|

. . . . AND THOSE AROUND TRING

CHAPTER IV.

THE MILLER, A CHEAT?

On the day of the battle of Lewes (14th May, 1264), during the

flight of Henry III’s troops before the victorious barons,

Richard, the king’s younger brother, took refuge in a windmill,

barring the door and for a while defending himself from the fury of

his pursuers. They jeered him, shouting, “Come out, you bad

miller! You, foresooth, to turn a wretched mill master,” which

suggests that from an early date the miller was not a person

held in high regard despite his importance to the welfare of the

community.

The Victorian image of the ‘hale and bold’ miller, who ‘wrought and

sang from morn till night’, was a romantic depiction. Although the

miller was a necessary member of our former rural communities, he

was often unpopular. Far from being the jolly red-faced figure, clad

in a dusty apron and with a song upon his lips, the villagers often

regarded him as cantankerous, mean-spirited and sometimes a cheat.

This view can be attributed in part to Geoffrey Chaucer who, writing

at the end of the 14th century, bequeathed to millers for the next

500 years a reputation for dishonesty that was undoubtedly supported

by at least a grain of truth.

Fig. 4.1: Robin the Miller,

from Chaucer’s Canterbury

Tales

In The Reeve’s Tale, Chaucer depicts a coarse and lewd man, who was

often violent in the bargain . . . .

|

“A rumbustious cheat of sixteen stone

Big in brawn, and big in bone,

He was a master hand at stealing grain

And often took three times his due

Because of feeling with his thumb,

He knew its quality.

By God! To think it went by rote,

A golden thumb to judge an oat!” |

Wealthier than the ordinary folk, the miller’s circumstances caused

jealousy and occasionally led to millers being targeted during bread

riots at times of famine. This arose from the system then prevalent

whereby the Lord of the Manor exacted ‘toll corn’ from the peasants

who were dependent upon the miller to produce supplies of flour for

their own use. Usually between one-sixteenth and one twenty-fourth,

it was an easy matter for the miller to set aside more than the

agreed toll and keep the surplus for himself.

As late as the 1880s it was reported that Henry Liddington, the

miller at Goldfield mill at Tring, was charged and convicted with

taking excessive tolls. Frederick Eggleton, one of Liddington’s

customers, complained, and the matter went to court. A report in the

Herts Mercury stated that . . . .

“. . . . it appeared that Eggleton’s wife and children had gleaned a

quantity of wheat, which when thrashed weighed 232 lbs. This was

taken to the defendant to grind, and when the flour was returned it

only weighed 108 lbs. Allowing 14 lbs. per bushel waste, which was a

fair amount, there was thus 60 lbs. short. Being dissatisfied, Eggleton went to the defendant and asked him for the offal, offering

him at the same time 2s. for the grinding of the wheat. The

defendant declined to give up the offal, and told Eggleton that he

had received all the defendant intended he should have.”

Found guilty, Henry Liddington was fined £10 plus costs. He

was probably was the last windmiller in Hertfordshire, if not in

England, to be convicted of this particular felony.

FOOD ADULTERATION

Besides cheating on weight, a dishonest miller might also adulterate

the flour. This was a more serious and potentially harmful matter,

but not uncommon throughout the food trade in bygone times. In The

Expedition of Henry Clinker by Smollett (1771), a country squire

comments thus on London’s food . . . .

“The bread I eat in London is a deleterious paste, mixed up with

chalk, alum and bone ashes: insipid to the taste and destructive to

the constitution . . . the tallowy rancid mass called butter is

manufactured with candle-grease and kitchen-stuff . . . .”

An example reported in The Northern Star in 1846, describes how

flour was adulterated with gypsum, a type of alabaster that could be

ground to a fine white powder. The report states that a considerable

quantity of gypsum was ground at a mill near Carlisle before being

sent to Liverpool. It was then traced to William Pattinson of

Cuddington Mill, near Weaverham, who was discovered by officers in

the act of mixing it with flour. The newspaper ranted amusingly . .

