|

NOTES AND

EXTRACTS

ON THE HISTORY OF THE

LONDON & BIRMINGHAM RAILWAY

CHAPTER 5

EASING THE GRADIENT

|

|

THE RULING GRADIENT

“There is scarcely a portion of this line, from one

end to other, which is not either carried by embankment

above the general surface of the country, or sunk below

it by means of excavation. It has, indeed, in point of

execution, been one of the most difficult works of the

kind in the kingdom. London clay, disrupted chalk, and

running sands, sadly impeded the progress of the works;

yet such is the perseverance of man, when he sets about

a work in earnest, that all the formidable difficulties

which sprang up in quick succession, and for awhile

seemed to arrest the progress of the works, have been

very creditably surmounted, and now is in full enjoyment

of the benefits of this vast undertaking.”

The Railways of Great Britain and

Ireland, Francis Whishaw

(1842).

In the age in which the London and Birmingham Railway was built,

civil engineers went to some lengths to reduce the natural gradient

of the land to a level, or at least a gently sloping surface on

which to lay their track. Their aim was to minimise the reduction

imposed by gravity on the limited tractive ability of the

locomotives then available, for the steeper the incline the greater

is the amount of effort wasted by a locomotive in overcoming gravity. George Stephenson had devoted much research to the subject:

“He had long before ascertained, by careful experiments at

Killingworth, that the engine expends half its power in overcoming a

rising gradient of 1 in 260, which is about 20 feet in the mile; and

that when the gradient is so steep as 1 in 100, not less than three

fourths of its power is sacrificed in ascending the acclivity. He

never forgot the valuable practical lessons taught him by these

early trials, which he had made and registered long before the

advantages of railways had become recognized. He saw clearly that

the longer flat line must eventually prove superior to the shorter

line of steep gradients as respected its paying qualities. He urged

that, after all, the power of the locomotive was but limited; and,

although he and his son had done more than any other men to increase

its working capacity, it provoked him to find that every improvement

made in it was neutralized by the steep gradients which the new

school of engineers were setting it to overcome.”

The Life of George Stephenson and of his Son,

Samuel Smiles (1862).

A firm believer in his father’s dictum, when Robert Stephenson

surveyed the route for the London and Birmingham Railway he set

himself a ruling gradient [1] of 1:330,

or approximately 16 feet in the mile. This he considered to be the maximum that a locomotive could manage

while hauling a useful load at speed. To the extent that his belief

was correct, engineering advances soon resulted in locomotives

capable of handling steeper gradients, but by then the deed was

done. The London and Birmingham Railway was thus built on easy

gradients conducive to high speed running, but at the expense of

considerable civil engineering work in the form of cuttings,

embankments, bridges, viaducts and tunnels. [2]

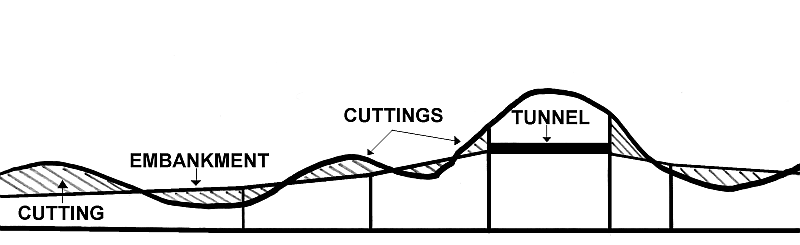

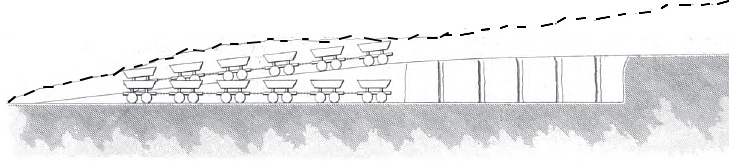

Reducing the gradient.

Cut and fill ― the spoil from excavations is used to form

nearby embankments. |

――――♦――――

|

CUT AND FILL

Most of the civil engineering necessary to achieve Stephenson’s

ruling gradient involved forming embankments and excavating

cuttings ― embankments to raise the level of the line above that

of the surrounding land, cuttings to lower it.

Where possible, the approach taken to the construction of both was that of ‘cut and fill’,

which involved transferring

the spoil excavated from a cutting to a nearby location where it

was required to form an embankment. This avoided the need to

buy extra land from which to obtain the material to form an

embankment, [3] and the builder was not left with the task of having to dispose

of the spoil from a cutting by spreading it over the adjacent land

in what were known as ‘spoil banks’.

To create a spoil bank, the Company first needed to agree

compensation terms with the landowner. The topsoil was then

removed from a tract of land adjacent to the work and the spoil

spread over it. When this operation was complete, the topsoil

was replaced over the spoil to restore

the land’s fertility. In his guide to the Railway, Freeling describes one such operation, which

took place about a mile and a half to the south of the Colne

Embankment near Watford:

“Pinner Park House just to the left of the line . . . . About 150

yards before this post, [13¼ miles] there is a large spoil bank to

the left; this is formed from the ballast taken from the

excavations. Before this is placed on the land, the soil is

carefully removed; the ballast is then laid down over the space, and

the soil placed thereon, which will produce crops the same year.”

The Railway Companion, from London to Birmingham,

Arthur Feeling (1838).

The excavation referred to was of Oxhey cutting, most of the spoil

from which was used to form the southern section of the Colne

Embankment (that used to form the northern section being taken from

the deep approach cutting to the south of Watford Tunnel):

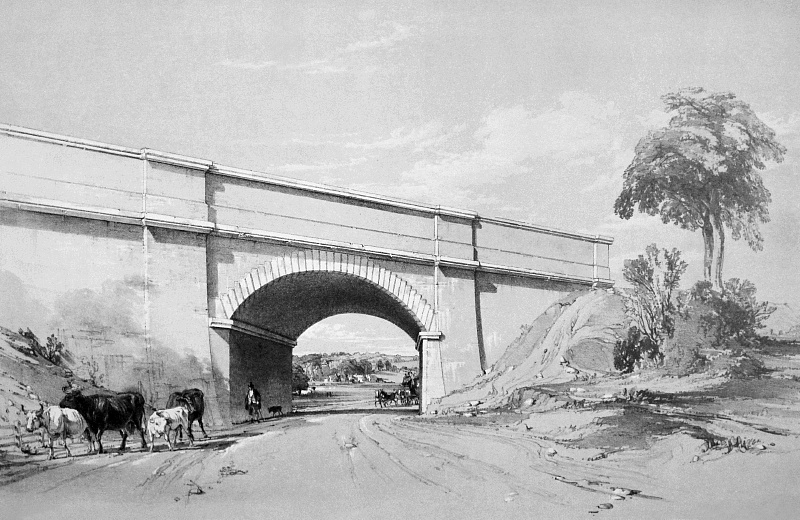

“It took nearly one million cubic yards of earth to make this

embankment, which is in some places above forty feet in height, and

is the largest throughout the whole line. Soon after entering upon

it the Railway goes over the London road, by a brick viaduct of five

arches, of forty three feet span each; they are composed of

ellipses, having voussoirs at the intrados; the centre arch is of an

oblique form, [“skewed”]

in order that the course of the road should be preserved as

heretofore . . . . The next bridge conveys the Railway over the

river Colne. It consists of five semicircular brick arches of

thirty feet span each, with side walls, and having a stone cornice

its whole length, ― the total length of the parapet walls being 312

feet. It has a light appearance; and viewed from the meadows

appears very lofty, being fifty feet high.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

Thus, the valley of the Colne was crossed by a combination of

viaducts and embankment, the latter being formed from spoil obtained

from nearby cuttings ― the principle of cut and fill. |

――――♦――――

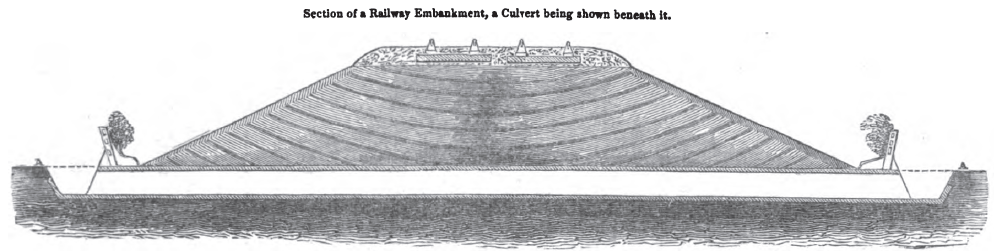

FORMING EMBANKMENTS

Note the inward-sloping layers.

|

The two approaches to forming an embankment were essentially

bottom-up and top-down.

The bottom-up approach involved forming the full width of the

embankment in shallow layers, a few feet thick, each layer being

laid slightly inward-sloping [4] and compacted before the next layer

was put down. According to a respected civil engineering manual of

the period, this produced a firm formation:

“The most expensive course is that of forming the bank in shallow

layers, running out each of them to the full length of the work, and

following with the upper layers after each lower one is completed. By allowing each layer to settle . . . . before the next is formed,

and, moreover, using beetles in ramming the earth down, an

embankment will be formed of the greatest possible density and

stability . . . . Both in embankments and excavations, the slopes

should be dressed to the intended face, as shortly as possible after

the formation is completed, and covered with turf, if possible, or

at least with soil sown with grass-seed.”

The

Practical Railway Engineer, G. D. Dempsey

(1847).

