

produced a noisy and spasmodic motion. By exhausting the waste steam through

the chimney rather than directly into the atmosphere, the boiler’s

steam-raising ability was improved, but the geared transmission

was unsuccessful. In service, the expected

savings failed to materialise and the locomotive was dismantled, its parts

being recycled.

Stephenson’s next locomotive was built in collaboration with the

colliery overseer, Ralph Dodds, in 1815. In it,

Stephenson replaced its predecessor’s

geared transmission with direct drive, the front and rears pistons

being connected to the front and rear axles with coupling rods,

which, in effect, formed cranks. To ensure that the front and rear cranks

remained at an angle of 90 degrees to each other, [17] the axles

were coupled using a chain drive, for which the pair applied for and were

granted a patent (summary at Appendix

II.).

A Stephenson locomotive showing

chain coupling and

‘steam spring’ suspension.

Stephenson’s final locomotive for Killingworth dates from 1816. In its

design his attention was directed towards distributing the

locomotive’s weight evenly over its wheels using some form of

suspension, a feature he had not provided previously. This need

arose from the poor condition of the colliery wagonways whose

uneven surfaces caused constant jolting resulting in much wear and

tear, while the weight of

the swaying locomotive, distributed unevenly over its driving wheels,

damaged the lightly laid rails. Derailments were not

uncommon:

“In order to avoid the dangers arising from this cause, Mr.

Stephenson contrived his Steam Springs. He so arranged the boiler of

his new patent locomotive that it was supported upon the frame of

the engine by four cylinders, which opened into the interior of the

boiler. These cylinders were occupied by pistons with rods, which

passed downwards and pressed upon the upper side of the axles. The

cylinders opening into the interior of the boiler, allowed the

pressure of steam to be applied to the upper side of the piston; and

that pressure being nearly equivalent to one fourth of the weight of

the engine, each axle, whatever might be it position, had at all

times nearly the same amount of weight to bear and consequently the

entire weight was at all times pretty equally distributed amongst

the four wheels of the locomotive. Thus the four floating pistons

were ingeniously made to serve the purpose of springs in equalising

the weight, and in softening the jerks of the machine; the weight of

which, it must also be observed, had been increased, on a road

originally calculated to bear a considerably lighter description of

carriage. This mode of supporting the engine remained in use until

the progress of spring making had so far advanced that steel springs

could be manufactured of sufficient strength to be used in

locomotives.”

The Life of George Stephenson,

Railway Engineer, Samuel Smiles (1858).

Although gas-filled suspension systems are widely used

today, Stephenson’s steam springs were not a success:

“The contrivance was introduced into some of Killingworth and Hetton

engines, but it is probable only about one-half or two-thirds of the

weight resting upon the axles was transmitted through the supporting

pistons. At any rate they did not move in their cylinders, although

they no doubt mitigated the force of the shocks between the engine

and the railway, as they allowed only a part of the weight of the

boiler and cylinders, instead of the whole, to act percussively upon

the axles. In their specification, Losh and Stephenson described the

supporting pistons as ‘floating pistons,’ which they were not; and

they added, evidently without understanding the true action of the

pistons, which was different in principle from the action of

springs, that inasmuch as they ‘acted upon an elastic fluid, they

produced the desired effect with much more accuracy than could be

obtained by employing the finest springs of steel to suspend the

engine.’ The whole arrangement was, on the contrary, defective in

principle, and objectionable on the score of leakage, wear, &c., and

as a matter of course was ultimately abandoned.”

Locomotive Engineering, and the

Mechanism of Railways, Colburn and Clark (1871).

Stephenson’s steam springs were later abandoned in favour of steel

leaf springs

when these could be manufactured to the required strength and when

locomotive cylinders were moved away from the vertical position they

had so far occupied. [18]

In addition to the steam suspension, in collaboration

with William Losh, his financial backer, Stephenson introduced other

innovations. Stronger and more ductile malleable iron was used in

the locomotive’s wheels in place of brittle cast-iron, which also

resulted in lighter wheels. He and Losh greatly improved the

quality of the track by devising a better means of joining the rails together ―

with half-lap rather than butt joints ― and for supporting the joint. Together with the

steam springs referred to, these innovations also became the subject

of a patent:

“A grant unto William Losh, of the town and

county of Newcastle-upon-Tyne, iron founder, and George Stephenson,

of Killingworth, in the county of Northumberland, engineer, for

their invented new method or new methods of facilitating the

conveyance of carriages, and all manner of goods and materials along

railways and tram-ways, by certain inventions and improvements in

the construction of the machine, carriages, carriage wheels,

railways, and tram-ways employed for that purpose.”

