|

NOTES AND

EXTRACTS

ON THE HISTORY OF THE

LONDON & BIRMINGHAM RAILWAY

CHAPTER 9

CONSTRUCTION ―

THE EUSTON EXTENSION

THE SECOND ACT (1835)

While the design and legal work necessary to

build the Railway along the route authorised in the 1833 Act was in

progress, the Board had second thoughts about the location of their

London terminus. Following some debate (initiated by Stephenson)

it was decided to change the location of the

London terminus from Camden Town (the site authorised in the 1833 Act)

to Euston Grove, about a mile to the south-east. This

change

required the authority of a further Act of Parliament, a considerable investment in

land, and extensive civil engineering work necessary to cut through a

built-up area.

It is to the benefit of

today’s travellers that those

long forgotten Board members considered the outlay worthwhile.

On the 3rd July 1835, there passed into law . . . .

“An Act to enable the London and Birmingham

Railway Company to extend and alter the Line of such Railway and for

other Purposes relating thereto . . . .

. . . . II. And be it further enacted, That

it shall be lawful for the said Company and they are hereby

empowered to make an Extension of the said Railway . . . .

commencing in a Field on the West Side of the High Road leading from

London to Hampstead, being the Site of the Depot or Station intended

to be made for the Use of the said Railway, in the Parish of Saint

Pancras in the County of Middlesex, and thence passing across the

Regent’s Canal between the First and Second Bridges Westward of the

Lock at Camden Town into and through the said Parish of Saint

Pancras, and terminating in a vacant Piece of Ground in a Place

called Euston Grove, on the North Side of Drummond Street near

Euston Square in the same Parish, and which said Extension of

Railway will pass through or into the Parish of Saint Pancras in the

said County of Middlesex.”

5 & 6 Gulielmi IV. Cap. lvi., RA 3rd

July 1835.

Section III. of the Act also authorised alterations to the route at

Wolverton, Weedon and Brockhall, by which two tunnels and a bad

curve were avoided.

The new station faced the Euston Road, [1] which became, de facto, the barrier for railway

termini approaching London from the north and west; King’s

Cross, Saint Pancras, Marylebone and Paddington stations are sited

along the Euston Road and its extensions.

――――♦――――

THE CAMDEN INCLINE

With an average gradient of 1:85, the ‘Euston

Extension’ ― also known as the ‘Grand Excavation’, but now generally

referred to as the ‘Camden Incline’ ― was to become the one section on the

Railway where the ruling gradient of 1:330 could not be

maintained. As built, the gradients along the sections of the

Extension were:

|

Gradient, Euston to Camden.

There are 80 chains to a statute mile [2] |

|

Chains |

|

Gradient |

|

Section |

|

12 |

………… |

Fall 1 in 156 |

|

Euston to Hampstead Road |

|

13½ |

………… |

Level |

………… |

ditto |

|

16½ |

………… |

Rise 1 in 66 |

………… |

Hampstead Road to Crescent Place |

|

17 |

………… |

Rise 1 in 110 |

………… |

Crescent Place to Park Street |

|

9 |

………… |

Rise 1 in 132 |

………… |

Park Street Bridge |

|

16 |

………… |

Rise 1 in 75 |

………… |

Park Street to Regent's Canal |

|

|

An artist’s impression of a

roller from the Camden Incline. |

|

LONDON AND

BIRMINGHAM RAILWAY

. . . . The stationary engine at Camden-town requiring

some trifling repair, the morning train on Saturday last

was worked up the incline by locomotive engines, which

were to take the trains on from the station last

mentioned when more than one engine is required. In the

present case it was expected that one would have

sufficed, and one accordingly was attached in front of

the train (the eleven o’clock), but a drizzling rain

falling, the power, shortly after the train started, was

found inadequate, and a second engine was despatched to

its assistance. When it reached the tail of the train,

the wheels of the engine in front unfortunately slipped,

and a partial collision occurred. It was, however,

sufficient to occasions a severe contusion on the head

of Hallam, one of the passengers in the last carriage of

the train. |

|

The Era,

30th June 1839. |

Due to its steepness and the inconvenience of manoeuvring

locomotives in the confines of the planned passenger terminus, it

was decided to work the Euston Extension, not with locomotives, but with an endless cable system powered by

a pair of stationary steam engines. These were located at the top of the Incline

at Camden Town:

|

“This rope is ten thousand nine

hundred and fifty feet in length, seven inches in

circumference, and weighs about eleven tons twelve

hundred weight; it runs over hollowed iron sheaves,

turning on an axle in an iron frame, placed at distances

of twenty-four feet. The mode, however, in which the

engineer has enabled the engine to draw the carriages

round a curve of considerable sharpness, is at once most

ingenious and beautifully simple . . . . As the curve

becomes sharper, the above pulley is placed the more out

of the centre of the line of rails over which the

carriages are passing ― and the nearer to the convex

side of the turning, the guard being towards the concave

side of the wall; consequently, as the rope is fastened

to the centre of the carriage, it is drawn into the

centre of the line as the carriage passes each sheave,

and when this is sufficiently passed to allow the rope

to drop by its own weight, it falls upon the guard and

slides at once into the groove of the sheave.”

Freeling's

Railway Companion, from London to Birmingham,

Arthur Freeling (1838). |

In July 1836, a tender was accepted from the engineering firm of

Maudslay, Sons and Field to supply two 60 h.p. condensing

steam engines capable of drawing trains up the Incline at 20 m.p.h. These were

installed in a subterranean engine house together with their boilers and the winding gear they were to drive.

The only hint that the traveller had of this machinery was a pair of

tall chimneys,

described by Francis Wishaw as

being of “beautiful symmetry and exquisite workmanship”. |

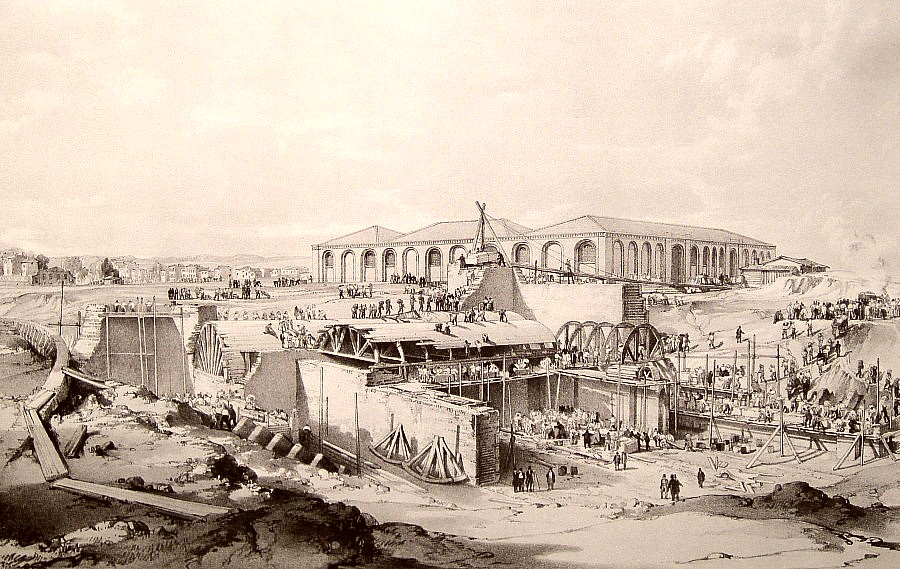

Camden Town Depot. Stationary

engine house in the course of erection,

by John Cooke Bourne, May 1837. The original engine house is shown

in the background.

|

In his history

of the line, Peter Lecount claims that locomotives were

capable of working the Extension, but were prevented from so doing

by the legislation, which aimed to prevent the nuisance caused by

their noise. Lecount appears to be referring to section 50 of the

1835 Act, which, while not referring to locomotive engines

specifically, can be read to impose the restriction to which he

refers:

“L. And be it further enacted, That the

said Company shall not fix, erect, or build, or otherwise work or

use, or permit or suffer any other Person or Persons to fix, erect,

or build or otherwise suffer to be worked or used, any Steam or

other Engine, Forge or Manufactory, on any Part of the Land or

Ground purchased of and conveyed to them by the said Charles Lord

Southampton by the Deed Poll dated the Third Day of January One

thousand eight hundred and thirty five, which may be or cause any

Nuisance, Annoyance, Damage, or Disturbance to the said Charles Lord

Southampton, his Heirs or Assigns, or any of his or their Lessees or

Tenants in the said Parish of Saint Pancras, without first obtaining

the Consent in Writing of the said Charles Lord Southampton, his

Heirs or Assigns.”