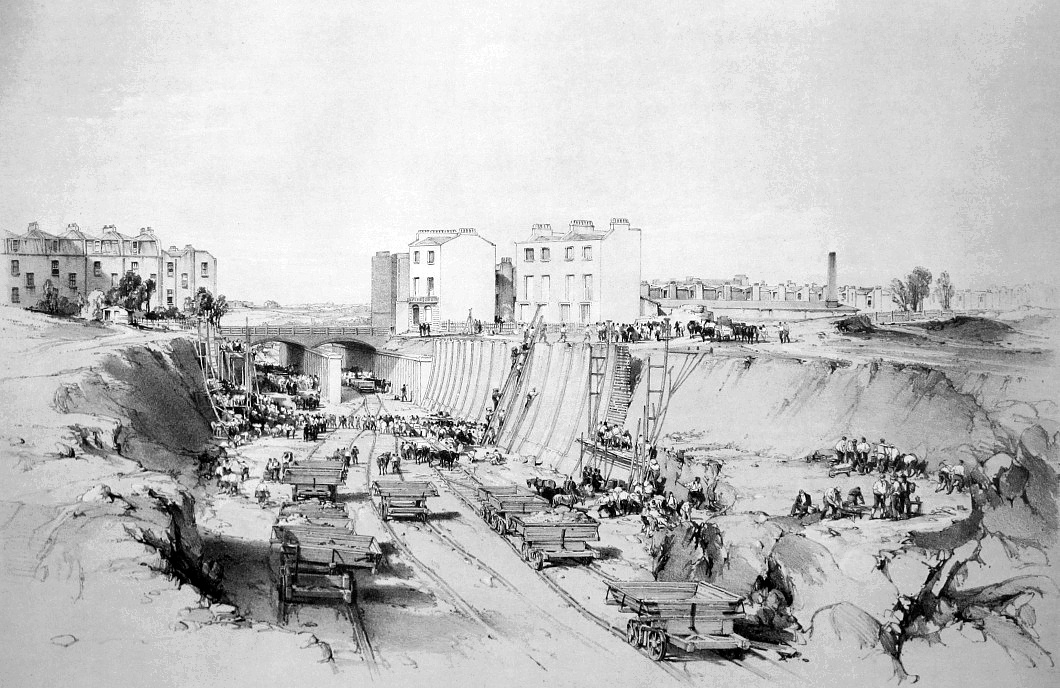

The turf or grass-seed helped to consolidate the slopes. |

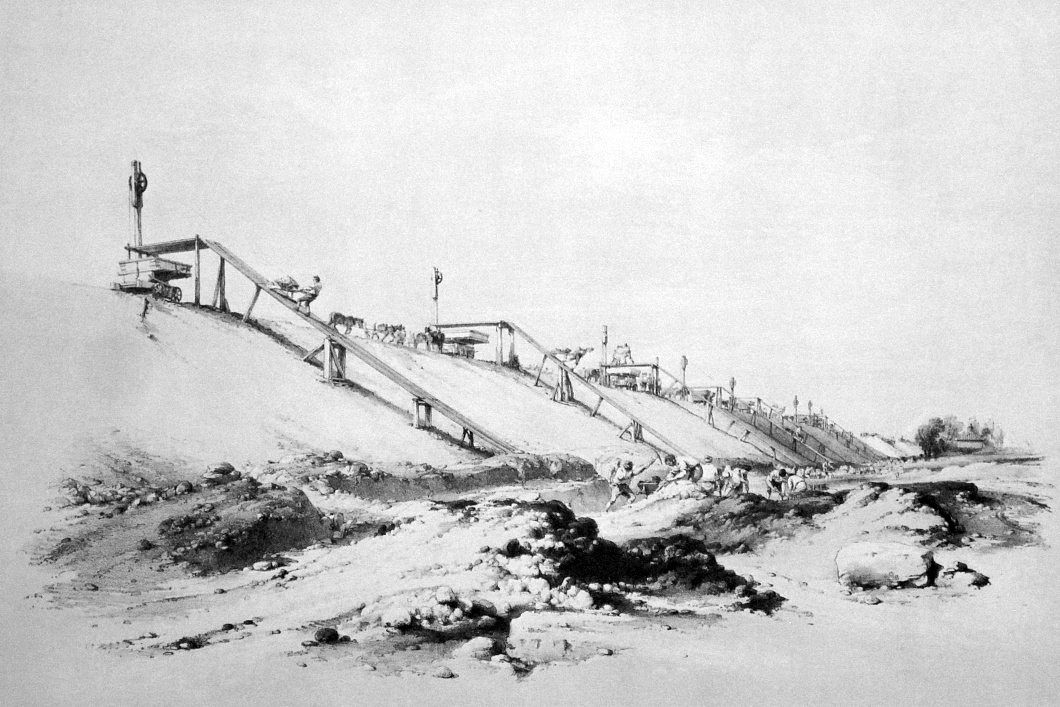

Forming the

Boxmoor Embankment bottom-up.

View of the Boxmoor embankment, when in progress,

shewing the method of forming it, from a side cutting, with horse-runs.

John Cooke Bourne, June, 1837.

|

The Boxmoor embankment (above) near Hemel Hempstead was formed in this

way, the spoil being lifted up the side of the embankment in a hazardous procedure involving ‘horse-runs’:

“Over Boxmoor the railway is continued on an embankment, formed

with materials conveyed from adjacent cuttings. The ballasting, &c.,

was raised from the surface on each side of the line by horse-runs,

as shown in the drawing, No. XVII. [above] The horse, in moving along the

top of the embankment, draws the rope attached to a wheelbarrow

round two pulleys, and thereby raises the barrow of earth up the

sloping board, together with the labourer who holds and guides it. This is a dangerous occupation, for the man rather hangs to, than

supports the barrow, which is rendered unmanageable by the least

irregularity in the horse’s motion. If he finds himself unable to

govern it, he endeavours, by a sudden jerk, to raise himself erect;

then, throwing the barrow over one side of the board, or ‘run’, he

swings himself round and runs down the other. Should both fall on

the same side, his best speed is necessary to escape the barrow,

which, with its contents, comes bounding down after him.”

Introduction to Drawings of the London &

Birmingham Railway, John Britton (1839).

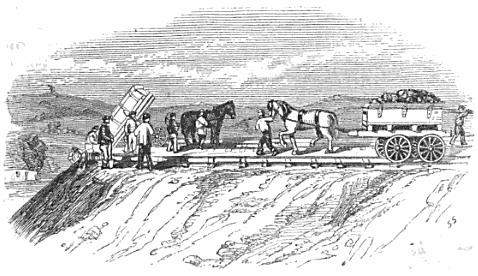

The top-down method of forming an embankment was generally preferred

because it was quicker. It involved extending the formation

gradually, at its full height, from both ends. The spoil from a

nearby excavation was conveyed to the workings along a light railway

in what today might be referred to as tipper trucks, but were then

called ’earth wagons’. Each wagon was then run up against a

buffer placed at the end of the workings, the momentum causing the

wagon’s tray, which was pivoted, to

swivel upright, tipping its contents over the edge.

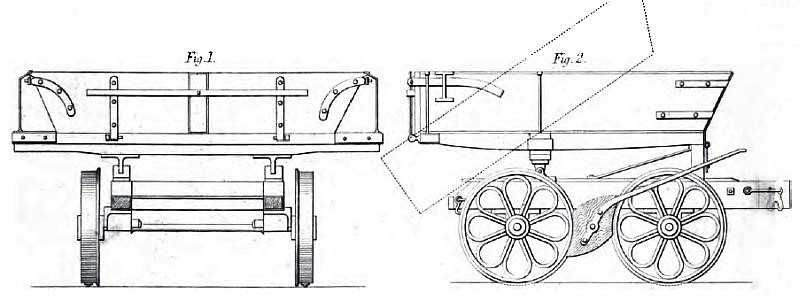

Earth wagons.

However, before the formation of an embankment could commence, the

earth wagons had first to be assembled, a task that Francis Conder

described in his memoirs:

“In a country town [Watford] where almost everyone knows

as much, or more, about his neighbours business as about his own,

the arrival and establishment of two civil engineers was accepted as

an outward and visible sign that, for good or for evil ,the great

railway experiment was about actually to be made. Before long, one

or two keen-visaged, weather beaten Yorkshire and Northumberland

men, neither graziers nor farmers, nor mechanics, but seeming to

possess some resemblance to each of these active classes, found

means of establishing themselves in roomy farm-houses, where the

rick-yard soon began to assume the appearance of a carpenter’s yard. Then men set to work in a field very near the mail coach road, where

the hill dropped rapidly to the valley, in constructing waggons of a

form utterly inconceivable either to a farmer or to a carrier. Cast

iron wheels, formed with the flange which is now so familiar to

every loiterer at a railway station, but which was then an

unexplained puzzle to most folk, were firmly keyed on to solid

axles; a ponderous oak framework was fixed on the axles, and a

special provision was introduced, for tilting up the large shallow

tray which rested on that framework. A stout, hale, well-humoured Yorshireman stood or sat in this field from early morning till

sunset, and inspected the progress of the waggon with a

never-flagging interest. People came to stare at him as much as at

his labourers.”

Personal Recollections of English Engineers,

F. R. Conder (1868).

The Yorkshireman with the never-flagging interest was possibly James

Copeland, contractor for the Watford to Kings Langley section, which

included the long Watford tunnel (and its deep cuttings at both approaches) and the Hunton

Bridge embankment. However,

writing in the Biographical Dictionary of Civil Engineers,

Mike Chrimes suggests John Willans Nowell, contractor for the Harrow section.

When the earth wagons had been assembled, work on the embankment

could begin. By this date horses were being replaced by

contractors’ locomotives, especially where there was a considerable

distance ― ‘the lead’ ― between the excavations where the spoil

was to be obtained, and the embankment where it was to be deposited. At

some point along the embankment workings, the track on which the

earth wagons ran would be fanned out through a system of points, to

four or even six lines, to enable tipping to take place across the

full width of the embankment. Robert Rawlinson, assistant engineer

for the Blisworth section (and later a sub-contractor), described

tipping spoil over the end of a forming embankment, a dangerous

practice known as ‘teeming’:

|

|

|

The tip. |

“The ‘tip’ is the place where the material is teemed over to form

the embankment; the tip is a removable point in a long embankment;

the extreme end of the embankment; and in a heavy embankment, such

as the Blisworth, at least 40 or 50 feet in height, it was a most

difficult operation, with the material they had to work, to keep

these tips at their ordinary level. To do so they were constantly

obliged to raise the levels, and run up hill a portion of the line;

but supposing they had got the ‘tip’ 10 feet high in the morning,

perhaps tomorrow morning they would find it 15 feet below the proper

level . . . . Subsided or slurred out at the sides. To do this work,

the rails are laid in long shunts; there are five or six lines of

railway at the tip-head, branching out of the two lines leading to

it. To run the waggons onto these shunts (sometimes the engine would

be on a road that was partially formed), the train of waggons

attached by a long chain 30 yards behind the engine; a velocity was

given to the engine and communicated to the waggons, and the engine

was then suddenly stopped, and a pair of points turned behind it,

and the waggons were then run in forward, that they might be tipped

into the embankment. Horses were employed to run the separate

waggons down to the tip-head, and when the end of the embankment was

raised above its level, they would take a short run for the horse to

get the waggon into motion and give it momentum, so as to carry it

on to the tip-head; and sometimes waggon, horse, men and all would

go over . . . .”