Patent Record Office, No

4067, 30th September, 1816.

Stephenson’s activities at this time, together with his views on

steam road vehicles, are dealt with in the 1869 article taken from the

Locomotive Engineers Journal at Appendix III.

The eventual form of Stephenson’s

Killingwoth locomotives.

In 1820, Stephenson was engaged by the owners of Hetton Colliery to

build an 8-mile railway linking the colliery to coal staithes on the

River Wear near Sunderland. Opened in 1822 (Appendix

IV.), the line

has the distinction of being the first railway (albeit private) designed to be

mechanically operated, in this case by a combination of locomotives

and stationary engines:

“On the original Hetton line there were five self-acting

inclines—the full wagons drawing the empty ones up—and two inclines

worked by fixed reciprocating engines of sixty-horse power each. The

locomotive travelling engine, or ‘the iron horse,’ as the people of

the neighbourhood then styled it, worked the rest of the line. On

the day of the opening of the Hetton Railway, the 18th of November,

1822, crowds of spectators assembled from all parts to witness the

first operations of this ingenious and powerful machinery, which was

entirely successful. On that day five of Stephenson’s locomotives

were at work upon the railway, under the direction of his brother

Robert; and the first shipment of coal was then made by the Hetton

Company at their new staiths on the Wear. The speed at which the

locomotives travelled was about four miles an hour, and each engine

dragged after it a train of seventeen wagons weighing about

sixty-four tons.”

The Life of George Stephenson,

Railway Engineer, Samuel Smiles (1858).

The five locomotives referred to ― built by Stephenson between 1820

and 1822 ― were developments of the 0-4-0 engines use at

Killingworth, with two in-inline vertical cylinders, chain-coupled

wheels and steam suspension.

――――♦――――

THE STOCKTON

AND DARLINGTON RAILWAY

An important development to emerge from the project to build the Stockton and Darlington

Railway (Appendix V.), was the creation, in 1823, of Robert Stephenson and

Company, the world’s first company specifically set up to build

railway locomotives. Until then, locomotives had been

manufactured locally, either in colliery workshops or general

engineering firms, [19] but Stephenson:

“. . . . had long felt that the accuracy and style of their

workmanship admitted of great improvement, and that upon this the

more perfect action of the locomotive engine, and its general

adoption, in a great measure depended. One principal object that he

had in view in establishing the proposed factory was to concentrate

a number of good workmen for the purpose of carrying out the

improvements in detail which he was from time to time making in his

engine; for he felt hampered by the want of efficient help from

skilled mechanics, who could work out in a practical form the ideas

of which his busy mind was always so prolific.”

The Life of George Stephenson,

Railway Engineer, Samuel Smiles (1858).

The company was set up by George Stephenson and his son Robert, Edward

Pease, Michael Longridge (a partner in the Bedlington Ironworks)

and Thomas Richardson, an iron founder and Pease’s cousin. Their

workshop was in premises at Forth Street, Newcastle, where the first works

manager was Timothy Hackworth, who soon moved to take up an

appointment with the Stockton and Darlington Railway,

there to become a distinguished mechanical engineer.

Timothy Hackworth probably had a hand in the design of the first

locomotive to leave the Forth Street works, which was of the usual

0-4-0 type, much in the Killingworth/Hetton tradition. Named Active,

by the opening of the Stockton and Darlington Railway, at which

event she hauled the inaugural train, she bore the name

Locomotion No. 1.

Locomotion No. 1,

Stockton and Darlington Railway (1825).

Steam, produced in a centre flue boiler, drove two in-line

vertical cylinders enclosed within the boiler, before being

exhausted into the chimney. Piston rods were coupled by crossheads

to the connecting rods, a major departure being that coupling rods

now replaced the endless chain; these

required return-cranks to be fitted to the wheels on the rear axle in

order to clear the connecting rod. A single crank set on the front

axle operated the valves for both cylinders, but because this gave an

angular advance in each running direction, valves with a form of lap and lead

were fitted. Stephenson’s

steam suspension had by now been abandoned.