. .

“Thus is our ‘daily bread’ adulterated; thus is the craft of the

mason carried on in our very stomachs, and mortar there produced

which is of mortal effect; and thus a family wishing to purchase a

stone of flour, is literally furnished with a flour of stone.”

For his crime Pattinson was fined £10 by Cheshire magistrates.

Further down the production line the bakers were also at it, using

alum (potassium aluminium sulphate, or potash, which in large

quantities is toxic) to bulk out flour while giving the bread a

whiter colour and causing it to absorb and retain a larger amount of

water than otherwise. This from the Hampshire Telegraph (1804) . . .

.

“Near 50 bakers have been convicted at the different Police Offices

within the last month, for selling bread deficient in weight. Many

of them were likewise fined for having alum in their houses, with a

view to mixing it with bread, a practice extremely prejudicial,

particularly to infants.”

Adulterating flour with alum remained a problem throughout the 19th

century, as this extract from a manufacturing journal of 1880

illustrates . . . .

“However happy the effects of alum may be in improving the

appearance of the bread and swelling the profits of miller and

baker, the effects upon those who are obliged to eat such bread are

liable to be most disastrous. . . . a very little alum in bread may

not prove immediately or seriously injurious, but no considerable

amount of such a powerful astringent is required to disorder

digestion and ruin health, as is shown by a vast array of competent

testimony.”

But there were occasions when millers did tamper with the grain with

good intention. This from a miller's handbook of 1881 . . . .

“A musty smell may be removed from grain by mixing powdered coal

with it and letting it stand for fourteen days, at the end of which

time the coal dust is removed by the purifying machine. This

treatment is said to remove every trace of mould, and the flour is

excellent.”

The reputation earned by millers endured to such an extent that

surprise was registered when an honest miller was encountered, as is

evidenced on a tablet in Great Gaddesden church, which reads . . . .

“. . . . In memory of Thomas Cook, late of Noak Mill in this parish,

who departed this life 8th December 1830, age 77. He was a good

Husband and tender Father, and an honest man, although a miller.”

THE MILLER’S TRADE

In giving their miller a reputation for greed and dishonesty, his

contemporaries rarely appreciated that windmilling involved high

fixed costs. The great millstones had to be dressed and set

periodically, machinery broke down and windmills often suffered

storm damage, which was expensive to repair, if indeed the storm had

not brought about the mill’s complete destruction. And to add to

these risks and costs, windless periods would cause the mill, quite

literally, to grind to a halt.

|

%20-%20miller%20at%20Blackboys%20post%20mill%20Framefield%20East%20Sussex.jpg) |

|

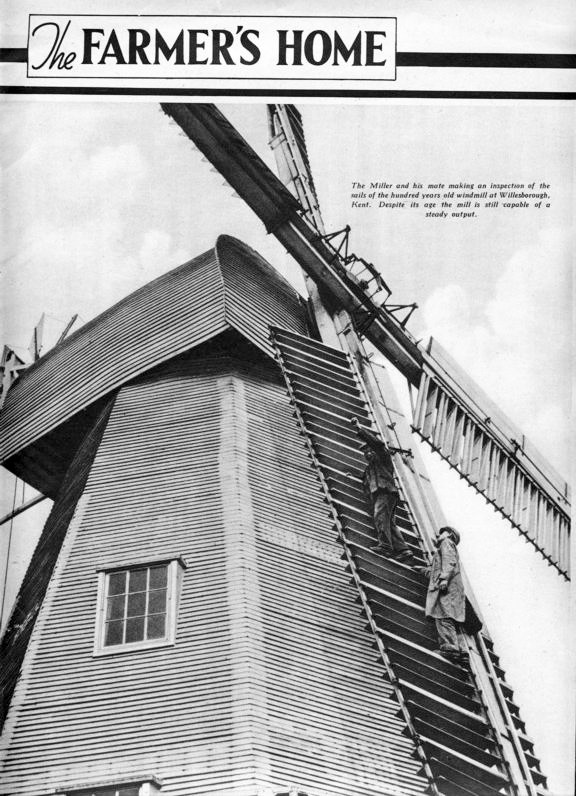

Fig. 4.2: two old

millers. Mr. J. B. Greater of Stratford St.