Robert Rawlinson ― Select Committee on Railway Labour

(1846). |

――――♦――――

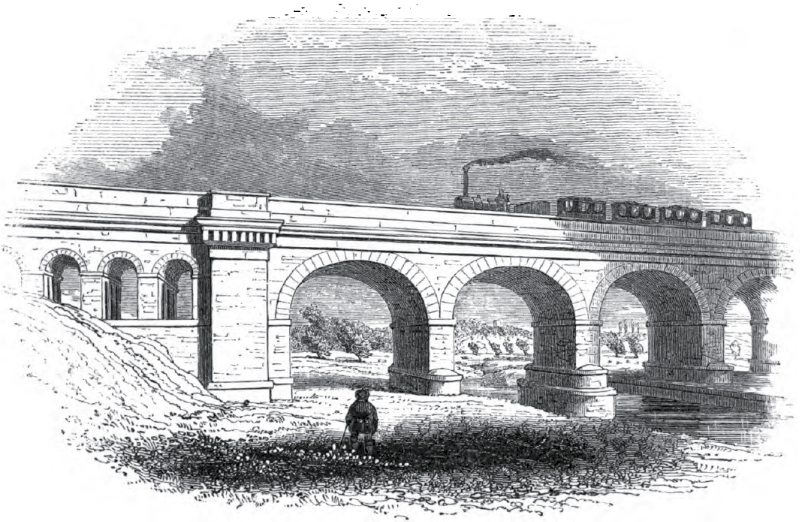

EXCAVATING CUTTINGS

Contractor’s locomotive hauling a train of

earth wagons in a cutting near Berkhamsted.

View of a cutting and bridge near Berkhamstead

(sic.), looking N.W.: shewing part of the town.

John Cooke Bourne, June 1837.

|

Building the London and Birmingham Railway involved upwards of 12 million cubic

yards of excavation, or over 100,000 cubic yards of earthwork per mile. The

heaviest cutting on the line is at Tring ― 2½ miles long, averaging

40 feet deep, the greatest depth being 60 ― from which something

over 1,400,000 cubic yards (approx 1.1 cubic metres) of spoil were

removed.

In some respects the approaches to excavating a cutting were

similar to those for forming an embankment.

One was to barrow the spoil out of the workings with the

use of horse-runs (described above), as is depicted in J. C.

Bourne’s famous drawing of the Tring Cutting excavation (below). The advantage of using horse-runs was that many

teams of labourers could be put to work simultaneously along the

full length of the cutting, rather than being restricted to working inwards from

the two

extremities:

“Although there were thirty to forty horse-runs in the Tring

cutting constantly working, during many months, and each labourer

was precipitated down the slope several times; such, from continual

practice, was their sure-footedness, that only one fatal accident

occurred. A moving platform was invented by the engineer to

supersede the necessity of thus risking life and limb, but the

workmen, who considered it was designed to lessen their labour and

wages, broke it.”

Introduction to Drawings of the London &

Birmingham Railway, John Britton (1839).

This

method was most useful in circumstances where the spoil was not to

be carried away, but consigned to adjacent spoil pits, although at

Tring, part of the spoil excavated probably went into

forming the 6-mile long embankment to the north of the cutting. |

Excavating the Tring

Cutting.

View of the deep cutting near Tring, with horse-runs, &c. John Cooks Bourne, June 1837.

|

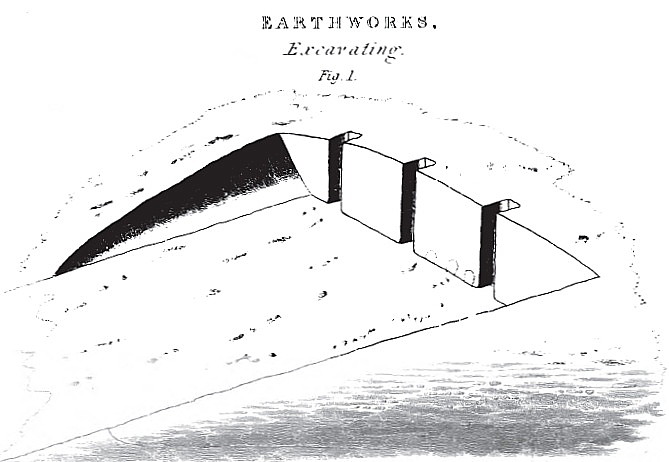

The alternative approach was to excavate from a cutting’s

extremities and convey the spoil away in trains of earth wagons.

This involved first creating a working faces at each end of the

section of rising ground through which the cutting was to be driven.

A trench or ‘gullet’ was then cut into the face of sufficient

breadth to accommodate a railway and train of earth wagons. Excavation then took place

at each side of the gullet, the spoil

being tipped into the waiting earth wagons below:

“In starting an excavation through a hill of considerable height,

it is desirable to get a fair face to the work, that is, one at

right angles with the direction of the cutting; and from this face

to start a system of gulleting or notching, by which labour is much

economised . . . . As the work proceeds into the hill, and the width

is increased to provide for the slopes, it becomes desirable to run

a ‘gullet’ along the centre of the cutting, in order to bring the

greatest number of [earth] waggons into use. Thus the temporary

rails being laid in the gullet, a train of waggons is sent forward

these receive all the produce of the harrowing on either side, which

is advantageously prosecuted in advance and alongside of the waggon-filling,

for the purpose of keeping the work level for starting the next

stage or layer of excavation.”

The Practical Railway Engineer,

G. D. Dempsey (1855). |

|

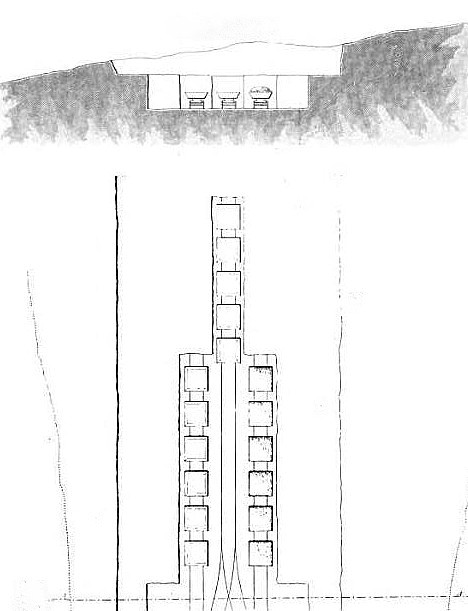

Above: excavating a cutting. A face is formed, then

one or more gullets are driven into it of sufficient width to

accommodate a train of earth wagons. The gullets are driven

forward as the work proceeds.

Below: this scheme in section and in plan as the gullets

are driven forward, showing the trains of earth wagons. Spoil

was shovelled or barrowed down into the wagons from both sides of

the cutting, which is gradually widened out:

“By the aid of the gullet the wagons can be brought close

alongside the material to be moved, and a couple of men being set at

work on each, the soil is deposited in them with an ease and

celerity far surpassing that which would be required had each spadeful to be conveyed even for the distance of a few yards. Meanwhile, as the stuff is removed by the workmen on either hand,

the gullet is continued into the hill by those a-head, while lumps

are showered into the wagons on all sides.”

Our Iron Roads,

Frederick Smeeton Williams (1852). |

|

|

|

|

|

Excavating at two levels: excavation was performed in layers.

As one layer was completed,

another was started at a lower level until the required depth was

reached. |

Excavating a

railway cutting.

Excavation at Park Village, showing the works in

progress. John Cooke Bourne, September 1836.

――――♦――――

|

INSTABILITY

IN CUTTINGS AND EMBANKMENTS

In the sense in which it is used here, instability refers to the

failure of earthworks resulting in slip:

“SLIP, or LAND-SLIP

― a slipping of the earth of a cutting, or embankment, which most

frequently occurs in the case of deep cuttings and high embankments;

they generally arise from the want of stability of the soil, and

general badness of foundation, also from the side-slopes being

formed too steep; but clayey soil will slip at almost any slope,

good drainage is, therefore, important in earthwork.”

A

Glossary of Civil Engineering, S. C. Brees (1841)

Slip was a problem that occurred at a number of points along the

Railway, sometimes several years after the earthwork in question had

been completed, this being referred to as ‘delayed slip’.

One cause of slip resulted from building the slopes of embankments

and cuttings at a steeper angle than that at which the material in

question would lie naturally at rest without slipping, its ‘angle of

repose’. But the steepness of a slope is not a straightforward

question to decide, for the angle of repose not only varies for

different materials, but can also be affected by the amount of

moisture they contain. For instance, a wall of damp sand can be

built almost vertical (as those who have seen the work of seaside

sand artists will appreciate); a pile of sand, when wet, will lie at

45º to the horizontal; when dry, at 34º; but when saturated, the

angle of repose reduces to as little as 15º. Sir Henry Parnell’s

much respected treatise on roads (based on the work of Thomas

Telford) offered this advice on the slope of cuttings and

embankments, and on the need for consolidation:

“When it is necessary to make a deep cutting through a hill, the

slopes of the banks should never be less, except in passing through

stone, than two feet horizontal to one foot perpendicular; for

though several kinds of earth will stand at steeper inclinations, a

slope of two to one is necessary for admitting the sun and wind to

reach the road. The whole of the green sod and fertile soil on the

surface of the land cut through should be carefully collected and

reserved, in order to be laid on the slopes immediately after they

are formed. If a sufficient quantity of sods cannot be procured in

the space required for the road, the slopes should be covered with

three or four inches of the surface mould, and hay seeds should be

sown on it; by this plan the slopes will soon be covered with grass,

which will be a great means of preventing them from slipping.”

A Treatise on Roads, Sir

Henry Parnell (1833).

Before the first London and Birmingham Railway Bill was placed

before Parliament in 1832, the Company commissioned two experienced

civil engineers to review Stephenson’s plans for the line; they were

Henry Palmer (1795-1844) and John Urpeth Rastick (1780-1856). At the

committee stage in the House of Lords, both engineers gave evidence,

in the course of which they expressed their opinions on the angles that

Stephenson planned for his slopes. Of the two, Rastick’s views are

the more enlightening; while generally content with Stephenson’s

plans, as was Palmer, he felt that shallower slopes were advisable,

especially were banks were to be formed in London clay. But

shallower slopes meant wider structures, which in turn meant that more

land had to be bought and more material had to be

excavated:

“Regarding the slopes, generally speaking, I agree with Mr.

Stephenson; perhaps there are instances in which it may be prudent

to increase them. I made a calculation of them at 3 to 1, instead of

what they are stated at by Mr. Stephenson, which made an addition of

£17,303; but I should not be inclined to make them as much as 3 to

1, (I have not had experience in London clay). Where the cuttings

are shallow 2 to 1, or less, is quite sufficient, and there are few

cuttings of great importance along the line. Mr. Stephenson makes

his deep cuttings 2 to 1, and his shallow cuttings 1½ to 1. One of

the principal cuttings is at Primrose Hill, there is another, rather

deep, where he crosses the London Road to Harrow, perhaps it may be

necessary to increase these slopes to 2½ to 1, the expense of which

would be under £5,000. In works of this nature slips will occur,

even in the best material.”

