|

. . . . AND THOSE AROUND TRING

CHAPTER III.

HOW A WINDMILL WORKS

INTRODUCTION

Little change occurred in windmill design from their first use in

Britain until the Industrial Revolution, when a number of

significant advances were made in the design of sails and machinery. But important though they were, these advances were slow to gain

acceptance and too late to make a significant impact, for by then

James Watt’s condensing steam engine was in the ascendant. From

about the mid-19th century, steam-powered milling began rapidly to

supplant wind and water power. This was followed by the introduction

of industrial-scale flour mills in which steel rollers replaced

grindstones to produce, in greater quantity, finer and more

consistent quality products. Mead’s (later Heygates) Flour Mill at

Tring (Chapter VII) is an early example of an industrial-scale flour

mill.

This chapter describes the general operation of a windmill and some

of the advances in design that were made towards the end of the

windmill era. A brief description of the modern roller mill is given

in the Appendix.

WHAT A WINDMILL DOES

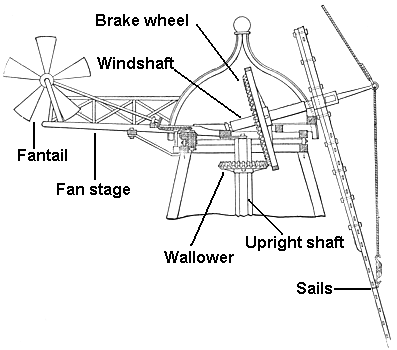

Fig. 3.1: the fantail (where one is

fitted) rotates the cap

automatically to keep the sails facing the wind

The mill was the first engine invented by man. For centuries, mills

driven by water or wind were the only machines that could convert

the power of nature into useful work. In the case of the windmill,

wind striking its sails exerts a force upon them that causes the

shaft to which the sails are attached to rotate. What then follows

depends on what task the windmill is to perform. Windmills have been

used for many purposes, such as pumping water, sawing wood and as

crushing machines in the preparation of oil, paper, spices, chalk

and pottery. Today, wind turbines are used increasingly to generate

electricity. But in Britain, the windmill’s most common use over the

centuries was to grind grain.

In a grain mill, the wind’s energy, harnessed by the windmill’s

sails, is transferred via a system of shafts, cogs and belts to

drive one or more pairs of millstones. Grain, fed between the

rotating millstones is ground into meal.

The remainder of this chapter describes the main steps in the

windmilling process; also the sails and the machinery that is usually

found within a windmill.

THE FLOORS OF A WINDMILL

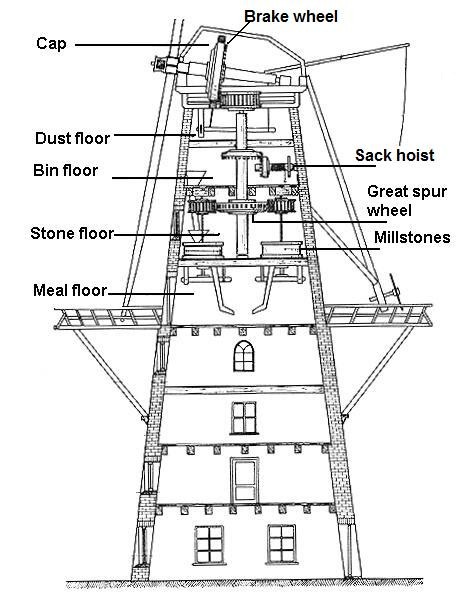

Fig. 3.2: schematic drawing of a

tower mill

Windmills do not follow a common design but they do share common

features, not least of which is that windmilling is a gravity-driven

process. Milling begins at the top of the mill and each succeeding stage

of the process is performed on the next floor down (in following

this process, the need for a mechanically powered hoist to lift sacks of grain

and meal up several floors of a windmill soon becomes clear!)

Windmills were built with different numbers of floors, [3] hence, the

windmilling process is not always exactly as described below. However, in general the following applies . . . .

