|

Although the fan-stage and fantail are long gone, the worm-gear that

the fantail drove remains in place together with cross-bars to

permit hand-winding (fig. 10.3), necessary when there was a very sudden

change in wind direction. This gearing connects via a vertical

spindle with an iron rack of some 300 iron teeth. Set into the cill,

the rack extends around the circumference of the cap (plate 24).

The 30 iron rollers

upon which the cap revolved also remain in place, some being just visible

above the rack.

Fig. 10.3: hand winding gear

in the cap

The cap is of wood and much larger than those at Quainton, Goldfield

and Hawridge tower mills. Its base consists of four cross members

that are mortised at each end into two massive beams that extend

across the mill. Above this, 24 substantial rafters arch upwards to

a pinnacle, forming the frame that supports the roof — quite

spectacular as one looks up at its apex (plate 23). The roof’s

interior is clad with wooden boarding, its exterior with zinc

sheeting.

Notable among the mill’s former machinery were its upright shaft —

reported to have been a ship’s mast — and its 4-ton, 18ft iron

windshaft, which remains in place and which the millwright Derek

Ogden, who worked on the mill in the 1960s, claimed to be the

biggest that he had ever seen (plate 25). Also remaining and clearly

visible from behind the mill, is the iron centre cross on which the

stocks that carried the sails were mounted. Originally, the sails

were of the ‘simple’ variety but these were later replaced; when the

mill was sold in 1875, the auctioneer’s catalogue described them as

being . . . .

“of modern construction, with all the

latest improvements, two of which are recently new, and the Fan

[fantail] will be found good and

efficient.”

Although long gone in Freese’s time, he describes the sails as

having been “double-shuttered anti-clock patents”, which can be seen

at fig. 10.2.

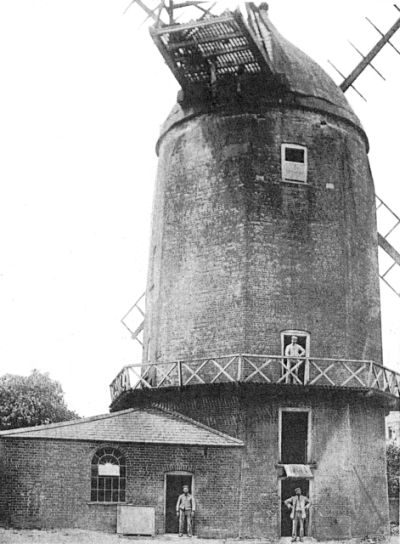

The mill originally had a gallery at second floor level (fig. 10.4)

but this was removed in 1947 when extensive repairs were carried out.

The

present gallery at cap level (plate 22) is a recent addition, constructed to

ease roof maintenance, for leakage has been a recurring and expensive

problem to deal with. A tall chimney stack was also built onto the

south side of the mill at some time after windmilling ceased, for it

would otherwise have impeded the fan-stage as it revolved.

STEAM MILLING

|

|

|

Fig. 10.4:

Wendover mill showing the engine house |

At some point in its life wind power was supplemented with a 12 hp

steam engine installed in an engine-house built onto the south side

of the mill . . . .

|

“. . . the former windmill at Wendover was converted to steam power

because the building of houses near to it affected the currents of

air. The late Mr. F. Purssell, the miller, said there was great

difficulty when the wind shifted suddenly into the opposite quarter,

and the sails started to revolve backwards. The sails had to be

wound round by hand to bring them into the wind again.”

In Buckinghamshire, G. Elland,

1923.

|

Stanley Freese describes the machinery as . . . .

|

“. . . . an exceptionally fine expansion engine, no doubt the best ever used

in a Buckinghamshire windmill . . . . starting from cold at 7.30

a.m., she would soon grind corn with about 40 lbs. of steam, but

would not operate the sack hoist until about 11.30 . . . . sometimes

the sack hoist was driven all day in order to replenish the

exceptionally capacious bins.” |

A flue from the engine’s boiler passed underground to a tall

brick-built chimney in the centre of the mill yard. Although it is

not known when the steam engine was installed, it is recorded that it

was by Hillsdons of Tring (Chapter V).

Milling is believed to have continued using both wind and steam, but

having been damaged severely by a storm the sails were removed in

1904.

