|

NOTES AND EXTRACTS

ON THE HISTORY OF THE

LONDON & BIRMINGHAM RAILWAY

CHAPTER 3.

PROBLEMS WITH THE TRACK

THE CAST-IRON PLATE RAIL

The development of the railway locomotive languished for some years

following Trevithick’s withdrawal from the field. This was not

wholly due to the absence of his inventive genius, nor to the

lack of a commercial driver for change, for the inflationary

pressures of the Napoleonic War had greatly increased the cost of

horse fodder and with it that of horse-powered traction. The

principal reason, as Trevithick had discovered at Pen-y-Darren and

later in London, was the absence of rails capable of withstanding a

locomotive’s weight and hammer blow. [1] More than a

another decade was to pass before rails became available that could

reliably withstand the stresses of locomotive traction.

This chapter reviews the main changes that took place in rail design

and technology leading up to the world’s first passenger-carrying,

steam-worked railway, the Stockton and Darlington.

Iron plate rails mounted on stone

blocks ― the Derby Canal Railway.

The development of the wagonway progressed with the coming of the

Industrial Revolution and the widespread use of iron. First,

wooden rails were reinforced with iron plating to reduce wear and to

further reduce friction. It was then a natural progression to the

all-iron L-shaped rail, [2] which was not

attacked by rot and could better withstand the weight of the wagons:

“Notwithstanding the imperfection both of

the railway and the impelling force, as compared with the improved

apparatus of the present day, the advantage was so considerable,

that a single horse could draw three tons of coals from the pit to

the river. There was, however, a drawback on the advantages, from

the expense of repairing the wear and tear of the decayed wood,

which was, indeed, under some circumstances, so great as to render

the use of rail-ways, made of this material, a very doubtful

benefit. At length iron was introduced, and found to succeed

remarkably well. But in the first instance the railways were not

made wholly of iron. Flat bars of this metal were fastened on the

top of the existing wooden rails, and this was considered a great

improvement. A greater still, however, which soon succeeded, was

making the rails wholly of iron, cast in short bars, united at their

extremities, and resting on square blocks of stone, instead of logs

of wood, arranged at short intervals along each side of the road.”

The British

Magazine, Vol. I., p. 121, 1830.

However, the introduction of iron reinforcement on wood, followed by

the replacement of wood with iron plates, increased wear on the

wagons’ wooden wheels. To combat this, iron tyres were

introduced followed by

iron wheels, both of which also reduced still further a railway wagon’s rolling resistance:

“The next improvement in order of time

appears to have been the use of cast-iron as a substitute for the

wooden rails, and these were tried on a small scale at the Colebrookdale iron works in Shropshire about 1767, at the suggestion

of Mr. Reynolds, one of the partners in that concern. About this

same time cast-iron wheels, turned in a lathe, and made with great

truth and accuracy, began to be used, and then it was that the great

advantage of these roads became apparent, for the advantage to be

gained by a rail-road depends in a great measure on the perfection

of the workmanship bestowed upon it, to make it truly smooth and

level, and on making the carriages that run upon it as free from

friction and inequalities of motion as possible.”

Elements of

Civil Engineering, John Millington (1839).

However, it is doubtful that iron wagon wheels were first used at Colebrookdale. Like much of our railway history, their first use was

probably in the North East of England. [3]

Although there were variations in design, by the end of the 18th

Century a typical iron wagonway consisted of L-shaped plate rails,

which we would describe today as ‘angle irons’. A wagon’s flat-rimmed

wheels ran along the rail’s flat surface (about 3½ inches wide), while

the uprights (about 4 inches high) kept the wheels aligned with the track. This contrasts with a modern railway, where the opposite applies ―

flanges guide the wheel along a flangeless track.

Plateway mounted on stone blocks ―

the Derby Canal Railway.

Plate rails were of cast-iron, generally in lengths of three to six feet, drilled to receive spikes [4]

and supported on either transverse timber sleepers, or on stone

blocks. It seems at this time that track-beds were unballasted, for

where timber sleepers were in use a civil engineering manual of the period speaks of the need to

support their ends:

“. . . . a transverse timber sleeper may be

let into the ground and a large heavy stone, or mass of rubble-work

in mortar, may be sunk below each of its ends to give it a firmer

bearing and prevent its sinking deeper.”