John Rastrick, from Railway Practice, S. C.

Brees (1839).

Speaking some years later about the construction of the Colne Valley

embankment, the Resident Engineer, G. W. Buck, informed a

parliamentary committee [5] that this embankment had been made

shallower than the angle of repose for the spoil from which it was

formed:

“The Watford Embankment is at present about 32 feet high; the

Permanent Angle of the Slopes is 2 to 1; but the Natural Angle at

which the Soil will stand immediately after teaming (the Angle of

Repose) is about 1½ to 1, which enables us to make the Embankment

temporarily wider at the head (as it is called by the workmen) and

get in 6 Teaming Lines of Road: after the Line has passed that

particular point, the work is trimmed down to 2 to 1, as it is no

longer required.”

G. W. Buck, from Railway Practice, S. C. Brees

(1839).

On the face of it, using the spoil from a cutting to form an

embankment seems the sensible thing to do, but the material can

sometimes be unsuitable for the purpose. The great Wolverton

Embankment is an example. It was formed on the cut and fill

principle using, in part, Oxford clay excavated from a nearby

cutting, with serious consequences:

“In the formation of the embankment at Wolverton, great

difficulties were encountered . . . . The length of the embankment

being one mile and twenty eight chains (deducting the viaduct), and

the height of a great part of it forty eight feet, some accidents

were to be expected, especially in bad weather; but no one could

have imagined what would take place on the south side of the

viaduct. Here the material, at the commencement, was composed of

sand, gravel, and blue clay: this stood very well; but when the

workmen went deeper into the cutting, they excavated some black,

soapy clay; this was tipped on to a turf bottom, and the weather

being also very unfavourable, although every care was taken to mix

dry stuff with the wet material, yet there occurred one of the

worst, if not the worst slip, along the whole line. Earth was tipped

in for day and days, and not the slightest progress was made; as

fast, in fact, as it was tipped in at the top it kept bulging out at

the bottom, till it had run out from 160 to 170 feet from the top of

the embankment; and at last a temporary wooden bridge was formed,

and, by wagoning the earth over this, the embankment between the

slip and the viaduct was formed, by first digging a trench, five

feet deep, and nearly the whole width of the embankment, and forming

a mound on each side to prevent it from giving way.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

|

Forming the

Wolverton Embankment.

View of the embankment near Wolverton, during its

progress: shewing the manner of forming embankments, and an accidental slip of earth. John Cooke Bourne, June 1837.

|

Likewise, the banks of cuttings driven through some types of strata

also have a tendency to instability. Much difficulty was experienced

excavating the Blisworth cutting:

“In the case of the great Blisworth cutting the strata were

unequal in consistency. About halfway up the face of the cutting a

stratum of limestone rock, 25 feet in thickness, was found, with

loose strata below and above it, and it was necessary to prevent the

lower stratum, consisting of wet clay, from being forced out under superincumbent mass by undersetting. A rubble wall, averaging 20

feet in height, was built on each side underneath the rock,

strengthened by buttresses at intervals of 20 feet, resting on

inverted arches carried across underneath the line. A puddle-drain

was formed behind each wall, with a small drain through the wall to

let off the water from behind.

Fig. 13 is an elevation of the west end of the cutting where it is

about 40 feet deep, showing clearly the method of undersetting, and

fig. 14 is a cross section of the side walls at the same place,

where the left-hand shows a section of the wall in the water, and

the right-hand side shows the section through a buttress, together

with the invert and drains. One of the walls is shown in front

elevation in fig. 15.”

Encyclopedia Britannica

9th Edition (1902).

During the construction of the line, formations in clay gained a

notorious reputation, particularly when the material was poorly

compacted. In

some clays, the particles from which they are formed are loosely

packed, allowing water to enter the body of the structure, which then softens and weakens it.

Furthermore, when clay dries out, fissures

form within it that also allow the ingress of water, a problem that

civil

engineers of an earlier generation discovered when dealing with leakage

in canals. A further

complication ― if one were needed ― is that this softening process in clay embankments and cuttings does not necessarily happen quickly;

the ingress of water into a structure is sometimes slow, but progressive,

taking several years before it is sufficiently weakened for failure

to occur. Such a delayed slip

occurred in the Bugbrooke cutting (Upper Lias clay) in 1842, several

years after its completion:

“ACCIDENT ON THE LONDON AND

BIRMINGHAM RAILWAY.

― The following official report has been addressed to the Board of

Trade, on the subject of a slip at the Bugbrooke excavation on

Saturday last, by Mr. Creed, the indefatigable Secretary to the

Railway: ―

‘Sir, ― I am instructed to report to you for the information of the

Lords of the Committee of Privy Council for Trade, that in

consequence of a slip, about 50 yards in length, which occurred on

the down side of the Bugbrooke excavation of this railway half-way

between the Blisworth and Weedon stations, about four o-clock in the

afternoon of Saturday the 24th inst., several thousand cubic yards

of earth covered both lines of rails, and obstructed for a time the

regular passage of the trains.

By extraordinary exertions, however, the up line was cleared before

eight o’clock the same evening; and the up as well as down trains

have since continued to pass uninterruptedly over it. Both lines

will, it is expected, be clear in the course of this week.

The only practical inconvenience which resulted from this occurrence

(for it was happily unmarked by casualty), was the exchange of

passengers between the carriages of the York up train and the 1h

30min. p.m. down train on the opposite ends of the slip, and the

delay of rather less than two hours in the arrival of the two other

trains.

The surface of the ground, both above and on the face of the

excavation, had presented no previous appearance to indicate a slip;

but the attention of the overlooker of the road and engine-man of

the 9h. 45min. a.m. down train having been called to this point by a

slight deflection of the rails of the down line inwards, it was

carefully watched. The company’s engineer is desired to examine the

slip, and to report as to the immediate cause.

I have the pleasure to add, that the directors have every reason to

be satisfied with the strict observance of regulations, and the

zealous exertions which were manifested on this occasions by every

person in their employ.

I have the honour to be, Sir,

Your most obedient servant,

R. Creed, Secretary.’”

The Northampton Mercury,

1st October, 1842.

Extra precautions ― in the form of shallow slopes, counterforts [6]

and retaining walls ― had therefore to be taken when excavating and repairing

cuttings in clay soils, and good drainage was

essential.

Another cause of instability lies in the nature of the ground, which

might be too soft to support an embankment’s weight. Following its

completion, the long embankment across the Colne Valley suffered

slippage due to its foundation sinking:

“The whole of the land near this spot is most precarious in

stability; and the effects are clearly visible in the amazing

‘slips’ which have taken place in the embankment across the valley. Oftentimes, in a very few hours, the level of the newly-formed

ground has sunk several feet, while the base of the embankment has

widened out to an enormous extent, causing infinite labour to bring

the level of the Railway back again to its original state, and to

make it solid enough for the passage of the trains; this has caused

many a sleepless night to the workmen and engineers. The length of

this embankment is about a mile and a half, and is composed entirely

of the finest materials for such a purpose ― chalk and gravel.”

The London and Birmingham Railway,

Roscoe and Lecount (1839). |

――――♦――――

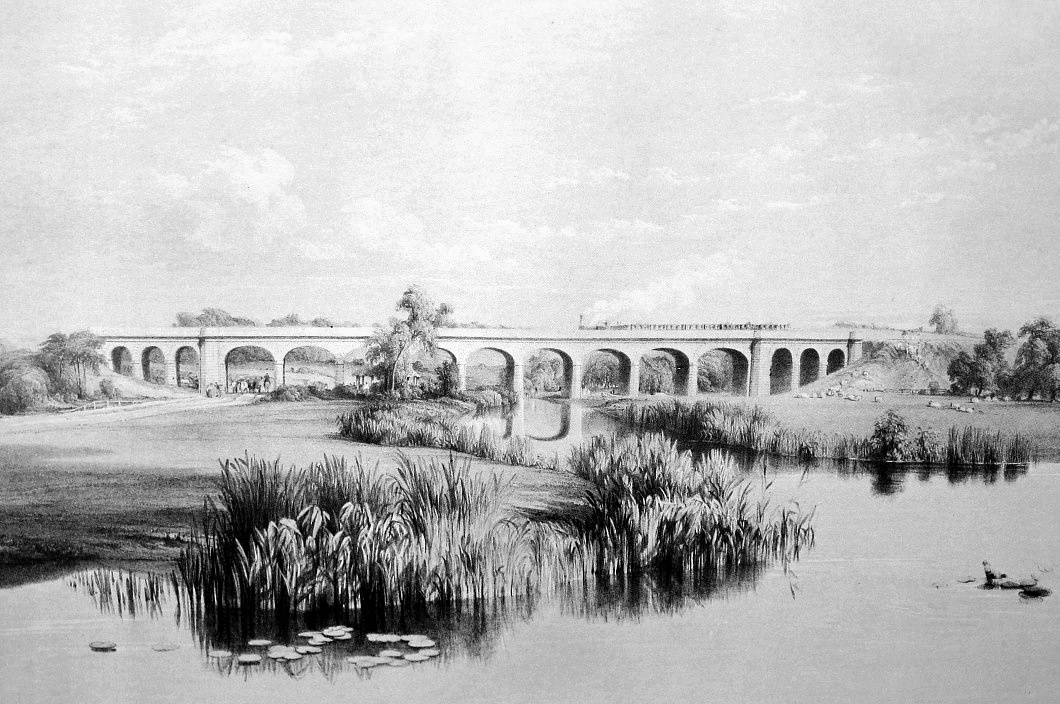

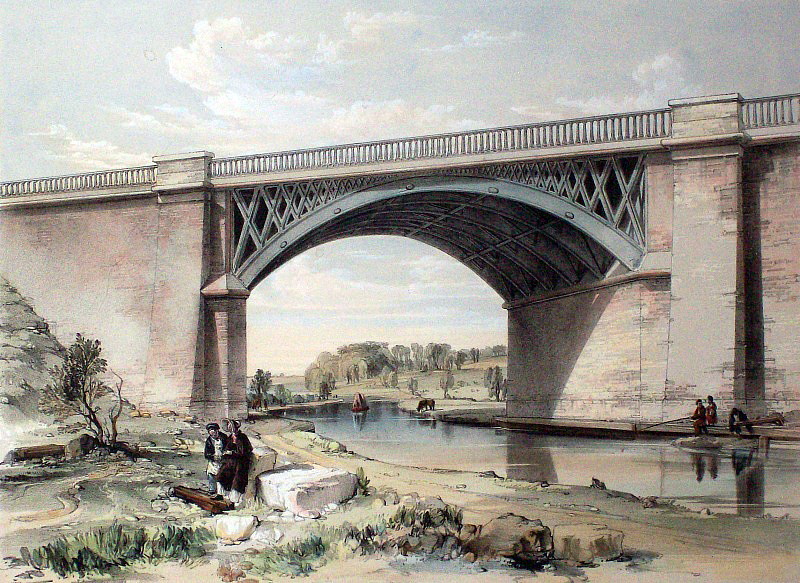

VIADUCTS

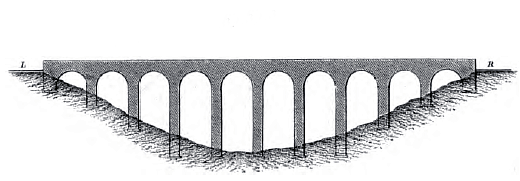

Wolverton Viaduct crossing the valley of the

Great Ouse.