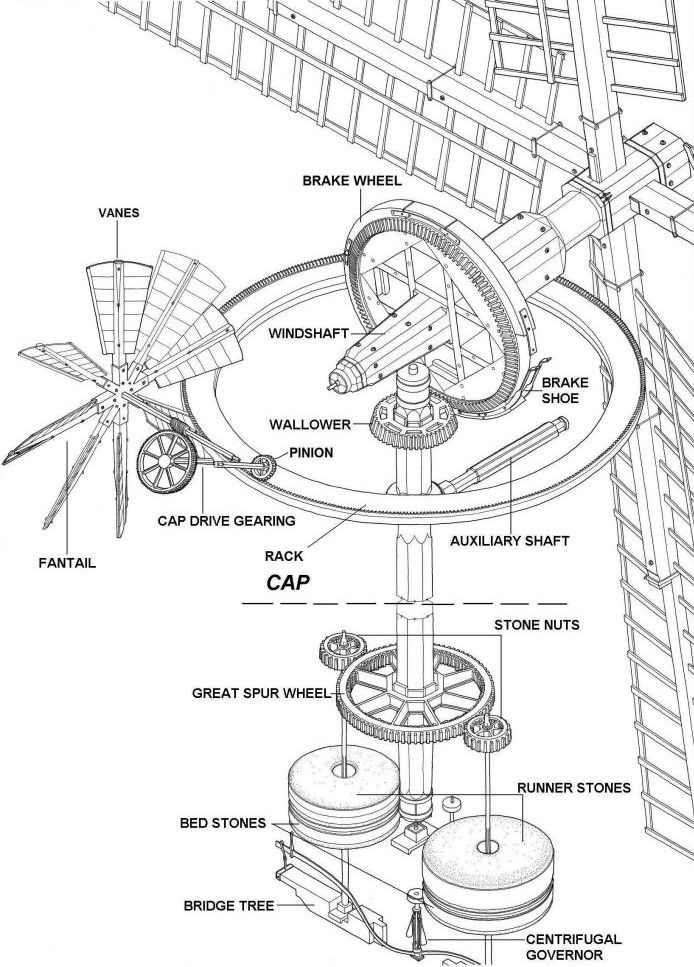

i. The cap, uppermost part of a windmill (fig. 3.1), houses the windshaft,

bearings, cogs and the top of the upright shaft, which transmits the

windshaft’s rotary motion down through the mill to drive the

machinery.

ii. The dust floor (fig.3.2), positioned under the cap, serves to

keep dirt from above from falling into the storage bins and to keep

dust rising up from below.

iii. The bin floor houses bins in which are stored grain for

cleaning; cleaned grain for milling; and meal to be sifted.

iv. The stone floor houses grain-cleaning machinery, the millstones

used to grind the grain, and machinery to sift the ground meal into

various grades of fineness.

v. The meal floor houses chutes from the stone floor above, down

which flows cleaned grain for milling, meal for sifting, and milled

products, each of which is collected in sacks.

THE WIND MILLING PROCESS

The first step in the milling process is to hoist the grain to be

milled up to the bin floor where it is loaded into a storage bin

ready to be cleaned. When required, the uncleaned grain is

discharged down a chute to the stone floor, where it is mechanically

cleaned, then discharged down a chute for collection on the meal

floor.

Sacks of cleaned grain are hoisted up the mill to the bin floor,

where they are stored in a bin ready for milling. When required, the

cleaned grain is discharged down a chute into a hopper on the stone

floor, from where it is trickled into the millstones, ground and

discharged down chutes for collection on the meal floor.

The sacks are then hoisted up the mill to the bin floor, from where

the meal travels downwards, this time through a flour dresser, which

sorts and distributes it according to its fineness, white flour

being the finest and bran the coarsest. All this machinery is powered

by the thrust of the wind as harnessed by the windmill’s sails.

