|

NOTES AND

EXTRACTS

ON THE HISTORY OF THE

LONDON & BIRMINGHAM RAILWAY

CHAPTER 7

CONSTRUCTION ―

CAMDEN TOWN TO CHEDDINGTON

INTRODUCTION

“It is not

a little curious to turn back, and watch the first

beginnings of a work of such magnitude as this railway,

which will cost more than £5,000,000. In November, 1830,

there was to be one line of rails only, and the work was

to be done for £6,000 per mile. The capital was then one

million and a quarter, and no greater velocity

contemplated than eight miles an hour. Shares got up to

nine and ten premium on the prospectus, at which many

hundreds were sold. Then it was determined to have two

lines; and at that announcement the shares fell directly

to a discount . . . . We wonder that the speculators of

those days would have thought, if they could then have

been informed what the real cost of the present two

lines would be. One thing is certain, there would not

have been a railway between London and Birmingham for

many a year.”

The History of the

Railway Connecting London and Birmingham, Peter

Lecount (1839).

|

|

Originally planned for completion in September 1837 within a budget

of £2.5M, the London and Birmingham Railway was at the time and in every

sense the largest civil engineering project yet undertaken in the

United Kingdom:

“Up to that time no railway of similar

magnitude had been attempted. The line from Liverpool to Manchester

was by comparison a trifling work. Its length was little more than a

quarter of the length of the new road, and its most important works,

including the Sankey viaduct (with nine arches each of fifty feet

span thrown over the Sankey valley, and running seventy feet above

the Sankey canal), its principal tunnel, 2,250 yards long, and its

firm highway over the bogs of Parr Moss and Chat Moss, are in

respect of magnitude not to be compared with the Kilsby tunnel, the

Blisworth cutting, and the Wolverton embankment and viaduct. A man

of iron nerve would have experienced some uneasiness at the

commencement of such an undertaking.”

The Life of Robert Stephenson,

John Cordy Jeaffreson (1866).

Jeaffreson might have included in his

list of Stephenson’s more daunting challenges the Primrose Hill and

Watford tunnels, and the Tring Cutting, although a great deal of

heavy engineering was needed elsewhere to overcome Nature’s

obstacles while maintaining the line’s 1:330 (16 feet to the mile) ruling gradient.

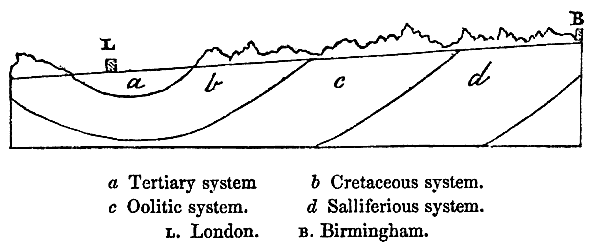

It might

assist those unfamiliar with the terrain to list the main geographical

features

that required civil engineering solutions

in the form of embankments, cuttings, viaducts, bridges and tunnels.

In their guide to the London and Birmingham Railway, Roscoe and Lecount describe the

landscape thus:

|

“The country between London and Birmingham

is a series of basins or low districts, separated from each other by

considerable ridges of hills; the object to be gained was,

therefore, to cross the valleys at as high a point as possible, and

the hills at as low a one . . . . The whole will, therefore, stand

thus:―

1. The basin at London formed by the Thames.

2. The summit at Oxhey, near the division of the counties of

Middlesex and Hertford.

3. The basin of the Colne river. [Watford]

4. The summit at Tring.

5. The basin of the Ouse, near Stoney Stratford.

[Wolverton]

6. The summit at Blisworth, opposite Towcester.

7. The basin formed at Weedon by the streams flowing into the River

Nene at Northampton.

8. The summit at Kilsby, opposite Daventry.

9. The basin of the River Avon, crossed near Wolston, about five

miles south of Coventry.

10. The summit of the Meriden ridge.

11. The basin at Birmingham formed by the river Rea, which flows

into the Tame. . . .

. . . . Although there were found during the progress of this great

work numerous and severe difficulties, there was nothing to indicate

anything like what was experienced, and without expending vast sums

in boring, they could never have been anticipated.”

The London and Birmingham Railway, Roscoe and

Lecount (1839). |

The London and Birmingham was planned to open at the same time as the Grand

Junction Railway (sketch map), the two lines sharing a

terminus at Curzon Street. But

great difficulty in overcoming the large bed of quicksand found at

the southern end of the Kilsby Tunnel in

Northamptonshire delayed completion of the London and Birmingham

line, and it was over 12 months after the Grand Junction Railway had

arrived in Birmingham (the GJR opened for business on 4th July 1837)

before a through service between London and the North-West was

established.

Construction of the London and Birmingham Railway commenced at both ends:

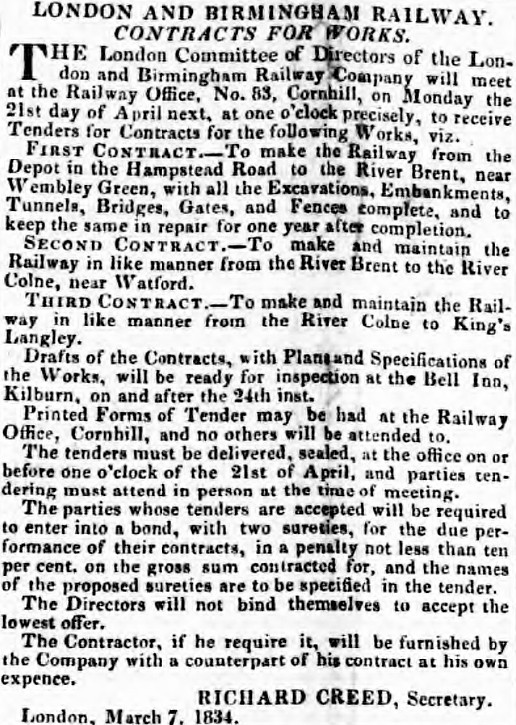

“LONDON AND BIRMINGHAM

RAILWAY ― The average number of workmen

employed on the line during the early part of the present summer was

about 12,000, and the weekly expenditure of the company about

£40,000. The quantity of earth excavated will be about 16 millions

of cubic yards. The weight of iron in the rails and chairs forming

the line of way will be 38,000 tons. There will be 290,000 stone

blocks of four cubic feet each, and 75,000 of five cubic feet each,

being together 1,535,000 cubic feet, or 105,000 tons of stone under

the cast iron chairs or pedestals which support the rails, and

exclusively of any used in the bridges, tunnels, &c.”

The Bucks

Herald, 23rd September 1837.

The line was opened in stages as work progressed. On 20th

July 1837, a service commenced on the section between Euston and Boxmoor (Hemel

Hempstead), which was extended to Tring on the 16th October. The line

could not be completed

in time for Queen Victoria’s coronation on the 28th June 1838, but

aware of the lucrative traffic the event would generate, on the 9th

April 1838, the Company

opened the section from Tring to a temporary station at Denbigh Hall

near Bletchley, and also from Birmingham to Rugby, a stagecoach

shuttle being used to bridge

the 38-mile gap. The line was eventually opened throughout on the 17th September 1838, the first passenger train

from London to Birmingham taking 5½ hours to complete the 112½ mile journey.

This, and the following three chapters, summarise the main civil engineering challenges

that Stephenson and his team had to overcome in building the line.

|

――――♦――――

|

ADVERTISING FOR TENDERS

“The Directors had placed equal portions of

the line under the separate superintendence of the respective London

and Birmingham Committees . . . . The directors deemed it advisable

that the execution of the whole line should be under the direction

of one engineer, and Mr. Robert Stephenson had been appointed to the

office, and had received instructions to stake out the line without

delay. The Directors had reason to believe that the railway will be

completed in about four years. The plan on which the work is to be

carried on is as follows:―

1st. That those parts of the line which require the longest time for

execution shall be commenced first, and the rest in succession, so

that the whole may be completed at the same time.

2nd. That the purchase of the land shall be made with reference to

this arrangement.

3d. That the payment of the calls shall be regulated so that no part

of the capital shall be demanded before it is actually required.

4th. That the works shall be executed by contract, by open

competition.

The only deviation from this plan is in reference to the end of the

line near London, which eleven Directors recommend should be

finished with expedition, from a conviction that the novelty and

convenience of a railway contiguous to the metropolis would excite

general interest, and prove an early and productive source of

revenue to the Company.”

The first general meeting of

the Proprietors, reported in The Morning Post,

20th September, 1833.

Stephenson spent the time between the passage of the London and

Birmingham Railway Bill (May 1833) and the letting of the first

three contracts (May 1834) assembling his project team, levelling and staking out

the course of the line, and drawing up plans

and specifications for every aspect of the work:

“The engineer wished to ascertain with

accuracy the amount of the work before him. To effect this, before

cutting a turf, he went over every inch of ground, and endeavoured

to calculate the exact cost of every operation necessary for the

accomplishment of his task . . . . In laying down the Liverpool and

Manchester Railway, George Stephenson had at the outset of the

undertaking only a general notion of the labour before him. The

details were not considered till their consideration could no longer

be deferred. Robert Stephenson saw that this plan of leaving each

day to take care of its own evils was little calculated for so vast

an undertaking as the London and Birmingham line.”