Elements of

Civil Engineering, John Millington (1839).

Where the lines were laid on timber, they were spiked directly into

the sleepers, whereas when laid on stone, holes had to be drilled

into the blocks, plugged with wood, and the lines spiked into the

plug. An advantage of using stone blocks was that the track-bed

between the lines was left clear for the horses’ hooves, but to

achieve this with timber the sleepers had to be let into the ground

or covered with gravel where they then became more prone to rot.

However, stone blocks had their disadvantages; they were more prone than

wood to vibration, which shook the rails loose, while the wooden

plugs gradually saturated and swelled, splitting the stone. Such was the construction of the Pen-y-Darren Tramroad [5]

on which Trevithick’s locomotive ran in 1804.

Besides colliery owners building wagonways, canal companies also

made considerable use of them during the canal era (little

realising they would evolve to supersede the canals), principally as

feeders in situations where they provided a more economic

alternative to a branch canal, or where the terrain was unsuitable

for a waterway. It was in the construction of such feeders that the

civil engineer Benjamin Outram’s name is now associated.

The Derby Canal Railway.

One example of Outram’s work was the ‘Derby Canal Railway’ (aka the

‘Little Eaton Gangway’), a typical wagonway of the period. Now

abandoned, the Derby

Canal was opened throughout in 1796 to form a link

between the Trent & Mersey and the Erewash canals in Derbyshire. As

a more economic alternative to a branch canal, Outram built a

wagonway to link the Denby collieries with the canal at Little Eaton

wharf. Priestly described this plateway thus:

“From the northern end of the main line

[of the canal] at Eaton, a railway

proceeds by Horsley and Kilboum, to Smithy House, which is nearly

four miles and three quarters in length. From Smithy House there is

a branch one mile and three quarters in length, to the collieries at Henmoor, situated one mile and a half east of the town of Belper;

another one mile and a half in length, by the potteries, to the

extensive coal works near Denby Hall; with a collateral branch out

of the last mentioned branch, three quarters of a mile in length, to

other collieries north of Salterswood.”

Historical

Account of the Navigable Rivers, Canals etc., Joseph Priestley

(1831).

The Derby Canal Railway used cast-iron

L-shaped plate rails, approximately three feet long, which

were spiked into stone sleepers. Its horse-drawn wagons had

detachable bodies, each of a capacity of about 1¾ tons, which were

loaded into barges by crane at Little Eaton Wharf, an early form of

containerisation. The wagonway’s principal cargo was coal, but it also carried stone,

pottery and other goods. It remained in use in its original

horse-drawn form until closure in 1908.

――――♦―――― |

|

THE EDGE RAIL.

William Jessop was one of the great civil engineers of his era, his name

being linked to a wide range of civil engineering projects that

include canals, docks and wagonways. He is also credited with the first use of the cast-iron

edge rail, the

predecessor of the modern railway line. [6]

Around 1794 ― the date is

uncertain ― Jessop engineered a wagonway to carry coal from Nanpantan,

on the Charnwood Forest Canal, to Loughborough. This was to have

been laid with plate rails of the Outram pattern, but, so the story goes, the trustees

of a turnpike road objected to the

obstruction posed by the rails’ raised flanges at a point where the

track crossed the carriageway. However, a further

problem with plate rails was that the debris thrown up

by the horses’ hooves lay on the rail’s flat surface and

obstructed the free running of the wagon wheels. Jessop’s use of

the edge rail solved both problems; where the rails crossed a road,

their upper edges could be recessed so as to lie level with the road

surface, thereby posing no obstruction to

traffic, and elsewhere their raised running surfaces remained substantially free

of stones and dirt.

“Edge rails succeeded plate-rails, having

been first used in 1785; the inconvenience arising from the dust

laying on the latter probably led to their introduction originally,

although the many other advantages possessed by them might hot have

been contemplated at the time, as the form of edge-rails is

certainly very superior, combining the least expenditure of material

with the greatest possible strength and the friction upon them is

less than upon tram-rails.”