|

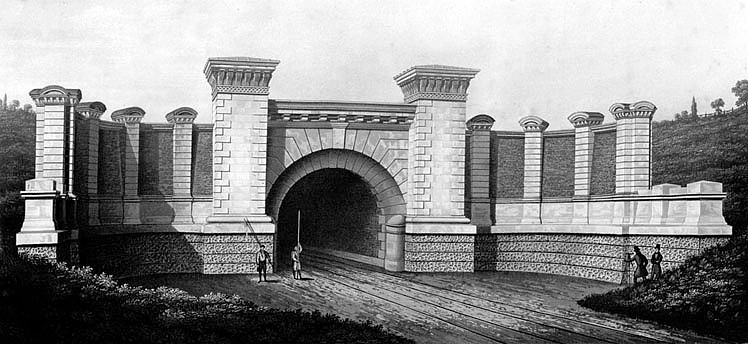

The following extract is from Stephenson’s specification for the Lawley Street viaduct. Its construction formed contract 1G, dated

August 1834, the contractor being James Nowell & Sons . . . .

“This Bridge or Viaduct, is for the purpose of carrying the

Railway on a perfectly level plane over Lawley Street, and the two

branches of the River Rea. It will consist of ten arches, each 50

feet span; the soffits of all the arches being brought to the same

horizontal line, at the height of 23 feet 6 inches, above the level

of the present surface of Lawley Street at its intersection with the

centre line of the Railway.

The Arch passing over Lawley Street will be built askew to suit the

angle of intersection of the street with the Railway, the remaining

nine to be built square.

The Direction of the bridge must be curved at a radius of one mile

and a quarter, so that the parapet walls shall be parallel with the

lines of Railway.

The Bridge must be built of brick with stone arch quoins

springing-course, string-course, plinth, and coping. Each front will

have two projecting pilasters, and the ends of the piers will

project from the face line of the arch in the manner shewn in the

Drawings No 1 and II.

All the Arches will be segments of circles and of similar form on

each front of the bridge . . . .”

From this it can be seen that a viaduct is a type of bridge composed of

multiple spans. In the case of the Lawley Street Viaduct it

was ten, the central span being

skewed (skewed bridges are described below).

In the context of a railway, viaducts were built to convey a line over an obstruction,

on the level (viz. para. 1 of the extract above). This might be a depression in the surrounding land, such as a river

valley; buildings in a built-up area of a town; or a major road,

especially where there was a considerable height difference

between road and rail. Some very considerable viaducts were built on

British railways, that at Ribblehead on the Settle and Carlisle line

being well known to railway enthusiasts . . . .

The former Midland Railway viaduct

spanning the valley of the River Ribble, North Yorkshire.

Photo:

chantrybee.

Viaducts often fulfil the same purpose as embankments, which had the general advantage in construction cost from being

able to utilise the spoil from nearby excavations. However . . . .

“. . . . as elevations are increased, embankments lose their

superiority over, and are soon superseded by, viaducts. This is

chiefly owing to the rapidity with which their sectional area is

increased as they become elevated, and the consequent large quantity

of land they require. These increasing effects are not experienced

in a viaduct.”

A Practical Treatise on the Construction and

Formation of Railways, James Day (1848).

But as the century progressed, the economic balance between

embankment and viaduct appears to have altered, to the

extent that viaducts became generally the cheaper option:

“During the development of the railway system in Britain, the

economy of bridge building has necessarily received much attention,

and has been illustrated by a multitude of structures, exhibiting

many varieties of design and of material. That this vast experience

has led to substantial improvements, and to saving in cost, may be

inferred from the fact, that in many cases bridges and viaducts of

great extent are now adopted in preference to mere earthworks, ― a

long viaduct being now available at less cost, original and current,

than an embankment of similar extent; whereas, in the early

experience of railway making, it is well remembered that the most

expensive earth-work was almost invariably adopted, both for economy

and ultimate sufficiency, in preference to any description, then

approved, of bridge work.”

The Practical Railway Engineer,

G. D. Dempsey (1855).

Viaducts were not necessary for bridging streams and minor roads,

which were crossed using a short bridge built into an embankment, or taken under

an embankment through a culvert or tunnel. However, where a crossing of significant

breadth was encountered, such as the Colne Valley (Watford) and the

valley of the Great Ouse (Wolverton), the practice on the London and

Birmingham Railway was to combine a viaduct with an embankment:

“Immediately after resuming our journey, we cross the Grand

Junction Canal by a handsome stone and iron bridge, and enter upon

the colossal embankment, which carries the [rail] road across the

Vale of Wolverton. At a short distance from the canal we cross the

rivers Ouse and Tow, by a handsome brick viaduct, whose magnificent

stupendousness will be better understood by reciting its various

proportions.

It consists of six elliptical arches, each sixty feet span,

springing, at a height of twenty one-feet from the ground, from

piers ten feet in thickness; the height, from the crown of the

arches to the basement of the piers, is about sixty feet. The whole

length of this viaduct, including the brick facing on each side of

the arches, is about one-eighth of a mile. In forming this viaduct,

it was found necessary to divert the original courses of the Ouse

and Tow. They now flow on together beneath this viaduct, in one

spacious channel paved with brick.”

The London and Birmingham Railway Guide,

J. W. Wyld (1838).

Civil engineering advice of the times warned of the importance of

erecting piers on firm foundations, especially in the case of a high

viaduct, where a considerable weight bore down on a comparatively

small area of foundation:

“For structures of this magnitude, the sufficiency of foundation

is of the first importance: the greater altitude not only imposes

greater weight of materials to be supported, but also evidently

requires that the cohesion of the foundations, and indeed of the

whole structure, be more perfect, as any defect or dislocation is

more likely to occasion extensive mischief in proportion as the

height is increased. If gravel or chalk can be reached, with a good

bed of concrete nothing need be apprehended; but if loam, sand, or

bog occurs, piling is found the better expedient.”

The Practical Railway Engineer,

G. D. Dempsey (1855).

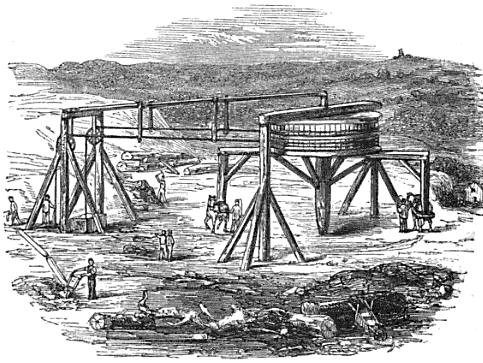

Occasionally, excavating the foundations for viaduct piers unearthed

the unexpected:

“Now for another curious ‘find’. On the line of the London &

Birmingham Railway I had to build a viaduct over the River Avon

between Wolston & Brandon Villages. On examination as to the

foundations to be expected I discovered that below the bed of the

river there were 25 feet in depth of peat lying on a bed of firm

gravel. This I found out by pushing down a long bar of iron. To

reach the gravel it therefore became necessary at each of the

abutments and piers of the viaduct to construct what are called

coffer dams, formed of planks driven down through the peat and into

the gravel to enable us to build up the foundations.

When the coffer dam was complete, we course had to excavate the

black peat. On arriving within about 5 feet of the gravel we found

complete trees lying, of course, on their sides with all their

branches crushed down quite flat: you may imagine our surprise to

find quantities of hazel nuts in the peat amongst the branches. Of

course they were very black and soft. I took out a large quantity of

them hoping to dry and keep them as a curiosity ― but as they became

dry they crumbled to dust. We went on sinking in the same character

of black stuff formed of coarse peat till the gravel bottom was

reached, but here our surprise was doubled for, lying on the surface

of the gravel we found skulls of the short horned breed of oxen,

quite complete with teeth, horns and all, with a great number of

bones not only of oxen but of sheep, hares & foxes, and most

wonderful of all, the leg bone of an elephant!”

The Dairy of John Brunton

(ca. 1890).

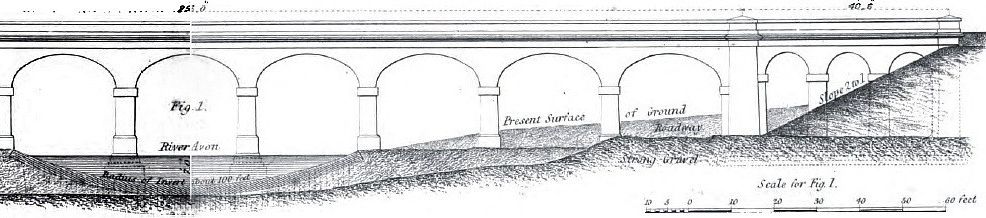

The viaduct to which Brunton refers is the London and Birmingham

viaduct, one of two railway viaducts that cross the River Avon near

Rugby. The other, Rugby Viaduct, is a now abandoned structure on the former Midland

Counties Railway between Rugby and Leicester. [7] |

West side of the viaduct over the River Avon,

near Wolston. John Cooke Bourne.

|

The London and Birmingham Railway viaduct is now Grade II listed, the English Heritage

description of it reading:

“Railway viaduct. c.1835. Brick faced

with rusticated sandstone ashlar with strongly projecting moulded

string course, and coped parapet. 9 elliptical arches and 6

narrower subsidiary round arches have rusticated voussoirs.