The Life of Robert Stephenson,

John Cordy Jeaffreson (1866).

With these preliminaries complete, the Company was in a position to advertise for tenders

to undertake the work, which had been

divided into sections, their extent depending on the complexity of the task.

For the reasons stated above, the Board stipulated that work was to

commence at the London end of

the line:

“In their former report, the Directors

announced the appointment of Mr. Robert Stephenson, as Engineer in

Chief. They have since succeeded, to their complete satisfaction, in

obtaining the services of a sufficient number of skilful and

scientific persons as Assistant Engineers, for conducting the Works

on every part of the Line, which has been arranged in sub-divisions

for this purpose.

Notwithstanding the obstacles which an unfavourable season has

presented to the field operations of the Engineers, the whole of the

Line from London to Birmingham has been staked out and levelled,

with the exception of a few points, to which Mr. Stephenson is

desirous of devoting his particular attention. He has requested

that the Plans and Specifications of the Works for the first twenty

miles from London will be complete by the 1st of March.

The Directors will then immediately advertise for Tenders for the

execution of the Works on that portion of the railway, and the Plans

and Specifications for other parts of the Line will follow in

succession as shall bring the remainder into completion, in

conformity with the intention announced in the former Report.”

Liverpool Mercury,

28th February, 1834.

Each sets of plans and specifications were produced in triplicate,

one copy being available for inspection by

potential contractors who, on the appointed day, submitted

sealed tenders for contracts in which they were interested. Tenders were then evaluated on the basis of experience and

reputation, price, and the adequacy of the contractor’s capital for

funding construction until payment became due from the Company for

completed work. Following the award of a contract, each of the sets

of documents were

signed by Stephenson and the successful contractor; one set went to

the Board, Stephenson retained a set, and a set went to the

Assistant Engineer for the district.

By August 1834, the

Company had let contracts for 42 miles of railway ― 21 miles at each end

of the line ― and the Board

was confident that before the close of the year contracts would have

been let for almost 80 miles. And so work commenced.

――――♦――――

ABANDONED CONTRACTS

If contemporary accounts are accurate, few of the works necessary to

surmount the landscape’s natural obstacles presented exceptional

problems, but those that did threw up challenges that were more than

the civil engineering contractors of the age could handle. During the course of construction, the Company was obliged to

revoke eight of the thirty contracts and make other

arrangements. The Castlethorpe and Weedon contracts were among those

re-let to other contractors, but a further eight were taken over by

the Company’s own engineers,

who then managed the work directly and provided the wherewithal to

complete it. Under these

circumstances, the Company was entitled to claim liquidated damages

for the additional costs arising from the contractor’s failure to

perform the contract, but this was not considered feasible:

“In reviewing the extent, and particularly

the nature of the country through which the Railway passes, no

person can be surprised that a vast number of unforeseen

difficulties should arise. In the progress of the works,

difficulties were developed which defeated the sagacity of the most

experienced contractors ― which set at defiance the knowledge of the

ablest engineers . . . .

. . . . The question has been asked,

Why

were not the securities of these contractors made to pay the fine

consequent on the breach of contract, and thus a portion of the

Company’s loss be recovered? The answer is plain: neither equity

nor sound policy could approve of such a line of procedure. If the

Company’s engineer, with all his experience, could not foresee these

hidden difficulties, how could a contractor estimate them? With such

discrepancies between the apparent labour, and that which, in

proceeding, was revealed, it would be a question for a jury, or

possibly the Chancellor, whether they would be liable. The attempt

to make them so would then have involved a law-suit, and its

consequent delay in the progress of the works ― a delay which would

be so injurious as to neutralise the benefits of a successful suit ―

a delay which, if the suit were unsuccessful, would have exposed the

Directors to a fearful responsibility. They, however, acted upon the

spirit of their contracts, and thus avoided the injury and the odium

which the reverse line of conduct would have ensured.”

The Railway Companion, from

London to Birmingham, Arthur Freeling

(1839).

Thus, the cost of building the line began to

rise significantly

above that estimated, although it is probably fair to say that none

of the contractors who did deliver what was expected grew rich in

the process. Speaking of the difficulties encountered during the

construction of the line, Robert Stephenson subsequently observed:

“After the works were let, wages rose, the

prices of materials of all kinds rose, and the contractors, many of

whom were men of comparatively small capital, were thrown on their

beam-ends. Their calculations as to expenses and profits were

completely upset. Let me just go over the list. There was Jackson,

who took the Primrose Hill contract — he failed. Then there was the

next length — Nowells; then Copeland and Harding; north of them

Townsend, who had the Tring cutting; next Norris, who had Stoke

Hammond; then Soars; then Hughes: I think all of these broke down,

or at least were helped through by the directors. Then there was

that terrible contract of the Kilsby Tunnel, which broke the Nowells,

and killed one of them. The contractors to the north of Kilsby were

more fortunate, though some of them pulled through only with the

greatest difficulty. Of the eighteen contracts in which the line was

originally let, only seven were completed by the original

contractors. Eleven firms were ruined by their contracts, which were

re-let to others at advanced prices, or were carried on and finished

by the company. The principal cause of increase in the expense,

however, was the enlargement of the stations. It appeared that we

had greatly under-estimated the traffic, and it accordingly became

necessary to spend more and more money for its accommodation, until

I think I am within the mark when I say that the expenditure on this

account alone exceeded by eight or ten fold the amount of the

Parliamentary estimate.”

The Life of George

Stephenson and of his son Robert Stephenson, Samuel Smiles

(1868).

Much had yet to be learned about estimating and

contracting for large-scale civil engineering projects, among which

was the impact on labour and material costs arising from other

railway projects competing for the same resources ― inflation was to

play its part in doubling the final bill for the line:

“Retardation of Railways by the High Price

of Labour. ― Owing to the great demand for labour the wages have

risen considerably, and increased obstacles are thrown in the way of

completing the lines which are in progress. The Birmingham,

Southampton, and other lines, we are informed, are not proceeding

with little more than half the rapidity they were. Of course this,

with the great rise in iron and other things, must tell materially

in the estimates, and tend much to retard that early benefit the

country would otherwise derive from these undertakings. Common

labourers are offered on the London and Birmingham Railway, from

fifteen to eighteen shillings per week, and masons four shillings

and sixpence per day, but even at these wages the application for

hands in many places has been unsuccessful.”

The Railway Magazine, Vol. 1

(1836).

“From the great increase in prices, which

took place almost immediately after the letting of the works, no

less than seven [eight]

contracts were thrown on the Company’s hands, and of course these

were the most difficult and expensive parts of the works, and in

each case, the directors had to purchase all kinds of implements and

materials at a vast expense, including five locomotive engines,

while, from the times at which these seven contracts took to

complete them, there was very little possibility of transferring

these implements (technically called the Plant) from one contract to

another. This, although a very expensive process, was the only one

to be followed, or the line could not be opened under at least a

year beyond the time contemplated.”

The London and Birmingham Railway, Roscoe and

Lecount (1839).

Construction contracts and the

eventual contractors (eight having failed),

from The Life of Robert Stephenson, John Cordy Jeaffreson

(1866). |

――――♦――――

|

THE BRENT CONTRACT

On 21st April 1834, the Company let three contracts covering the

first 21 miles from London. Messrs. Jackson and

Sheddon took the Brent (or Primrose

Hill) contract, a 5¾-mile section that included a deep cutting and tunnel

under high ground adjacent to Primrose

Hill, a tunnel at Kensall Green, and a long embankment across the

Brent Valley.

The Primrose Hill Tunnel was to be 1,120 yards long, 24 feet wide, 22 feet high,

with 5 shafts and

brick-lined throughout. The main problem for the

contractors lay in the nature of the terrain through which the

tunnel was

to be driven, blue London clay:

“The Brent contract, a length of six miles,

was let to an experienced contractor for the sum of £119,000; the

party failed, and the Company were obliged to do the work, which in

consequence of the peculiarity of the soil, has cost them £250,000. This contract included the Primrose-hill Tunnel, which is 1100 yards

in length, and proceeds entirely through what is termed London clay,

the most unmanageable and treacherous of all materials, the

difficulty of tunnelling through which can only be appreciated by

practical men. Unsuccessful attempts have been made to tunnel

through it at former times, the most memorable of which was the

Highgate Tunnel. The Primrose-hill Tunnel is, however, the largest

work that has ever been effectually performed through the same

material.”

The Railway Companion, from London

to Birmingham, Arthur Freeling (1838).

In the age in which the Primrose Hill Tunnel

(map) was built,

tunnelling in general remained fraught with difficulties, among which was

estimating its cost, as that at Kilsby was to prove. Excavation alone was expensive, but

especially so in London clay, which is a tough material and very

difficult to remove. Lecount states

that hatchets and cross-cut saws were the most effective tools, for

spades, pickaxes and blasting proved to be of little use.