A Glossary of Civil Engineering,

S. C. Brees (1844).

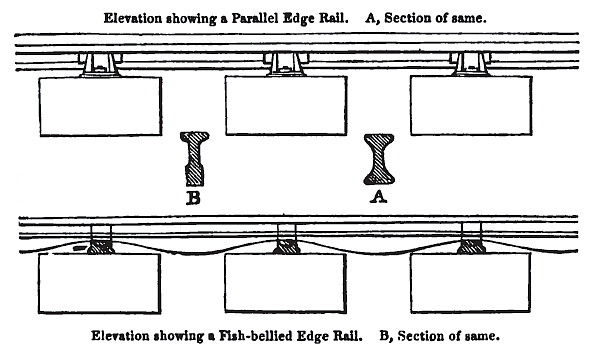

The earliest iron edge rail consisted of a cast-iron bar, laid on

edge and generally

three feet long (due to cast-iron being brittle, it could only be

laid in short lengths). The underside of the rail was

elliptical to provide greater strength between the supports, which

gave rise to the description ‘fish bellied’. The rails were mounted

in a succession of iron chairs, each being spiked to either a timber

or a stone block sleeper. Vehicles that ran upon edge rails

required flanged wheels, which kept them aligned

with the track.

The iron edge rail was not adopted immediately and co-existed with

the plate-rail for some years:

“It was of course a great saving of

material to cast a flange on the tire of the wheels only, instead of

along the whole length of the line; but plate-rails with the flange

upon them continued in use notwithstanding, in virtue of the force

of prejudice. In 1797, Mr. Jessop’s edge-rails were laid down on the

Lawson Main Colliery Railway, near Newcastle; but in 1800, Mr. Wm. Outram laid plate-rails, with a flange, on the Little Eaton Railway,

in Derbyshire. In 1801 the Wandsworth and Croydon Railway was laid

with these flange rails, and in 1803 the Croydon and Merstham

Railway. It was not till about 1812 or 1815 that edge rails got the

mastery.”

The Railway Register, Hyde

Clark (1847).

In 1794, Jessop entered into partnership with Benjamin Outram and

others in an ironworks, ‘Benjamin Outram and Company’, [7]

that Outram had set up some years previously at Butterley in

Derbyshire, and the business began manufacturing both types of rail.

――――♦―――― |

|

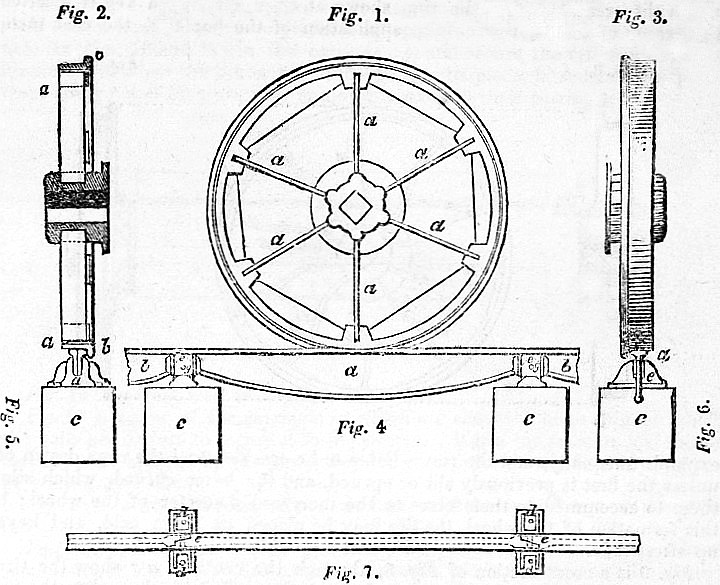

LOSH AND STEPHENSON’S PATENT

In 1816, George Stephenson contributed to the development of

the iron edge rail by devising an improved method for joining and

fixing the rails in place. At the time, railways were poorly laid,

the outcome being an uneven track on which locomotives and wagons

were subjected to excessive wear and tear from the considerable

jolts they experienced in passing over protruding rail joints,

sometimes being derailed. Stephenson replaced the existing butt

joints between each rail with half-lap joints, which extended the

rails over each other for a short distance at their ends. He also

redesigned the supporting chair, so that the joint between the rails

rested upon the apex of a curve in place of a flat surface. To

reduce the number of rail joints, the chairs were moved from 3 feet

to 3 feet 9 inches or 4 feet apart.

