|

|

|

|

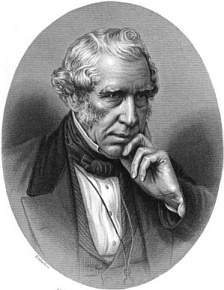

Fig. 5.2: Sir

William Fairburn,

civil engineer |

The 19th

century civil engineer, Sir William Fairbairn (1789-1874) [5] began

his working life as an apprentice millwright at Newcastle-upon-Tyne. In his Treatise on Mills and Millwork (1865), Fairbairn provides an

interesting insight into the millwright’s work during the 18th

century:

|

“. . . . the millwright of the last century was an itinerant

engineer and mechanic of high reputation. He could handle the axe,

the hammer, and the plane with equal skill and precision; he could

turn, bore and forge with the ease and despatch of one brought up to

these trades, and he could set out and cut in the furrows of a

millstone with an accuracy equal or superior to that of the miller

himself. These duties he was called upon to exercise, and seldom in

vain, as in the practice of his profession had he mainly to depend

upon his own resources.” |

Thus, the millwright’s trade combined elements of those of the

carpenter, blacksmith and stone mason, while he needed to be of a

practical and resourceful turn of mind. His occupation also demanded

the ability to design mills and milling machinery, which required

the application of arithmetic and geometry to the manufacture of all

the components of a working mill. Fairbairn tells us that . . . .

“. . . . he could calculate the velocities, strength, and power of

machines, could draw in plan, and section, and could construct

buildings, conduits, or watercourses, in all the forms and under all

the conditions required in his professional practice. . . ."

During the windmill era, the millwright performed much of the work

of today’s civil engineer and it is not difficult to see why some of

the more gifted among their ranks became our first great civil

engineers. Expertise also flowed in the opposite direction. John

Smeaton, famous for the Eddystone Lighthouse (and the first to

proclaim himself a “civil engineer”), while not a millwright by trade,

performed valuable research into the design of milling equipment. He

investigated sail design and was the first to employ cast iron in

place of wooden parts in the construction of milling machinery.

Fairbairn also tells us something about the millwright’s standing in

society . . . .

“. . . . living in a more primitive state of society than ourselves,

there probably never existed a more useful and independent class of

men than the country millwrights. The whole mechanical knowledge of

the country was centred amongst them, and, where sobriety was

maintained and self-improvement aimed at, they were generally looked

upon as men of superior attainments and of considerable intellectual

power.”

Perhaps Fairbairn’s opinion was rose-tinted, for the two local

millwrights for whom we have been able to obtain information, while

offering the range of skills that he describes, do not appear to

have matched them with a high degree of business acumen.

THE DECLINE OF THE MILLWRIGHT’S TRADE

As the Industrial Revolution progressed, millwrights were pressed

into service to build the first powered textile mills. James Watt’s

condensing steam engine developed into an economical and reliable

driving force and, unlike wind and water power, one that offered a

stable source of motive power. Gradually, wind and water mills were

replaced, first by steam-driven machinery and eventually by electric

power, while small local grain mills gave way to large factory units

catering for entire regions of the country. As for the millwright,

his work was mostly lost in the evolution of other trades, such as turners,

fitters, machine makers and mechanical engineers.

LOCAL MILLWRIGHTS

THE HILLSDONS OF TRING

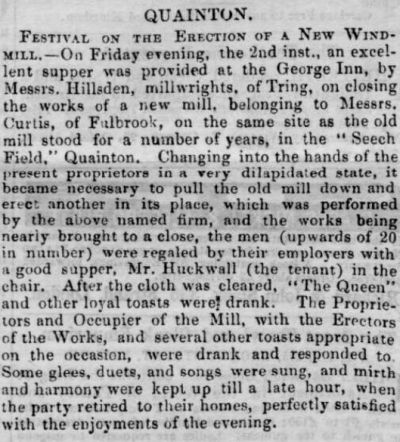

Fig. 5.3: Bucks Herald,

10th November 1855

Waddesdon-born John Hillsdon came to Tring in about 1825. The 1841

Census records him living at Tring Wharf with his wife and five

children, where he worked as a miller at Gamnel Wharf mill (Chapter

VII) together with his 16-year old son, John.

By 1850 John had left Gamnel to trade on his own account, describing

himself as a ‘Millwright’ and occupying premises on the corner of

Chapel Street and King Street in Tring. Ten years later the Hillsdon’s venture into the world of business had proved unwise, for

their financial affairs were in a parlous condition. On 15th

December 1860 an announcement appeared on the front page of The

Bucks Advertiser & Aylesbury News:

|

|

|

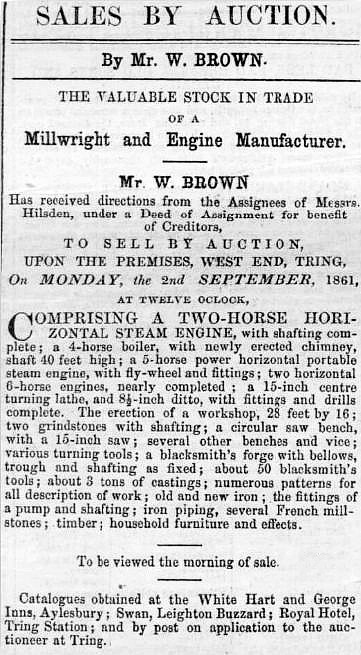

Fig. 5.4: Bucks

Herald, 24th August 1861.