Fig. 10.5: the miller’s house

THE MILLERS

|

|

|

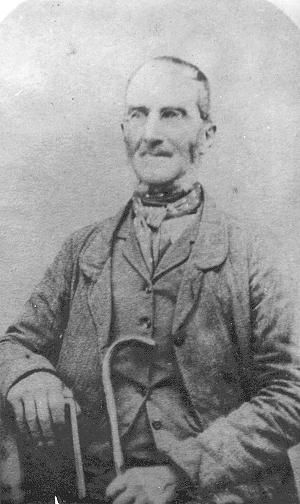

Fig. 10.6: Charles

Burton |

Wendover Mill had a number of occupiers up to 1875. Local trade

directories list Thomas Horwood and Thomas Andrews as millers in

1842 and 1850 respectively; the 1851 Census lists Charles Burton. In

1861 the diary of Thomas Grace of Tring records that he accompanied

his brother-in-law, Edward Mead, to look over the mill and that

Edward agreed to pay £100 a year in rent. Mead operated the mill

until 1869 when Thomas Edward Biggs took over.

In 1875, due to the expiry of the lease, the mill was offered for

sale by auction. The name Zachariah Phillips appears on the

auctioneer’s ground plan, which suggests that the freehold remained

in the possession of the original owners, the Phillips family. The

sale was conducted by Reader & Son at the Bell Hotel, Aylesbury. Their catalogue describes the property as a . .

. .

“Brick-built, octagon-shaped, roomy

FREEHOLD WINDMILL

of five stories, driving three pairs of stones,

with the whole of the gearing complete

also, attached thereto, a

12-HORSE-POWER STEAM ENGINE

and boiler, with high Shaft, driving two pairs of Stones . . . .”

In addition to the windmill were granary, store houses, cart sheds,

stables, the miller’s house, out-houses, yard and garden. The

catalogue goes on to describe in detail the mill’s structure and

equipment (see Appendix I).

The mill was bought by William Purssell for £1,000, but others ran

it for the names of Francis Beesley (1877) and George Butterfield

(1883) appear in the records. On William Purssell’s death in 1887,

his son Frank took over from Butterfield and continued to operate

the mill until his death in 1922.

In his account, Freese suggests that in its early life the windmill

was unsuccessful commercially and it was not until Frank Purssell’s

time that business began to look up . . . .

“. . . . he took her over from a Mr Butterfield. Steadily the

business improved under his management, and he confounded the

pessimists by building up a very flourishing and successful trade,

which was still very good when he passed away in 1922 . . . . mostly

English wheat was ground in the old days, some of it coming by canal

to Wendover Wharf, but with the steam engine they latterly ground

much Russian barley and American maize, etc. and flour was made

until about 1912; generally speaking there was a loss of about 7

lbs. per bushel.”

Following Frank’s death in 1922 his son Basil carried on, but by

then business was beginning to decline, probably due to competition

from larger and more efficient roller mills. By 1925 the mill was

only working two days a week due to “difficulties of the trade”. In

the following year, the General Strike and its coal shortage led to

the mill’s closure. The machinery was removed in 1929 and the engine

house and chimney were demolished two years later.

THE WINDMILL IN DOMESTIC LIFE

Fig. 10.7: the mill following

conversion to a dwelling c.1930

By the time of its closure, the mill’s floors were in poor

structural condition with rot affecting some of the joists, probably

due to damp seeping through flaws in the bonding of the brickwork. The mill’s cap was also perishing and there was talk of demolishing

the top two floors. This drastic action was avoided, and in

1931 the mill was converted to a private house. Freese, writing

during the 1930s, reports that . . . .

“. . . . some big long irons or bolts were inserted by which the

weak fourth floor is now practically suspended from the curb of the

mill, whilst the fifth floor has two iron girders set into the wall

just below, giving support to the rotten ends of the two main

joists. New staircases have been installed . . . . and the ground

floor has been converted to a cosy living room by Miss Marion

Fawcett, the actress and playwright, who is now the tenant, whilst

the second floor contains two comfortable bedrooms and a bathroom,

the upper floors being vacant .”

Miss Fawcett, who leased the mill for 15s. a week, continued the

tenant until 1946 when the mill again fell into disuse. Basil Purssell, writing to the

Bucks Herald in October 1954, stated that .

. . .

“In October 1948, when a gale blew in part of the back cap, Mr

Freese was a great help. Together with a London workman, Mr. Carew,

who had been working therein that summer, he repaired the roof

temporarily for £50 and it was a courageous job. . . . the late Mrs.

Frank Purssell planned the preservation of the mill back in 1931,

the idea being to convert it into a comfortable home . . . after

that considerable sums of money were spent on maintenance both by

the owners and the leaseholder, London actress Marion Fawcett.”