Fish-bellied rail, showing (top)

curvature in the supporting chair and (bottom) a half-lap joint.

The effect of these changes, while reducing the number of rail

joints, helped to maintain an even line. Were a sleeper to tilt from

the horizontal, the rail would remain tangential to the curved base

of the chair in which it was seated, while the half-lap joint with

the adjacent rail kept it locked in place.

Stephenson, together with William Losh, part owner of Losh, Wilson &

Bell, who at the time employed Stephenson for two days a week at

their Walker Ironworks, applied for a patent to cover this

invention. Registered on 30th September 1816, the patent ― an

extract of which is at Appendix I. ― included

the steam suspension

and the application of malleable iron to rail vehicle wheels

referred to in Chapter 2.

――――♦―――― |

|

THE MALLEABLE IRON RAIL

An important step in the development of the iron rail took place at

the Tindale Fell Railway (aka Lord Carlisle’s Railway), an early

mineral line that served the extensive collieries and lime works at

Tindale Fell in Cumbria. The line had been laid partly with

cast-iron and partly with malleable iron [8]

rails. Over a period of years its operators noticed that while

the malleable iron rails remained in good condition, those of

cast-iron became worn and liable to fracture, an outcome that ran contrary to rceived

wisdom on the subject. Because malleable iron was vulnerable to rust and was

also more expensive than cast-iron to manufacture, it had been

considered unsuitable for use in railway lines. However, when

put to the test it was discovered that

the impact and friction of traffic rolling along a malleable iron

line work-hardened the surface, [9] which caused

it to resist rust, while malleable iron’s greater manufacturing

cost was more than offset by the much smaller gauge of bar necessary

to provide the equivalent strength of cast-iron.

The experience at Tindale Fell came to the attention of the civil

engineer Robert Stevenson (1772–1850), who referred to it in a report: [10]

“Before the period alluded to, the rails in

use had been almost invariably made of cast-iron or timber; but my

father, in his notes, says, ’I have no hesitation in giving a

decided preference to malleable iron, formed into bars from twelve

to twenty feet in length, with flat sides and parallel edges, or in

the simple state in which they come from the rolling mills of the

manufacturer.’ He also recommends that they should be fixed into

guides or chairs of iron, supported on props placed at distances in

no case exceeding three feet, and that they should be connected with

a clamp-joint, so as to preserve the whole strength of the material. It is not a little singular that this description, given about forty

years ago [1818], may, to use

engineering phraseology, be not inaptly called a ‘specification of

the permanent way’ of our best railways at the present day.”

Biographical Sketch of the Late

Robert Stevenson: Civil Engineer, Alan Stevenson (pub. 1861).

So wrote Stevenson Jnr. of his father, known principally for his

construction of the Bell Rock and other northern lighthouses,

although he was also involved in a range of civil engineering

work. George Stephenson obtained a copy of Stevenson’s report,

which he passed to Michael Longridge, part owner of the Bedlington

Ironworks, [11] who in turn passed it to John

Birkinshaw, the works’ principal agent; and to Birkinshaw must go

most of the credit for establishing the Bedlington company’s

reputation:

“The Bedlington Iron and Engine Works will

be remembered in industrial history more for the contribution made

to the development of the early railways than for any other single

reason. It is no coincidence that the company’s peak of production

and fame was paralleled by the excitement of railroad and locomotive

development in this country and abroad.”

The North Eastern Railway,

William Weaver Tomlinson (1915).

Birkinshaw contacted Lord Carlisle’s agent for information on the

use of malleable iron rails, and was told that:

“Our rails are one and a half inches

square, and stand upon stones about ten inches square, and are

placed at one yard distance from centre hole to centre hole. Our

railway carries four tons weight, and has never cost us any thing

yet, as to expense of the malleable iron, except creasing

[track maintenance]. The iron I

cannot see the least alteration with, although it has now been laid

eight years. The cast-iron is a daily expense; it is breaking every

day.”