Bankruptcy sale of Hillsdon’s assets |

|

“Notice is hereby given that by indenture dated the 7th day of

December 1860, John Hillsdon the elder and John Hillsdon the younger

of Tring, in the County of Hertford, Engineers, assigned all their

personal estate and effects whatsoever and wheresoever to William

Smith Simkin of No 6 Leadenhall Street, London, Ironmonger, and John

Nevins of Nos 1 & 2 Great Guildford Street, London, Ironmonger, upon

Trust for the benefit of themselves, and all the creditors of the

said John Hillsdon the elder and John Hillsdon the younger . . . .

In the presence of John Merritt Shugar of Tring, Solicitor.” |

In spite of this drastic measure, in the following year Johns senior

and junior — now described as agricultural machine makers — are

found in the records of the Hertford Union Gaol & House of

Correction, imprisoned for debt. By no means an uncommon offence at

that time, the Hillsdon’s fellow inmates were other assorted

traders, including a china dealer, a market gardener and a straw hat

maker.

In May, 1861, John Jnr. petitioned for his discharge, his debts

amounting to £587. 14s, offering to pay 10s in the pound. All

his creditors concurred, save one, a solicitor, to whom Hilsdon owed

£21, but the objection was set aside and John was discharged.

What happened to his father is unrecorded, but they

weathered the storm and returned to carry on business in the same

premises as before. In 1869 John junior placed an ambitious

advertisement for Tring Iron Works in Kelly’s Trade Directory, where

he is described as “engineer; millwright; manufacturer of portable

and fixed steam engines, water wheels; corn, bone, bark and colour

miller; and iron and brass founder”. No more is heard of John junior

in Tring, but it is believed that he and his wife emigrated to New

Zealand, leaving there seven years later for the USA. George

Hilsdon, a younger son, also followed the family tradition and

remained with his father at the King Street business.

The firm of Hillsdon was undoubtedly involved in a wide range of

mill-related business, but all that is now known is that they erected the tower mill at

Hawridge Common (Chapter IX), installed the steam engine at

Wendover windmill (Chapter X)

and were possibly involved in the construction of Goldfields and

Waddesdon mills. [6] John senior is last recorded in 1871, a widower of 76

living in lodgings in Frogmore Street, Tring. It is believed that

the Hillsdon’s firm, Tring Ironworks, closed around 1905.

WILLIAM COOPER OF AYLESBURY

Almost all that is known of William Cooper and his business are

contained in two account books now held in the Buckinghamshire

Archives.

On October 11th, 1831, an announcement in the London Gazette stated

that the partnership between William and Joseph Cooper, Millwrights

and Smiths of Aylesbury, Bucks, had been dissolved by mutual

consent. The following year William Cooper was declared bankrupt,

his two account books passing into the custody of the court. One is

a general ledger in which are recorded his business transactions

between May 1827 and September 1832, the other records expenses

incurred between April 1830 and January 1831 in connection with

fitting out Champness windmill at Fulmer.

In common with the Hillsdons, the ledger shows that Cooper performed

a surprising range of work. This extended from simple repairs

to stoves and locks, to more complex work on agricultural machinery,

through to the installation of all the equipment at Fulmer and

Quainton windmills. The ledger also shows that Cooper

worked on some thirty wind and water mills in and around Aylesbury,

including a windmill at Tring (but unclear which) and those at Waddesdon (Chapter

XIV), Wingrave (Chapter XIV),

and Wendover. He also undertook work on the treadmill in

Aylesbury Gaol and on an unspecified type of mill at Winslow

Workhouse.

The cost of fitting out Champness mill was £445 8s.10d., of which

almost half was for labour, the balance being for canvas (121

yards), tacks (22,000), screws (13 gross), nails, chisels, ironwork,

timber, and “Different things”. Wages paid to the skilled men were

four shillings a day, while the daily rate for the two labourers was

two shillings.

Among Cooper’s smaller jobs are recorded the repair of butter

churns; roughing of horse shoes; mending wagons; repairing a kitchen

range; mending a rat trap; ringing pigs; mending plough shears; and

to a Mr. Collins he supplied “12 stoves different sizes”. If nothing

else it seems that the millwright of the age was versatile.

What led to Cooper’s bankruptcy is unknown, although in the Fulmer

book there are references to expenses of a legal nature: “Copy of a Rit” (writ), expenses for “Sherrfs officer”, and “Lawyer Charge”,

which suggest that he might have been owed money for work on the

mill. There are also several entries that refer to the purchase of pints

and quarts of gin and rum.

Apart from these account books, the Aylesbury Poor Rate Book for

1831-2 records that Cooper’s premises were in Walton Street on a

site now occupied by the White Swan, but by 1835 the foundry had

gone. |