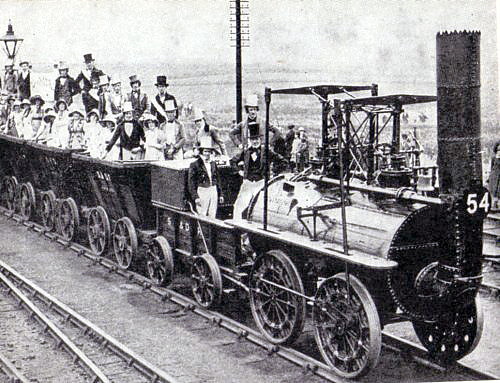

Replica of Locomotion No. 1

pictured during the 1925 centenary cavalcade.

Locomotion No. 1 was followed by three further locomotives of the

class, Hope (November 1825), Black Diamond (April 1826) and

Diligence (May 1826). Each exhibited a major weakness inherent their

single flue boilers, an abysmally poor thermal

efficiency. While heavy fuel consumption presented no significant

drawback in areas where fuel was cheap and plentiful, elsewhere the

steam locomotive would have proved more expensive to operate than

horse traction. Referring to the Locomotion class, the author of the

following article gives some idea of the extent of the heat wasted

in a single flue boiler (exacerbated by wasteful combustion due to the absence of an

external firebox):

“These were constructed after Stephenson’s most matured designs, and

embodied all the improvements which he had contrived up to that

time. No. 1 engine, the ‘Locomotion,’ which was first delivered,

weighed about eight tons. It had one large flue or tube through the

boiler, by which the heated air passed direct from the furnace at

one end, lined with fire bricks, to the chimney at the other. The

combustion in the furnace was quickened by the adoption of the

steam-blast in the chimney. The heat raised was sometimes so great,

and it was so imperfectly abstracted by the surrounding water, that

the chimney became almost red hot.”

Locomotive Engineers’ Journal, Vol. 4, January 1870.

The situation was improved by converting the boilers in these

locomotives to return flue, as in Trevithick’s Catch-Me-Who-Can,

which increased the heating area from 63 to 125 square feet. This

doubled the boiler’s evaporative power, but at the inconvenience of placing

the fireman at the opposite (chimney) end of the boiler to the

driver.

Comparing Stephenson’s Locomotion No. 1 with Trevithick’s

Catch-Me-Who-Can, of 1808, it is difficult to see that any material

advance had been made in locomotive and boiler design during the

intervening years. Locomotion’s coupled driving wheels were,

perhaps, the only significant distinguishing feature, although

Rocket, of 1829, while greatly advanced in other ways, reverted to

the twin driving wheels last employed by Trevithick. Thus, while

Stephenson undoubtedly promoted the steam railway locomotive as the

universal workhorse it was to become, several fundamental

improvements were yet to be made:

“. . . . Stephenson foresaw the further advantage of locomotive

power, and he had an abiding faith in the Locomotive Engine. As

improvements appeared he distinguished them clearly, and applied

them successfully, in most instances at least; for in the

Killingworth, Hetton, and Stockton and Darlington engines he

overlooked the advantages of the return flue boiler and small

chimney of the Wylam engine. But there is no ground for asserting,

as has been done, that George Stephenson was the inventor of any

essential part of the Locomotive Engine; and it is difficult to say

in what respect he improved its structure or working, otherwise than

by adopting and successfully executing the plans and suggestions of

plans of others. There was, indeed, great merit in this, ― as much

probably as Stephenson ever claimed for himself in this respect; and

it no more detracts from his acknowledged sagacity and skill as an

engineer, or his singular worth as a man, that he did not ‘invent’

the Locomotive Engine, than it is a reproach to Sir Isaac Newton

that he did not originate the electric telegraph.”

Locomotive Engineering, and the

Mechanism of Railways, Colburn and Clark (1871).

By comparison, Trevithick had the greater imagination ― perhaps even

a touch of genius about him ― but, sadly, his inability to persevere

was his undoing:

“Trevithick began better than Stephenson: he had friends in Cornwall

and in London; and he ought not to have left to Stephenson to work

out the locomotive engine and the railway. Trevithick was always

unhappy and always unlucky; always beginning something new, and

never ending what he had in hand. The world ever went wrong with

him, as he said, ― but in truth he always went wrong with the world. The world had done enough for him, had he known or had he chosen to

make a right use of any one thing. He found a partner for his

high-pressure engine, ― he built a locomotive, ― he had orders for

others for Merthyr Tydvil and for Wylam, ― he set his ballast engine

to work, ― and he drove his tunnel under the Thames for a thousand

feet; ― but no one thing did well; all were afraid, and at length no

one would have anything to do with him. It was not that his mind was

more fruitful than that of Stephenson, who in this short time had

made improvements in pit work, and railways, built a locomotive, and

found out the safety lamp, and who throughout his life was ever

working out something new. What it was, was this ― Stephenson never

lost a friend, and Trevithick never kept one.”