THE SAILS

|

|

|

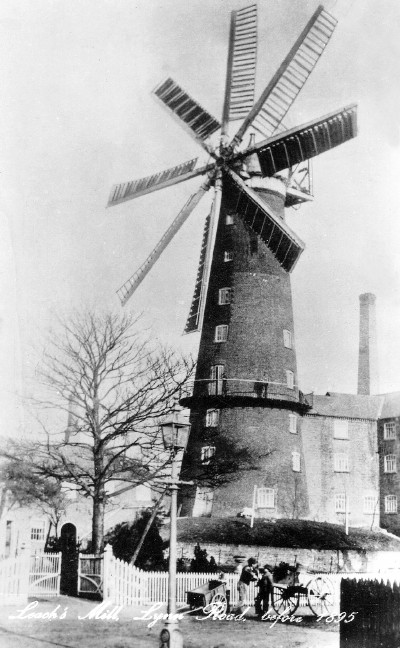

Fig. 3.3: Leach’s

Mill, Wisbech. Ceased milling ca. 1895. |

A

windmill’s sails are usually four in number, but five, six and

eight-sailed windmills (fig 3.3) were also built. More sails

generate more power with a smoother torque, but at greater cost,

weight and maintenance.

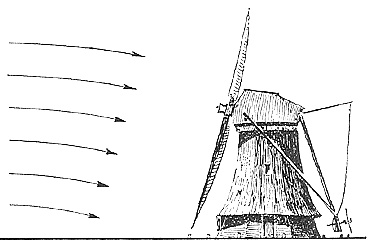

A windmill’s sails do not rotate in the vertical plane, but are

slightly inclined to it, for it was discovered that a slight

inclination of about 15° increases the wind’s effect (fig. 3.4). This is due to wind currents near to the ground meeting more

frictional resistance than higher up, to the extent that at a level

of 43 ft above ground-level, wind velocity is some 10 per cent

greater than at 20 ft. To accommodate the tilt of the sails, the windshaft

has also to be inclined at the same angle below the horizontal, with

its rear end held in place by a firmly-embedded bearing to enable it

to rotate while preventing it from sliding backwards (plate 17;

plate 25).

A further discovery was that sails worked more efficiently if,

rather than being set flat across the sail stock, a slight twist is

applied, this being more accentuated nearest the windshaft (about

18°) lessening towards the tip (about 7°); this twist can be seen in

the sails of Quainton mill (plate 26).

A major problem for the miller was to regulate the speed of rotation

of the sails and thus of the millstones. The optimum sail speed for

a grain mill generally lies in the range 11 to 15 revolutions per

minute; speeds much above that run the risk of over-driving the

stones and burning the grain, while even higher speeds — sometimes

referred to as the mill ‘running away’ — could damage the machinery

and, indeed, the mill itself.

Fig. 3.4: flow of air currents

near the ground.

Small differences in sail speed can be adjusted by changing the

amount of grain fed to the millstones or changing the gap between

them, both of which affect the load placed on the sails. But a large

change in wind speed has to be dealt with by altering the sail area

exposed to the wind, either by increasing or reducing it, a process

called reefing (fig. 3.5).