In 1820, Birkinshaw registered a patent ― and extract of which is at

Appendix II. ― for rolling rails of malleable iron:

“These rails are generally rolled into

lengths of fifteen feet, subdivided into bearing lengths of three

feet each; eighteen feet lengths were recommended by the patentee,

but experience has shewn that the former are the most practicable. The joinings of the ends of these rails, were at first square at the

ends, similar to the old cast-iron rails; but they are now formed

with a half lap . . . . and thus they now possess all the properties

of the improved cast-iron rails.”

A Practical Treatise on Rail-roads,

Nicholas Wood (1836).

This was a vital breakthrough in railway engineering, for this new

type of rail could withstand the stresses caused by locomotive

movement.

“KlLLINGWORTH COLLIERY,

June 28, 1821.

Robert Stevenson, Esq.

Sir, ― With this you will receive 3 copies of a specification of a

patent malleable-iron rail invented by John Birkinshaw of Bedlington,

near Morpeth. The hints were got from your Report on Railways, which

you were so kind as to send me by favour of Mr Cookson some time

ago. Your reference to Tindale-fell Railway led the inventor to make

some experiments on malleable-iron bars, the result of which

convinced him of the superiority of the malleable over the cast-iron

― so much so, that he took out a patent. Those rails are so much

liked in this neighbourhood, that I think in a short time they will

do away the cast-iron railways. They make a fine line for our

engines, as there are so few joints compared with the other. I have

lately started a new locomotive engine, with some improvements on

the others which you saw: it has far surpassed my expectations. I am

confident a railway on which my engines can work is far superior to

a canal. On a long and favourable railway I would stent my engines

to travel 60 miles per day with from 40 to 60 tons of goods. They

would work nearly fourfold cheaper than horses where coals are not

very costly.

I merely make these observations, as I know you have been at more

trouble than any man I know of in searching into the utility of

railways; and I return you my sincere thanks for your favour by Mr

Cookson. If you should be in this neighbourhood, I hope you would

not pass Killingworth Colliery, as I should be extremely glad if you

could spend a day or two with me, ― I am, sir, yours most

respectfully,

(Signed) G. STEPHENSON”

Biographical Sketch of the Late Robert Stevenson:

Civil Engineer, Alan Stevenson (pub.

1861).

――――♦―――― |

|

RAILS FOR THE STOCKTON AND DARLINGTON

Prior to Stephenson being appointed Engineer to the Stockton and

Darlington Railway Company, the directors reached two important

decisions; that the line was to be a railway laid with edge rails, as

opposed to a tramway laid with plate rails, and that Stephenson was to

undertake a further survey of the line. Both decisions

were possibly assisted by a letter (dated 22nd June 1821) to one of the

Committee members from that great promoter of railways, William

James:

“This railway pioneer [James],

who, in the capacity of engineer of the Stratford and Moreton

Railway, had visited most of the railroads in the kingdom, described

the edge-rail as ‘infinitely preferable’ to the plate-rail, and

eulogised, in no measured terms, the North-country engineers,

ranking Stephenson next to Watt in point of mechanical ability.”

The North Eastern Railway,

William Weaver Tomlinson (1915).

Following completion of the survey toward the end of 1821,

Stephenson was appointed engineer to the Company. Despite his

connection with William Losh and the Walker Ironworks, he declined

to recommend the use of Losh’s patent cast-iron rails, opting

instead for Birkinshaw’s patent malleable iron fish-bellied rails

of 28 lbs. per yard. In Stephenson’s opinion:

“The great object in the construction of a

railroad is that the materials shall be such as to allow the

greatest quantity of work to be done at the least possible

expenditure; and that the materials also be of the most durable

nature. In my opinion Birkenshaw’s patent wrought-iron rail

possesses these advantages in a higher degree than any other. It is

evident that such rails can at present be made cheaper than those

that are cast, as the former require to be only half the weight of

the latter, to afford the same security to the carriages passing

over them, while the price of the one material is by no means double

that of the other. Wrought-iron rails, of the same expense, admit of

a greater variety in the performance of the work, and employment of

the power upon them, as the speed of the carriages may be increased

to a very high velocity without any risk of breaking the rails;

their toughness rendering them less liable to fracture from an

impulsive force, or a sudden jerk. To have the same advantages in

this respect, the cast-iron rails would require to be of enormous

weight, increasing of course the original cost.”