“The formation over part of which we have

come is called the London clay, and constitutes the lower

portion of what geologists call the tertiary

formation [from 65

million to 1.806 million years ago]. It consists of immense beds of argillaceous matter

resting above the chalk, which latter has, at some very remote

period, formed the floor of a gulph of the sea or bed of the mouth

of a large river, which has gradually been filled up by muddy

depositions, from 300 to 600 feet thick, now constituting the London

clay. The clay with which this chalk basin has been filled up, forms

the site of the British metropolis and neighbourhood; it extends on

the north and west to the Chalk Hills of Wiltshire, Berkshire,

Oxfordshire, Buckinghamshire, and Hertfordshire. On the east it

reaches to the sea, and on the south terminates at the North Downs.”

Osborne’s London & Birmingham

Railway Guide, E.C. and W. Osborne (1840).

A more acute difficulty associated with London clay was

already known, for some years previously the Highgate Tunnel, which

passes through the same terrain, collapsed. Its failure was attributed

to the immense pressure exerted by London clay when exposed to

air [1] and the inability of the tunnel’s brick lining to

withstand it:

“The London clay is penetrated by the

Primrose Hill Tunnel, and presents a close, compact, and dry

appearance. This tunnel was perfectly free from water, but a more

than usual thickness of brick lining was necessary, arising from

an extraordinary pressure, probably caused by the swelling of the

clay, on exposure to the atmosphere.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

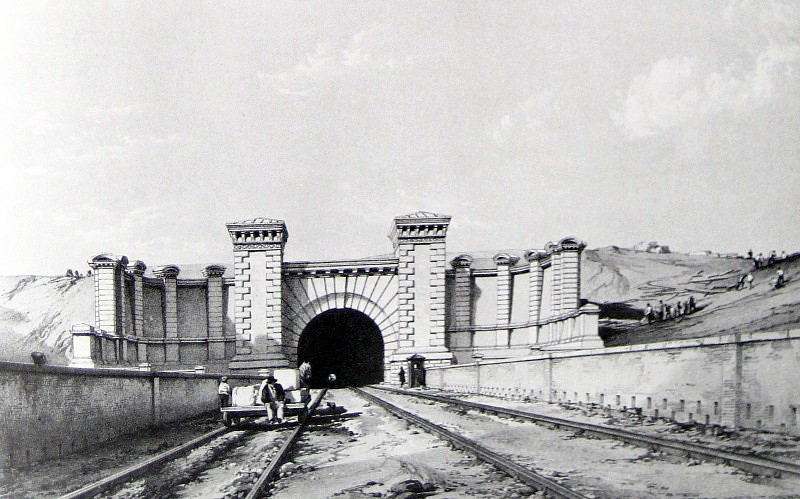

Portal at Primrose Hill Tunnel under

construction, April 1837. John Cooke Bourne.

Towards the end of 1834, the Company

was obliged to take over the work from

Jackson and

Sheddon,

the contractors, who had become bankrupt.

In their place, Stephenson appointed John Cass Birkinshaw to take

over supervision:

“The London and Birmingham Railway was

commenced in the year 1834, and Mr. Birkinshaw was appointed

assistant engineer at the London or Camden Town end. But he did not

long retain that position, for the contractor having become

bankrupt, the works were carried on by the company, and Mr.

Birkinshaw, as having already had much experience, was considered by

Mr. Stephenson a proper person for their direction and management. The heaviest works were the Primrose Hill tunnel, made through the

London clay, the open-cut tunnel at Kensal Green, and the Brent

bridge, beyond which his portion of the line did not extend far. The

works were well done, and elicited favourable remarks both from Mr.

Stephenson and from the chairman of the company.”

From an obituary of John Cass Birkinshaw

(1811-67) held by the Institution of Civil Engineers.

|

|

|

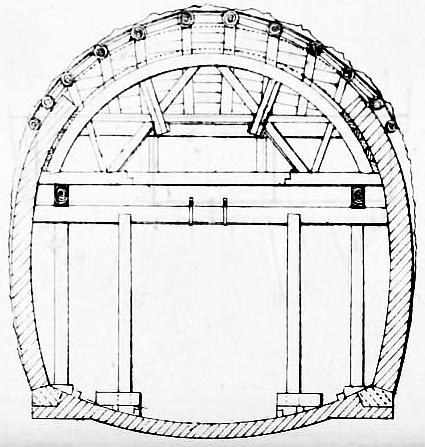

Section of Primrose Hill

Tunnel,

showing timbering and the brick invert (bottom). |

In view of the clay’s ability to exert substantial force as it expanded,

Stephenson and Birkinshaw adopted unusual precautions. Excavation was limited to nine feet in

advance of the tunnel’s brick lining, and very strong timbering was

used to support the arching until the brickwork was complete. Owing

to the extraordinary expansivity of the moist clay, the pressure

on the brickwork was such that it forced the mortar from between the

joints, bringing the bricks’ inner edges into contact, a

problem made worse by the local bricks having hollow surfaces that

made them unfit to bear great pressure. Lecount states in his history of the Railway that the

bricks were ground into dust and, by degrees, the tunnel’s dimensions

insensibly but irresistibly contracted. In his biography of the Stephensons, Samuel Smiles also refers to the problem:

|

“The pressure behind the brickwork was so

great that it made the face of the bricks to fly off in minute

chips, which covered his [Stephenson’s]

clothes while he was inspecting the work.”

Life of George Stephenson

and his son Robert Stephenson, Samuel

Smiles (1868). |

This difficulty was overcome using very hard bricks laid in Roman

cement, which, by setting hard before the external pressure became

great enough to force the bricks into contact, enabled the whole

surface of the brick to resist the pressure, rather than just its edges. The thickness of the brick lining was also increased in

most parts of the tunnel to twenty seven inches and the invert (an

inverted arch on the tunnel floor) to eighteen ― the invert, it

appears, had been abandoned as a cost-cutting measure:

“In the original designs for the tunnels on

the Loudon and Birmingham Railway, all the sections contained

inverts, of rather slighter

depth than the arch. In the Watford tunnel, through solid chalk, the

invert was found to be altogether unnecessary, and its place was

supplied by ordinary footings to the side walls. A similar change,

which was not only a saving of a large expense, but a means of very

considerably increasing the rate of progress of the limiting works

of the line, was accordingly attempted in the Primrose-hill tunnel;

but the hard London clay, though requiring a pick axe to cut it,

soon showed such unmistakeable menace of rising from the floor to

fill the whole excavated area, that the original section was

re-established.”

Personal Recollections of

English Engineers, F. R.

Conder (1868).

Other than the engineering problems thrown up by London clay, inclement weather also played its part in

delaying the tunnel’s completion and the opening of the

first section of the line:

“The Directors, in their late Reports,

expressed an expectation that the first 21 miles of the railway from

London would be completed in the spring of 1837. They regret to say

that, owing to the late unexampled season, this expectation cannot

now be realised before the summer. The engineer reports that the

continued bad weather for the last four months, defeated his

calculations in a degree which no former experience could have led

him to anticipate. In some descriptions of soil this delay could not

have taken place to such an extent as in the London clay, which

is exemplified by the progress of the works on other parts of the

line, where the material is more favourable; but in the London

district the incessant falls of rain have rendered it quite

impracticable to proceed with them uninterruptedly. With the

excavations and embankments on the Primrose-hill contract he

persevered until the extra expense was such as to induce him to

suspend further operations; a step, in the propriety of which, the

Directors fully concurred.”

Report of the 7th half-yearly General

Meeting, Northampton Mercury, 18th February 1837.

South

entrance to the Primrose Hill Tunnel by John Cooke Bourne, 1837.

“Leaving Kentish Town on the right, and

passing under Chalk Farm bridge, we enter the Primrose Hill cutting. If the traveller should now happen to look out from the window of

the carriage, he will behold stretching across the line the noble

entrance of the Primrose Hill tunnel. This is a bold and massive

structure, erected in that style of architecture which is usually

termed the Italian; and consists of two wings and a centre, raised

upon a rusticated basement.”

Drake’s

Road Book of the London and Birmingham Railway, James Drake (1839).

The

Brent section also included the 320-yard Kensal Green Tunnel,

probably the World’s first ‘cut and cover’ railway tunnel:

“Kensal Green Tunnel: The Railway passes

under the Edgeware Road and Kilburn Wells. At Kensal Green, a deep

cutting was made to pass under the Harrow Road, at a very acute

angle; after which the channel was covered over, and the roadway

newly made. This gallery, or covered way, called the Tunnel, at

Kensal Green, is 966 feet 6 inches in length.”

The Literary World, Vol. 2 (1840).

Judging from the absence of reports, the tunnel appears to have been completed

without serious incident, but that cannot be said for the embankment and

viaduct across the Brent Valley:

“Here

is a slight excavation of about 150 yards, which is succeeded by an

embankment of one mile and a half in length, which is, in some

places, from 35 to 40 feet high; under it is a small tunnel, two

field bridges, and what we must call the Brent Viaduct . . . . it is

85 yards long, and consists of one main arch, and three others in

each abutment; the former is 37 feet from the level of the river

Brent, which flows through it . . . . it is in some places nearly

forty feet in height, and it contains 101,923 cubic yards of earth.”