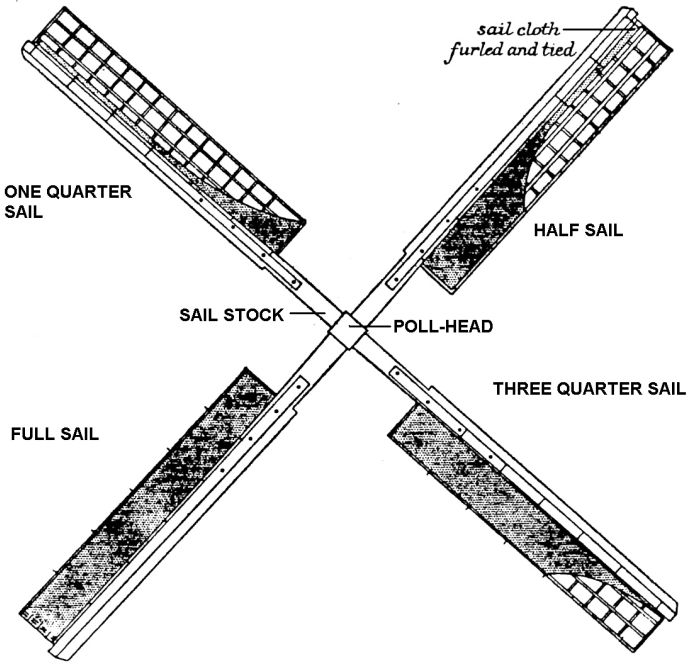

Fig. 3.5: different degrees of

reefing a simple cloth covered sail.

For centuries before the development of more advanced and better

controlled sail systems, sails comprised a lattice framework over

which the sailcloth was spread (plate 10). Such common sails

required two men for reefing, one to climb on the sweeps to carry

out the task and one to control the brake; should the brake fail

during the operation, the man on the sweep was in for a spectacular

ride.

Towards the end of the 18th century, developments in sail design

eased the reefing process. Roller reefing employed banks of cloth

blinds mounted on rollers (comparable to a household roller blind)

that could be adjusted with a manual chain from the ground without

stopping the mill. Other systems replaced the sailcloth with sets of

wooden shutters (comparable to Venetian blinds) mounted along each

sweep. These systems employed some form of tensioning that caused

the shutters to spill the wind automatically if its force exceeded a

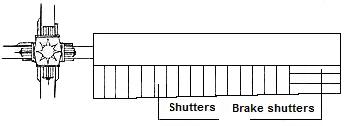

set limit. A later invention, the air brake (fig. 3.6), comprised

shutters placed longitudinally at the tip of each sweep that turned

automatically if the wind exceeded a set strength, thereby

disturbing the sail’s profile and slowing it.

Fig. 3.6: top, a sail fitted

with shutters and air brake.

Bottom, a sail for simple cloth covering.

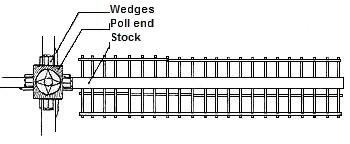

The development of hollow windshafts permitted control rods to be

inserted through their centre (fig. 3.7). This enabled sail settings

to be adjusted from within the mill automatically under the action

of counter-weights.

|

Fig. 3.7: towards

the end of the windmill era, shuttered sails were

introduced that enabled a degree of automatic reefing by

applying tension weights to balance the wind pressure

falling on the shutters. The two forces were

balanced through the striker rod (which passes through

the centre of the windshaft), the shutters bars and

moveable linkages/levers. |

While these developments were not without their complexities when

compared to common sails, they reduced manual effort while improving

the windmill’s efficiency as a motive force.

THE MACHINERY

Different hardwoods were used in the construction of milling

machinery. Cogs were often of applewood, hornbeam or beech, wheels

and shafts of oak, whilst the dowels used to join together wooden

parts were of holly. However, from the middle of the 18th century

cast-iron parts were used increasingly, although iron-to-iron

gearing was avoided, for it was found that iron-to-wood gearing ran

more quietly and was easier and cheaper to maintain and, most

important, it avoided the risks of sparks causing a dust explosion. [4] Problems

associated with manufacturing and handling large iron castings were

avoided by the use of small sections bolted together, an example

being the dozen or so sections that make up the 18ft diameter iron

rack in the cap of Wendover mill (plate 24).

Fig. 3.8:

general arrangement of a windmill fitted with a cap and fantail, and

two sets of stones.

In order to rotate the millstones, the (near) horizontal rotation of

the windshaft must first be converted into a vertical rotation. This

is achieved using a form of bevel gearing. The inner end of the

windshaft is fitted with a large toothed wheel, the brake wheel, the

teeth of which mesh with a cog, the wallower, which is set at an

upright angle to it. The brake wheel, when rotated by the windmill’s

sails in the horizontal, causes the wallower to rotate in the

vertical (fig. 3.8).