Andrew, Suffolk and

Mr. J. Paris of

of Blackboys post mill, Framefield, East Sussex |

Millers who could not afford to maintain their millstones in the

most efficient working order had to make do with a more precarious

margin of profit. In his book Wheat and the Flour Mill (1920),

Edward Bradfield, had this to say about the tedious but important

process of dressing millstones . . . .

“. . . . half the miller's art — and it was an art

— was comprised

in laying out and dressing the stone. Properly to lay out a stone;

to attain the absolute balance; to mark out the quarters, lands, and

furrows and, finally, to give the requisite fineness of dress to the

surface, required the skill and judgment, and steadiness of hand and

eye, of no mean order, and the old stone millers rightly prided

themselves on the quality of their work.”

The millstones being set and dressed and the motive power being

available — which, for a windmill, cannot be taken for granted — the

process of milling can commence. The first task was to blend the

various varieties of wheat to produce flour of the required

character, then to rid the grain of impurities, such as stones,

twigs, alien seeds and other extraneous matter that would adulterate

the flour. This extract from an 1867 edition of The Miller magazine

describes the process at that time . . . .

“The art of mealing, as it is called, consists in the judicious

choice of wheat and in the proper arrangement of the machinery, so

that the whole of the flour which the wheat is capable of producing

may be obtained at one grinding.

The proper proportions of the wheat for grinding are mixed in a bin,

after which the grain is passed through a blowing apparatus in order

to separate dust and light particles. It is next passed through a

smut machine, consisting of iron beaters enclosed within a skeleton

cylindrical frame covered with wire, the spaces being wide enough to

allow the impurities of the grain to fall through. The beaters

revolve 400 or 500 times in a minute and by their action against the

wires scrub the wheat, and remove portions of dust, smut, and

impurities.

After this, the wheat is passed through a screen, arranged spirally

on a horizontal axis, the revolutions of which scatter the seeds

over the meshes, and allow small shrivelled seeds to pass through. The grain is next exposed to a current of air from a fan, which

completes the removal of chaff, dirt, smutt-ball, etc.

The result of all this elaborate cleaning is greatly to improve the

whiteness of the flour, and also its wholesomeness; and its

necessity is evident from the accumulation of impure matter in the

cases of the screens.”

Fig. 4.3: a miller bagging up the product

As the wheat passes from the last cleaning machine, it falls down a

canvas tube into the hopper which supplies the millstones, where a

jigging kind of motion is kept up, so as to shake the corn into the

trough over the stones in equable quantities; and so long as this

action is going on properly, a little bell is made to ring, the

motion of which ceases with the supply of wheat.”

This activity supposed that the wind was blowing sufficiently to

drive the mill. Windless periods left the miller with a growing

backlog of grain and no income, so when a windy period arrived it

was usual for him to work day and night for several days on end to

get as much done as possible while the wind lasted. It is

unsurprising that even small country mills introduced small steam

engines to drive the equipment when these became available.

A TOUGH BUSINESS

As well as requiring great skill and experience, the miller’s work

was often arduous. Many worked ancient post mills fitted with simple

sails, tail-poles, and manually-tentered stones. The miller had to

be alert to any change in the wind; to an experienced miller’s ear,

the condition of the mill was evident from the sound of its

machinery, while badly-adjusted stones could be detected from the

smell of scorched meal (“nose to the grindstone”).