Canted piers between each arch. Larger piers between main and

subsidiary arches and to ends have octagonal caps. 2

subsidiary arches to west are bricked up and largely hidden by the

embankment. Built for the London and Birmingham Railway.” |

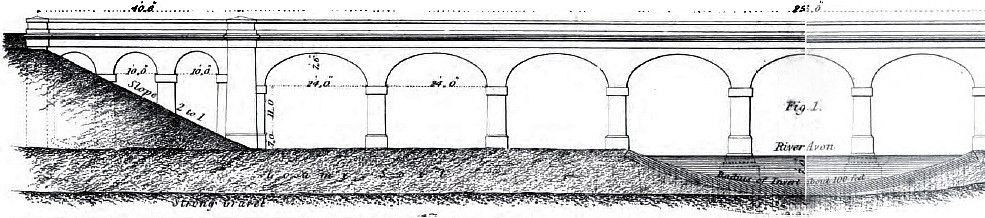

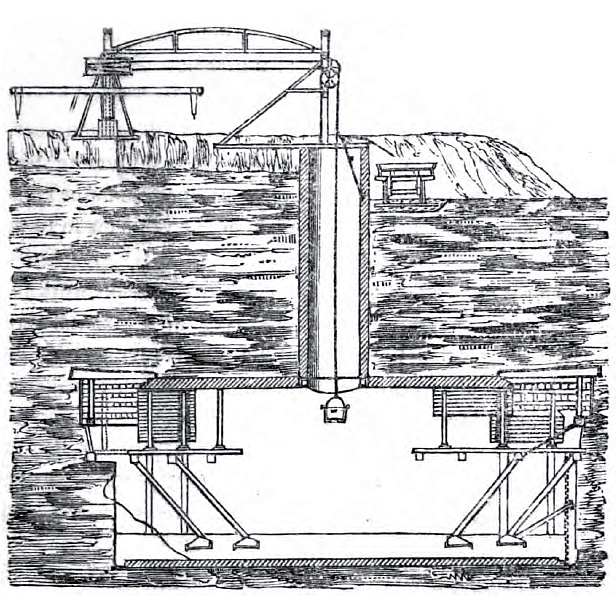

Elevation of the River Avon Viaduct, London &

Birmingham Railway.

|

“This viaduct, of which the total length is about 350 feet, consists

of nine semi-elliptical arches, 24 feet span, and 7ft. 6in. rise,

and three semicircular arches at each end, of 10 feet span, faced

entirely with stone. Each of the six end arches has a brick inverted

arch between the piers above the foundations, which are carried

along uniformly in a solid bed beneath these arches, with such steps

and at such levels as the nature of the substratum required. The

three middle arches have an inverted arch of brick-work

[visible in the drawing], which forms

an artificial channel for the river. This invert is faced at each

end with a row of sheet piling, driven through the loam into a bed

of strong gravel beneath. All the foundations which do not reach

this gravel are built upon thick beds of concrete, and a layer of

the same material covers the whole of the arches, forming a level

bed for the gravel in which the sleepers of the railway are laid.”

The Practical Railway Engineer, G. D. Dempsey (1855).

――――♦――――

TUNNELS

A levelling party at work,

Primrose Hill Tunnel.

“TUNNEL: a subterraneous gallery or passage

excavated or dug through the earth for the passage of a canal, road,

or railway.”

A Glossary of Civil Engineering,

S. C. Brees (1844).

“TUNNELS: The principal tunnels on this

[London and Birmingham]

line are those of

Primrose Hill, which is 1120 yards in length; Kensal Green (curved),

320 yards; Watford, 1830 yards; Leighton (curved) 272 yards; Weedon,

418 yards; Kilsby, 2398 yards; and Berkswell, 300. The Kilsby

tunnel, which is by far the chief work of the kind on this railway .

. . .”

The Railways of Great Britain and Ireland, Francis Wishaw (1842).

Tunnelling is a further means of reducing gradient, although whether

that approach was to be preferred to excavating a cutting

depended on circumstances:

“The choice between the two methods will depend

on the nature of the soil at the dividing ridge, and the comparative

expense of the two methods: in general, it is said, that tunnelling

is to be preferred to deep cutting when the depth to be excavated is

above sixty feet; and, also, when the cost of a running yard of each

is the same, it is said that deep cutting is generally to be

preferred, from the greater facility and despatch with which it can

be done.”

An Elementary Course of Civil Engineering,

Dennis Hart Mahan (1838).

Other factors for the civil engineer to consider were whether a

short tunnel with long approach cuttings was preferable to a longer

tunnel with shorter approaches; similarly, whether a short tunnel

under a high point of the ridge was preferable to a longer tunnel

under a lower point. In each case the cost of sinking shafts needed

to be considered, while the nature of the ground and its tendency to

slip was a factor to consider in deciding the length of the approach

cuttings; and while cuttings posed the risk of slip, tunnelers had

to face that of the roof collapsing before ― and possibly after ― a

lining had been put in place:

“In soils which required to be arched, it is seldom

safe to sink the working shafts directly over the crown, as they

would weaken the earth and might occasion cavings-in. It is

therefore recommended, in such cases, to mark out the lines of the

piers of the arch, and to sink the working shafts ten or fifteen

feet on the outside of these lines. ”

An Elementary Course of Civil Engineering,

Dennis Hart Mahan (1838).

This advice appears not to have been taken by the contractor

excavating the Watford Tunnel, when one of the working shaft

collapsed above the tunnel arch:

“In tunnels bored through chalk, it is often necessary

to act with great caution, as it sometimes contains large holes

filled with gravel, which, on being opened during the execution of

the works, pours in on the unsuspecting miner like water. Thus in

the Watford tunnel, which passes through the upper chalk formation,

where it is covered with a thick irregular bed of gravel, such

breakings-in occasioned great inconvenience and delay. The chalk

fissures, sometimes a hundred feet in depth, filled with gravel,

which when worked into, ‘rushed down with such violence, as to

plough the sides of the tunnel as if bullets had been shot against

it.’ Such an accident, occurring at the foot of one of the working

shafts, overwhelmed ten men who were there at work . . . .”

Our Iron Roads, F. S. Williams (1852).

The approach to tunnelling was developed by the canal

engineers. This was further refined at Blisworth, on the Grand Junction Canal,

where James Barnes drove a small pilot heading (or ‘driftway’) in

advance of the main excavation, mainly to assist drainage, but

it also provided a more complete examination of the strata while

providing a further check on the tunnel’s correct alignment.

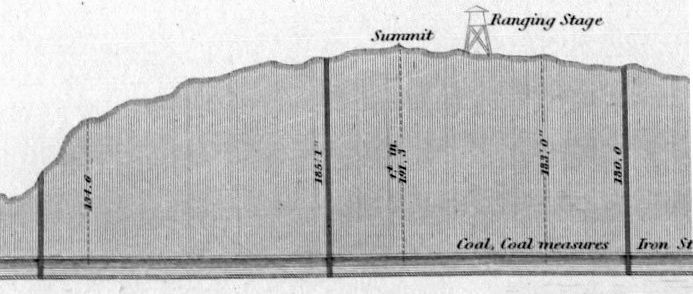

The alignment of the tunnel having been decided, the first task was

to mark this out with pegs on the ground

above. In setting the direction, when one end of the tunnel was

not visible from the other, ranging towers were built to assist with

alignment, although by the time the London and Birmingham Railway was

built reliable Ordnance Survey maps were available. It

was then necessary to test for the presence of any potential hazards

in the underlying strata ― subterranean watercourses, quicksand,

gravel and unstable formations ― that might make necessary a change

in the tunnel’s alignment, by making trial borings to collect

samples:

“A careful preliminary examination is made of

the geological strata, so far as these can he discerned from the

external features of the country; and levels or soundings are taken,

from which a profile of the surface of the ground to be passed under

may be formed. To test the character of the underground strata,

before letting the works to contractors, vertical borings are made

through the site of the proposed tunnel, or trial shafts are sunk

with the same object. No matter how thorough this preliminary

examination may be, the nature of the strata throughout cannot be

ascertained with perfect accuracy; and it may so happen, as in the

case of the Kilsby Tunnel, that the most dangerous part of the

ground may not be disclosed.”

‘Difficulties of Railway Engineering’, The London Quarterly Review,

Issue 205 (1858). |

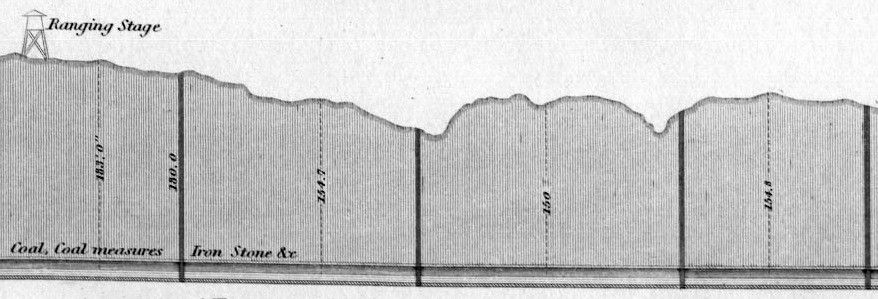

Section through

Telford’s Harecastle Tunnel showing a ranging tower and exploratory shafts.

|

Excavation was commenced from each end of the tunnel, and from the

bottom of working shafts sunk at intervals along the tunnel’s

length. A small heading was first driven between the shafts,

and carried on through the length of the tunnel; this served to

verify its

alignment and level. Francis Conder, a pupil of Charles Fox, left an account of

the completion of this

stage of excavating the Watford Tunnel:

“The line through the tunnel was straight, and had been

set out and pegged over the surface, as in other portions of the

route. At every furlong in length a shaft had been sunk, with the

intention of opening a drift way (a small heading) from end to end,

and thus running both line and level through under ground, before

commencing the main excavation and lining of the tunnel, which it

was intended to carry on through three of these shafts, properly

enlarged, using the others for ventilation . . . . a week after the

completion of the headway, ― which week had been spent in knocking

off elbows here, raising the roof there, and lowering the floor in

another place, with occasional loss of time and of temper, as some

intruder came blundering through the long narrow cavern, ― the pupil

of the sub engineer,

[Conder]

the only one of the staff left on his legs, had the extreme

satisfaction of viewing the red signal lamp, fixed at the north end

of the head-way, from the southern extremity, over a regular and

exact line of candles, one close to each shaft. The question of the

direction of the tunnel was thus solved . . .”

Personal Recollections of English Engineers,

F. R. Conder (1868).

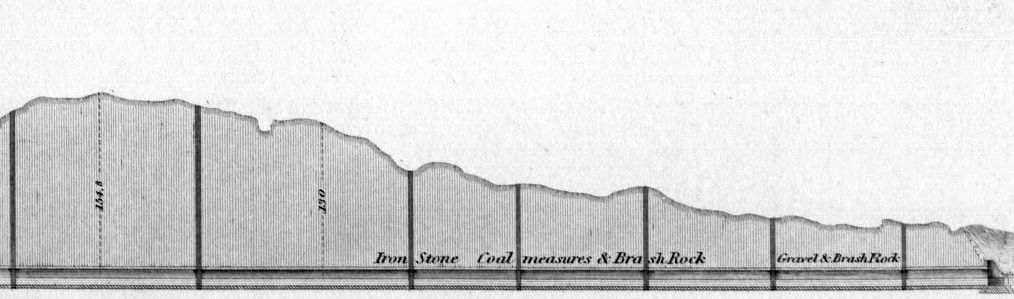

Above: longitudinal

section through a tunnel under construction,

showing a shaft, worked by a

horse gin, and two working faces.