The wallower is mounted on the upright (or main) shaft, which

transmits its rotary motion downwards through the mill. Mounted on

the base of the upright shaft is another large toothed wheel, the

great spur wheel. This in turn meshes with the cogs — called stone

nuts — that drive the millstones. In this way the wind’s energy is

captured and then put to work to grind grain and drive other

machinery for cleaning, sifting and hoisting grain.

As its name implies, the brake wheel’s other function is to stop the

mill. In fig. 3.8, the brake is the circular shoes that surround the

brake wheel. To stop the mill, a lever is pulled to tighten the

brake-shoes causing them to grip the periphery of the brake wheel

and thus slow the rotating windshaft or clamp it in place.

THE MILLSTONES

Windmills are generally equipped with several sets of millstones (plate

14). Each set comprises a rotating runner stone and a stationary bed

stone which, depending on their diameter, weigh in the region of two

tons. Different types of stone are used to grind different types of

grain. Stones of grey millstone grit from Derbyshire are used to

grind coarse meal for stock feeding. The millstones employed to

grind wheat for flour are made of French Burr, a hard silicate found

in the Seine valley. Burr stones are constructed in segments,

cemented together and bound with heavy iron bands.

Fig. 3.9: millstones and their

associated equipment.

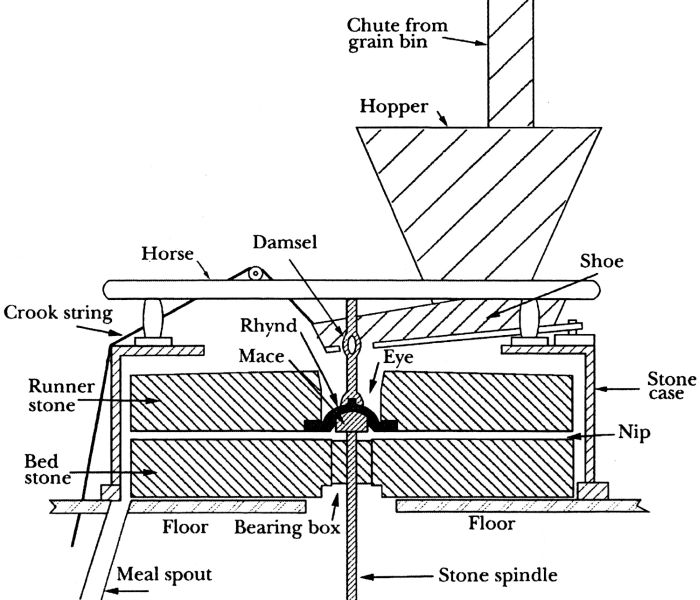

In operation, the millstones (fig. 3.9) are fed from a hopper, which

trickles grain along a wooden trough — the shoe — into the eye (a

hole through the centre of the runner stone) where it is ground

between runner and bed stones. The shoe is kept in a continual state

of agitation by a rotating crank. Called the damsel, due to its

chattering sound when in operation, it serves to keep the grain

flowing steadily down the shoe into the eye.