Working old mills especially, could prove challenging when wrestling

with wind and rain. When aware of a gathering storm, the miller had

to apply the brake and reef the sails, a task that could take two

men 30 minutes or more. Turning a post mill in a strong wind was

also a slow job and could be an exhausting one. This was the

experience of James Saunders, (1844-1935) who drove an old post mill

at Stone near Aylesbury (fig. 4.4) . . . .

Fig. 4.4:

the remains of Stone (near Aylesbury) post mill c.1900

“Many a time when I was out shifting the

cloths in a storm [reefing the sails],

the water has run off them down my arms and out of my trouser legs.

Of course there was no chance of getting dry clothes until I went

home, and in the winter they have sometimes been frozen onto me for

hours . . . .”

In more modern mills, self-reefing patent sails eliminated this

arduous task.

Another aspect of milling that could, from time to time, make it a

tough business was competition with other millers. Here Saunders

reflects on a mill that he drove at High Wycombe . . . .

“. . . it was not a good neighbourhood and already overrun by

millers. There were ten flour mills in the valley before we started;

many of them paper mills converted into flour mills during the bad

spell for paper-making, but all of them adding to the competition. Indeed when we began there was almost as many millers as bakers.”

And so in a buyers’ market flour prices were driven down. This from

the Bucks Advertiser, April 1876 . . . .

“Bucks County Lunatic Asylum.

To Millers —

Persons willing to supply FLOUR (about 9 sacks per week) as set

forth in the printed forms of tender, for three months from the 18th

day of March 1876 are requested to deliver at the Asylum at Stone,

tenders on or before ten o–clock on the morning of Thursday the 16th

instant . . . . Addressed to the Committee of visitors of the Bucks

County Lunatic Asylum. A sample of flour will be shown at the

Asylum; and a sample must be sent with the tender.”

Another business risk that affected farmer and miller alike, was a

poor wheat harvest. For several years James Saunders lived on the

verge of bankruptcy, only surviving through the good offices of a

sympathetic bank manager . . . .

“No country miller is likely to forget 1879, the worst year by far

that I have ever known. The crop of English wheat was all bad alike,

and country millers were entirely out of the market. Moreover, the

competition of American flour became more severe; agents were

travelling round practically everywhere offering it to every little

village baker. Many mills were shut down at this time and never

restarted again.”

DANGEROUS WORK

Great care had also to be exercised in working a mill in an age when

moving machinery was not always properly shielded, if at all, from

the unwary. This from the Hampshire Telegraph (1804) .

. . .

“A few days since, as John Ringer, aged 26, was attending a boulting mill

[it sifts meal into flour, etc], in a windmill belonging

to Mr. Francis Bacon, of Dickleburgh, the cogs caught hold of his

frock smock, and so entangled him, that he was carried round by the

same for three hours, in which time he was reduced to a most horrid

spectacle.”

. . . . and from the Caledonian Mercury (1800) . . . .

“Yesterday evening the proprietor of the mill at Holyrood, had both

legs most dreadful fractured, by the breaking of the millstone. Mr. Comins, the Staff Surgeon, being sent for, found the limbs in so

shattered a state, that he was under the necessity of amputating

both limbs immediately.”

For effective operation, windmills need a consistent draught with

minimal turbulence from the surrounding landscape. Thus, they were

often sited on isolated ground, but this left them more exposed to

damage by storms and lightning strikes, problems made worse by their

position generally being out of easy reach of water with which to

fight fires. This from The Standard (1829) . . . .

“During the thunderstorm on Thursday, the windmill at Toot Hill,

near Ongar, was struck with the lightning and literally dashed to

pieces; parts of it were driven nearly 100 yards, and the corn

strewed about; and a man buried in the ruins has since been got out

alive, but dreadfully bruised. The leg has been amputated . . . .”

. . . . two days later a further report of this incident appeared in

The Morning Chronicle, embellishing the earlier details by informing

readers that the victim was the miller . . . .

“. . . . and his right hand mangled in a most frightful manner. . .