A Practical Treatise on the

Construction and Formation of Railways, James Day (1848).

But malleable iron had yet to win the day, for after

consulting a number of eminent engineers the Committee concluded

unanimously that two-thirds of the railway should be laid with

malleable iron and the remainder with cast-iron, the chairs in both

cases to be of cast-iron. [12] By the 8th July

1823, the Belington Ironworks had delivered 900 tons of malleable

iron rails, [13] while the Neath Abbey Company

supplied 243 tons of cast-iron rails, chairs, and crossing plates. [14]

The sleepers posed a similar problem to the rails ― uncertainty. At

the outset there was a considerable discussion as to

whether stone blocks or wooden sleepers were more suitable for the

permanent way. Eventually the Committee decided to try both, the

stone being sourced from local quarries at Brusselton and timber

shipped to the Tees from Portsmouth, where it had been recovered

from scrapped wooden-wall warships. In time it was realised that

stone sleepers were too unyielding for the weight of the new

locomotives, causing damage to the iron rails, and both they and the

wooden blocks were replaced by more compliant transverse wooden

sleepers. The redundant stone blocks served out their days as

edgings to the platforms of stations, and in the seawall and slipway

at Saltburn-by-the-Sea (a partly successful speculative development

carried out by Edward Pease’s youngest son, Henry) where they can

still be seen, the fastening holes for the iron chairs being plainly

visible.

CHAPTER

4

――――♦―――― |

|

APPENDIX I.

LOSH AND STEPHENSON’S PATENT

from:

Patents for Inventions.

Abridgements of Specifications Relating to Railways,

(1868).

A.D. 1816, September 30. ― No. 4067.

LOSH, William, and STEPHENSON,

George. ― “Improvements in the construction of railways and

tramways.”*

“The invention relates to edge round-top’d fish-backed, plate

tramway, and barrow-way plate rails. In the construction of our edge

railways our objects are, to fix both the ends of rails, or separate

pieces of which the ways are formed, unmoveable in or upon the

chairs or props by which they are supported, and to place them in

such a manner that the end of any rail shall not project above or

fall below the corresponding end of that with which it is in

contact, or with which it is joined; also to form the joinings of

the rails with the pedestals or props which support them in such a

manner that if these props should vary from their perpendicular

position in the line of the way the joinings of the rails with each

other would remain as before such variation, and so that the rails

shall bear upon the props as firmly as before. The formation of the

rails or plates, of which a plate railway consists, being different

from the rails of which the edge railways are composed, we are

obliged to adopt a different manner of joining them, both with each

other and with the props and sleepers on which they rest; but in the

joining these rails or plates upon their chairs and sleepers we fix

them down unmoveable, and in such a manner that the end of one rail

or plate does not project above or fall below the end of the

adjoining plate, so as to present an obstacle or cause a shock to

the wheels of the carriages which pass over them; and we also form

the joinings of these rails or plates in such a manner as to prevent

the possibility of the nails which are employed in fixing them in

their chairs from starting out of their places from the vibration of

the plates, or from other causes.”

The patentees also describe improvements in the construction of

railway wheels and locomotive engines.

___________

* “A grant unto William Losh, of the town and county of

Newcastle-upon-Tyne, iron founder, and George Stephenson, of

Killingworth, in the county of Northumberland, engineer, for their

invented new method or new methods of facilitating the conveyance of

carriages, and all manner of goods and materials along railways and

tram-ways, by certain inventions and improvements in the

construction of the machine, carriages, carriage wheels, railways

and tram-ways employed for that purpose ― 30th September, 1816,

Patent Record Office, No 4067.”

Engineers and Mechanics Encyclopedia 1839.