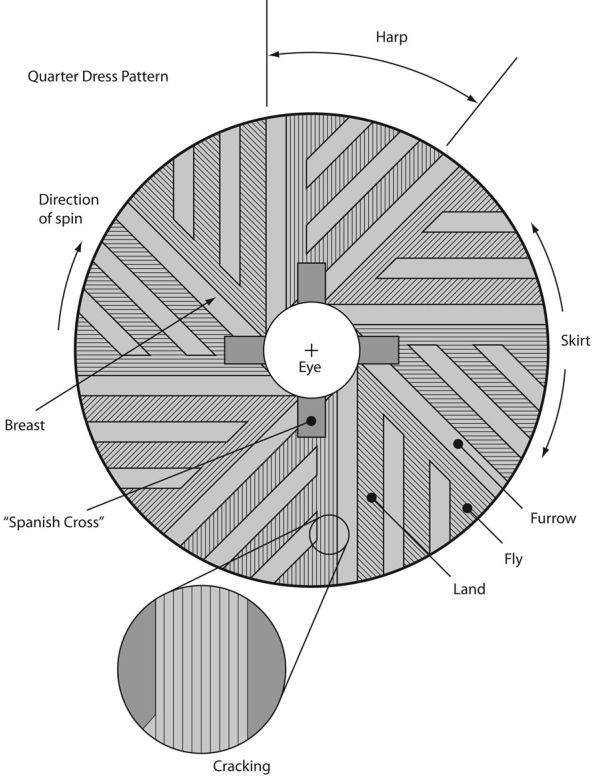

Each stone has a pattern of grooves cut into its surface (fig. 3.10). The

grooves act like scissors, cutting the grain as well as moving it

outwards from the centre to the periphery of the millstones. As the

meal emerges from between the stones, it is swept inside the

circular wooden container that encases them — the tun or stone case

— into the top of a chute, or meal-spout, which funnels it down to

the meal floor below where it is bagged.

|

Fig. 3.10:

plan view of a millstone. This is a runner stone;

a bedstone would not have the "Spanish Cross" into which

the supporting millrynd fits. |

In regular use, the grooves in a millstone wear down and need to be

dressed periodically; that is, re-cut to keep their cutting surfaces

sharp. This is a tedious and exacting task, sometimes

performed by the miller but often by an itinerant stone dresser

(fig. 3.11). The work was

executed using various tools including a mill bill, a

tempered steel blade clamped in a wooden handle, rather like a small

pickaxe, and used as a chipping tool. Today, power tools are often

used.

|

|

|

Fig. 3.11: a stone

dresser using a mill bill. |

Adjusting the gap between the stones — a process called tentering —

is carried out using a system of screws or levers that move the

runner stone up or down. This gap, or nip as millers call it, helps

to determine the fineness of the meal; the smaller the nip, the

finer the meal. Only slight adjustments are required, for the

stones, when grinding, are only about the thickness of a postcard

apart.

Fig. 3.12: the centrifugal

governor.

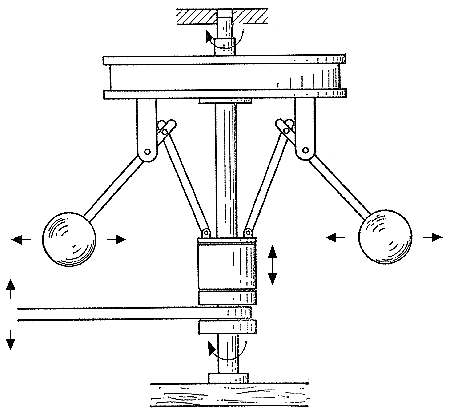

Tentering can be performed manually, but the centrifugal governor

(fig. 3.12 & plate 2) can perform the task more efficiently. This ingenious

device is driven from the rotating upright shaft. As the speed of

rotation of the sails — and thus of the shaft and the millstones —

increases, a pair of heavy metal balls linked to the governor’s

spindle begin to fly outwards under the increasing centrifugal

force. This causes their collar to rise up the spindle, and in so

doing to move the levers that adjust the gap between the millstones. An increased gap results in more grain being fed into the eye of the

millstones, which increases the load on the sails, slowing their

speed of rotation and that of the millstones.

The optimum speed of rotation of a runner stone depends on its

diameter and on the quality of the output required. A rule of thumb

followed by millers was to divide the diameter of the stone (in

inches) into 5,000 for flour and 6,000 for coarser meal. Thus the

optimum speed for a 48 inch runner stone, set to produce meal, would

be 125 rpm — assuming, of course, there was sufficient wind to drive it at that

speed.