. upon further examination, large splinters of wood, and even grains

of wheat from the hopper, were found driven into various parts of

his body.”

This from the Times (1954) . . . .

“One of the last four working windmills in Lincolnshire, a county

which at one time had over 400 in use, has been struck by lightning

. . . the sails crashed through an adjacent engine house and were

smashed to pieces . . . . and the foot thick shaft was snapped off

when the lightning struck.”

The absence of means to turn old post mills into the wind

automatically made them particularly prone to storm damage. Indeed,

both the post mills at Pitstone (see Chapters

V & VI) were damaged

beyond repair when struck from behind by sudden squalls before they

could be winded, the outcome being chaos to their internal shafts

and gearing before their sails were eventually torn from their

windshafts.

Fig. 4.5: the miller and his

mate inspecting the patent sails of Willesborough mill, Kent.

This smock mill survives in full working order

The vulnerability to storms of old windmills fitted with

simple cloth sails, is illustrated in this experience of James

Saunders while driving his post mill at Stone near Aylesbury . . . .

“A modern windmill is one thing, an antiquated post mill 400 years

old, as mine was said to be, is quite another. . . . It was in

October or November, at a time when I was so busy I had not kept a

proper lookout for storms . . . and a tremendous hurricane caught me

unawares. My first warning was that the mill was running faster and

faster, but I was not really disturbed then until I had put the

brake on and gone down to take some cloth off. Outside it was as

black as pitch. I felt my way round to one sail and was just

beginning to uncloth when the gale came on like mad. It blew me

against the round-house, and away went the sails as if there was no

brake on at all. I shall never forget how I rushed back up the

ladder. The whole mill rocked so that the sacks of meal that were

standing in the breast were thrown down like paper, but I got to the

brake lever somehow and threw all my weight on it. I knew that if

the brake were kept on she was bound to catch fire, so I let her

off, and round she went, running at such a rate that the corn flew

over the top and smoke blinded and suffocated me. . . . The sparks

were flying out all round the brake as she groaned and creaked with

the strain, but it still didn’t stop the sails; and I doubt whether

anything could, had not the hurricane itself subsided as suddenly as

it sprung up.”

And storms did cause mills that had ‘run away’ to catch fire; this

from the Morning Post (1818) . . . .

“We this day give some further melancholy details of the effects of

the late violent storm . . . at Exmouth, the violence of the gale

carried round the vanes of the windmill with such velocity as to

cause the works to take fire, and the vanes were ultimately blown

off, and dashed to pieces.”

More substantially built tower mills fitted with patent sails and

with fantails (and thus

less likely to be tail-winded), weathered storms better, but when the

sails were damaged, repairs could be very expensive. To keep costs

down, millers did what running repairs they could themselves —

particularly the lengthy task of dressing the millstones — and only

resorted to a millwright or the village carpenter for specialist

jobs.

“MAN KILLED

BY A WINDMILL — Last week a man named

James Messenger, was killed at Houghton Regis, by the sails of a

windmill. It appeared that whilst about his work there he

imprudently passed close to the sweeps of the sails to get to a

door, and one of the fans struck him on the back part of the head.

The poor man was struck to the ground with great violence and was

picked up insensible. His master rendered assistance and

forwarded a messenger to Dunstable for a surgeon, who, in

examination found that there was no fracture of the skull, but the

poor man was labouring under a severe concussion of the brain, and

in a few days after he died.”

Bucks Herald, 26th February

1842.

FIGURES OF SPEECH: RELICS OF

THE MILLER’S TRADE

The millers of the past are not completely forgotten, although few

people realise this when they refer unknowingly to aspects of the

miller’s trade, for certain of their idiomatic expressions remain in

common use today:

Grind to a halt: refers to any process that will stop as a result

of a lack of materials or due to a breakdown in machinery. In a

mill, the millstones would literally “grind to a halt” if the wind

was not strong enough to drive them.