By 1953 the mill was again in a poor state of repair and at risk of

demolition. It was offered for sale and an advertisement in the

New

Statesman caught the eye of Kenneth and Margaret Roberton, who

bought the mill and moved in on Coronation Day, 1953. Again, the

Bucks Herald . . . .

“The new owner, who is the well-known musician Kenneth Roberton,

spent a further £600 this summer on renovation.”

The domed roof was rebuilt in the mid 1960s making the top two

floors habitable and from the 1970s until his death in 2003, Kenneth Roberton used them as the base for his music publishing business,

Roberton Publications. His obituary in the Bucks Herald stated that

he was a tireless campaigner for the town’s interests, helped to

found the Wendover Society, as well as fighting for the rights of

residents and battling against developments that he felt would

adversely affect the town.

A further piece of structural work on the cap is recorded in an

article on the mill in the Bucks Advertiser in June, 1971 . . . .

“in the summer of 1969, the familiar black cap was replaced with a

shining white aluminium one . . . .”

. . . . that the present occupier had to replace when the aluminium

was discovered to be leaking through its joints. The cap is now clad

with zinc sheeting, the fastenings of which are sheltered from the

rain by fold-over joints.

Today the windmill, which is Grade II listed, is a very comfortable

family home. Its five levels contain five bedrooms, three reception

rooms, three bathrooms and a kitchen (Appendix II) — but looking back at some of

the old repair bills, one cannot help forming the impression that

those who would live in an old windmill need a deep pocket!

――――♦――――

APPENDIX I.

AUCTIONEER’S PARTICULARS (1875)

ENGINE HOUSE

A superior 12-horse-power horizontal Steam Engine by Hillsdon,

Tring, working expansively with 11-inch cylinders, 2ft. 4ins stroke,

large fly wheel (11-feet diameter), steam and exhaust pipes, with

governors, pump, &c., bed plate, and brick foundation. An excellent

Cornish boiler (only recently put in), 18ft. by 4ft. 6ins, with flue

2ft. 3ins diameter, dome, safety valve, pressure gauge, water gauge,

and the brick setting thereof. Hand-force pump for feeding boiler.

THE MILL

GROUND FLOOR. — Crank shaft from steam engine, 5½-inch diameter, and

14ft. long, driving two pairs of wheat stones on first floor, on

cast-iron upright frames, with plummer blocks and brasses, carrying

two bevel wheels, driving pinions, on stone spindle, with iron

bridge-trees and brass steps, iron rising screws one drum on end of

shaft, for driving dressing tackle on 1st Floor two meal bins and

shoots, jogging screen for offals, sack jumper, and step ladder.

FIRST FLOOR. — Two pairs of 4ft. wheat stones (driven by steam power),

with damsels, wood hoppers and casing, stone spindles, bevel wheels

and pinions, iron shaft, driving pulley, cast-iron housings,

housings, and wood shoot. One 21-inch lay shaft, 9ft. 6ins long, with plummer blocks and three pulleys, driving the 3ft. 6ins dressing

machine, with 16-inch cylinder, pulleys, plummer blocks and shaft,

complete in deal case flour bin, offal bin.

SECOND FLOOR. ― Spur wheel and three stone nuts and spindles, bridge

trees, rising screws, and governors, three jogging screens to part

the offals, three meal bins, three spouts, apparatus and chain for

hoisting by steam power.

THIRD OR STONE FLOOR.

— Two pairs of wheat and one pair of barley

stones, 4ft. and 4ft. 6 in diameter, with damsels, wood hoppers, and

casings, stone spindles, spur wheels and pinions, iron shaft,

driving pulley, cast iron housings, and wood shoots one lay shaft,

about 10ft. long, with hanger and plummer blocks, bevel pinions for

driving smutter, dressing machine, and bolting mill one crown wheel,

on wallow shaft and iron pinion one dressing machine, 4ft. 6ins long,

with 16-inch cylinder, and apparatus feed, &c. one horizontal

smutting machine, 2ft. 2ins long, 16 inches diameter, with shaft,

pulleys, &c. bolting machine, 6ft. long, with spindle, pulley, plummer blocks, &c.

FOURTH FLOOR. — Hoppers to smut machine two others six large bins.

FIFTH STORY. — Iron wind shaft, with large iron boss and break wheel

cast iron wallow wheel, working into break wheel, with oak upright

shaft, circular rack, and hand-gear to fan-tail self-acting hoisting

tackle, with wood barrel break and lever, and about 84 feet of

quarter-inch chain.

YARD. — 53 feet of smoke flue, brick smoke shaft, base 6ft. square,

height about 55 feet. |