5 & 6 Gulielmi IV. Cap. lvi.,

R.A. 3rd July 1835.

That said, locomotives were used to work the Incline when

operation of the winding engines was suspended for repair or

maintenance. In all likelihood the noise of the

heavy endless cable being dragged over a long succession of squealing

rollers was probably comparable in nuisance to that of a steam

locomotive under load. |

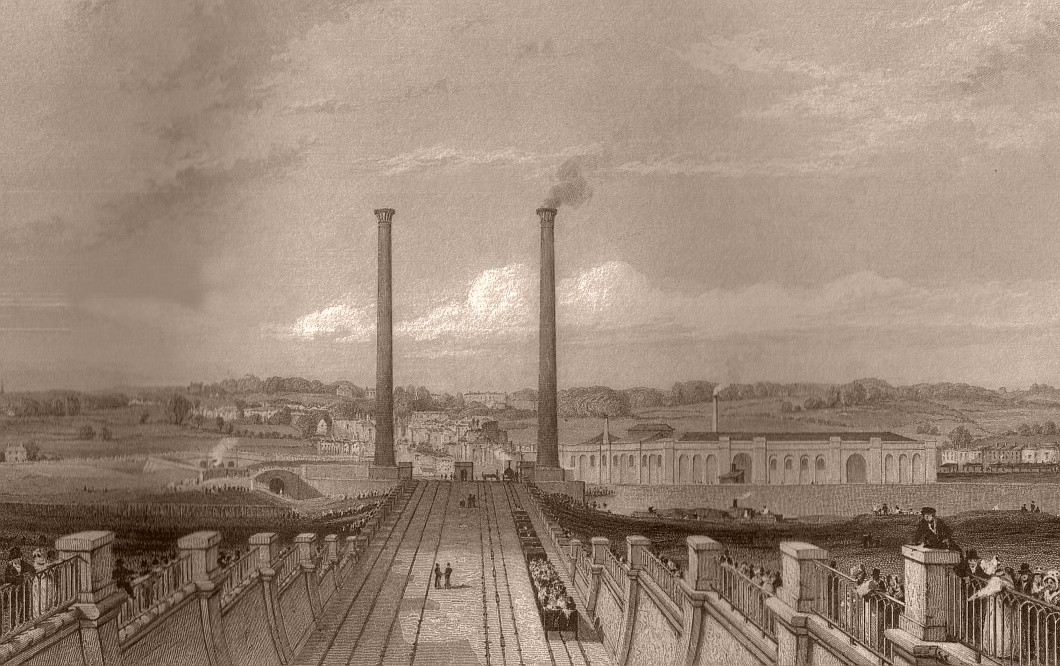

The stationary steam engine chimneys and the

locomotive workshops (right background), looking towards Camden. By E. Duncan, 1838.

Barges on the Regent’s Canal are just visible below the

workshops ― the canal bridge marked the summit of the incline.

Camden Town Depot. Locomotive Engine

House, Chimneys of Stationary Engine, with rails, eccentrics, &c. ― looking

towards London.

By John

Cooke Bourne, 1838.

|

“The land being on a considerable rise

outwards from London is worked, as before named, by endless ropes

passing over pulleys in the middle of the tracks, which ropes are

set in motion by the stationary steam engines at Camden Town. Great

precaution is required in attaching the carriages to the rope; and

this is generally done by one man, who is trained for that purpose. The way in which he effects the fastening is by means of a small

rope, called a ‘messenger’, having a slip knot at one end, which he

passes over the rope, and holds the other in his hand as he stands

on the foremost carriage in order to release the train when it

reaches Camden Town, or in case of accident. By a signal given to

the engineer, the engines are stopped in an instant. The train is

generally drawn up this length of railway in three or four minutes,

during which time the passenger passes under several very handsome

stone and iron bridges and galleries; the most extensive are those

under the Hampstead-road and Park-street . . . . When the train

arrives at the Iron Bridge which carries the line over the Regent’s

Canal, the carriages are detached from the rope, and allowed to run

along the line till they meet the locomotive engine by which it is

afterwards propelled.”

The London and Birmingham Railway,

Thomas Roscoe and Peter Lecount (1839).

It was during this period that the need for a signalling system

between Euston Station and the Camden stationary engine house led (on the 25th July 1837) to a trial of Cooke and Wheatstone’s electric telegraph, of

which more in the next chapter. However, on grounds of cost and

reliability the Directors opted for a pneumatic signalling system,

which, at Euston, was used to force air along a tube to sound an organ pipe

in the Camden stationary engine house. An identical system

operated in the opposite direction, alerting those at Euston of the impending arrival of an up-train:

“As soon as the reeking engine-funnel of an

up-train is seen darting out of the tunnel at Primrose-Hill, one of

the Company’s servants stationed there, who deals solely in

compressed air ― or rather who has an hydraulic machine for

condensing it ― allows a portion to rush through an inch iron pipe;

and he thus instantaneously produces in the little signal-office on

the up platform of Euston Station, where there is always a signal

man watching by night as well as by day, that loud melancholy whine

which has just arrested our attention, and which will continue to

moan uninterruptedly for five minutes. The moment this doleful

intimation arrives, the signal-man, emerging from his little office,

touches the trigger of a bell outside his door, which immediately in

two loud hurried notes announces to all whom it may concern the

arrival at Camden Station of the expected up-train; and at this

moment it is interesting to watch the poor cab-horses, who, by

various small muscular movements, which any one acquainted with

horses can readily interpret, clearly indicate that they are

perfectly sensible of what has just occurred and quite as clearly

foresee what will very shortly happen to them.”

The London Quarterly Review,

Volume LXXXIV (1848).

The cable system remained in use until 1844, when

it was replaced with locomotive haulage:

“Upon trial it was found, that the

locomotive engines could surmount the inclined plane between Euston

and Camden Stations with the ordinary trains, and that with the

assistance of a second engine, the heavy trains could also be passed

to Camden Station. A saving of ten minutes in time was the result,

as well as economy in the cost of working the stationary engines and

inclined-plane rope. After numerous successful trials, the engines

and rope were, in April, 1844, abandoned, and in course of time the

stationary engines were sold, and they are now doing duty in a flax

mill in Russia.

The saving in time thus effected was of little, or no value; and

attention being directed to the locomotive stock, it was found, that

even with two engines, the required speed could not be attained with

the heavy trains. A number of locomotive engines of large dimensions

were ordered, and by degrees the stock has been brought to consist

almost entirely of this class.”