Show one’s metal/Show one’s grit: is a figure of speech that today

has more to do with demonstrating courage than experience, although

it derives from the latter. When a miller employed an itinerant

stone dresser to resharpen his millstones, the miller invited him to

display his tools and his hands for the miller’s inspection to

demonstrate his experience. The stone dresser’s tools are made of

iron, and the back of the hands and arms of an experienced stone

dresser would be blackened by the multitude of embedded fragments of

metal and grit from the task of resurfacing the stones. Hence, to

“show his metal”.

Rule of thumb: refers to the habit of the miller rubbing the flour

between his thumb and forefinger to assess whether it was too

coarse; if it was, he would reduce the gap between the grinding

stones to produce finer flour.

Grist to the mill: refers to a source of profit or advantage. Grist

is the grain brought to a mill to be ground. In the days when

farmers took grist to the mill the phrase would have been used to

denote produce that was a source of profit.

Keep your nose to the grindstone: means to apply yourself

conscientiously to your work. This might have derived from the habit

of millers, who checked that the stones used for grinding were not

overheating, by putting their nose to the stone in order to smell

any burning. But it is equally likely to have come from the

knife-grinder’s trade.

Run-of-the-mill: for a mill to produce flour of a consistent

output, the grain had to be of a certain quality, as had the milling

process. Thus flour that met whatever criterion that had been set

was described as run-of-the-mill, what we today might otherwise

describe as “standard”.

A millstone around one’s neck: is a Biblical metaphor meaning a

burden or large inconvenience one has to endure.

To be put, or to go through the mill: means to be exposed to

hardship or rough treatment, just like grain being ground.

Don’t drown the miller: little heard today, it derives from the

miller’s once crucial position in rural society in the production of

flour to make bread. This figure of speech was intended to convey

the value of an asset (however unpopular, as the miller often was),

for the obvious consequences of drowning the miller would be to

deprive the community of a vital, possibly even life-sustaining,

service. “Drowning” probably derived from watermills and their

millponds, being far more numerous than windmills.

――――♦――――

APPENDIX I.

WHEAT FLOUR AND BREAD

Wheat flour is finely-ground grain. It is one of our most important

foods, for it is the principal ingredient in most types of bread,

biscuit and pastry.

Wheat probably developed from the accidental crossbreeding of

certain grasses, and by mutation. It was cultivated long before the

beginning of recorded history, archaeologists having found evidence

that it was grown in western Asia Minor at least 10,000 years ago. The ability to sow and reap cereals may be one of the reasons that

led man to live in communities, as opposed to following a wandering

life hunting and herding animals. The Egyptians were to develop

grain production along the fertile banks of the Nile. By about

3,000 B.C. they had evolved tougher varieties of wheat and had become

skilful in baking bread.

|

|

|

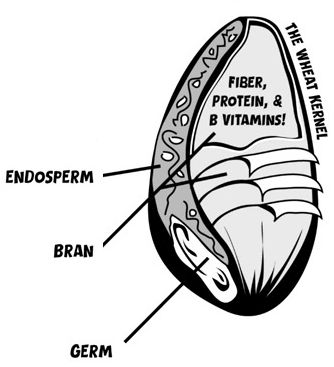

Fig. 4.6:

milling essentially separates bran and germ from

endosperm, reducing the endosperm to a uniform particle

size called ‘flour’ |

Wheat grain needs to be crushed to extract the flour, but not all

the grain is used. A grain of wheat (the kernel) has three main

parts; bran is the tough outer covering; the embryo plant, or

germ,

is found in the bottom of the kernel; the remainder is the

endosperm, a material composed largely of starch with some sugar. It

is the endosperm alone that is used in the commercial

mass-production of white flour.