Below: a horse gin.

――――♦――――

BRIDGES

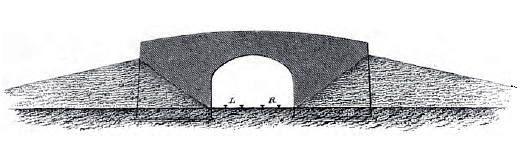

A bridge provides a means of crossing a waterway or highway.

In common with a viaduct, a bridge is not a structure for regulating

a railway’s gradient. However, this chapter is the

most appropriate place in which to describe some of the bridges on

the line that were constructed under Stephenson’s direction.

Generally speaking, the situations in which the need for a bridge

arises are where a railway and

highway or waterway intersect either on the level, or at different levels.

Each requires a different bridging solution, depending on whether the intersection

is at a right angle, or an oblique angle ― the latter introduces

complications when the bridge is to be built from bricks and/or masonry.

Where a railway and highway intersected on the level, the cheapest

solution was to build a level-crossing. While this required minimal

civil engineering, it introduced safety implications, especially on

a mainline carrying high-speed traffic. [8] The alternative was to raise or

lower the road to provide sufficient clearance, it being impractical

to alter the level of the railway. [9] In considering where the

balance of advantage lay in the two approaches, the following advice

was offered:

“In economy of brickwork, the bridge in cutting has the

advantage, as the footings require to be sunk only 18 inches or 2

feet below the slope; while the bridge in bank . . . . will require

the abutments so much below the original surface. The latter will

also require fences on the approaches, which the former will not. On

the other hand, the bridge in cutting will involve more expense in

drainage than the bridge in bank; and this consideration must

be entertained with full regard to the comparative levels of the

surrounding districts, and will frequently be found to outweigh all

the other advantages of the sunk bridge.”

The Practical Railway Engineer,

G. D. Dempsey (1855). |

|

|

|

|

Raised bridge |

Sunk bridge |

|

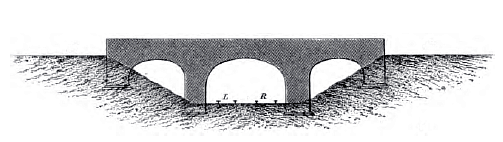

Dempsey then goes on to advise on the situation where a road

crossing needs to be made with a railway on a shallow (approximately

16 feet) embankment, or in a shallow cutting:

“In either instance, the best structure will be obtained by

adopting a bridge with parapets parallel throughout, or very

slightly diverging from each other at each end; by making it

sufficiently long to allow easy slopes for the banks, an ample width

of road, and for the abutments to cut well into the slopes on each

side; thus dispensing altogether with wing or retaining walls which

are always expensive and seldom secure.”

The Practical Railway Engineer,

G. D. Dempsey (1855). |

|

|

|

|

Railway in cutting |

Railway on embankment |

An elegant bridge

built into the Blisworth Embankment.

The road leading from Towcester to Northampton.

|

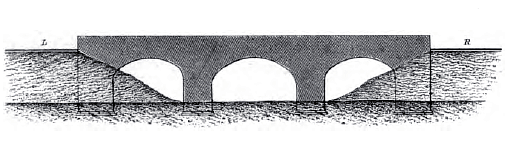

Where there is a considerable difference in height between road and

rail, a viaduct then becomes necessary:

“. . . . where the difference of levels is very considerable, and

an extended structure or viaduct is required, economy of

construction becomes additionally important. A reduced width of

viaduct, so as to provide for one line of rails only, has been

sometimes recommended; but this is a kind of economy which can be

justified only under peculiar circumstances, and which may be

productive not only of much inconvenience and hindrance, but of

greater ultimate expense than the double width would at first

involve.”

The Practical Railway Engineer,

G. D. Dempsey (1855).

And where viaducts are concerned, Dempsey joins other commentators

in stressing the importance of the “sufficiency of foundations” if

“extensive mischief” is to be avoided. |

|

|

|

Railway in cutting |

Railway on embankment |

|

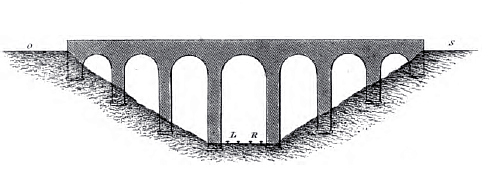

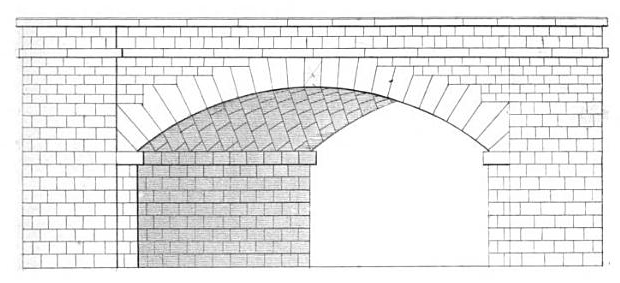

Where a highway and waterway intersect at right angles, the abutments of

a bridge built to negotiate the crossing are parallel and stand

opposite each other, and the courses of brickwork or stonework are

can be built up horizontally. But a complication arises where the

intersection is not a right angle. Sir Charles Fox summed up the

problem:

“Wherever a canal is thus crossed at an angle, we must either

divert the canal, so as to bring it at right angles to the railway

[Fig. 1 below];

or we must build a common square bridge of sufficient span to allow

the canal, its course being unaltered, to pass uninterruptedly under

it [engraving below]; or we must erect a proper skew bridge

[Fig. 2 below]. The first of these is

often impracticable, as provisions are generally inserted in the

Acts of Parliament, for preserving the canal from any alteration in

its course; and even if this were not the case, the diversion of a

canal causes great expense, and is attended with much inconvenience

to its traffic: the second is a most unscientific mode of overcoming

the difficulty, and would also involve very serious expense arising

from the necessity of making use of an arch of much larger

dimensions than would be required were the proper oblique arch

erected in its stead . . . . It is for the above reasons that

oblique arches are now so frequently erected; and a good method of

building them, is therefore, of considerable importance.”

On the Construction of Skew Arches,

Charles Fox (1836).

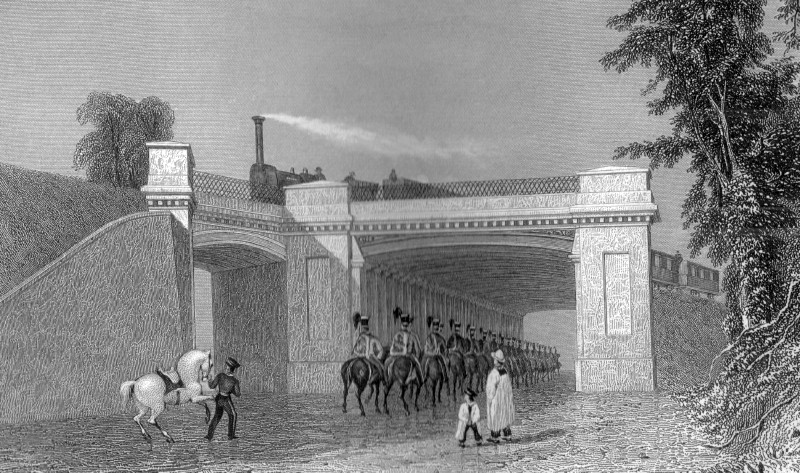

A common square bridge of extra span, built at an angle

― odd-looking and ugly.

A contemporary engraving showing the London &

Birmingham Railway crossing Watling Street,

near to the site of the temporary station

at Denbigh Hall.

The

‘skew arch’ enables a bridge to span an obstacle at other

than a right angle, but when built of bricks and/or masonry ― the structure

then being built up in courses of brickwork and/or stonework ― the

construction is not straightforward. Although the bridge abutments

remain equal and parallel, they are no longer directly opposite each

other:

“In skew bridges, in order to keep the thrust in the proper

direction, it is necessary to place the courses of stones at an

angle with the abutment, whereby each stone loses its parallelism

with the surface of the road, and is therefore laid on an inclining

bed.”

On the Construction of Skew Arches,

Charles Fox (1836).

The eminent canal engineer James Brindley never succeeding in

working out a solution to the problem of constructing a strong

skew arch, and in consequence all his overbridges were built at

right angles to the waterway, with double bends in

the roadway, where necessary (as in fig. 1 above). To this day, many of them cause

inconvenience to their users:

“Down to that time [late 18th century] such bridges had

always been built in the same way as common square arches, the

voussoirs being laid in courses parallel with the abutments. How

very defective such an arch would he may be seen by reference to

Fig. 3, in which lines are drawn to indicate the direction of the

courses. It is evident that here the portion cdfe is the only

part of the arch supported by the abutments; the triangular portions

cdg and efh being sustained merely by the mortar,

aided by being bonded with the rest of the masonry. This plan could

therefore only be adopted for bridges of very slight obliquity, and

even then with considerable risk.”

The Penny Cyclopaedia, Vol. 22 (1842).

“About the time

mentioned above, Mr. Chapman [10] was employed as engineer to

the Kildare canal, a branch from the Grand Canal of Ireland to the

town of Naas, on which it was desired to avoid diverting certain

roads which had to be crossed. He was therefore led to think for

some method of constructing oblique arches upon a sound principle,

of which he considered that the leading feature must be that the

joints of the voussoirs, whether of brick or stone, should he

rectangular with the face of the arch, instead of being parallel

with the abutment. Thus the courses instead of taking the direction

shown in Fig. 3, were laid in the manner indicated in Fig. 4

. . . . Mr. Chapman observes that the lines on which the beds of the

voussoirs lie are obviously spiral lines, and to this circumstance

may be attributed much of the singular appearance of oblique

arches.”