Paper by R. B. Dockray published in

the

Proceedings of the Institution of Civil Engineers, Volume 8

(1849). |

――――♦――――

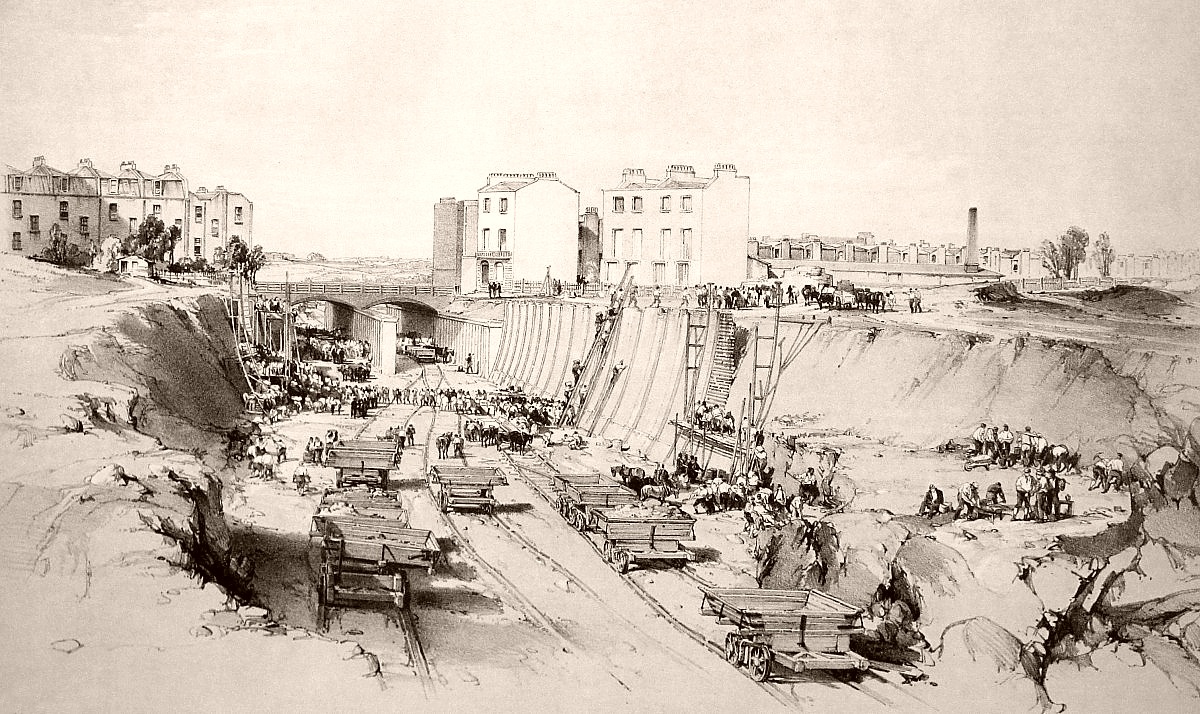

BUILDING THE EXTENSION

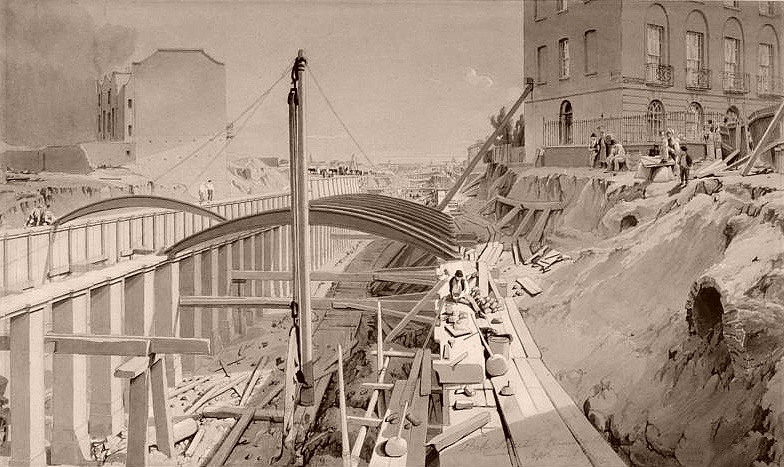

Excavation at Park Village, showing the work

in progress.

John Cooke Bourne, September 1836.

|

“The first shock of a great earthquake had,

just at that period, rent the whole neighbourhood to its centre. Traces of its course were visible on every side. Houses were knocked

down; streets broken through and stopped; deep pits and trenches dug

in the ground; enormous heaps of earth and clay thrown up; buildings

that were undermined and shaking, propped by great beams of wood. Here, a chaos of carts, overthrown and jumbled together, lay topsy

turvy at the bottom of a steep unnatural hill; there confused

treasures of iron soaked and rusted in something that had actually

become a pond. Everywhere were bridges that led nowhere;

thoroughfares that were wholly impassable; Babel towers of chimneys,

wanting half their height; temporary wooden houses and enclosures,

in the most unlikely situations; carcases of ragged tenements, and

fragments of unfinished walls and arches, and piles of scaffolding,

and wildernesses of bricks, and giant forms of cranes, and tripods

straddling above nothing. There were a hundred thousand shapes and

substances of incompleteness, wildly mingled out of their places,

upside down, burrowing in the earth, aspiring in the air, mouldering

in the water, and unintelligible as any dream. Hot springs and fiery

eruptions, the usual attendants upon earthquakes, lent their

contributions of confusion to the scene. Boiling water hissed and

heaved within dilapidated walls; whence, also, the glare and roar of

flames came issuing forth: and mounds of ashes blocked up rights of

way, and wholly changed the law and custom of the neighbourhood. In

short, the yet unfinished and unopened Railroad was in progress . .

. . ”

Dombey and Son, Charles

Dickens (1846-8).

On the 9th December 1835,

William and Lewis Cubitt were awarded the contract to build the Euston

Extension [3] for the sum of £76,860, [4]

the contract including a penalty to be invoked should the work not

be complete by the 1st January 1837. Stephenson appointed Charles Fox Resident Engineer

although he, himself, maintained a close interest in the progress of

the work. |

|

|

|

Above: Park Street, Camden Town, 18th September 1836.

Below: Park Village, 26th August 1836.

|

|

|

|

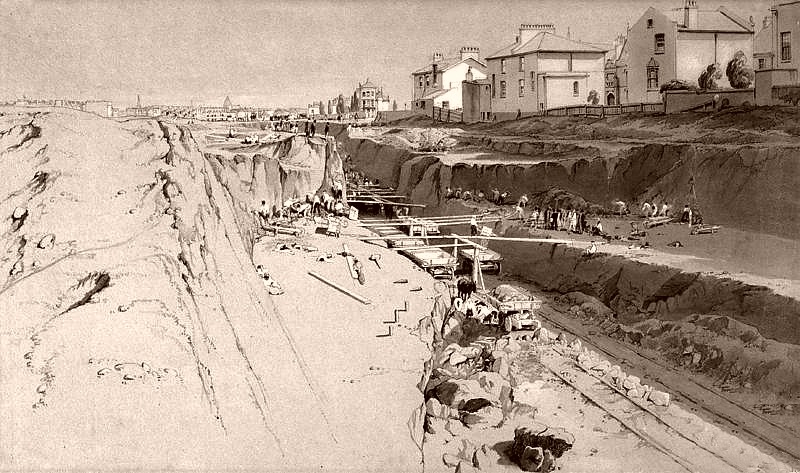

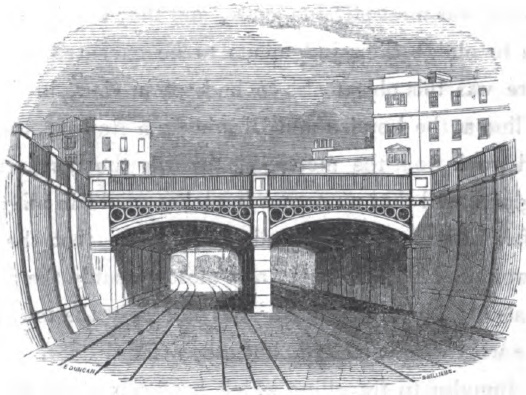

Park Street Bridge.

Note the endless cable in

the centre of the track and the railway ‘policemen’, forerunners of

today’s signalmen. |

|

Partly to economise on land purchase and bridge construction

(along its short length, the line originally passed under seven bridges) most of the Extension lies in a walled cutting, the walls

being of stronger than usual construction throughout. The

thickness of the walling can be seen in Cooke Bourne’s drawing below.

Hampstead Road Bridge from the

Camden side.

John Cooke Bourne, 11th August

1836.