The first task to perform before wheat can be ground into flour is

to remove the heads from the top of the stalks. These are then

threshed, a process that removes the edible grains from the rest of

the head, called chaff. The grain is then ground to separate the

bran, endosperm and germ. The resulting meal is sifted into various

grades, white flour being the finest. White flour contains only the

endosperm, while wholemeal flour contains all parts of the grain,

which gives it a brownish appearance. Although wholemeal flour is

more nourishing it suffers the disadvantages of a shorter shelf-life

and, when used for baking, a poorer rising characteristic than white

flour.

The earliest type of bread is believed to have been made from grains

of wild grass, which were crushed by hand between two stones. The

resulting meal was mixed with water to form dough, which was then

baked on a stone over an open fire. This type of bread would have

been very coarse and heavy in texture.

Yeast is known to have been used by the Egyptians in around 4,000

BC, first in brewing and then in baking. Perhaps wild yeast first

drifted onto a dough that had been set aside before baking, causing

it to rise enough to make the bread lighter and more appetizing than

usual. This accidental process was then reproduced deliberately. But

a more plausible theory is that, maybe by way of experiment, ale was

used instead of water to mix the dough. The rise would have been

greater than from wild yeast, and the effect would have been easier

to explain and reproduce. The Egyptians also invented the closed

oven and bread assumed great significance, being used instead of

money; the workers who built the pyramids were paid in bread.

By 1,000 BC, leavened bread had become popular in Rome, and by 500

BC a circular stone wheel turning on top of another fixed stone was

being used to grind grain; pairs of grindstones became the basis of

all milling until the late 19th century and are still used today in

the production of stone-ground flour. It is in this period that the

waterwheel was invented by the Greeks and later adopted by the

Romans who brought it to Britain.

During the Middle Ages, the growth of towns and cities saw a steady

increase in trade and bakers began to set up in business, with

bakers’ guilds being introduced to protect their interests while

controls also appeared to govern the price and weight of bread. By

Tudor times, bread had become a status symbol, the nobility eating

small white loaves, merchants and tradesmen wheaten cobs, while the

poor ate bran loaves (the most nutritious).

During the 18th century sieves made of Chinese silk were introduced,

which helped produce finer, whiter flour and white bread gradually

became more widespread. Tin from Cornish mines was used to make

baking tins resulting in bread (‘tin loaves’) that could be sliced and

toasted more easily and it was not long before the sandwich was

invented. At this time, and until well into the Victorian age, bread

was generally made from mixed grain; barley and rye breads took

longer to digest and were favoured by labourers while the rich

continued to eat the more expensive white wheat bread.

In the early 19th century, cheap imported wheat was becoming

plentiful. To protect British grain prices and the income of the

landed gentry, the Corn Laws of 1815 imposed a high import tariff on

foreign-grown grain. The price of bread rose to as much as 2s.6d. a

loaf, when some wages were only 3s. shillings a week. But despite

the terrible suffering of the disenfranchised poor, the Corn Laws

were not repealed until 1846.

The 19th century also saw the introduction of town gas, which

replaced wood and coal to fuel bakers’ ovens, producing much more

even results, and the large automated baking units that followed

increased bread production significantly.

Today, 76 per cent of the bread we eat is white, with sandwiches

accounting for about half of this. Large bakeries producing wrapped

and sliced bread. It was introduced here in the 1930s and accounts for 80 per

cent of UK bread production. In-store bakeries produce about 17 per

cent and the remainder of the bread we eat is sold in local bakeries.

Some traditional millers continue to use millstones, which unlike

the steel rollers used to mill mass-produced flour, allows the

miller to leave the whole grain intact, thereby adding a depth of

flavour to the flour. Most commercial flour has the germ removed. Many independent bakers make a point of using stone-ground flours

grown in Britain and milled at smaller-scale mills. The

resulting bread has more character and flavour, such as that produced in the small bakery attached to

Redbournbury Water

Mill, St. Albans (generally open to the public on Sunday

afternoons).

――――♦――――

APPENDIX II.