Civil Engineer and Architect’s

Journal, p.300, Vol. XI. 1848.

CHAPTER

3

――――♦――――

APPENDIX I.

BLENKINSOP’S LOCOMOTIVE

From the Leeds Mercury, 18th July, 1812.

In our paper of the 27th ult. we mentioned a successful experiment

made on the Iron-rail-way between Hunslet and Leeds, to ascertain

the powers of a Steam-impelled Machine, by which the conveyance of

coals, minerals, and other articles is facilitated, and the use of

horses dispensed with. This Machine, at once so simple, powerful and

beneficial, has, as was to be expected, excited a considerable share

of public attention, and we now subjoin a Drawing of the Machine and

toothed Rail-way, accompanied by an abstract of the Specification of

the Patent granted on the 10th of April, 1811, to the Inventor, Mr.

JOHN BLENKINSOP, of

Middleton, near this place.

SPECIFICATION.

—First, There is placed upon the road over which the

conveyance is to he made, a toothed Rack or longitudinal piece of

cast-iron, having the teeth or protuberances standing either

upwards, or downwards, or sideways, in any required position; and

this toothed Rack is continued and duly placed all along, or as far

as may be required upon the ground or road.

— Secondly, There is connected with a Carriage required to bear and

convey goods alone the road, a Wheel having teeth at the

circumference thereof, so formed and placed as to become connected

with, and fairly to act upon the teeth belonging to the rack when

the Carriage shall he suitably placed with regard to the same.

— Thirdly, The Wheel is made to revolve and drive the Carriage along

by the application of a Steam- Engine placed upon and carried along

with the Carriage. And further, the Wheel is connected with the

first mover by a Crank, assisted by a Fly, and the connection is

made either directly with the arbor of the wheel, or indirectly by

other wheel-work, when the crank or other driving piece cannot with

convenience or effect be fixed upon the arbor of the wheel.

— Fourthly, In order to render the motion of the carriage more easy,

the Patentee avails himself of the contrivances and expedients

heretofore used for improving roads, such as Platforms, Pavements,

connected Timbers, and more especially the Iron rail-way, upon which

the untoothed or common wheels of the carriage are made to run, and

in that case the longitudinal pieces are connected with the

Rail-road itself, or otherwise by preference. One of the sides or

range of pieces forming the said Rail-way is cast with teeth, that

the same side or range shall constitute the toothed Rack, and at the

same time afford a regular and even bearing for the Wheels and for

the Toothed wheel, which (if its plane be vertical,) may he made

with a side run to bear upon the smooth part of the Rail and prevent

the teeth from locking too deep.

― And lastly, Motion is given to other carriages by attaching the

same to the carriage upon which the first mover is placed and these

other carriages are fitted up as usual without the Toothed-wheel,

and where the same may be preferred, use is made of two

Toothed-wheels, acting upon correspondent racks on each side.

――――♦――――

APPENDIX II.

THE DODDS AND STEPHENSON PATENT

From:

Patents for Inventions.

Abridgements of Specifications Relating to the Steam Engine,

Vol. I (1871).

A.D. 1815, February 28. ― No. 3887.

DODDS, Ralph, and STEPHENSON, George. “The friction of four wheels

propelled by two engines will propel several tons weight upon an

iron railway. This was done by a cog-wheel upon each bearing axis,

spurred on by a cog-wheel upon each engine’s axis, with an interleading cog wheel to combine the two engines together and keep

them at right angles from one another.” Another method was “to

combine the two engines together with cog-wheels which spur

themselves along a cog railway or waggon way;” “but we,” say the

Patentees, “apply the power of the engine to the travelling wheels

of the carriage, by joining one end of each connecting rod to a pin

fixed to one of the spokes of each of the travelling wheels; which

connecting rods are joined at both ends by ball and socket joints,

to give way to the rise and fall of the road; and there is also a

joint where the piston rod is joined to the yoke, that it may give

way to the ball and socket joints.” “The engines are kept at their

proper distance apart by each bearing axle having two cranks near

its centre with two connecting rods fitted at right angles to each

other, and extending from one crank to the other.”

2. Or two grooved wheels that have notches into which the projecting

bolts of the endless chain fall, and in which it works, are fixed in

the centre of each axle.