The Railway Companion, from London

to Birmingham, Arthur Freeling (1838).

This embankment was constructed from pieces of

broken up London clay,

but was not soundly compacted, leaving fissures within the structure

that gradually caused the interior to become saturated with rainwater.

The clay softened, resulting in

slippage:

“With

reference to that portion between London and Tring, the permanent

road is in tolerably good order, except on the Brent Embankment near

London and on the Colne Embankment near Watford. Both these works

have continued to subside, with scarcely any intermission, more or

less rapidly since their formation; the former from the slippery

nature of the material which composes it, the latter from the

unsoundness of its substratum in the valley of Colne. The gradual

subsidence of embankments admits of no other remedy than maintaining

the level of the railway by the constant supply of new sound

material adapted for ballasting, which in the present case may

fortunately be obtained from a convenient spot, and at a moderate

expense, for there is in the Company’s possession at the south end

of the Watford Tunnel, a large store of excellent gravel and chalk,

sufficient to meet all the demands of the line and stations between

Watford and London for some years.”

The Mechanics’ Magazine,

Volume XXVIII (1838).

Severe weather also delayed work on the Brent

Embankment (and also at Wolverton and Tring, where excavation of the long

Tring Cutting came to a standstill). Despite these setbacks,

at the General Meeting held in February 1837 the Chairman was able

to inform those present that the Brent contract was nearing

completion:

“The

works of the Primrose-hill contract, which have been continued by

the Company under the direction of the engineer, are nearly

completed with the exception of the Brent embankment. The

Primrose-hill and the Kensal-green tunnels are finished and

traversed by the Company’s engines, and the permanent way is laid

through a great part of this contract. Of the embankment on the

south side of the Brent bridge, about 58,000 cubic yards remain

unfinished, to complete which, under an ordinary state of the

weather, would require three months. That portion of the embankment

which is north of the bridge is brought up to it, but not yet raised

to the railway level. On the completion of the embankment north of

the Brent, the engineer proposes to expedite the formation of the

south portion of it by making 6,000 or 8,000 cubic yards of side

cutting, thus guarding against further disappointment as far as

practicable.

From this point to Watford no work appears to require especial

mention, the completion of the Watford tunnel and the small quantity

remaining in the excavations at each end, rendering any detailed

remarks on this part of the line unnecessary.”

Report of the 7th half-yearly General

Meeting, Northampton Mercury, 18th February 1837.

The Primrose Hill Tunnel was eventually completed in January 1837 at a cost of £280,000,

over twice the contract price, but despite the Chairman’s optimistic

forecast for completion of the Brent Embankment, tipping and

compacting more material to counter slippage was still proceeding in

1838.

|

――――♦――――

|

THE WATFORD EMBANKMENT AND VIADUCTS

The ‘Bushey

Arches’ viaduct near Watford ― a public house sign, now in Watford

Museum.

The second of the London contracts covering the section from the River Brent to the

River Colne was let to Nowell & Son. This work, which included

a cutting

through the Oxhey Ridge ― the original plan being for a tunnel

― does not appears to have presented

any particular engineering challenges:

“Mr. Stephenson reported that from the

nature of the soil at the proposed Tunnel under Oxhey Lane,

and from the comparisons of Messrs. Nowell & Sons prices for

tunnelling in the Schedule of extras and the prices of excavations,

he considered it would be for the advantage of the Company that this

portion of the Line should be made an open cutting. That

Messrs. Nowell & Sons were willing to substitute the excavation for

the Tunnelling without any additions to the sum for which they have

contracted.

Minute No. 179. Resolved that the Engineer-in-Chief be

authorised to make necessary arrangements with Messrs. Nowell &

Sons, and that the portion of land at Hatch End required for spoil

be reserved for that purpose.”

Board Minutes, 24th September

1834.

The completed Oxhey cutting impressed one travel writer sufficiently to prompt

him to pen a description:

“On the left appears Oxhey Ridge. This

ridge is part of a chain of hills which extend from Chipping Barnet

to Uxbridge, and for a considerable distance form the boundary

between Middlesex and Hertfordshire. The materials of which they are

composed are principally sand and clay; and it was on account of the

difficulty of carrying a tunnel through such a description of

ground, that the railway was made to cross them by a cutting,

notwithstanding their great elevation. In passing through this

excavation, we cannot avoid being struck with astonishment at the

immense amount of labour which its construction must have required;

it being a mile and a half in length, and in many places between

thirty and forty feet deep. It is crossed by several bridges, the

principal of which is Oxhey lane bridge, a noble structure of three

arches, but attracting attention chiefly by its extraordinary

height. A short opening which occurs immediately after passing this

bridge enables us to catch a glimpse of Oxhey Wood; and, upon the

termination of the cutting, we behold amid some prettily wooded

scenery on the left the little village of Oxhey, with its antiquated

chapel and remarkable churchyard, ― remarkable, indeed, if we may

place any credit in the asseverations of a rustic, who solemnly

assured us that its silent denizens were wont to be buried in a bolt

upright posture.”

Drake’s Road

Book of the London and Birmingham Railway, James Drake (1839)

Oxhey Lane Bridge

in a later era.

The contract also included the

southerly of the two

mainline viaducts [2] in the Colne Valley,

the London-road viaduct, known locally as the ‘Bushey Arches’. This

is a 5-arch structure of which the arch spanning the former

‘Sparrows Herne’ turnpike (Bushey Heath to Aylesbury) is the first

skew arch to the design of Assistant Engineer George Watson Buck:

“Soon after entering upon it

[the Watford embankment] the Railway

goes over the London road, by a brick viaduct of five arches, of

forty-three feet span each; they are composed of ellipses, having voussoirs at the intrados; [3]

the centre arch is of an oblique form, in order that the course

of the road should be preserved as heretofore. This may be thought a

bad feature in a design of this kind, but it was unavoidable, the

trustees having compulsory clauses in the Act of Parliament to

compel the Company to adopt this form of arch. The manner in

which the engineer has overcome the defect in the design is

admirable, and it is scarcely perceptible to the observer: it is a

very massive structure, and cost in its erection £9,700. The other

arches are square with the line of Railway; and at either end are

retaining walls built into the embankment, making the total length

of the viaduct three hundred and seventy feet.”

The

London and Birmingham Railway, Roscoe and

Lecount (1839).

The London Road

Viaduct’s skewed arch.

|

“Mr.

Stephenson reported that one arch of the Watford Bridge

is turned and that another is nearly so, and that a

third, a skew arch, is in such a state of forwardness

that he expects the whole to to completed in two months.”

Board minutes, 26th

November 1834.. |

The London-road viaduct is followed by a 1½-mile long embankment, the

River Colne being bridged by the 5-arch ‘Colne Viaduct’ ― both

embankment and viaduct threw up

engineering challenges.

The problem that the contractors faced

with the Colne embankment lay not in the use of unsuitable material

from which to form it, [4] nor in excessively

steep slopes, but in the valley’s weak sub-stratum that was unable to

withstand the loading. As with the Brent embankment the only

remedy was to continue tipping material until the formation

stabilised:

“It

has been found useless to remove the bog, on account of the water it

contains, and the only alternative is therefore to allow the

embankment to proceed and settle as it may. It is very low

near the ends, and descends rapidly and somewhat irregularly; the

men ought to be constantly cautioned against their danger in taking

off the horses from the [earth]

waggons, and are much exposed to going over. The brakes

however are simple and well managed.”

Report to the Visiting Committee, 27th and 28th May, 1836.

“The

Sub-Committee had the satisfaction to find that the Embankment at

Watford, under Messrs. Nowell's, was proceeding in conformity with

the directions of the Committee, that the Bog earth was removed and

replaced by sound material from the side sutting, and that the

embankment was in consequence assuming the necessary stability.

The difficulties at this point are not likely to retard the

completion of the first 21 miles of the Railway.”

Report to the Visiting Committee, 1st and 2nd September 1836.

“It

took nearly one million cubic yards of earth to make this

embankment, which is in some places above forty feet in height and

is the largest throughout the whole line . . . . The

whole of the land near this spot is most precarious in stability;

and the effects are clearly visible in the amazing ‘slips’ which

have taken place in the embankment across the [Colne]

valley. Oftentimes, in a very few hours, the level of the

newly-formed ground has sunk several feet, while the base of the

embankment has widened out to an enormous extent, causing infinite

labour to bring the level of the Railway back again to its original

state, and to make it solid enough for the passage of the trains;

this has caused many a sleepless night to the workmen and engineers.

The length of this embankment is about a mile and a half, and is

composed entirely of the finest materials for such a purpose ― chalk

and gravel.”

The London and Birmingham

Railway, Roscoe and Lecount (1839).