Because the base of the chair is not flat, but forms an arch, should

the sleeper tilt, as shown in the diagram, the rail remains

tangential to the arch. It is further prevented from protruding by

being fixed to its neighbour by a half-lap joint.

――――♦―――― |

|

APPENDIX II.

JOHN BIRKINSHAW’S PATENT

from

The Engineer’s and Mechanic’s Encyclopedia

Luke Hebert (1836).

Specification of the Patent granted to JOHN BIRKINSHAW,

of Bedlington Iron-Works in the County of Durham; for an Improvement

in the Construction of malleable Iron Rails, to be used in Rail

Roads, whereby the Cost is reduced, and the Expense of Repairs of

broken Rails saved. Dated October 23, 1820.

“My invention consists in the adaptation of wrought or malleable

iron bars or rails of a peculiar form, instead of cast-iron rails,

as heretofore. From the brittle nature of cast-iron, it has been

found, by experience, necessary to make the bars of a railroad

sufficiently strong to bear at least six times the weight intended

to be carried along the road, by which the original cost of a

railroad was considerably augmented; or if light rails were used,

the necessity of frequently repairing entailed a heavy expense upon

the proprietors.

To obviate these objections, I have invented a bar to be made of

wrought, or malleable iron, the original cost of which will be less

than the ordinary cast-iron rails or bars, and, at the same time,

will be found to require little (if any) reparation in the course of

many years. The rails or bars which I have invented are formed as

prisms, though their sides need not of necessity be flat. Figs. 1

and 2 show sections of the bar thus formed; the upper surface upon

which the wheel of the carriage is to run is slightly convex, in

order to reduce the friction; and the under part rests in the

supporting-blocks, chairs, rests, standards, or pedestals, which are

mounted upon the sleepers. The wedge-form is proposed, because the

strengths of the rail is always in proportion to the square of its

breadth and depth. Hence this form possesses all the strength of a

cube equal to its square, with only half the quantity of metal, and,

consequently, half the cost. Sufficient strength, however, may be

still retained, and the weight of metal further reduced, by forming

the bars with concave sides, as shown in section, by Figs. 3 and 4. The mode of making iron bars of a great variety of forms, we have

already generally explained in our account of the iron manufacture.”

――――♦―――― |

|

FOOTNOTES |

|

1. |

‘Hammer blow’ refers to

the vertical forces transferred to the track by a locomotive’s

driving wheels. Although most is due to the unbalanced reciprocating

motion, which in slow-moving early locomotives would not have been

significant, the piston thrusts also contribute to it. The result is

that rails are subjected to an intense and regular pounding, which

can cause damage. |

|

2. |

There is some dispute

over the invention of cast-iron rails. They are generally credited

to John Curr, being first used underground in mines at Sheffield c.

1776, only later being used overground. Another claim is that

cast-iron rails were used at Coalbrookdale c.1768. |

|

3. |

“The

cast-iron waggon wheel was really a north-country invention. As

early as may, 1731, Elias Thornhill of Sunderland, whitesmith,

obtained a grant of a patent for ’his new invention of making the

rim or edge of coal waggon wheels with iron or steel and with iron

ribs or tabbs and iron bolts, rivets, and screws for the fastening

the same.’ (Archaeologia Aeliana, vol. xxiv., p. 226)”

The North Eastern Railway,

William Weaver Tomlinson (1915). |

|

4. |

Commenting on the

Dowlais-Merthyr railway, William Taitt of Dowlais wrote on 17th

March 1791:

“We are now making Rails for

our own Waggon way which weigh 44 li or 45 li [pounds]

per yard. The Rails are 6 feet long, 3 pin

holes in them, mitred at the ends, 3 Inches broad Bottom, 2½ In. top

& near 2 In. thick . . . .”