LONDON FIXED ENGINE

PLANES. ― From the Euston station to

the Camden depot there are four lines of way, which are carried as

far as Park Street between retaining walls: the clear width occupied

here is about 56 feet; the walls are about 19 feet in height, and

are built to a curved batter, with a radius of about 60 feet, the

versed sine being about 4 feet 10 inches; lowest part of the

foundation is 7 feet from the level of the rails; the thickness of

brickwork decreases from the footings upwards, being at the bottom 3

feet 11½ inches, and at the top 2 feet 7½ inches. The whole length

of these extends to upwards of 2,200 yards.

In this length there are seven bridges and archways over the

railway, each of which is in two spans. Some of these bridges are

built of brick and faced with stone; and others have iron ribs

resting on brick piers.

From Park Street to the Regent’s Canal bridge at Camden Town the are

near the general surface of the ground; and the railway is enclosed

on either side with neat iron railing and pedestals of brick resting

on dwarf walls.

As these planes are considerably curved in some portions, both

vertical sloping sheaves are used for the rope; they are fixed in

cast iron cases embedded in the ballasting.

The Railways of Great Britain and

Ireland, Francis Wishaw (1842).

Due to the section

between Park Street and the Hampstead Road being driven through

London clay, Stephenson’s specification laid down exactly how the

excavation was to proceed ― on no account was the its face to be carried on more than 40 feet in advance of the

completed retaining wall without the Engineer’s written permission. This

stipulation took into account the characteristic of London clay to

stand for a short time after being cut, but then to bulge outwards with

force as it

absorbed moisture:

“One of those extraordinary difficulties to

which cuttings through the London clay must ever be liable, occurred

in this excavation. To facilitate the removal of the material, a

gullet had been

formed and a temporary railway laid down, when a season of excessive

wetness set in; the works however proceeded with that perseverance

which characterises the resident engineer Mr. Fox ― when one morning

the treacherous material gave way, the gullet was filled up, and the

labour of weeks (estimated at a cost of about £800) was destroyed in

a night, by an accident which could not have been anticipated, as no

previous experience had enabled engineers or directors to provide a

preventative, or to expect such a result . . . . One hundred and

eighty thousand cubic yards of clay were removed from this cutting.

During the progress of this portion of the line, the Company had no

less than 1,000 men employed upon this mile and a quarter of ground.”

The Railway Companion, from London

to Birmingham, Arthur Freeling (1838).

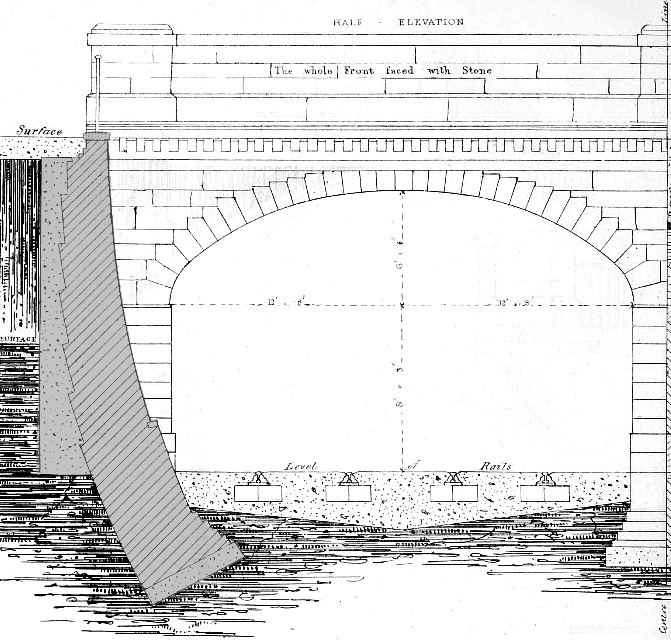

The plans and specifications for the Extension illustrate the

substantial construction of its retaining walls:

Bridge for intended street on the

Duke of Bedford’s estate upon the Exn. L & B Railway.

The retaining wall, shaded grey, is typical of those built along the

Extension.

“Sections

and Elevations of the Retaining Walls are shewn on the various

drawings.

The faces of these walls will be a Curved

Batter; [5]

the radius of this batter will be 50 feet, giving an average batter

of 2 inches per foot on 20 feet in every case, excepting in the

walls from Crescent Place to Park Street, which have a radius of 61

feet 8 inches, being an average batter of 2 inches to a foot on 20

feet. The whole of the brickwork of the walls will be laid in

courses radiating from the supposed centre of the curve of the

batter. The walls will increase in thickness the nearer they are to

the foundations, by half brick offsets, and the footings will

consist of steppings of two courses of brick, projecting one quarter

of a brick.

One foot thickness of Concrete will be placed under the footings of

the walls, it will project 6 inches from the footings in the front,

and be flush with the neat work behind.

The space at the back of the walls shall be well Punned [6]

in with clay. The faces of the walls will be broken at intervals of

16 feet, or thereabouts, as near thereto as consistent with dividing

a given length of wall into an equal number of parts, by Pilasters 4

feet by 4 inches wide, projecting half brick, built and bonded with

the rest of the wall. Counterforts [7]

will be built at the back of the wall, equidistant between the

pilasters and bonded into the wall. A stone plinth 6 inches thick

must be built in at the required height, and the wall above it will

recede ¼ of a brick from the face of the plinth.”

An extract from Stephenson’s work

specification, published in Railway Practice, S. C. Brees

(1838).

In addition to the work involved in excavating and walling the

Extension, the line passed under seven road

bridges and crossed the Regent’s Canal on an iron bowstring bridge,

probably designed by Charles Fox . . . .

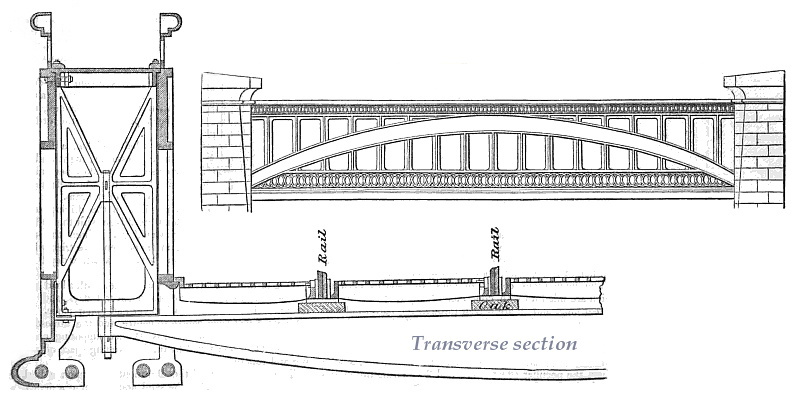

The Regent’s Canal Bridge.

“The earliest railway bridge on the

bowstring principle is that over the Regent’s Canal, near Chalk

Farm, on the London and Birmingham Railway.

It is composed of three main ribs of cast-iron open panel work,

whose outline is parallel, but which includes an arc extending to

its extremities of length and depth, and intersecting the vertical

bars which form the panels. The span is 50 feet and the height of

the ribs 10 feet. The section of each rib is in the form of a hollow

rectangle 2 feet 11 inches wide, and the space between its sides is

filled with diagonal bracing-frames 5 feet 10 inches apart. The

railway is carried by cast iron girders of the fish-bellied shape,

28 feet between bearings and 1 foot 10 inches deep in the middle;

they are suspended from the bracing-frames in the main ribs by

wrought-iron suspension rods 2¼ inches diameter; there being sockets

in the bracing-frames to receive their upper ends, and in the ends

of the cross-girders to receive their lower ends.