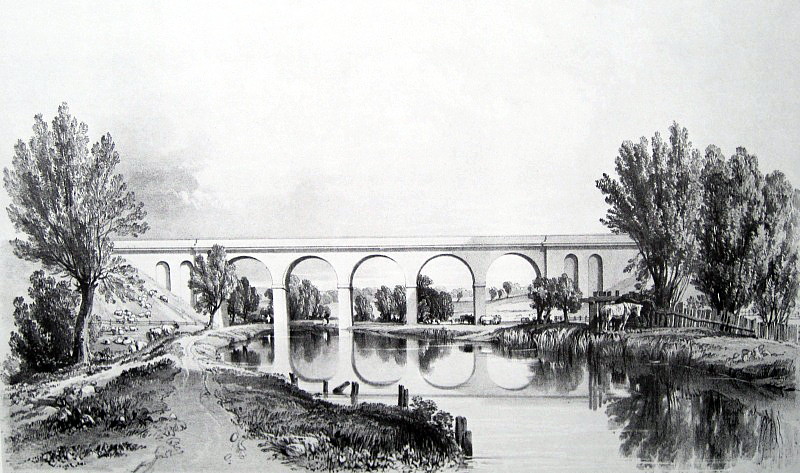

The Colne Valley embankment

and River Colne Viaduct,

by John Cooke Bourne (1837).

Note the abandoned stone

sleepers, right foreground above.

And the same problem affected the

viaduct over the Colne. Both Conder and Lecount recalled the

considerable excavation that was necessary to find firm ground on

which to rest the viaduct’s piers:

“. . . . long trains of brick-carts and

timber-carriages commenced a service from the nearest canal wharf,

and piles of bricks, and heaps of half-wrought freestone from

Yorkshire quarries, began to accumulate near the waggon-building

field. Then there was a great-field day of the engineers, a display

of lines and levels and measuring tapes, an arbitrary infringement

on the turnpike road, and the foundations of the great new viaduct

were commenced. It was necessary to press this work as rapidly as

possible, as some million and more cubic yards of embankment had to

be carried over it and tipped to form the southern portion of the

great Colne Valley Embankment. For seventeen feet the workmen had to

sink, before arriving at a foundation sufficiently firm to sustain

the weight of the piers.”

Personal

Recollections of English Engineers, F. R.

Conder (1868).

“The construction of this bridge

[the viaduct]

was a work of considerable skill and labour, the foundations being

of the loosest material possible; in fact, it may almost be called a

floating bridge ― for it rests entirely on platforms of wood, having

sheet piling to protect them. The cost of its construction was

little less than £10,000.”

The

London and Birmingham Railway, Roscoe and

Lecount (1839).

The Colne

Viaduct, by John Cooke Bourne (1837).

|

――――♦――――

|

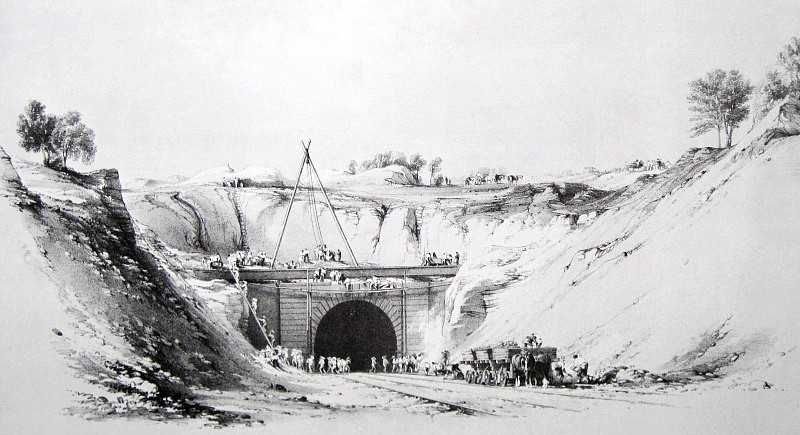

THE WATFORD TUNNEL

Watford Tunnel face, 6th June

1837, by John Cooke Bourne.

Stephenson’s

original plan was to route the line to the west of Watford

and into the Gade Valley; then,

to proceed northwards in close company with the Grand

Junction Canal to Hunton Bridge where the line would have joined

the existing route. However, the Earls of Essex

and of Clarendon, landowners of the Cassiobury and Grove estates

through which the line was to pass, were implacably opposed to

this scheme (and, indeed, to the Railway as a whole). Thus, as

an alternative, George Stephenson & Son submitted a report

recommending that the line pass to the east of Watford and then

northwards through what is now the long Watford Tunnel:

“The alteration at Cassiobury as an expedient

to avoid the private grounds of Lords Essex and Clarendon is

unquestionably an expensive one, but after thorough examination of

that neighbourhood keeping in view the necessity of avoiding

Cassiobury Park and the adjoining plantation belonging to Lord Essex

we are inclined to recommend the adaption of it, though it involves

the necessity of a Tunnel.

This leads us to notice the circumstances of Tunnels occurring in

the line we are now recommending. It is certainly desirable to

avoid such mode of surmounting high grounds if it were practicable

at a moderate expense but we are induced to recommend Tunnels in

some situations when the depth of the cutting is very great in order

that the first cost of the line may be greatly diminished.”

Report dated 21st

September 1831.

In evidence given before a

Committee of the House of Lords, Stephenson expressed his feelings

plainly on the

need for this deviation:

“I have been nearly two years examining the country for the

proposed line to Birmingham, which begins at Oxhey Lane and goes

from thence to the South end of Watford, through the Colne valley,

and passes the parks of Lords Clarendon and Essex, avoiding the

same by a tunnel and an acute curve, which would be attended with no

inconvenience . . . .”

Abstract of Evidence given

before a Committee of the House of Lords, June 1832.

The Watford Tunnel and its two deep approach cuttings formed part of

the contract let to Copeland and Harding, which covered the section from the

southern end of the Colne crossing to King’s Langley:

“Just past here is the entrance to the Watford Tunnel; it is 24

feet wide, and the crown of the arch is 25 feet high; it is

ventilated by six shafts, the largest of which is a memorial of the

death of the persons buried here during the excavation; the shaft was

increased in size to get out their bodies; the tunnel is one mile

170 yards in length; upwards 120,000 cubic yards of earth were taken

out of it.”

The Railway Companion, from

London to Birmingham, Arthur Freeling

(1839).

“. . . . I made my escape into the wider,

though more reasonable, turmoil of the tunnel. There was no day

there and no peace: the shrill roar of escaping steam; the groans of

mighty engines heaving ponderous loads of earth to the surface; the

click-clack of lesser engines pumping dry the numerous springs by

which the drift was intersected; the reverberating thunder of the

small blasts of powder fired upon the mining works; the rumble of

trains of trucks; the clatter of horses’ feet; the clank of chains;

the strain of cordage; and a myriad of other sounds, accordant and

discordant. There were to be seen miners from Cornwall, drift-borers

from Wales, pitmen from Staffordshire and Northumberland, engineers

from Yorkshire and Lancashire, navvies — Englishmen, Scotchmen, and

Irishmen — from everywhere, muck-shifters, pickmen, barrowmen,

brakes-men, banksmen, drivers, gaffers, gangers, carpenters,

bricklayers, labourers, and boys of all sorts, ages and sizes; some

engaged upon the inverts beneath the rails, some upon the drains

below these, some upon the extension of the drifts, some clearing

away the falling earth, some loading it upon the trucks, some

working like bees in cells building up the tunnel sides, some upon

the centre turning the great arches, some stretched upon their backs

putting the key-bricks to the crown — all speaking in a hundred

dialects, with dangers known and unknown impending on every side;

with commands and countermands echoing about through air murky with

the smoke and flame of burning tar-barrels, cressets, and torches. Such was the interior of Watford tunnel.”

‘Navvies as they used to be’, from Household Words, Vol. XIII., 19th January 1856.

At Watford, the terrain becomes predominantly chalk, but soft

chalk rent by gravel-filled fissures as much as one hundred feet

deep:

“The gravel is most abundant in the neighbourhood of Watford,

covering the upper chalk which in many places it penetrates, or in

other words, the large fissures or rents in the chalk are filled

with gravel, and as this latter material is very loose and mobile,

it was the occasion of much difficulty and danger in the excavation

of the Watford tunnel; for at times, when the miners thought they

were excavating through solid chalk, they would in a moment break

into loose gravel, which would run into the tunnel with the rapidity

of water, unless the most prompt precautions were taken.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

These fissures were cut into on several occasions, but on the 17th

July 1835 there occurred an inrush of gravel at the foot of one of

the working shafts that buried alive ten of the miners at work in the

tunnel:

“The shaft in question, one of the four in this length of tunnel

(1,700 yards), is termed a gin-shaft, and has been sunk about 90

feet below an elevated platform erected for the purpose of removing

the earth. The shaft has been very lately sunk, and two nine-feet

lengths of tunnel had been bricked, the third being, it is stated,

just mined and ready for the bricklayers. The shaft was about to be

bricked on Friday morning, between 5 and 6 o’clock, by a party

consisting of five bricklayers and six labourers, who composed what

is termed the night gang; and had the appalling event taken place a

few hours afterwards, the morning gang would have been at work, and

the loss of human life must have been awful in the extreme . . . .