THE FANTAIL

Even a small change in wind direction can result in a significant

reduction in the torque the sails generate if they are not

repositioned. In older windmills, ‘winding the mill’ involved hard

manual effort. In the case of a post mill, the entire superstructure

needed to be turned by pushing on a large beam (the tail post) that

protruded from the rear of the mill. In later smock and tower mills,

only the top floor (fig. 3.1) needs to revolve, but this still

required manual effort. The fantail automates the process by using

the wind itself to wind the sails. Later windmills usually adopted

this feature, which could also be built onto the tail posts of old

post mills (plate 31).

A fantail comprises gearing driven by a small set of sails (vanes),

which are aligned at right angles to the main sails and positioned

at the rear of the mill. Its purpose is to rotate the cap

automatically when a change of wind direction occurs, which it

achieves via a system of gears that mesh with a toothed rack around

the inside of the cap (fig. 3.8). When the sails are properly

winded, the vanes of the fantail are at right angles to the wind, so

they derive no thrust from it and

do not rotate. But should the wind change direction, its force then

falls on one side or the other of the fantail, causing its

vanes to rotate and drive the gearing that rotates the

cap and winds the sails, a clever feat of automation.

However, while very useful in normal working conditions, the fantail

provided no guarantee against a mill being tail-winded by a sudden

change in wind direction, as sometimes accompanies a thunderstorm;

thus fantails might be supplemented by a hand crank, an example

being in the cap of Wendover mill (fig.

10.3). And unless the fantail drive

could be disconnected, a further problem for the miller was how to

turn the windmill’s sails off the wind in a sudden squall in order

to stop them. Things were rarely straight-forward in windmilling.

ANCILLARY EQUIPMENT

|

|

|

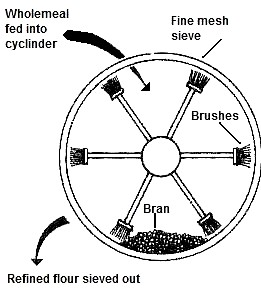

Fig. 3.13:

principle of the flour dresser. The cylinder is tilted

at an angle. The wholemeal is fed into the upper

end and passes through the machine under gravity, the

bran being ejected at the lower end. |

Because windmills use gravity feed to clean and grind grain, filter

the meal produced and bag the end product, a sack hoist is an

essential piece of equipment if the drudgery of lifting sacks

manually up the mill, on numerous occasions, is to be avoided. The

sack hoist takes the form a simple rotating chain, driven by an

auxiliary shaft which is in turn geared to the upright shaft (plate

3). As it rotates, the sack hoist is used to lift the sacks of grain

or meal up through a succession of trapdoors to the bin floor of the

mill.

The auxiliary shaft also powers other windmill machinery. That used

prior to the grain being milled might include a smutter, which removes the

black spots of smut caused by a fungus disease that can grow on

grain if its gets damp; a separator, used to separate grain from

other foreign matter, such as stones, weeds, and sticks; a scourer,

used to separate usable grain from debris such as dirt, dust, and

chaff.

Following milling, a flour dresser (fig. 3.13) is used to sift the

meal into its various grades of fineness. The dresser consists of a

cylindrical drum, covered in wire mesh of increasing grades of

fineness, and set at an angle. Inside the drum revolves a set of

brushes. Meal, fed into the upper end of the cylinder is rubbed

against the mesh screens by the brushes as it falls through the

cylinder under gravity. The finest meal, white flour, can pass

through the finest mesh screen; next comes semolina flour, which

passes through the next grade of mesh, leaving the coarsest product,

bran. Each grade is ejected into canvas chutes which feed sacks on

the meal floor below.

The mill might also drive an oat crusher, used to crush oats for

animal feed.

――――♦――――

APPENDIX

THE ROLLER MILL

Although the subject of this book is windmills, some mention should

be made of the technology that in the latter part of the 19th

century was to sweep away both wind and water mills so rapidly.

The steam engine was the first major advance. The first

steam-powered mill, Albion Mill, was established in 1786 by Matthew Boulton and James Watt. It employed a Watt steam engine of 150 hp to

drive 20 pairs of millstones, and was capable of grinding 10 bushels

of wheat per hour, all day and regardless of wind strength. Albion

Mill was the industrial wonder of the age, but in 1791 it burned

down. The cause was never discovered, but it was widely believed to

be an act of arson by local millers and millworkers who believed

their livelihood was threatened by the new technology.