3. Applying the friction of the bearing wheels in this way, the

engines propel 60 tons or upwards upon an iron railway. If a greater

burden is to be moved, the friction of other two wheels is added,

and they are made to carry the water that supplies the engine. A

groove is made in each, and a groove in the last two bearing wheels

of the carriage, into which an endless chain falls. By the

propelling force of the engine this is moved along, together with

the bearing wheels of the water carriage attached to it.

――――♦――――

APPENDIX III.

GEORGE STEPHENSON’S

EARLY RAILWAY DEVELOPMENTS

from the

Locomotive Engineers Journal,

Volume 3 (1869).

Mr. Stephenson’s experiments on fire damp and his labours in

connection with the invention of the safety lamp, occupied but a

small portion of his time, which was mainly devoted to the

engineering business the colliery. He was also giving daily

attention to the improvements of his locomotive, which every day’s

observation and experience satisfied him was still far from being

perfect.

At that time, railways were almost exclusively confined to the

colliery districts, and attracted the notice of few persons except

those immediately connected with the coal trade. Nor were the

colliery proprietors generally favourable to locomotive traction. There were great doubts as to its economy. Mr. Blackett’s engines at

Wylam were still supposed to be working at a loss; the locomotives

tried at Coxlodge and Heaton, proving failures, had been abandoned;

and the colliery owners seeing the various locomotive speculations

prove abortive, ceased to encourage further experiments Stephenson

alone remained in the field after all the other improvers and

inventors of the locomotive had abandoned it in despair. He

continued to entertain confident expectations of its eventual

success. He even went so far as to say that it would yet supersede

every other tractive power. Many looked upon him as an enthusiast,

which no doubt he was, but upon sufficient grounds. As for his

travelling engine, it was by most persons regarded as a curious toy;

and many, shaking their heads, predicted for it “a terrible blow up

some day.” Nevertheless, it was daily performing its work with

regularity, dragging the coal wagons between the colliery and staiths, and saving the labour of many men and horses. There was

not, however, so marked a saving in the expense of working, when

compared with the cost of horse traction, as to induce the northern

colliery masters to adopt it as a substitute for horses. How it

could be improved and rendered more efficient as well as economical

was never out of Mr. Stephenson’s mind. He was quite conscious of

the imperfections both of the road and of the engine; and he gave

himself no rest until he had brought the efficiency of both up to a

higher point. He worked his way step by step, slowly but surely;

every step was in advance of the one preceding, and thus inch by

inch was gained and made good as a basis for further improvements.

At an early period of his labours, or about the time when he had

completed his second locomotive, he began to direct his particular

attention to the state of the road; as he perceived that the

extended use of the locomotive must necessarily depend in a great

measure upon the perfection, solidity, continuity, and smoothness of

the way along which the engine travelled. Even at that early period,

he was in the habit of regarding the road of the locomotive as one

machine, speaking of the rail and the wheel as “man and wife.”

All railways were at that time laid in a careless and loose manner,

and great inequalities of level were allowed to occur without much

attention being paid to repairs; the result was that great loss of

power caused, and also great wear and tear of machinery, by the

frequent jolts and blows of the wheels against the rails. His first

object, therefore, was to remove the inequalities produced by the

imperfect junction between rail and rail. At that time (1816) the

rails were made of cast-iron, each rail being about three feet long;

and sufficient care was not taken to maintain the points of junction

on the same level. The chairs, or cast-iron pedestals into which the

rails were inserted, were flat at the bottom; so that whenever any

disturbance took place in the stone blocks or sleepers supporting

them, the flat base of the chair upon which the rails rested, being

tilted by unequal subsidence, the end of one rail became depressed,

whilst that of the other was elevated. Hence constant jolts and

shocks, the reaction of which very often caused the fracture of the

rails, and occasionally threw the engine off the track.

To remedy this imperfection, Mr. Stephenson devised a new chair,

with an entirely new mode of fixing the rails therein. Instead of

adopting the butt joint, which had hitherto been used in all

cast-iron rails, he adopted the half-lap joint by which means the rails

extended a certain distance over each other at the ends, somewhat

like a scarf joint. These ends, instead of resting upon the flat

chair, were made to rest upon the apex of a curve forming the bottom

of the chair. The supports were extended from three feet nine inches

or four feet apart. These rails were accordingly substituted for the

old cast-iron plates on the Killingworth Colliery Railway, and they

were found to be a very great improvement upon the previous system,