In loosening a portion of the wood work previous to bricking the

shaft, it is supposed the earth gave way and buried the unfortunate

men, carrying the whole of the wood work with it . . . . The men

must be buried upwards of 80 feet below the surface of the earth,

and although 60 men are actively engaged in digging out the bodies,

it is probable that six or seven days will elapse before they are

extricated.”

The Bucks Herald, 25th July

1835.

“After more than a month of incessant exertions on the part of

Messrs. Harding and Copeland, the contractors for the Watford line

of the London and Birmingham Railway, and a vast number of labourers

who were relieved every twelve hours, the bodies of some of the

unfortunate men, who were buried under more than eighty feet of

earth, by the sudden falling in of the shaft in Russell Wood,

Levesdon Green, Watford, in this county, have been dug out. Early on

Saturday morning the miners were enabled by crawling between the

interstices made by the fallen timbers, to see the legs of some of

the sufferers, and to know that before many more feet of the gravel

and chalk had been removed (the distance from the surface being

about eighty-four feet) they would come to the bodies . . . . At

three o’clock in the afternoon an extended hand presented itself to

the view of the bystanders, on the side of the opening opposite to

that which the first eruption of the gravel is supposed to have

taken place. The body on being cleared was found in a sitting

posture, with the head thrown back; it is presumed the poor fellow

was looking upwards at the moment he met his death, have heard the

cry of “ware” from the men at the top of the arch; his face was

crushed and the legs broken.”

The Bucks Herald, 22nd August

1835.

In view of the risk of tunnelling through such hazardous terrain,

the workforce was reluctant to continue. Many years later, Francis

Fox, son the Charles Fox, the tunnel’s Resident Engineer, recalled

his father’s strategy for getting the men back to work:

“Whilst engaged in the construction of the Watford Tunnel in

1834, he received instructions to go to Birmingham. He asked to be

allowed to remain, for they were working in very soft and dangerous

ground; but his request was declined, and he was sent to Birmingham.

He had not been gone more than a few days when a message was

received that the tunnel had fallen in, and eleven men had been

killed. He immediately hurried back, and found that there was a

panic on the spot. Up to this point is what my father himself told

me, but a very old friend of mine further related that, when the

tunnel had fallen in and had produced this panic, my father went to

the works and said to the men, ‘That tunnel has to be put through,

cost what it will, and therefore I want you men to volunteer.’ Not

one of them would do so. ‘Very well,’ he said, ‘I will do it’; and

he got into the bucket, and was just about to be lowered down the

shaft, when the ganger, using language more strong than elegant,

said he ‘would not see the master killed alone.’ He went down with

him, and these two finished the length through the dangerous ground,

after which the men returned to work.”

River, Road, and Rail ― some

engineering reminiscences, Francis Fox MInstCE (1904).

By February 1837, the Chairman was able to report that all that

needed to be done on the Watford Tunnel was a small amount of work

on the excavations at either end. |

――――♦――――

|

KINGS LANGLEY TO CHEDDINGTON

A romantic view

over Boxmoor looking towards Berkhamsted.

The contracts for the Kings Langley to

Aldbury [5] section were let to ‘W. & L. Cubitt’, a

name connected with many notable Victorian construction projects

including the 1-mile Camden Town to Euston

railway extension, and both Euston and King’s Cross stations. Although

there were no engineering problems of note on this section, it

included several interesting features; the fine iron skew segmental

arch bridge across the Grand Junction Canal at

King’s Langley (alas, now

defaced in concrete reinforcement), a masonry skew bridge at

Boxmoor, Boxmoor embankment, the

long retaining wall adjacent to Berkhamsted Castle and the Northchurch Tunnel.

George Watson Buck’s masonry skew arch bridge at Boxmoor.

Referring to this bridge, Roscoe and Lecount were of

the opinion that . . . .

“The science of bridge

building has, of late years, made rapid strides towards

perfection, and there are many instances where arches of

immense span have been erected; but we believe no

example exists of such an oblique arch executed in brick

work as that now under notice. The square span

across the road is twenty-one feet; but the obliquity

causes the span on the face of the arch to be lengthened

to more than thirty-nine feet; its facial form is that

of a flat segment of a circle; and the acute angle of

the quoins is chamfered off until it reaches the obtuse

angle, where it vanishes. This gives the bridge the

appearance of having one voussoir more than it really

has; and also obviates the defects which generally

attend the construction of skew bridges, by the acute

angles of the quoins being broken off or injured, either

by settlement or accidental blows. The idea of cutting

off the acute angles of such arches emanated, we

believe, from Mr. George Buck, the resident engineer of

the line from London to Tring. The perfect manner in

which the whole of the stone work, and the spiral

courses of the bricks, are executed, reflects great

credit upon the builders, Messrs. Cubitt of London.”

At Berkhamsted . . . .

“. . . . work had begun in 1834 with a

massive earthmoving operation needed to take the line across the

outer moat of the Castle, and huge quantities of bricks were needed

to make a stable base (Birtchnell 1972, 87). The original station (Birtchnell

1975, xiii, 22-3) was a handsome brick building in Elizabethan

style, and stood almost opposite the Castle Street canal bridge. It

was replaced in 1872 prior to the widening of the tracks . . . . ”

Extensive Urban Survey ―

Hertfordshire: English Heritage and Hertfordshire County Council

(2005).

Berkhamsted Castle is said to be the first building to receive what

in today’s language would be described as a ‘preservation order’. Sections 98 and 99 of the 1833 Act stipulated that the Railway was

not to deviate from the authorised line (100 yards in either

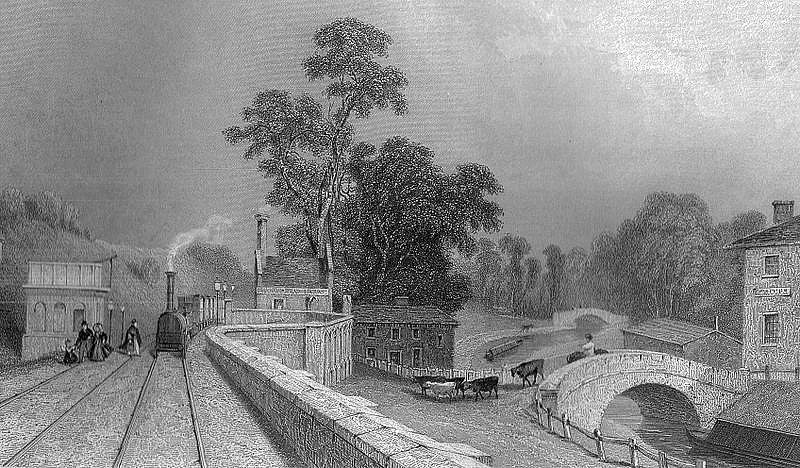

direction was usually permitted) when passing through the grounds of

Berkhamsted Castle, neither were any structures ― except for

the necessary bridges, culverts, etc. ― to be erected, while section 100

forbad the Company from making bricks or burning lime anywhere

within the parish.

The original Berkhamsted Station.

The Grand Junction Canal is to the right in the picture

― note the absence of platforms.

At this point the Railway passes between the Canal and Berkhamsted

Castle atop

the substantial retaining wall in the foreground.

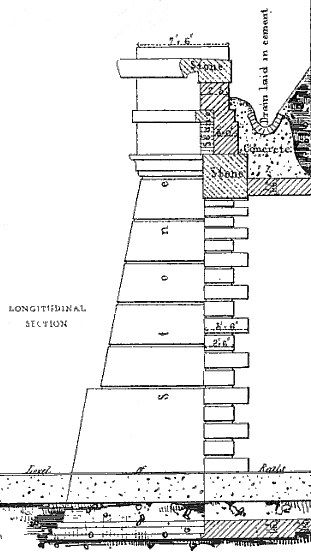

Nevertheless, the Railway cut through the Castle’s outer gate and

earthwork defences, running atop a substantial retaining wall, the

requirements for which Brees cites as a model for specifying

railway construction work. This is an extract:

“RETAINING WALL AT BERKHAMPSTEAD CASTLE.

“This Wall is for the purpose of retaining the Railway Embankments

along the part of the road from Berkhampstead to Berkhampstead

place, immediately in front of the Castle. Pilasters are to break

forward half a brick from the face of the wall, at a distance of 20

feet, as near as may be, centre to centre, and they are to run flush

into the plinth at the bottom, which must project half a brick. The

top course of the Plinth must consist entirely of headers, neatly

bevelled off, and laid in cement. A piece of stone, of the

dimensions and form shown, is to stand out as a string-course from

the pilasters, and in the manner shown in the drawings, and along

the wall, at the same level, a half brick projection of equal depth

is to be continued, the bricks of which must be rubbed on the outer

surface. Where the road passes under the Railway, this arrangement

is altered, as will be seen from the drawings. A torous moulding

extending as far as the outside of the pilasters in front of the

abutments. Immediately behind the pilaster, the wall must be broken

by counterforts, of the form and dimensions shown in the drawings,

and they must be well bonded into its substance. The footings are to

be carried down 1 foot 6 inches below the present surface, and

whatever is the section of the ground, they must in no part be

formed at a less depth . . . .”