The rails were spiked to

transverse wooden sleepers. |

|

5. |

The Pen-y-Darren

tramroad was a single track plateway with a gauge of 4 feet 4 inches over

the flanges of the L-shaped cast-iron plate rails, or 4 feet 2 inches

between the inside of the flanges. The plates were 3 feet long,

weighed 56 pounds each, and were spiked to rough stone blocks about 18

inches square. |

|

6. |

Most writers on this

subject credit Jessop with the first use of the iron edge rail, but

flanged wheels on wooden rails were in use in the North East of

England well before:

“The flanged cast-iron wheel had been used in the North of England

for half a century before Jessop introduced the iron edge rail, and

was not only mentioned by Bishop Pococke in 1760, but described and

illustrated in 1765 by Monsieur Jars, who actually gives the depth

of the flange, viz., from an inch to an inch and a half (Voyages

Métallurgiques, vol i., p.202). . . . The flanged waggon wheels had

merely to be transferred from the wooden to the iron rails when the

latter were laid down.”

The North Eastern Railway,

William Weaver Tomlinson (1915). |

|

7. |

Following Outram’s

death in 1805, ‘Benjamin Outram and Company’ was rename the

‘Butterley Company’, and continued trading (as an engineering

company) until 2009. |

|

8. |

Malleable iron is a

form of cast-iron that is easier to work with than pure iron. It is

made by melting scrap steel and pig iron and then carefully

controlling the cooling of the mixture over many hours. This results

in an iron that is very tough but not brittle. |

|

9. |

In metallurgy: work

hardening is the increase in hardness of a metal induced,

deliberately or accidentally, by hammering, rolling, drawing, or

other physical processes. |

|

10. |

“One

point, however, deserves particular notice here, as likely to be

attended with the most important advantage to the railway system,

which is the application of malleable iron instead of cast-iron

rails. Three miles and a half of this description of railway have

been in use for about eight years on Lord Carlisle’s works, at

Tindal Fell, in Cumberland, where there are also two miles of

cast-iron rail; but the malleable iron road is found to answer better in

every respect. Experiments with malleable iron rails have also been

made at Mr. Taylor’s Works, at Ayr, and Sir John Hope’s at Pinkie;

and, upon the whole, this method, as in the case of the Tindal Fell

Railway, is not only considerably cheaper in the first cost than the

cast-iron railway, but is also much less liable to accident. In the

use of malleable iron bars, the joints of the railway are

conveniently obtained about twelve feet apart, and three pedestals

are generally between each pair of joints.”

Report of a Proposed Railway from

the Coal-field of Mid-Lothian to the City of Edinburgh p.26

(1818). |

|

11. |

Soon to enter

partnership with the Stephensons in the Newcastle locomotive

manufacturing firm of Robert Stephenson & Company. |

|

12. |

George Stephenson to

William James, postmarked 20th December, 1821:

"With respect to the Stockton and

Darlington Railway Company advertising for cast-iron rails, it was

merely to please a few of the subscribers who have been brought over

by some of the cast-iron founders, but they have only advertised for

one-third to be cast-iron."

The Two James’s and the Two Stephensons ( 1861) p. 48. |

|

13. |

“The specifications for the malleable iron rails prescribed that

they should be fifty-six pounds per double yard; that the breadth of

the top of the rail should be two and one-fourth inches, and the

depth at the end two inches; that the depth at the middle should be

three and one-fourth inches; that the depth at the top flange should

be three-quarters of an inch; that the thickness of the web at the

top should be three-quarters of an inch; that the thickness of the

web at the bottom should be half an inch; that the edge should be

rounded and the surface flat; that the rails should be perfectly

straight, and fit to the chairs accurately; and that a sample rail

and chair, or patterns thereof, should be furnished to the company.”

A History of the Stockton and

Darlington Railway, J. S. Jeans (1875). |

|

14. |

“The weight and dimensions prescribed for the cast-iron rails and

accessory chairs were as follow:― ‘The length of each rail to be 4

feet, cast from good pig-iron; the weight per double yard to be 115

lbs.; the weight of the chairs to be 10 lbs. each, or 15 lbs. per

double yard; the breadth at the top of the rail to be 2¼ inches; the

depth at the end to be 4 inches; the depth at the middle to be 6

inches; the depth of the top flange to be 1 inch; the thickness of

the web at the top to be five-eighths of an inch.’”

A History of the Stockton

and Darlington Railway, J. S. Jeans (1875). |

――――♦――――

|