The centre main rib performs double duty; and its bracing-frames

have double sockets, and carry two suspension rods. In addition to

the ribs themselves in resisting the strain of the load there are

longitudinal tie-bars under each rib, there being four under each

outside rib in a horizontal row, and eight under the centre rib in

two horizontal rows. These tie-rods are secured to the bearing ends

of the main ribs, and are in three lengths, each united by sockets, gibs, and keys. Upon the cross-girders are oak sleepers for the

rails; and the entire space between the rails is filled in with

cast-iron plates perforated in the form of trellis-work. The

outsides of the outer ribs are ornamented with cast-iron mouldings

and fret-work. This bridge is of very bold design and certainly a

novelty as regards construction.”

The Encyclopaedia Britannica,

Vol. 12 (1856).

Alas, this fine bridge is long gone:

“The works associated with the original

station included bridges to carry various existing roadways over the

line and to carry the line over the Regent’s Canal. Of these

bridges, three are illustrated and described by Simms. [8]

They are the Stanhope Place Bridge, the Park Street Bridge, and the

bridge over the Regent’s Canal. The Stanhope Place Bridge,

consisting of two segmental masonry arches, was removed when

Stanhope Place was diverted into Mornington Terrace in the

’nineties. The Canal bridge has also been destroyed, but that over

Park Street still exists, as does that carrying Granby Terrace. The

two-arched Ampthill Square road bridge was taken down in 1898 and

replaced by girders. The bridge over Wriothesley Street, the first

to be built, had been demolished as early as about 1846-47, when

Wriothesley Street was closed. The cutting running south for a short

way from Park Street and spanned by segmental cast-iron struts, is

the original structure of 1836-37.”

Survey of London: volume 21: The

parish of St Pancras part 3 (1949). |

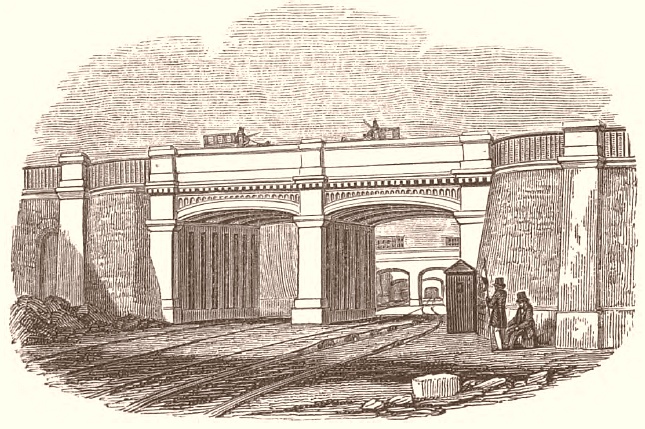

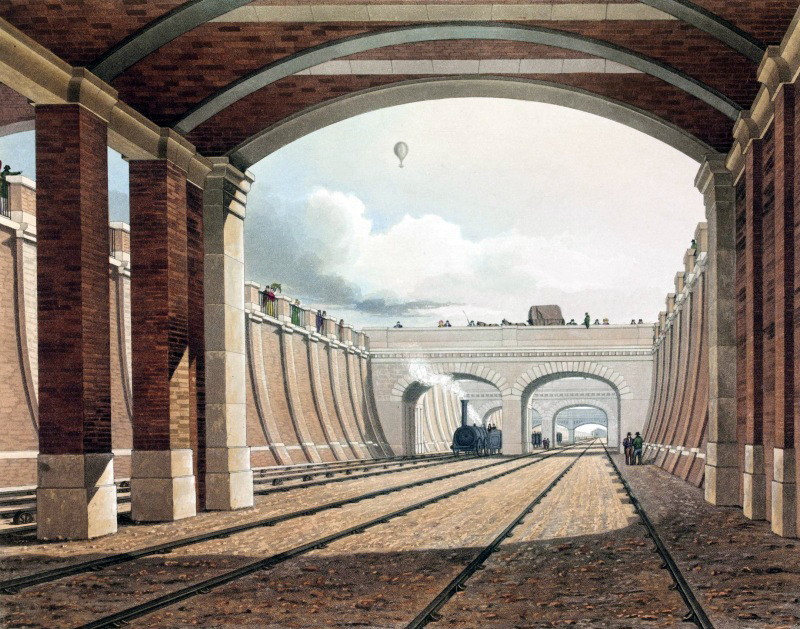

Above: the iron bridge over the Hampstead

Road.

Below: the same bridge under construction.

George Scharf, May

1836.

View taken from under the

Hampstead Road Bridge,

Looking towards the station at Euston Square, 18th September,

1837.

|

|

|

|

The Hampstead Road

Bridge. |

“From Euston Square to Camden Town the

Railway is formed by a wide cutting or trench, about eighteen or

twenty feet deep, the sides of which are composed of beautifully

executed brick work, having an iron balustrade at top, which when

the trees and shrubs of the adjoining gardens have sprung up, will

form a pleasing object . . . . The whole of this length is

excavated from the London clay; and the walls which form the sides

are curved, in order to resist the inward pressure; they are as much

as three bricks thick at the top and seven at the bottom; the number

of bricks used in forming these gigantic walls was about sixteen

millions.”

The London and Birmingham Railway, Roscoe and Lecount (1839).

By July 1837, the Euston Extension was complete and the first experimental passenger

journey to be made on the London and

Birmingham Railway took place. It was not without incident ― from the casual

manner in which derailments are referred to, it seems that they, at

least, were not

uncommon:

LONDON AND BIRMINGHAM RAILWAY.

“Thursday week the directors gave an excursion to a select

party of their friends by way of experiment preparatory to the

public opening of the railway from the station at Euston grove to

Box-moor and back.

At one o’clock (the hour appointed for starting)

a train, consisting of eleven carriages, left the station, gliding,

by its gravity, down a gently inclined plane for 200 or 300 yards,

when the engine was immediately attached, amidst the loud and hearty

cheers of a great number of spectators outside the line. The

distance (25 miles) was performed in an hour and eight minutes. At

Box-moor an elegant lunch was provided for the company in an marquee

pitched on a neighbouring rising ground. The weather was fine, and

every one seemed delighted with the scene. A second train of twelve

carriages left town at two o’clock, and reached Box-moor at few

minutes after three.

The train which started at one left for town at

four; but in consequence of some mismanagement as to the supply, we

believe, of water to the boiler, and the wheels of the engine

getting off the rail, sundry stoppages occurred by the way, which

protracted its arrival till ten minutes to six. Just as this

train had reached the terminus at the back of Euston square, the

engine having been disengaged, but the impetus still continuing at a

considerable velocity, the men whose duty it was to check the motion

by working what are technically called the ‘breaks,’ not being

sufficiently expert, or miscalculating their power, the carriages

came with frightful force against the barrier wall at the extremity

of the line, dashing it to atoms, and causing a rebound which

frightened all and damaged not a few. The concussion was so

great that those sitting opposite in the different carriages being

thrown against each other with great violence, we are sorry to say

some instances of serious injury occurred. Among others Lord

Hatherton received a severe bruise on the cheek; Mr. N. Calvert,

formerly M.P. for Hertfordshire, violent contusions on the face; two

gentlemen and a lady had their noses broken; others lost their front

teeth, and several sprained their wrists and arms.”

The Bucks Herald, 22nd July 1837.

Other than giving a couple of clues, the article’s author fails to

mention travelling over the Camden Incline. After the

stationary engine had hauled the train up the Incline from Euston,

the writer’s reference to “gliding

by gravity, down a gentle incline plane” refers to the final

section beyond the Regent’s Canal bridge, down which the

carriages descended under gravity to Camden Depot where a locomotive

was attached. On the homeward

journey the locomotive was detached near the top of the Incline.

The coaches were then pushed to its summit, from where they descended

to Euston under gravity, the descent being controlled by the

carriage brakes ― or in this particular case, by collision with the barrier wall.