Railway Practice: a collection of

working plans and practical details, S. C. Brees (1847).

From Berkhamsted, the line continues northwards along the Bulbourne

Valley in close company with the Grand Junction Canal, through

Northchurch and Dudswell towards its summit and the long cutting

through the depression in the ridge of the Chilterns known as the ‘Tring Gap’:

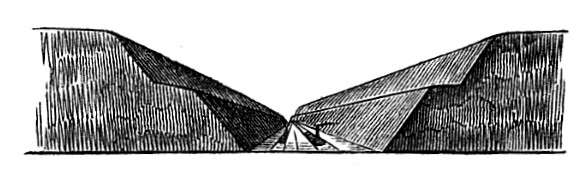

“We now enter the Dudswell excavation; it

is in some places fifty-three feet deep, and, including the tunnel,

three quarters of a mile in length, of which the North Church Tunnel

is nearly one half; the road from Ashridge to North Church passes

over the tunnel . . . . The traveller will have observed one

peculiarity in this excavation; from the nature of the soil; and the

depth of the excavation; it was found necessary to make a platform,

or gallery, about half way up; this is about ten feet in width, and

then the slope again commences; this platform gives great security

to the slopes, and prevents their falling in; the following diagram

will give a better idea than mere description.”

The Railway Companion, from

London to Birmingham, Arthur Freeling

(1839).

Although Freeling and Roscoe both refer to the ‘Dudswell

excavation’, it is at Northchurch where the cutting

― approaching a mile in length ― commences, deepening as it

approaches the

high ground at its northern end under which it passes through the Northchurch Tunnel. Both Freeling and Roscoe refer to the slopes of

the cutting being divided by a ‘bench’, which Freeling depicts thus:

“The upper strata of the Dudswell

excavation are formed of wider slopes than the lower portion, owing

to a different nature of the soil; and it also has a bench where

they unite, to give security to the slopes.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

“Bench, or Berm: a ledge left

on the face of a cutting to strengthen the same. Steep cuttings

should always have ledges to support them, particularly in canal

work to prevent the mould from the upper part, falling down into the

water; chalk may also be executed at a very steep inclination by

their assistance. Ledges are likewise generally made at a change of

slope, occasioned by meeting with a different soil.”

A Glossary of Civil Engineering,

Samuel Charles Brees (1841).

The Tunnel is probably better known than would otherwise be the case

through publication of the charming watercolour of its southern

portal under construction, by the artist and civil engineer Samuel Brees

(1810c.-65):

Northchurch Tunnel, September 1837. A

watercolour by S. C. Brees.

The contractor was W. & L. Cubitt.

“At about the middle of it we pass through

the North Church Tunnel, the length of which is one fifth of a mile.

It has two handsome fronts of stone, with side walls of brickwork,

and is the same height and proportions as the Watford Tunnel.”

The London and Birmingham Railway,

Roscoe and Lecount (1839).

Brees also reproduced the specification and

plans for the tunnel in the first edition of his series of books on

Railway Practice, from

which the following elevations are taken:

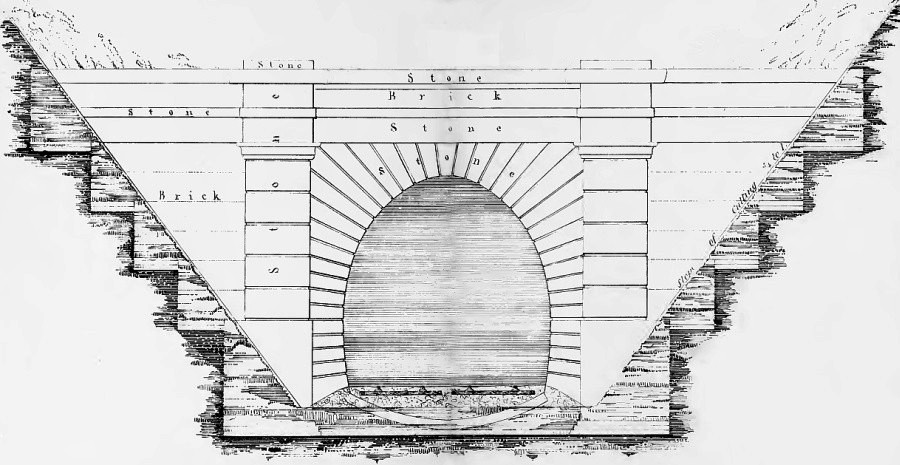

|

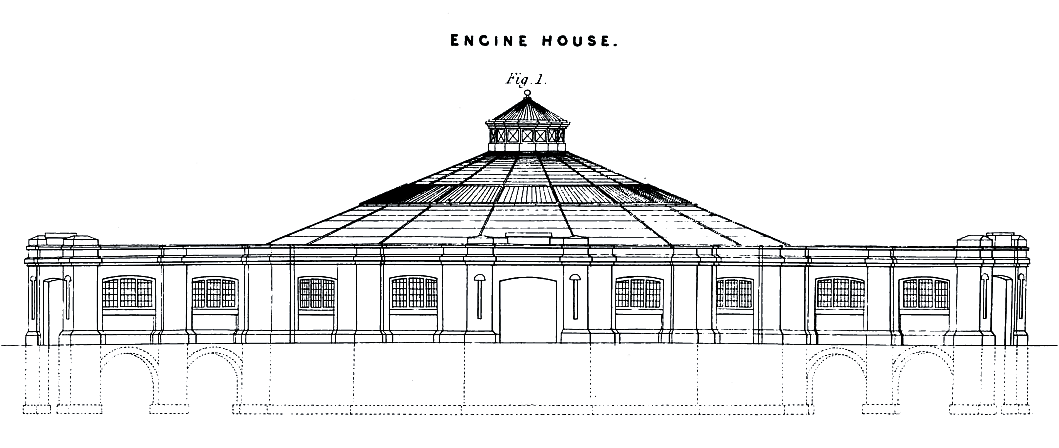

An elevation from Stephenson’s

plans for the Northchurch Tunnel,

reproduced in Railway Practice by S. C. Brees

(1838).

|

|

|

Northchurch Tunnel

portal,

reproduced in

Railway Practice by S. C. Brees

(1838). |

|

“This Tunnel is to consist of a brick Arch,

of the form shewn in the drawings, supported by carved Side Walls,

standing upon stone skew backs, which are to be bedded upon the

counter or Inverted Arch, forming the base of the tunnel: this part

is to be one and a half brick in thickness, excepting the shaft, as

shewn on next drawing, and the arch and side walls are to be two

bricks thick throughout the whole length of the tunnel, excepting

for a length of 7 feet 3 inches at the front, and at a distance of

12 feet on each side of the shaft, together with the shaft length,

where they will be three bricks thick, or in such other places as

the Engineer may think it requisite to make them thicker: in which

latter case the Contractor shall be paid for the increase according

to the rate mentioned in his Schedule of Prices. The Arch, if of the

thickness of one and a half brick, shall consist of three half brick

rings: if it be two bricks thick, it shall consist of four and a

half brick rings, and so on, and each ring shall contain five

courses of bricks more than the ring immediately beneath it . . . .”

An extract from Stephenson’s

specification for Northchurch Tunnel, from Railway Practice by S. C. Brees

(1838). |

The document went on to specify that excavation was to proceed in

what by then was the usual manner, of sinking shafts at intervals

along the tunnel’s alignment, from the bottom of which a narrow

heading was then excavated for the tunnel’s full length before

widening out commenced. The heading served to prove the correct

level and alignment, and help reveal any unexpected hazards that had

not been detected by trial boring:

“The Contractor must also sink two other

shafts on the centre line of the tunnel, one at each end of it, and

drive a Heading 4 feet wide and 5 feet high, the whole length of the

tunnel. This Heading must be carried through, before any part of the

main tunnel is commenced, and must be supported and kept open during

the execution of the whole work, by timbering or such other means as

may be deemed necessary by the Engineer . . . .”

An extract from Stephenson’s

specification for Northchurch Tunnel,

from Railway Practice by S. C. Brees

(1838).