The Penny Cyclopaedia, Vol. 22 (1842).

|

|

|

|

|

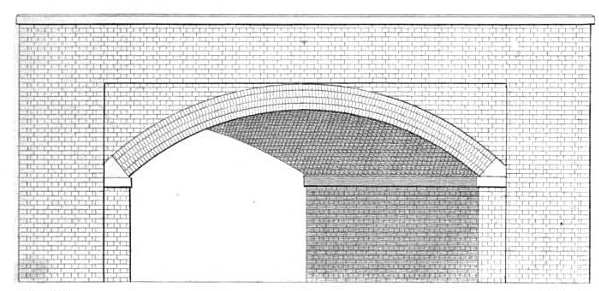

Masonry and brick skew arch bridges. |

Various methods were later described for designing skew arches, three that

were put forward being developed by engineers who worked on

the London and Birmingham Railway ― Charles Fox, John Hart and George

Watson Buck. Each wrote a treatise on the subject, [11] that by Buck

becoming a standard text for many years. The bridge carrying the London and Birmingham Railway over the

London Road at Boxmoor in Hertfordshire, adjacent to what is now

Hemel Hempstead station on the West Coast Main Line, is an example

of a ‘segmental’ arch. It is constructed in masonry, with a brick

barrel, stone quoins and a 58° angle of skew. Designed by Buck, it

was completed in 1837.

Boxmoor Skew Bridge.

West side of an oblique arch, in the embankment at

Boxmoor, to carry the Railway over the Turnpike. John Cooke Bourne,

1838.

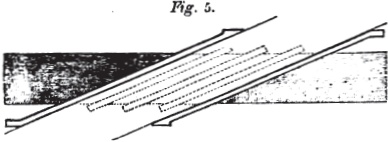

Where bricks or masonry is replaced with iron beams, such as in Nash

Mills Bridge (shown below), the problem of obliquity mostly disappears:

“The construction of skew bridges of iron or timber is

comparatively simple, the ribs or girders of which such bridges arc

composed being of the usual construction, laid parallel with each

other, but the end of each being in advance of that next preceding

it. Fig. 5 represents the ground plan of such a bridge, the

dotted lines indicating the situation of the ribs upon which the

platform is supported.

The extraordinary iron bridge by which the Manchester and Birmingham

railway is conducted over Fair field street, Manchester, at an angle

of only 24½º, is a fine example of this kind of skew-bridge. It

consists of six ribs, of rather more than 128 feet span, although

the width of the street is only 48 feet, resting upon very massive

abutments of masonry. The total weight of iron in this bridge, which

is considered to be one of the finest iron arches ever built, is 540

tons. It was erected from the design of Mr. Buck, who has

constructed several other oblique bridges of great size and very

acute angles.”

The Penny Cyclopaedia, Vol. 22 (1842).

Iron skew segmental arch bridge

(about 65ft in span and 82ft deep with 6 iron ribs) at Nash Mills,

Kings Langley,

now sadly defaced by concrete

reinforcement.

East side of Nash Mill Iron Bridge, near King’s

Langley, over the Grand Junction Canal.

John Cooke Bourne, 1838.

Sadly, the fine ironwork seen here was replaced by

British Rail with concrete during track modernisation. |

|

Among the other interesting bridges designed for the line was the

iron bowstring bridge [12] that crossed the Regent’s Canal towards the

upper end of the Euston Extension. The problem for Charles Fox ― to

whom the bridge is usually credited ― was to cross, almost on

the level, the 50ft width of the

canal and towing path while allowing sufficient

clearance for canal traffic. The bridge approaches had therefore to be raised.

This was achieved using the large quantities of

spoil excavated from both the approach cutting to the nearby Primrose

Hill Tunnel and from the Camden Incline. All predominantly blue

London Clay, it was used to fill in the area subsequently

occupied by the Camden Depot. [13] The

spoil bank so created raised the former ground level by some 15ft, thereby

creating (among other things) the necessary clearance required by

the Regent’s Canal Company for waterway traffic to pass beneath the

bridge.

The use of cast iron girders in a span

of that width was considered risky, and considerable testing was

carried out to prove the robustness of the design:

“Opposite this post, on the right or eastward, is the Stanhope

Arms, Camden Town; and about 18 yards past is the beautiful iron

bridge which carries the railway across the Regent’s Canal. This

bridge is divided in the centre by one of the main girders to which

the railway is suspended. The bridge deserves a much more elaborate

description than our space permits, and is a fine specimen of the

combination of lightness and strength which science can effect.

Instances of the care with which the works on this line have been

completed, were furnished in the erection of this and the Park

street bridge, in forming which, upwards of 100 tons of iron were

broken by the severe tests to which the girders, &c. &c. were

exposed; the directors, in the person of their indefatigable

engineer, thus evincing a most laudable anxiety to secure the public

from accident or even alarm. It may be here remarked, that all the

iron work in the bridges has been proved to three times the weight

it will have to sustain.”

The Railway Companion, from London to Birmingham,

Arthur Freeling (1838). |

Above: half elevation for

the bowstring bridge over the Regent’s Canal, London and Birmingham Railway.

Below: the same bridge as depicted by

John Cooke Bourne, May 1837.

|

“This is one of

the boldest specimens of construction on the whole line, the Railway

being entirely suspended by attached rods, as shown upon the several

plates. We believe it is the first application of the suspension

principle to carry locomotive engines and trains as used upon a

Railway.

The railway platform contains four lines of rails, and is hung on

wrought iron suspension rods, which are supported by massive cast

iron main beams, of which there are three pair, well braced

together, and spanning the canal by a length of 50 feet, and at an

elevation of 12 or 13 feet above the level of the water. These beams

are cast with a flat arch rising in their depth, and strong

horizontal tension rods, well coupled, are fixed to counteract any

inclination of the ribs to spread at the abutments. The Railway

platform consists of a number of fish bellied girders, each 28 feet

long, and which are supported by the suspension rods and laid

athwart the bridge. These rods are securely keyed to the main beams. Oak beams are fixed across the girders upon which the railway chairs

are secured, and cast iron gratings are filled in between the

spaces, which complete the bridge.”

Railway Practice: A Collection of Working Plans

and Practical Details of Construction, S. C. Brees (1859).

The following is a section from the contract specification:

“This Bridge will

consist of three Main Ribs of cast iron, properly secured. Each main

rib will consist of two ribs, properly connected, and each of these

will be cast in one piece. The Cross Girders will be secured to

these ribs, and the thrust of the arch sustained by tie bolts. The

open Ornamental work of the face will be bolted to the main ribs,

(vide Plates 11 and 12). The Roadway Plates to be fixed as drawing

(vide Plates 11, 12, and 13), and they will be perforated for

drainage. No ballasting will be laid on the bridge. The Chairs will

be fixed on oak blocks, firmly secured to the girders.

Coffer Dams will have to be sunk by the Contractor at his own

expense, and included in the amount of his tender, in order to get

in the foundations of the abutments. Concrete will be employed in

these foundations, as shown on the drawings. The Abutments will

principally consist of brickwork, set in mortar, (except so much as

is included between the foundations and the level of 1 foot above

top water level, for 18 inches from the face of the work, which must

be set in Roman cement.) The abutments will be faced with stone, and

stones will have to be built and bonded in various parts, as shown

on the drawings.”

Railway Practice: A Collection of Working Plans

and Practical Details of Construction, S. C. Brees (1859). |

CHAPTER

6

――――♦――――

|

FOOTNOTES |

|

1. |

Generally speaking, ‘ruling grade’ on a railway is usually

synonymous with ‘maximum gradient’. Although the ruling gradient on

the London and Birmingham Railway was 1 in 330 (16 feet to the

mile), the short Camden Incline down to Euston Station (initially

cable worked) was far steeper, descending . . . .

“. . . . from

the terminus at Euston Square for 12 chains, at 1 in 156, is then

level for 13 chains, and the succeeding 59 chains are divided into

four gradients ascending to Camden Town at 1 in 66, 1 in 110, 1 in

132, and 1 in 75 respectively.”

The

Practical Railway Engineer,

G. D. Dempsey (1855) |

|

2. |

Averaged out

over the entire length of the London and Birmingham Railway, the

volume of earthworks (cuttings and embankments) is estimated to have

amounted to 142,000 cu yards per mile (Page 102, The Practical Railway

Engineer, G. D. Dempsey (1855)) |

|

3. |

Where the

material to form an embankment could not be obtained from nearby

cutting or tunnel workings, it had to be excavated from the adjacent

land on either side of the line. The locations from where it was dug

became known as ‘borrow pits’. |

|

4. |

Because the outside walls sloped slightly inwards, they

were better able to resist the internal outwards thrust from the

centre of the formation. The top of the embankment was profiled at

the end of construction. |

|

5. |

Abstract of

Evidence on the Great Western Railway, given before a Committee of

the House of Lords, June, 1835. |

|

6. |

“COUNTERFORT,

a pier or buttress, generally applied at the back of retaining walls

in modern civil engineering, for the support of the same, and

likewise for the purpose of forming a tie to the material at the

back of the wall. Counterforts are also sometimes carried up on the

face of a wall.”

A Glossary

of Civil Engineering,

S. C. Brees (1841). |

|

7. |

Rugby Viaduct (Grade II listed). This structure, comprising 11

elliptical arches, is around 700 feet long and spans both Leicester

Road and the River Avon. Opened in 1840 by the Midland

Counties Railway, it is one of the country’s oldest disused

viaducts, forming part of the first rail route between London and

York. Engineered by Charles Vignoles, it is built in red brick

with a facing of Staffordshire blue brindles and sandstone

dressings. |

|

8. |

The Highway

(Railway Crossings) Act, 1839, required railways companies to

build and maintain gates at level crossings over roads, and provide a

person to open and shut them. |

|

9. |

The situation

of having to cross a waterway on the level, or tunnel beneath it, did

not arise on the London and Birmingham Railway. |

|

10. |

William Chapman

(1749–1832), English civil engineer, developed the first methodical

technique for the design of skew arches, his ‘spiral method’ being

described in Rees’s Cyclopædia. Chapman considered the arch

to be a series of arch slices, parallel to the arch faces and at an

angle to the abutments. The arch soffit (the curved underside) is

drawn out into a flat plane, a parallelogram grid drawn on this, and

then these diagonal lines (each one representing an arch slice)

transferred to the centring of the constructed arch. |

|

11. |

On the

Construction of Skew Arches,

Charles Fox (1836); A Practical Treatise on the Construction of

Oblique Arches, John Hart (1839); A Practical and Theoretical

Essay on Oblique Bridges, G. W. Buck (1839). |

|

12. |

In a thrust arch

bridge, the vertical and horizontal forces are transmitted along the

arches, requiring substantial abutments and foundations to prevent

the arch from flattening. In a bowstring bridge, the deck carries

the horizontal forces in tension, thus the abutments need only

support the vertical load. This allows bowstring bridges to be

constructed with less robust foundations. |

|

13. |

This lay between the Regent’s Canal, Gloucester Road (now Gloucester

Avenue), the western edge of

Stables Yard and Chalk Farm Lane (now Regent’s Park Road). |

――――♦――――

|