――――♦――――

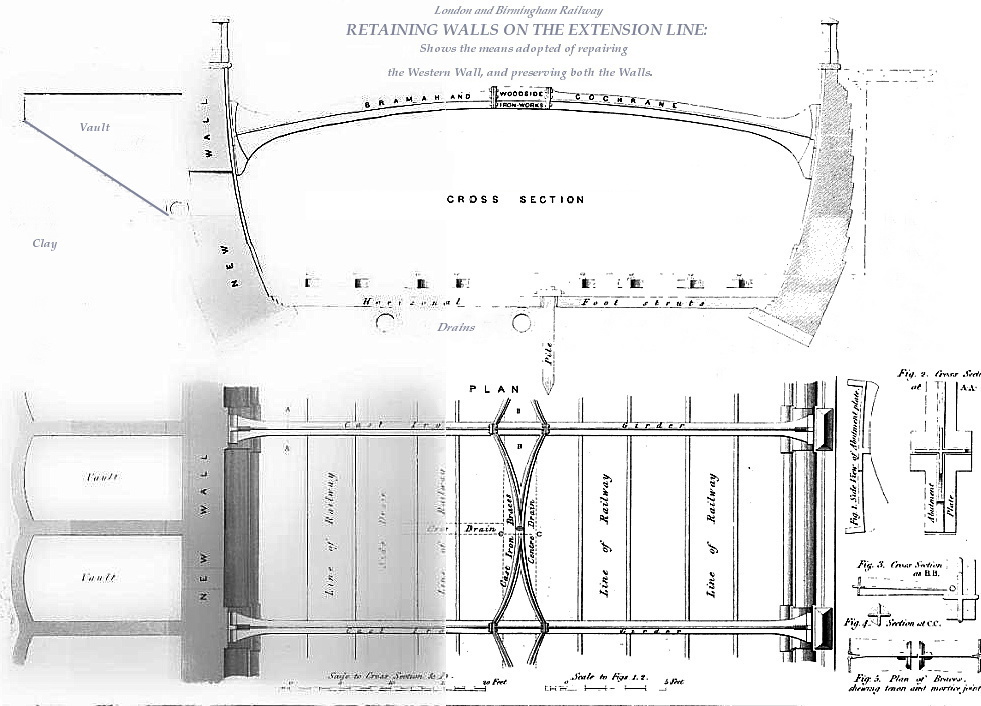

FURTHER PROBLEMS WITH LONDON CLAY

In Railway Practice, Dempsey drew on

examples to provide sound advice on the dangers of earth swelling

when saturated, even when retained by substantial brickwork:

“Many

instances are recorded of the failure of these structures, which has

commonly resulted from the saturation and consequent swelling of the

earth behind them; and these effects have occurred frequently,

despite the most judiciously-selected forms and materials, and the

best attainable system of back drainage. Indeed, unless the material

be adapted to stand by itself, be thoroughly impervious to water, or

so completely drained that very little reaches the back of the wall,

it is certain that this uncontrollable agent will make its way

through the work, and produce sooner or later the disastrous

consequences which have already marred the designs of railway

engineers.”

The Practical Railway Engineer,

George Drysdale Dempsey (1855).

The Primrose Hill Tunnel was not to be

Stephenson’s only run-in with London clay. By 1843 (six years

after the Extension had opened), the clay to the rear of the Extension’s western wall

had become

saturated through inadequate drainage. Such was the force it

then exerted, and despite great care having been taken in the wall’s design,

sections of it were thrust forward. The remedy that Stephenson

applied was improved drainage, to which he added reinforcing struts between the facing

walls at top and bottom, and vaults behind the upper

sections of the western wall:

“This

excavation intersects the London clay, the dip of which at that part

inclines downwards towards the east. The consequence is, that the

wall on the west side is required to sustain constantly an enormous

thrust, which is, of course, much increased when the clay becomes

swollen by absorbing water from the western environs lying towards

Primrose Hill, which are above the level of the top of the cutting.

This wall of the excavation, although built of great thickness, with

a curvilinear batter, substantial footings, and bedded and backed in

good concrete, and withal, carefully built, showed early symptoms of

its inability to withstand the pressure acting behind it; and the

upper part of the wall, the weakest, becoming displaced to a

considerable extent (in some instances more than 12 inches), it was

deemed necessary to adopt the ready means of a temporary support

offered by timber shoring.

Meantime, holes of 6 or 8 feet in length, and 3 inches in diameter,

were bored through the wall and the backing, and inclining upwards

by the apparatus known as ‘Watson’s Boring Machine’; and the

perforated tubes used by the inventor of that machine were then

introduced, and fixed into the wall. By this precaution much of the

water was prevented from accumulating within the clay; and in some

parts the clay appeared to be in some degree drier than it was

previously; but in other parts the frequent discharge of water

through the wall showed the activity of the mischievous agent, and

it became highly necessary to adopt so permanent method of giving

support to the failing wall, and preventing any further alteration

of its position.

Under the able direction of Robert Stephenson, Esq., the Consulting

Engineer to the Company, and R. B. Dockray, Esq., the Resident

Engineer, three measures were promptly adopted, which have been

found to answer their purpose admirably. These measures were:

First, introducing cast iron girders of a large section

between the eastern and western walls, so as to serve as abutments

for the latter against the former.

Second, embedding strong wooden horizontal foot-struts

between the footings of the two walls, so as to prevent the lower

part of the western wall from yielding forward, when the upper part

was strengthened by the cast iron girders.

Third, reducing the weight pressing against the western wall

by excavating the clay, and constructing spacious vaults with strong

walls.

Besides these arrangements, a large side drain was constructed near

the western wall, which drain received the water, by means of cross

channels formed with drain-tiles, from the clay behind the wall;

perforations in the wall being formed for that purpose.”

Discussion at the Institution of

Civil Engineers, reported in

The Practical Railway Engineer,

G. D. Dempsey (1855). |

Drawing showing remedial action in

the Euston Extension following damage to the retaining walls by saturated London clay, ca. 1842-3.

The diagram shows, on the western side, the vaults; also the

cast-iron girders placed across the cutting, braced with transverse

cast-iron struts.

From Railway Practice, by J. D. Dempsey (1845).

|

The above (time ravaged) drawing illustrates the remedial action

that Dempsey describes;

note also (on the plan) the cast-iron bracing between the girders.

――――♦――――

DEVELOPMENTS AT CAMDEN DEPOT

Because the decision to extend the line from Camden Town to Euston

was taken shortly

after the 1833 Act had been obtained, Camden never developed into a

major passenger station ― it did, however, become a major depot. Other than housing the stationary steam

engines and winding gear for working the Incline, Camden fulfilled a number of other

important roles, particularly with regards to goods traffic:

“The works on the old station

were,

1st, the stationary engine-house, which

consisted of vaulting under the railway adjoining the Regent’s

Canal; the boiler-houses opening to the railway, and two very

handsome chimneys, which formed conspicuous objects in the district.

Two condensing engines of 60 H.P., built by Messrs. Maudslay and

Field, were used to draw the trains from Euston up the inclined

plane, (averaging 1 in 85) to Camden Station, whence they proceeded

on their journey by locomotive power.

2nd. A locomotive engine-house capable of

accommodating fifteen engines, together with the requisite fitting

shops and offices.

3rd. Sixteen coke ovens.

4th. Two goods sheds and stabling, together

with a small accommodation for stores, and a shop for repairs of

waggons.”

Paper by R. B. Dockray published in

the

Proceedings of the Institution of Civil Engineers, Volume 8

(1849).

Some of the Company’s offices were also located at Camden in,

it would seem, insalubrious surroundings:

“After

serving a few months in the audit office, and in the opening of the

through line to Birmingham, I was drafted from the Manager’s office

to Camden Station, in connection with the Stores and

Construction Departments. This was a change for the worse as regards

my personal comfort. The office was a rough wooden erection, with an

earthen floor, and contained, by day, myself in my great coat, the

stores of all kinds, a table, a small cabin stove, and the mice. Chalk Farm was in the country then, and I had to prepare my meals at

the small stove, and to consume them assisted by the mice, who

evidently had a great contempt for my presence. The place was always

muddy. The station had been raised from the road by the earth from

the Primrose Hill Tunnel, and this new clay produced a Slough of

Despond, which I have only seen equalled at the Royal Agricultural

Show, at Kilburn, a few years ago.”