GLEANING

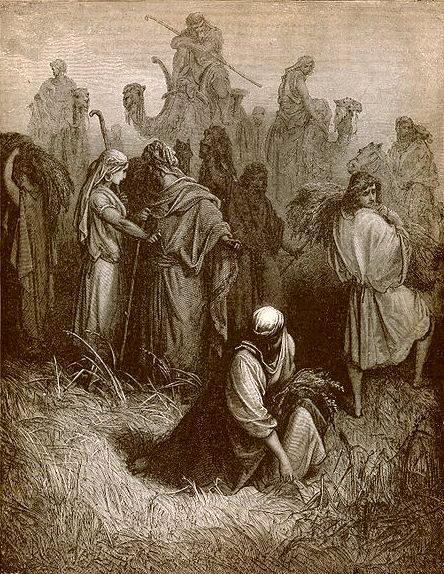

Fig. 4.7: ‘The Gleaners’, by

Gustave Doré (1832-83)

Gleaning is gathering grain left by the reapers. Some cultures

promoted it as an early form of welfare system and in this context

the Bible makes several references to gleaning, including

Deuteronomy (24:19–21), which states the law thus . . . .

“When you are harvesting in your field and you overlook a sheaf, do

not go back to get it. Leave it for the alien, the fatherless and

the widow . . .”

. . . which led to one poor biblical widow meeting her husband to

be, for the romance between Ruth and the wealthy Boaz (Ruth 2) first

sparked into life when Boaz caught sight of Ruth gleaning in his

field after the reapers, as depicted by Doré (fig. 4.).

But gleaning did not always have a happy ending and until well into

the 19th century it could lead to the prison cell. Under the heading

A WOMAN IMPRISONED FOR GLEANING, the Birmingham Daily Post, 12th

August 1868, carried a report of a “poor woman” imprisoned by

Chester Magistrates. The newspaper informed its readers that a

certain farmer had complained: “I have had such a great deal of

damage I want to make an example.” And an example their honours duly

made; “You must go to jail for seven days,” was the verdict of the

bench, but on sentence being passed one of the magistrates had

second thoughts . . . .

“‘I won't be a party to that. Seven days! All the papers in the

country will be down us.’

The defendant turned very pale, and, bursting into tears, said,

‘Seven days for that! Don't send me to gaol from my four poor

children, and one sucking at the breast.’”

Meanwhile the farmer was also back-tracking, for while he wished for

some punishment “he did not ask for so much as that”. The commotion

that followed caused their honours to reconsider, following which

the sentence was reduced to a fine of 5s.6d. damages with 8s. costs

(the wage of a farm labourer at that time was around 10s. a week);

but as the defendant could not pay, she served three days in jail.

Fig. 4.8: ‘Gleaners’, by

Jean-François Millet (1814–75)

Despite the threat of jail, gleaning was commonplace, although

subject to local rules as this extract from the Farmer's Handbook of

1814 describes . . . .

“The custom of gleaning is universal, and very ancient: in this

country, however, the poor have no right to glean but by permission

of the farmer; but the custom is old and so common, that it is

scarcely ever broken through. It much behoves the farmer, in some

places, where it is carried to excess, to make rules for the

gleaners, and not to suffer them to be broken, under any pretence

whatever.”

Each area of the country had its own customs, for instance at Gamnel

Wharf mill in Tring, there was a day set aside to grind ‘gleaners’

corn’, the cost of which was paid by keeping the bran, or,

alternatively a quart out of a bushel of wheat. This old tradition

worked well, except when the treatment of a gleaner was not

scrupulously honest, as in the case of Frederick Eggleton and the

miller of Goldfield described above.

Gleaning remained an extremely important feature of rural life until

the beginning of the 20th century, especially in times of

agricultural depression when farm work was scarce. Many villagers

relied on the flour that was derived from their autumn gatherings in

the wheat fields to last the family throughout the year. |