Although Northchurch Tunnel appears to have posed no particular

civil engineering challenges during its construction, that does not mean

that the excavation was free of hazards for those who undertook the

work. But in that era, injury and loss of life in the workings was probably to be expected at some

stage during tunnel excavations:

“Frazer accordingly put in for, and

obtained a contract to carry a portion of the drift through

Northchurch tunnel; over this job he appointed George his gaffer,

and George then got me to be appointed his assistant and

time-keeper. So to Northchurch tunnel we went, early in October;

and, under the directions of the engineers, opened the drift at the

north end of the tunnel; sinking a shaft about midway on our length,

which was, I think, about one hundred and fifty yards. By the middle

of November we had six gang of navvies at work . . . . The soil

through which we were carrying the drift of Northchurch tunnel was

of a most treacherous character, and caused many disasters. Despite

every precaution, the earth would at times fall in, and that, too,

when and where we least expected. Thus, in the fifth week of our

contract, notwithstanding that our shoring was of extra strength and

well strutted, an immense mass of earth suddenly came down upon us. This came from the tapping of a quicksand. One stroke of a pick did

it. The vein was shelving and the sand, finding a vent, ran like so

much water into the open drift; which was of course speedily choked

up. George Hatley was at once on the spot; and, under his directions

efforts were promptly made to clear away the sand, so that the

shoring should be re-strengthened if possible before the earth above

(deprived of the support afforded by the sand) should collapse. The

most strenuous efforts were made in vain. There came a low rumbling,

like the distant booming of artillery, then followed crashes louder

than the thunder, startling us from our labour; and, while we were

hurrying away, down came the whole mass of earth, masonry, timber,

and sand, crushing five men under it.

Of these men three were dug out alive, and removed — terribly

mangled — to the West Herts Infirmary; the other two were found

dead.”

‘Navvies as they used to be’, from Household Words, Vol. XIII., 19th January 1856.

This article is reproduced in full in the

Addenda.

Northchurch Tunnel under

construction, June 17th 1837, by John Cooke Bourne.

The original West Herts Infirmary was founded by the eminent

surgeon, Sir Astley Paston Cooper, one of the Railway’s most

implacable opponents. [6] The hospital opened in

January 1827 for the “gratuitous relief of the necessitous poor”.

Construction of the London and Birmingham Railway

inevitably added to the hospital’s work, which by this time had moved from its small

beginnings to larger premises in Hemel Hempstead. The Railway

Company Directors donated £21 and the Contractors a further £25, but

they later arranged to pay 8s. a week for any workman admitted. Delay in treatment ― especially for men excavating the Tring Cutting

― could result in death from loss of blood, and the Hospital staff

suggested that gangers should be shown how to apply a temporary

tourniquet.

On emerging from the Northchurch Tunnel, the line continues its

ascent through Dudswell to Tring where it reaches its highest point at 419ft above sea level. Tring station also marks the beginning of

the 2½-mile cutting through the Tring Gap, the excavation of which

was undertaken by Thomas Townshend (1771c.-1846), a successful

contractor with experience of large-scale earthworks on the

Birmingham Canal, most notably the huge cutting at Smethwick.

|

|

|

Tring Cutting, Grand

Union Canal. |

Work on the Tring Cutting commenced in September 1834. According to correspondence published in The Mechanics’ Magazine,

by the following year good progress had being made:

“The work through Tring Hill is proceeding very well, and, I may

say, rapidly. A ‘temporary bridge’ has been constructed across the

canal at Seabrook, to carry the earth over (the embankments being

finished as far as there). I understand it is not the intention of

the Company to put up the permanent bridge till all the earth shall

have been carried over. But the foundations for it have been put in

some time. The top is to be of iron. Mr. Townsend [sic.]

has lately been laying down a fresh set of rails (parallel

wrought-iron ones) in lieu of the common cast-iron, and a new set of

waggons have been put on the work. The temporary bridge over the

canal is something like a bridge when compared to that which was put

over the canal at Wolverton, and pulled down by the Canal Company.

[7]

(By-the-bye, I think a vote of thanks ought to have been passed by

the Railroad Company and forwarded to the Canal Company, thanking

them for their unbounded kindness in destroying a bridge which must

have broken by its own weight, and occasioned, probably, a great

loss of life. By what I can learn, they get on very badly in that

quarter). Mr. Townsend will complete his part, before the others are

well begun. He keeps his men very steadily at work.”

――――――――

“The excavation for the London and Birmingham Railway, through

Tring-hill, is proceeding rapidly. Mr Townsend

[sic.] the contractor has

upwards of 500 men employed besides a great number of horses. It

is expected they will intercept the ‘Bulbourne springs’ when they

get deeper. These springs at present come directly into the Grand

Junction Canal. There is only one fault to be found with the

work in this neighbourhood, and that is the steepness of the banks,

they being only, for the excavations, in the ratio of nine inches

horizontal to one foot perpendicular. In the event of a sharp frost,

this ground, which is a sort of chalk rag, will slake down like

lime, and will consequently be a great nuisance after the road is

finished. The banks of the Grand Junction Canal, in the deep

cuttings collateral with the railroad, are more than one to one, yet

the slips which have occurred after a sharp frost have been

prodigious.”

From letters published in The

Mechanics’ Magazine, Volume 23, 1835.

The magazine’s second correspondent was correct in his belief that

the excavation would intercept the Bulbourne Springs, as had been

James Barnes’ experience some 40 years earlier when excavating the

Grand Junction Canal cutting half a

mile to the west (See Chapter

VII., A Highway laid with Water). Robert Stephenson was later to report that:

|

“The Tring cutting on the L and B R/Way presents another

forcible example of the constant and rapid absorption of water by

the chalk. In the execution of that cutting a very large

quantity of water was encountered, notwithstanding the situation was

on the summit of the chalk ridge, forming the actual brim of the

basin, where it could not be supplied with any water but such as

fell upon the immediate neighbourhood, yet it yielded upwards of one

millions gallons per day, and continues to yield an extraordinary

quantity up to this hour, without any sensible diminution.”

Minutes of proceedings of the Institution of Civil

Engineers: Volume 90, Part 4. |

The

“large quantity of water” to which Stephenson refers is now

channelled from the railway cutting through a heading to enter the

canal summit.

The culvert

that drains the Tring Railway Cutting into the summit of The Grand

Union Canal.

The flow of water shown here was after a period of

dry weather. The arch is about 4feet high.

During the drought of

1934, Edward Bell, the canal company’s surveyor, reported that he

was able to walk through the dried out heading, but not wishing to

retrace his steps he emerged into the railway cutting ― he mentions, as he climbed up the steep embankment, “feeling

very scared as an express train thundered along below”.

Tring Cutting after the track had

been widened during the 1870s to accommodate four tracks.

“The Tring Excavation is about two miles

and a half long. The strata through which it was cut are composed of

the lower or grey chalk formation, without flints. It averages forty

feet, and for about one quarter of a mile is fifty-seven feet in

depth. Out of this hill were taken one million and a half cubic

yards of earth, which had to be lifted to the surface a height of

forty feet and then deposited in ‘spoil banks’. It was executed by

means of a number of ‘horse runs’

so called by excavators from the men being drawn up planks nearly in

a perpendicular position by horses. A rope is attached to the front

of the barrow containing the soil, while the excavator takes firm

hold of the handles, and both barrow and man are drawn up the plank,

― the latter having his body nearly horizontal during the ascent. It

is a fearful practice; and should any accident occur, by the

breaking of the rope or restiveness of the horse, the workman is

precipitated to the bottom in an instant.”

The London and Birmingham Railway, Roscoe and

Lecount (1839).

From a later era, a horse-run in use

on the Manchester Ship canal workings.

By February 1837, the Chairman was able to report to the General

Meeting that work on the Northchurch Tunnel was complete, and the

Board was optimistic that the line would be opened to Tring by the

Autumn. However, the heavy rain during the winter of 1836-37, together with the influx

of water from the Bulbourne Springs, brought work in the cutting to a

standstill:

“The

quantity of water yielded by the cutting, in addition to that which

has fallen in rain, together with the argillaceous character of the

chalk in the Tring contract, rendered it absolutely necessary to

stop proceedings on the embankment, and to confine them to the

side-cutting and spoil. It is but justice, however, to the

contractor to add that he persevered in carrying on the embankment,

until the engineer reported that it became positively impassable. Notwithstanding this temporary delay, the engineer is of opinion

that the completion of this contract will certainly not be much

protracted beyond October next.”

From the Report to the 7th

half-yearly General Meeting, February 1837.

In October 1837 ― apparently to the surprise of all concerned ―

Townshend relinquished his contract and the Company took over the

work:

“Another unpleasant affair for the Company

arose from the person who had the Tring contract becoming bankrupt ―

a matter least expected, perhaps, of any. He was a man of capital

and talent, and had established a reputation for years as an able

contractor. The works he had on his hands were of the most extensive

nature, and ought to have paid him well; when, to the surprise of

every one who knew him, he was suddenly declared to be in

difficulties through his contracts on the Grand Junction line, and

ultimately went into the [London]

Gazette, leaving his works at Tring, including the heavy cutting

through the chalk, to be finished as best it might.”

The History of the Railway

connecting London and Birmingham, Peter

Lecount (1839).

The reasons for

Townshend’s bankruptcy stemmed from difficulties over contracts he

had with the Grand Junction Railway Company coupled with a

substantial increase in wage rates, but within seven months he had

paid off his creditors and was able to return to

contracting during his final years.

The winter of 1837-38 was another of unusual severity, which delayed

work until the frost broke up. Stephenson was able to report to the

General Meeting held in February, that the Cutting was almost

complete and the next section of the line from the south would

shortly be opened:

“The

Tring Contract, which comprehended the most extensive excavation on