Fifty Years on the London & North

Western railway, David Stevenson (1891). |

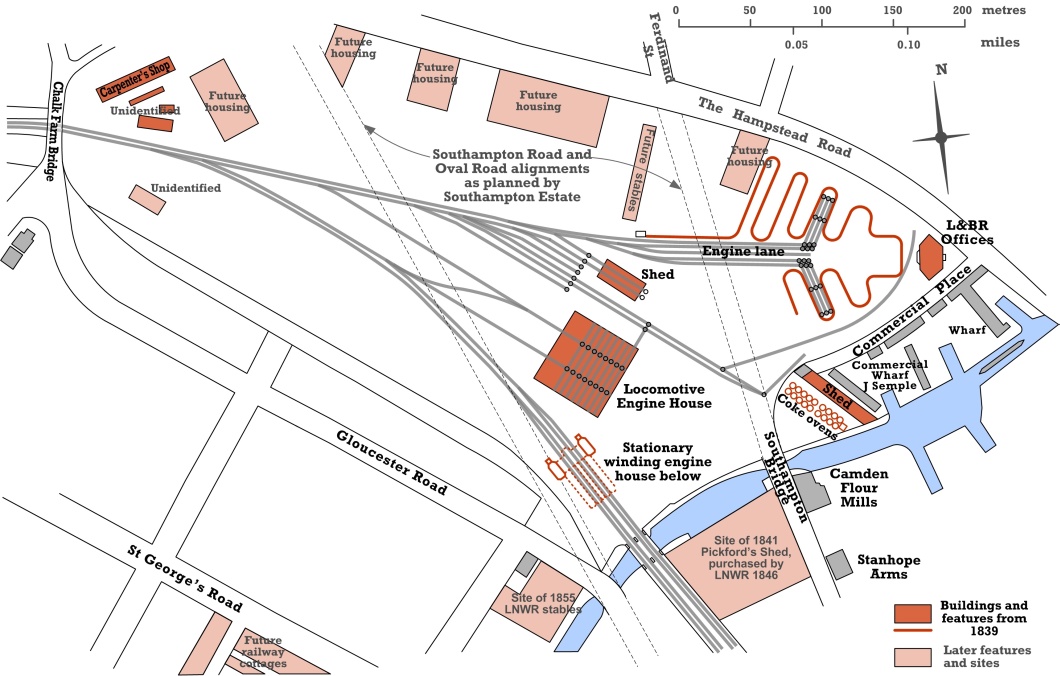

Camden Depot in 1839.

The section in blue is

the Regent’s Canal.

This map is

reproduced by

kind permission of Peter Darley,

Camden

Railway Heritage Trust.

As the Company gained experience in

operating a trunk railway and as the volume of goods traffic increased,

in common with most of the stations along

the line, Camden’s function and layout changed considerably during

its early years . . . .

. . . .

The whole of these works, (except those of a temporary nature) were

constructed in the most substantial and permanent manner. In the

design every pains was taken to anticipate the wants of the traffic; yet such has been the rapid development of the railway system,

that in the lapse of ten years from the opening of the line, it has

been found necessary to sweep away almost every vestige of these

works, and entirely to remodel the station.”

Paper by R. B. Dockray published in

the

Proceedings of the Institution of Civil Engineers, Volume 8

(1849).

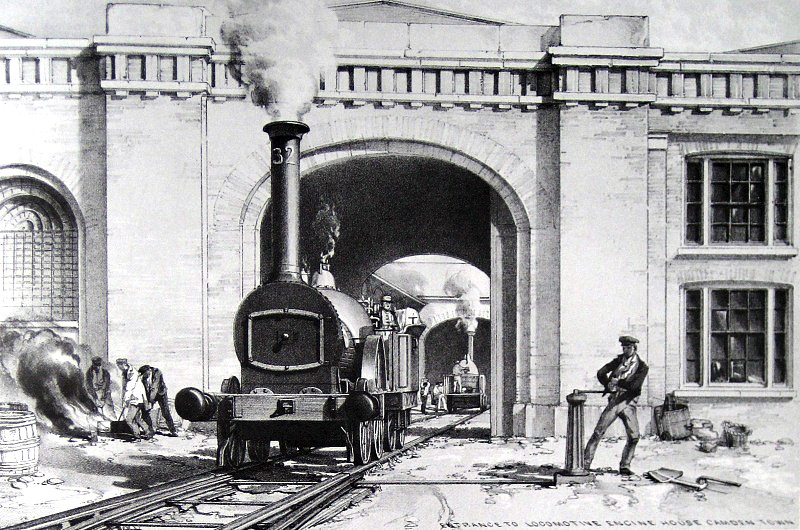

Bury 2-2-0 No. 32 leaving the

original Camden

engine house, by John Cooke Bourne, May 1839.

This locomotive was built by Mather Dixon & Co. of Liverpool.

“The locomotive engines’ station at the

Camden depot is a rectangular building of brick, enclosing an open

quadrilateral space, and is situate on the right side of the railway

going from London, and near to the high chimneys belonging to the

fixed engines. The entrance to this station is by branches from the

main line, which pass under two archways in front of the structure;

in each of these gateways is an engine turn-table, and a

water-column on either side of the way, and above is fixed a large

tank.”

The Railways of Great Britain and

Ireland, Francis Wishaw (1842).

“As

soon as an engine has safely dragged a passenger-train to the top of

the incline at Camden Station, at which point the coupling-chains

which connected it with its load are instantly unhooked, it is

enabled by the switchman to get from the main line upon a pair of

almost parallel side rails, along which, while the tickets are being

collected, it may be seen and heard retrograding and hissing past

its train. After a difficult and intricate passage from one set of

rails to another advancing or ‘shunting’

backwards as occasion may require, it proceeds to the fire-pit, over

which it stops. The fireman here opens the door of his furnace,

which by a very curious process is made to void the red-hot contents

of its stomach into the pit purposely constructed to receive them,

where the fire is instantly extinguished by cold water ready laid on

by the side. Before, however, dropping their fire, the drivers are

directed occasionally to blow their steam to clean; and we may

further add that once a-week the boiler of every engine is washed

out to get rid of sediment or scale, the operation being registered

in a book kept in the office. After dropping his fire, the driver,

carefully taking his firebars with him, conducts his engine into an

immense shed or engine-stable 400 feet in length by 90 in breadth,

generally half full of locomotives, where he examines it all over,

reporting in a book what repairs are wanting, or, if none (which is

not often the case), he reports it

‘correct’. He then takes his lamps

to the lamp-house to be cleaned and trimmed by workmen solely

employed to do so, after which he fetches them away himself. Being

now off duty, he and his satellite firemen go either to their homes

or to a sort of club-room containing a fire to keep them warm, a

series of cupboards to hold their clothes, and wooden benches on

which they may sit, sleep, or ruminate until their services are

again required; and here it is pleasing to see these fine fellows in

various enjoying rest and stillness after the incessant noise;

excitement; and occasional tempests of wind and rain; to which ― we

say nothing of greater dangers ― they been exposed.”

Quarterly Review, Volume

LXXXIV (1848).