Rotating millstones, sometimes steam-driven, continued to be used

for grain milling until the late 19th century, when roller mills — a

Swiss invention — appeared, the first being built in Hungary in

1874. Edward Mead (Chapter VII.) is believed to have installed the U.K.’s

first roller mill at Chelsea in 1881. The combination of steam power

and the roller milling process led directly to the flour mills of

today.

|

|

|

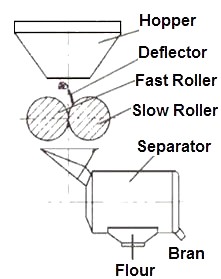

Fig. 3.14:

the principle of the roller mill. In practice, the

meal passes through several stages of roller milling to

produce fine white flour. |

Roller milling (fig. 3.14) crushes the grain, not between revolving

millstones, but between a series of fluted steel rollers of about 12

inches in diameter. The rollers are set with a specified gap between

them and spin towards each other at high, but at different, speeds;

the surface of each roller is also grooved with a different pattern.

In a modern flour mill, before milling commences, the grain is

cleaned of any extraneous matter using a variety of techniques

including sifters and magnets (to remove metallic particles). It is

then conditioned to ensure uniform moisture content and blended with

other wheats to provide a mix capable of producing flour of the

required character. Then, using a reduction process, the grain is

crushed by a succession of rollers, the fine flour particles being

sifted out at each pass of the rollers while the residue (bran) is

sent on to the next set of rollers in a repetitive manner. Thus,

roller milling is a series of crushing and sifting operations,

ideally suited for making clean white flour.

Roller mills offer several other advantages over traditional milling

methods. They eliminate the cost of dressing millstones and enable

the production of a larger amount of better-grade flour from a given

amount of wheat, quicker and to a consistent standard. Rollers are

also superior for milling the harder wheats used for bread by

reducing the wheat kernel slowly into flour fragments to separate

out the bran.

Roller milling made possible the construction of larger, more

efficient grain mills, hastening the abandonment of the small

country wind and water mills, and of stone grinding. Indeed, so

successful were the roller mills that within 30 years of their

introduction into Britain in 1881, more than three-quarters of the

wind and water mills that had served for centuries so faithfully, if

erratically, had been demolished or abandoned. This is what Edward

Bradfield, an old miller who was writing in 1920, had to say about

this milling revolution . . . .

“Then came the changes. ‘High grinding,’ ‘gradual reduction’ and the

‘roller system’, one after the other, came to revolutionize the

trade. The flour was greatly improved by the new methods and the

trade of the stone millers was decimated. The new methods allowed

the brittle stony wheats then coming into fame to be made into

excellent flour which the stone millers could not equal. Yet many of

them, who clung to the traditional system which had brought them

fame, wealth and honour, made heroic efforts to stay the onslaught,

but failed.”

However, the roller mill revolution brought with it a drawback. The

friction of the rollers caused the meal to become hot, which led to

some nutrients in the flour being damaged. This was not realized at

a time when essential dietary needs were little understood.

Today, the

‘Bread and Flour Regulations’ govern the use of additives

as well as requiring the addition of certain nutrients to ensure

that a wholesome product emerges from the flour mill. This from the

Federation of Bakers . . . . .

“The Bread and Flour Regulations require that flour should contain

not less than 0.24mg. thiamin (vitamin B1), 1.60mg. nicotinic acid

and 1.65mg. of iron per 100g. of flour. These amounts are found

naturally in wholemeal flour. White and brown flours must be

fortified to restore their nutritional value to the required level.

In addition calcium carbonate, at a level of not less than 235mg.

and not more than 390mg. per 100g. of flour, is added to all flours

except wholemeal and certain self-raising varieties. This ensures

the high nutritional value of all bread, whether it is white, brown

or wholemeal.” |