Edward Bury’s weak-winded 4-wheeled engines were soon rendered

obsolete by developments in locomotive engineering, and were

eventually replaced with more powerful 6-wheelers. One outcome

from this change was that the

turntables in the original engine house were rendered too short to handle their longer replacements, while

the building was too small to accommodate anything larger. To

complicate matters further, a reduction in freight rates during 1845

led to a sudden increase in the volume of goods passing

through Camden. The outcome

was that in order to enter or leave the engine house, locomotives had to

cross lines that were being used increasingly to marshal freight trains, while down passenger trains,

which no longer needed to stop at Camden to acquire their locomotive

(the stationary winding engine having by now been abandoned), were crossing the yard at speed. These factors combined to

heighten the risk of collision:

“THE ACCIDENT

ON THE LONDON AND BIRMINGHAM

RAILWAY . . . . The mail train which

leaves Birmingham (having previously arrived from Liverpool) at

fifty-five minutes after twelve, at night, is due at the London

terminus at thirty-two minutes after five. About a quarter past five

on Tuesday morning this train arrived at the Chalk-farm end of the

tunnel, and proceeded at full speed onwards towards the platform at

the Camden station. The train, which consisted of from ten to

sixteen carriages, including the trucks and post-office vans,

continued its progress until arriving on the London side of

Chalk-farm bridge, where the down luggage train, which was some few

minutes behind its time, was crossing from the branch curve lines

leading to the luggage storehouses on to the main line. The fog was

so thick that it is described as utterly impossible for any one to

see beyond twenty of thirty feet, and the result was, that before

any measure could be taken to stop the speed of the mail train, it

ran into the luggage train, dashing three of the luggage vans, and

three of the carriages in the mail train, literally to atoms.”

Morning Post,

31st July 1845.

Changes were necessary. Widening the Chalk Farm Bridge allowed extra lines to be built

into the Depot, thereby helping to separate passenger traffic from

other activities. In 1846, the original engine house was replaced by two new buildings at opposite sides of the yard

for handling passenger and ‘luggage’ (goods) locomotives respectively. The goods engine house, known today

as the ‘Roundhouse’, is one of the few buildings from the

Railway’s early years to survive:

“The goods engine-house is circular, and

160 feet in diameter, having twenty-four lines of railway, each

sufficient for an engine and tender, radiating from a central

turnplate 41 feet in diameter. This form of building was found best

adapted to the situation in which it is placed. The turnplate is one

of Handcock’s, made by Messrs.

Lloyds, Foster, and Co.; the struts and beams are of oak. To guard

against damage to this table, from engines running upon it from any

line not corresponding with that on the revolving top, a strong

casting is fixed round the periphery of the top, and projects

upwards to the level of the rails. This casting has no apertures for

the flanches of the wheels, except at the ends of the rails upon the

table itself; thus an engine cannot easily be run upon it, except

when the revolving top is so turned that the two sets of rails shall

correspond.”

Paper by R. B. Dockray published in

the

Proceedings of the Institution of Civil Engineers, Volume 8

(1849). |

The goods engine house at Camden,

known today as the ‘Roundhouse’.

The conical slate roof has a

central smoke louvre (now glazed) and is supported by 24 cast-iron

Doric columns arranged

around the original locomotive

spaces and a framework of curved ribs.

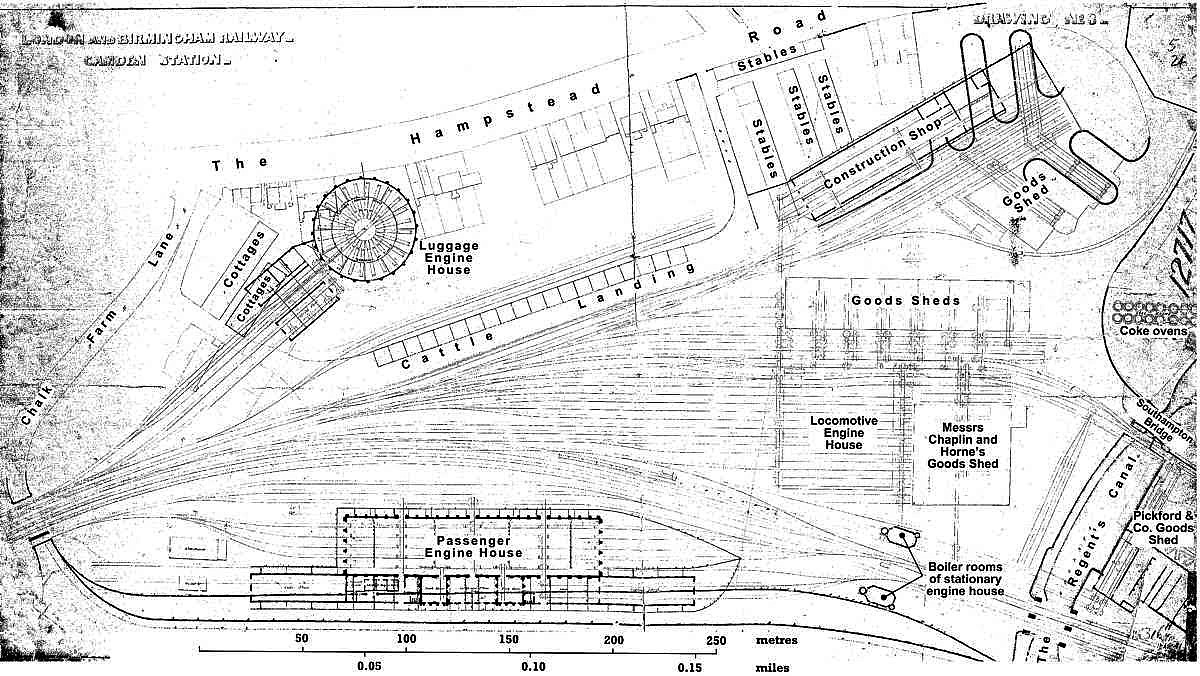

Camden Depot in 1847

Reproduced by

kind permission of Peter Darley,

Camden

Railway Heritage Trust.

|

After about a decade in

use, the Roundhouse also became too small to fulfil its intended role. Over the decades that followed it served various unrelated purposes,

including some 50 years as a bonded store for Gin distillers W. & A. Gilbey

Ltd. In recent years the building has become associated with

the performing arts . . . .

Restored to something of its original condition, the Roundhouse is

now regarded as a notable example of mid-19th century railway

architecture and, as such, was declared a National Heritage Site in

2010.

|

CHAPTER

10

――――♦――――

|

FOOTNOTES. |

|

1. |

Euston Road was then known as ‘The New Road’. In

1852, the central section of The New Road, between Osnaburgh Street

and Kings Cross, was renamed Euston Road, the eastern section became

Pentonville Road and the western section Marylebone Road. |

|

2. |

For surveying, the

statute mile is divided into eight furlongs; each furlong into ten

chains; each chain into four rods (also known as poles or perches);

and each rod into 25 links. This makes the rod equal to 5½ yards or

16½ feet in both Imperial and U.S. usage. |

|

3. |

Stephenson’s plan for

Euston Station had been approved in the previous month. |

|

4. |

Roscoe and Lecount, who state the outturn was £91,528. |

|

5. |

“BATTER: the face of a retaining or other

wall when built in a leaning position, the top part falling back

within the line of base; walls of this description are sometimes

termed, ‘tallus walls’. The batter of a wall is either straight or

curved; the latter are also generally commenced straight from the top, the greatest degree of curvature being given to the bottom of

the wall. The average rate of the batter of the walls upon the

London and Birmingham Railway is 2½ inches to the foot, and 1 inch

to the foot for the wing walls of bridges.”

From

A Glossary of Civil Engineering, S. C. Brees (1844). |

|

6. |

“PUNNING: a

mixture of good tempered clay and sand reduced to a semi-fluid

state, and rendered impervious to water by manual labour, as working

and chopping it about with spades. It is used for the purpose of

retaining the water in any particular situation, or for excluding it

from any works: and it is usually spread in layers of about 12

inches in thickness.”

From

A Glossary of Civil Engineering, S. C. Brees (1844). |

|

7. |

“COUNTERFORT:

a pier or buttress, generally applied at the back of retaining walls

in modern civil engineering, for the support of the same, and

likewise for the purpose of forming a tie to the material at the

back of the wall. Counterforts are also sometimes carried up upon

the face of a wall.”

From

A Glossary of Civil Engineering, S. C. Brees (1844). |

|

8. |

F.

W. Simms, Public Works of Great Britain (1838). |

――――♦―――― |

.htm_cmp_poetic110_bnr.gif)